Abstract

Pre-twin is widely accepted as an efficient method for weakening the basal texture to improve the plasticity of magnesium alloys, particularly for formability. However, the enhancement is limited since the largest Schmid factor (SF) of basal slip cannot be achieved. In-plane simple shear strain is used to control the twin orientation in accordance with Schmid law to further decrease the basal texture and improve the formability of the Mg alloys sheet. Consequently, secondary regulation of initial twin orientation (SRITO) technology, a novel combination procedure, was developed. In this method, the AZ31 Mg alloys sheet is compressed to pre-twins with various volumes (1%, 3%, and 5%), then the twin orientation is regulated by in-plane simple shear strain for the second time. Compared with the as-received sample, the average fracture elongation of the annealed sample with the best properties improves from 15.3 to 28.8%, and the Erichsen value increases from 2.8 to 6.1 mm due to the regulation of twin orientation.

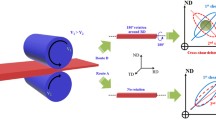

Graphical Abstract

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

J. Kim, H. Liao, X. Ou, Z. Zhang, K. Kang, T. Lee, F. Pan, Met. Mater. Int. 28(11), 2613–2620 (2022). https://doi.org/10.1007/s12540-022-01176-x

J. Chen, R. Sun, G. Li, M. Fang, G. Xu, M. Zhang, J. Li, Met. Mater. Int. 28(11), 2677–2690 (2022). https://doi.org/10.1007/s12540-021-01158-5

Q. Ran, H. Yan, J. He, N. Li, Y. Lei, Met. Mater. Int. 28(8), 2012–2022 (2021). https://doi.org/10.1007/s12540-021-01095-3

A.H. Eftekhar, S.M. Sadrossadat, M. Reihanian, Met. Mater. Int. 28(5), 1062–1074 (2021). https://doi.org/10.1007/s12540-021-00984-x

H. Abedi, M. Emamy, J. Rassizadehghani, H. Mirzadeh, Met. Mater. Int. 28(5), 1105–1113 (2021). https://doi.org/10.1007/s12540-021-01065-9

N. Li, L. Yang, C. Wang, M.A. Monclús, D. Shi, J.M. Molina-Aldareguía, Mater. Sci. Eng. A 819, 141408 (2021). https://doi.org/10.1016/j.msea.2021.141408

X. Huang, K. Suzuki, N. Saito, Mater. Sci. Eng. A 508(1–2), 226–233 (2009). https://doi.org/10.1016/j.msea.2008.12.052

F. Liu, X. Liu, B. Zhu, H. Yang, G. Xiao, M. Hu, Met. Mater. Int. 28(6), 1361–1371 (2021). https://doi.org/10.1007/s12540-021-00996-7

F. Zhao, T. Suo, B. Chen, Y.L. Li, J. Alloys Compd. 798, 350–359 (2019). https://doi.org/10.1016/j.jallcom.2019.05.260

N. Fakhar, M. Sabbaghian, J. Alloys Compd. 862, 158334 (2021). https://doi.org/10.1016/j.jallcom.2020.158334

L. Gao, F. Li, Y. Wang, X.M. Xiao, P. Da Huo, Met. Mater. Int. 28(8), 1960–1970 (2021). https://doi.org/10.1007/s12540-021-01077-5

Q. Liao, W. Hu, Q. Le, X. Chen, Y. Jiang, Met. Mater. Int. 28(5), 1143–1156 (2021). https://doi.org/10.1007/s12540-021-00978-9

S.K. Dewangan, M.K. Tripathi, M.K. Manoj, Met. Mater. Int. 28(5), 1169–1183 (2021). https://doi.org/10.1007/s12540-021-00980-1

X. Xu, Y. Deng, X. Guo, Q. Pan, Met. Mater. Int. 28(7), 1620–1629 (2021). https://doi.org/10.1007/s12540-021-01050-2

L.L.C. Catorceno, H.F.G. de Abreu, A.F. Padilha, J. Magnes. Alloys 6(2), 121–133 (2018). https://doi.org/10.1016/j.jma.2018.04.004

Q. Sun, T. Xia, L. Tan, J. Tu, M. Zhang, M. Zhu, X. Zhang, Mater. Sci. Eng. A 735, 243–249 (2018). https://doi.org/10.1016/j.msea.2018.08.051

W. He, Q. Zeng, H. Yu, Y. Xin, B. Luan, Q. Liu, Mater. Sci. Eng. A 655, 1–8 (2016). https://doi.org/10.1016/j.msea.2015.12.070

H. Pan, F. Wang, M. Feng, L. Jin, J. Dong, P. Wu, Mater. Sci. Eng. A 712, 585–591 (2018). https://doi.org/10.1016/j.msea.2017.11.123

S. Bouvier, H. Haddadi, P. Levée, C. Teodosiu, J. Mater. Process. Tech. 172(1), 96–103 (2006). https://doi.org/10.1016/j.jmatprotec.2005.09.003

J.-Y. Kang, B. Bacroix, R. Brenner, Scr. Mater. 66(9), 654–657 (2012). https://doi.org/10.1016/j.scriptamat.2012.01.040

H. Zhang, G. Huang, L. Wang, H.J. Roven, Z. Xu, F. Pan, Scr. Mater. 69(1), 49–52 (2013). https://doi.org/10.1016/j.scriptamat.2013.03.011

P. Yang, Scr. Mater. 50(8), 1163–1168 (2004). https://doi.org/10.1016/j.scriptamat.2004.01.013

M.D. Nave, M.R. Barnett, Scr. Mater. 51(9), 881–885 (2004). https://doi.org/10.1016/j.scriptamat.2004.07.002

A. Jain, S.R. Agnew, Mater. Sci. Eng. A 462(1–2), 29–36 (2007). https://doi.org/10.1016/j.msea.2006.03.160

S.-G. Hong, S.H. Park, C.S. Lee, Acta Mater. 58(18), 5873–5885 (2010). https://doi.org/10.1016/j.actamat.2010.07.002

B. Song, N. Guo, T. Liu, Q. Yang, Mater. Des. 62, 352–360 (2014). https://doi.org/10.1016/j.matdes.2014.05.034

Y. Xin, H. Zhou, H. Yu, R. Hong, H. Zhang, Q. Liu, Mater. Sci. Eng. A 622, 178–183 (2015). https://doi.org/10.1016/j.msea.2014.11.027

S.-J. Kim, D. Kim, K. Lee, H.-H. Cho, H.N. Han, Mater. Charact. 109, 88–94 (2015). https://doi.org/10.1016/j.matchar.2015.09.007

W. Cheng, L. Wang, H. Zhang, X. Cao, J. Mater. Process. Tech. 254, 302–309 (2018). https://doi.org/10.1016/j.jmatprotec.2017.11.052

Y.J. Kim, J.U. Lee, Y.M. Kim, S.H. Park, J. Magnes. Alloys 9(4), 1233–1245 (2021). https://doi.org/10.1016/j.jma.2020.11.015

Y. Xin, H. Zhou, G. Wu, H. Yu, A. Chapuis, Q. Liu, Mater. Sci. Eng. A 639, 534–539 (2015). https://doi.org/10.1016/j.msea.2015.05.070

H. Zhang, C. Yan, C. Li, Y. Xin, Q. Liu, J. Alloys Compd. 696, 428–434 (2017). https://doi.org/10.1016/j.jallcom.2016.11.315

X. Huang, K. Suzuki, N. Saito, Scr. Mater. 60(8), 651–654 (2009). https://doi.org/10.1016/j.scriptamat.2008.12.035

Y. Xin, M. Wang, Z. Zeng, M. Nie, Q. Liu, Scr. Mater. 66(1), 25–28 (2012). https://doi.org/10.1016/j.scriptamat.2011.09.033

J.A. del Valle, F. Carreño, O.A. Ruano, Acta Mater. 54(16), 4247–4259 (2006). https://doi.org/10.1016/j.actamat.2006.05.018

D.H. Kang, D.W. Kim, S. Kim, G.T. Bae, K.H. Kim, N.J. Kim, Scr. Mater. 61(7), 768–771 (2009). https://doi.org/10.1016/j.scriptamat.2009.06.026

S. Yi, J. Bohlen, F. Heinemann, D. Letzig, Acta Mater. 58(2), 592–605 (2010). https://doi.org/10.1016/j.actamat.2009.09.038

Acknowledgements

The authors thank Central Government Guided Local Science and Technology development projects (YDZJSX2021A010), China Postdoctoral Science Foundation (2022M710541), National Natural Science Foundation of China (51704209, 52274397), Projects of International Cooperation in Shanxi (201803D421086, 201903D421076), Shanxi Province patent promotion implementation fund (20200718), Research Project Supported by Shanxi Scholarship Council of China (2022-038), Taishan Scholars Project Special Fund (2021), the Ministry of Science and Higher Education of the Russian Federation for financial support under the Megagrant (No. 075-15-2022-1133) and the National Research Foundation (NRF) grant funded by the Ministry of Science and ICT (2015R1A2A1A01006795) of Korea through the Research Institute of Advanced Materials.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xue, L., Wang, L., Lu, P. et al. Influence of In-Plane Simple Shear Strain on the Grain Orientation Regulation and Stretch Formability of Pre-twinned AZ31 Magnesium Alloy Sheet. Met. Mater. Int. 29, 2965–2977 (2023). https://doi.org/10.1007/s12540-023-01434-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-023-01434-6