Abstract

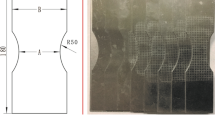

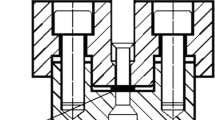

In this work, the onset of failure induced by severe strain at elevated temperature was numerically estimated with cross-formed empirical hardening law describing material softening. The hardening law can replicate the rate-sensitive behavior of aluminum alloy 7075 sheets (thickness of 2.0 mm) with initial hardening and progressive material deterioration caused by dynamic recrystallization, dynamic recovery, and micro-void development. The characterized material was applied to the two-step hybrid forming process consisting of a drawing at 400 °C followed by a pneumatic forming at 470 °C to produce a shock absorber housing with an extremely complex shape. The user-defined subroutine codes, VUMAT (ABAQUS/Explicit) and UMAT (ABAQUS/Standard), were sequentially utilized for the drawing and the pneumatic forming, respectively. The identified hardening parameters based on uniaxial tensile tests were validated by simulating the two-step hybrid forming process and compared with the conventional Voce type law (converging function) and the combined Swift-Voce type law (ever-increasing function) since they play a key role in accurately predicting the onset of failure induced by severe strain localization. Finally, simulation results are reasonably well matched with experiments in terms of the moment of failure occurrence, failure location, final blank shape, and thickness distribution.

Graphic Abstract

Similar content being viewed by others

References

I.N. Fridlyander, V.G. Sister, O.E. Grushko, V.V. Berstenev, L.M. Sheveleva, L.A. Ivanova, Met. Sci. Heat Treat. 44, 365–370 (2002)

M. Tisza, I. Czinege, Int. J. Lightweight Mater. Manuf. 1, 229–238 (2018)

E.S. de Argandona, L. Galdos, R. Ortubay, J. Mendiguren, X. Agirretxe, Comp. Methods Mater. Sci. 15, 51–57 (2015)

K. Zheng, Y. Dong, D. Zheng, J. Lin, T.A. Dean, J. Mater. Process. Tech. 268, 87–96 (2019)

J. Lee, H.J. Bong, D. Kim, Y.-S. Lee, Y. Choi, M.-G. Lee, Met. Mater. Int. 26, 682–694 (2020)

Y. Choi, J. Lee, S.S. Panicker, H.-K. Jin, S.K. Panda, M.-G. Lee, Int. J. Mech. Sci. 170, 105344 (2020).

A.J. Barnes, J. Mater. Eng. Perform 16, 440–454 (2007)

P.A. Friedman, S.G. Luckey, W.B. Copple, R. Allor, C.E. Miller, C. Young, J. Mater. Eng. Perform. 13, 670–677 (2004)

J. Liu, M.-J. Tan, Y. Aue-u-lan, A.E.W. Jarfors, K.-S. Fong, S. Castagne, Int. J. Adv. Manuf. Tech. 52, 123–129 (2011)

B. Kaushik, S. Basak, H.J. Choi, S.K. Panda, M.G. Lee, Influence of evolution in anisotropy during strain path change on failure limits of sheet metals. Met. Mater. Int. (2020). https://doi.org/10.1007/s12540-020-00896-2

M. Cockcroft, D. Latham, J. I. Met. 96, 33–39 (1968)

P. Brozzo, B. Deluca, R. Rendina, A new method for the prediction of formability limits in metal sheets in Proceedings of the 7th Biennal Conference of the International Deep Drawing Research group, Amsterdam, October 9-13, 1972

S.E. Clift, P. Hartley, C. Sturgess, G. Rowe, Int. J. Mech. Sci. 32, 1–17 (1990)

K. Chung, H. Kim, C. Lee, Int. J. Plasticity 58, 3–34 (2014)

K. Chung, C. Lee, H. Kim, Int. J. Plasticity 58, 35–65 (2014)

Y. Koh, D. Kim, D.-Y. Seok, J. Bak, S.-W. Kim, Y.-S. Lee, K. Chung, Int. J. Mech. Sci. 93, 204–217 (2015)

W. Kim, T.B. Stoughton, M.-G. Lee, Int. J. Mech. Sci. 193, 106146 (2020)

H. Kim, Characterization method for hardening and strain-rate sensitivity at elevated temperature based on uniaxial tension and creep tests, Ph.D. thesis, Seoul National University (2015)

H. Kim, J.W. Yoon, K. Chung, M.-G. Lee, Int. J. Mech. Sci. 187, 105913 (2020)

E. Voce, J. I. Met. 74, 537–562 (1948)

W.F. Hosford, R.M. Caddell, Metal Forming: Mechanics and Metallurgy (Cambridge University Press, Cambridge, 2011)

D.-Y. Seok, D. Kim, S.-W. Kim, J. Bak, Y.-S. Lee, K. Chung, Met. Mater. Int. 21, 54–71 (2015)

T. Al-Samman, G. Gottstein, Mater. Sci. Eng. A 490, 411–420 (2008)

J.C. Tan, M.J. Tan, Mater. Sci. Eng. A 339, 124–132 (2003)

X.-Y. Yang, Z.-S. Ji, H. Miura, T. Sakai, T. Nonferr. Metal. Soc. 19, 55–60 (2009)

J. Koike, R. Ohyama, T. Kobayashi, M. Suzuki, K. Maruyama, Mater. Trans. 44, 445–451 (2003)

E.H. Lee, J. Appl. Mech. 36, 1–6 (1969)

ASM Handbook Committee, Properties and Selection: Nonferrous Alloys and Special-Purpose Materials (ASM International, Materials Park, OH, 1990)

K. Chung, N. Ma, T. Park, D. Kim, D. Yoo, C. Kim, Int. J. Plasticity 27, 1485–1511 (2011)

L. Ying, T. Gao, H. Rong, X. Han, P. Hu, W. Hou, J. Alloy. Compd. 802, 675–693 (2019)

W. Xiao, B. Wang, K. Zheng, Int. J. Adv. Manuf. Tech. 92, 3299–3309 (2017)

T. Gao, L. Ying, P. Hu, X. Han, H. Rong, Y. Wu, J. Sun, J. Manuf. Process. 50, 1–16 (2020)

Acknowledgements

This study was financially supported by the Industrial Technology Innovation Program (No.10077492) funded by the Ministry of Trade, Industry and Energy (MOTIE) and the Fundamental Research Program of the Korea Institute of Materials Science (PNK6850) funded by the Ministry of Science and ICT (MSIT), Republic of Korea.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hong, JH., Kim, H., Kim, W. et al. Failure with Strain Localization of Aluminum Alloy 7075 Sheets at Elevated Temperature and its Application to Two-Step Hybrid Forming. Met. Mater. Int. 28, 871–886 (2022). https://doi.org/10.1007/s12540-020-00949-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00949-6