Abstract

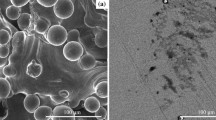

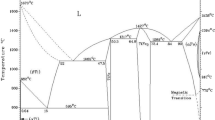

Titanium (Ti) and its alloys have attractive properties like high strength-to-weight ratio, excellent formability, biocompatibility, and corrosion resistance. These alloys are conventionally produced via subtractive manufacturing (SM) method, but recently new additive manufacturing (AM) method has been developed and can fabricate desired products by melting and stacking powders using a laser, electron beam, or a plasma arc. From a mechanical perspective, the strength and ductility of AM Ti alloys are comparable to or above those fabricated via SM because of their unique microstructure. However, AM Ti alloys corrosion resistance is still unknown, because of their defects and formation of martensite phase resulting from rapid solidification, hence new strategies were developed to evaluate localized corrosion resistance Consequently, a measurement method based on electrochemical critical localized corrosion temperature (E-CLCT) was adopted as ISO 22,910:2020 but its application should be limited at normal ranges of pH and temperatures corresponding to the human body because of the temperature scan during the E-CLCT testing. Therefore, electrochemical critical localized corrosion potential (E-CLCP) was introduced and proposed in this paper as a new criterion in evaluating the resistance against localized corrosions in biomedical AM Ti alloys in human body environments. AM Ti alloy samples without a hole and crevice former as well as an electrochemical polarization cell were used in the artificial physiological fluids. This study explores how to efficiently evaluate the localized corrosion resistance of AM Ti alloys such as Ti-6Al-4 V by measuring E-CLCP values in the artificial physiological fluids.

Graphic Abstract

Similar content being viewed by others

Change history

23 July 2021

A Correction to this paper has been published: https://doi.org/10.1007/s12540-021-01085-5

References

P. Lu, M. Wu, X. Liu, W. Duan, J. Han, Met. Mater. Int. 26, 1182 (2020)

J. Chávez, O.J. Alemán, M.F. Martínez, H.J. Vergara-Hernández, L. Olmos, P. Garnica-González, D. Bouvard, Met. Mater. Int. 26, 205 (2020)

W.D. Zhang, J. Ren, B. Liu, Y. Liu, Z. Wu, J. Qiu, Met. Mater. Int. 26, 973 (2020)

T. Bhardwaj, M. Shukla, N.K. Prasad, C.P. Paul, K.S. Bindra, Met. Mater. Int. 26, 1015 (2020)

G. Suprobo, A.A. Ammar, N. Park, E.R. Baek, S. Kim, Met. Mater. Int. 25, 1428 (2019)

T.J. Horn, O.L. Harrysson, Sci. Prog. 95, 255 (2012)

D.-I. Seo, J.-B. Lee, J. Electrochem. Soc. 166, C428 (2019)

D.I. Seo, J.B. Lee, Corros. Sci. 173, 108789 (2020)

D.I. Seo, J.B. Lee, J. Electrochem. Soc. 167, 101509 (2020)

ISO 22910, Corrosion of metals and alloys–Measurement of the electrochemical critical localized corrosion temperature (E-CLCT) for Ti alloys fabricated via the additive manufacturing method (International Organization for Standardization, Geneva, 2020)

ISO 17475, Corrosion of metals and alloys–Electrochemical Test Methods– Guidelines for Conducting Potentiostatic and Potentiodynamic Polarization Measurements (International Organization for Standardization, Geneva, 2005)

S. Tsujikawa, Y. Hisamatsu, B. Gijutu, Corros. Eng. Jpn. 29, 37 (1980)

ASTM G192-08, Standard Test Method for Determining the Crevice Repassivation Potential of Corrosion Resistant Alloys Using a Potentiodynamic-Galvanostatic-Potentiostatic Technique (ASTM International, West Conshohocken, PA, 2008)

J.-B. Lee, D.-I. Seo, H.-Y. Chang, Met. Mater. Int. 26, 39 (2020)

Acknowledgments

This work was supported by the Technology Innovation Program (20006868, Standard Development for Corrosion testings of Additive Manufactured (3D Printing) Bio-metallic material) which is funded By the Ministry of Trade, Industry, & Energy (MOTIE, Korea)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: In the original publication, the abstract section was missing from this article and it has been included.

Rights and permissions

About this article

Cite this article

Lee, JB., Seo, DI. & Chang, HY. Evaluating Corrosion Resistance of Biomedical Ti-6Al-4 V Alloys Fabricated via Additive Manufacturing Using Electrochemical Critical Localized Corrosion Potential. Met. Mater. Int. 27, 2353–2359 (2021). https://doi.org/10.1007/s12540-021-00972-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-00972-1