Abstract

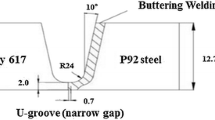

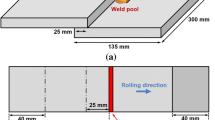

A study for evaluating the weld joint strength reduction factor (WSRF) due to creep was conducted for alloy 740H-P92 dissimilar metal weld joint to be used advanced ultra-supercritical fossil power plants. To this end, a series of the creep rupture tests were carried out for P92 and alloy 740H parent metals and alloy 740H-P92 dissimilar metal weld joint at elevated temperatures ranging from 600 to 700 °C. Additionally, for the creep tested specimens, hardness measurement and microstructure observation were performed. Weldment creep rupture test used specimens of transverse cross-weld type. In the creep test result, weldment creep rupture strength was almost same as that of the P92 parent metal when analyzed as a function of Larson-Miller parameter (LMP). However, when analyzed as a function of creep rupture time for individual temperatures, it showed a tendency to be lower than that of the P92 parent metal after certain times. The difference between two creep strengths increased with increasing time. Based on the analysis result for creep rupture time at each temperature, the WSRF for 100,000 h creep life was determined as 0.84 at 600 °C, 0.72 at 650 °C and 0.58 at 700 °C through extrapolation. Additionally, from the results of investigation on hardness and microstructure, it was shown that the creep life of alloy 740H-P92 dissimilar metal weld joint was dominantly determined by the characteristics of the heat affected zone (HAZ) on P92 side.

Graphic Abstract

Similar content being viewed by others

References

N. Saito, N. Komai, Y. Sumiyoshi, Y. Takei, M. Kitamura, T. Tokairin, Mitsubishi Heavy Ind. Tech. Rev. 52, 27 (2015)

W.G. Seo, J.Y. Suh, J.H. Shim, H.S. Lee, K.B. Yoo, S.H. Choi, Mater. Charact. 160, 110083 (2020)

Y. Yuan, Z.H. Zhong, Z.S. Yu, H.F. Yin, Y.Y. Dang, X.B. Zhao, Z. Yang, J.T. Lu, J.B. Yan, Y. Gu, Met. Mater. Int. 21, 659 (2015)

S.C. Kim, J.H. Shim, W.S. Jung, Y.S. Choi, Met. Mater. Int. 25, 713 (2019)

J. Vivas, C. Capdevila, E. Altstadt, M. Houska, I. Sabirov, D. San-Martin, Met. Mater. Int. 25, 343 (2019)

D. Liu, R. Guo, Y. Hu, M. Shen, Y. Tang, L. Zhao, D. Li, X. Wang, Met. Mater. Int. 26, 854 (2020)

J. Kangazian, M. Shamanian, Met. Mater. Int. 25, 1287 (2019)

K.Y. Shin, J.W. Lee, J.M. Han, K.W. Lee, B.O. Kong, H.U. Hong, Mater. Charact. 139, 144 (2018)

K.Y. Shin, J.W. Lee, J.M. Han, K.W. Lee, B.O. Kong, H.U. Hong, Korean J. Met. Mater. 56, 375 (2018)

Y.W. Ma, B.O. Kong, K.W. Lee, J.M. Han, in Proceedings of 2016 KSME Materials and Fracture Division Spring Conference, Kalhotel, Jeju, April 7–8, 2016 (Korean Society of Mechanical Engineers, Seoul, 2016), p. 65

Y.W. Ma, B.O. Kong, K.W. Lee, J.M. Han, in Proceedings of 2017 KSME Fall Conference, Jeju International Convention Center, Jeju, November 1–3, 2017 (Korean Society of Mechanical Engineers, Seoul, 2017), p. 1351

M. Sireesha, S.K. Albert, S. Sundaresan, Metall. Mater. Trans. A 36, 1495 (2005)

T. Matsunaga, H. Hongo, M. Tabuchi, Mater. Sci. Eng. A 695, 302 (2017)

J. Lee, J. Hwang, D. Bae, Met. Mater. Int. 24, 877 (2018)

P. Mohyla, Z. Kubon, R. Cep, I. Samardzic, Metalurgija 53, 175 (2014)

J. Shingledecker, A. Amato, G. Moino (ed.), Recommendations for Weld Strength Reduction Factors (Electric Power Research Institute (EPRI), Palo Alto, 2010)

A. Klenk, M. Speicher, K. Maile, Procedia Eng. 55, 414 (2013)

M. Prager, in Serviceability of Petroleum, Process, and Power Equipment, ed. by D. Bagnoli, M. Prager, D.M. Schlader. The 1992 Pressure Vessels and Piping Conference, New Orleans, Louisiana, June 21-25, 1992. Life assessment of chrome-moly welds, PVP-Vol. 239/MCP-Vol. 33 (ASME, New York, 1992), pp. 253–265

F. Masuyama, Int. J. Pres. Ves. Pip. 87, 617 (2010)

T. Wakai, Y. Nagae, T. Onizawa, S. Obara, Y. Xu, T. Ohtani, S. Date, T. Asayama, in Proceedings of the ASME 2010 Pressure Vessels and Piping Division/K-PVP Conference, Bellevue, July 18–22, 2010. Vol. 3 (American Society of Mechanical Engineers, New York, 2010), pp. 475–483

J. Storesund, S.T. Tu, Int. J. Pres. Ves. Pip. 62, 179 (1995)

ASTM E139–11 (2018), Standard Test Methods for Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic Materials (ASTM International, West Conshohocken, 2018)

M. Tabuchi, Y. Takahashi, in Proceedings of the ASME 2006 Pressure Vessels and Piping/ICPVT-11 Conference, Vancouver, July 23–27, 2006. Vol. 6: Materials and Fabrication (American Society of Mechanical Engineers, New York, 2006), pp. 529–534

ASME B31.3-2018: Process piping: ASME code for pressure piping, B31./ the American Society of Mechanical Engineers, New York, NY: American Society of Mechanical engineers (2018), Print

K. Laha, K.S. Chandravathi, P. Parameswaran, S. Goyal, M.D. Mathew, Metall. Mater. Trans. A 43, 1174 (2012)

D.R. Barbadikar, T. Sakthivel, A.R. Ballal, D.R. Peshwe, P. Syamala Rao, M.D. Mathew, Mater. High Temp. 35, 427 (2018)

D.J. Abson, J.S. Rothwell, Int. Mater. Rev. 58, 437 (2013)

Acknowledgements

This work was supported by Korea Evaluation Institute of Industrial Technology(KEIT) grant funded by Korea government Ministry of Trade, Industry and Energy (No. 10052860). Authers also acknowledge the financial support of the National Research Foundation of Korea (NRF) grant funded by the Korean government Ministry of Science and ICT/MSIT (NRF-2020R1A2C4002291).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ma, Y.W., Lee, K.W., Kong, B.O. et al. Evaluation of Weld Joint Strength Reduction Factor due to Creep in Alloy 740H to P92 Dissimilar Metal Weld Joint. Met. Mater. Int. 27, 4408–4417 (2021). https://doi.org/10.1007/s12540-021-00988-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-00988-7