Abstract

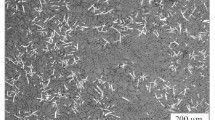

The effect of the ternary alloys composition and overheating of their melts (at 100–370 K above the liquidus temperature) on the morphology and composition of aluminides in the Al–Sc–Ti, Al–Sc–Zr, Al–Sc–Hf systems were investigated. It was shown that during the crystallization of these melts under certain conditions, the primary precipitated phase are the complex aluminides Al3(ScxZr1−x), Al3(ScxTi1−x), Al3(ScxHf1−x) having a metastable cubic lattice with L12 structure, which matches the α-Al structural type. The variety of growth forms of aluminides is explained by a combination of a number of factors: the magnitude of overheating of the melt, the difference in the diffusion coefficients of transition metals, and the local concentration of transition metals in the respective growth zones.

Graphic Abstract

Similar content being viewed by others

References

Z. Li, H. Jiang, Y. Wang, D. Zhang, D. Yan, L. Rong, Effect of minor Sc addition on microstructure and stress corrosion cracking behavior of medium strength Al–Zn–Mg alloy. J. Mater. Sci. Technol. 34(7), 1172–1179 (2018)

J. Zhang, H. Wang, D. Yi, B. Wang, H. Wang, Comparative study of Sc and Er addition on microstructure, mechanical properties, and electrical conductivity of Al-0.2Zr-based alloy cables. Mater. Charact. 145, 126–134 (2018)

S.H. Wu, P. Zhang, D. Shao, P.M. Cheng, J. Kuang, K. Wu, J.Y. Zhang, G. Liu, J. Sun, Show more grain size-dependent Sc microalloying effect on the yield strength-pitting corrosion correlation in Al–Cu alloys. Mater. Sci. Eng. A 721(4), 200–214 (2018)

N. Belov, E. Naumova, T. Akopyan, Effect of 0.3% Sc on microstructure, phase composition and hardening of Al–Ca–Si eutectic alloys. Trans. Nonferrous Metals Soc. China 27(4), 741–746 (2017)

D. Erdeniz, W. Nasim, J. Malik, A.R. Yost, S. Park, A. De Luca, N.Q. Vo, I. Karaman, B. Mansoor, D.N. Seidman, D.C. Dunand, Effect of vanadium micro-alloying on the microstructural evolution and creep behavior of Al–Er–Sc–Zr–Si alloys. Acta Mater. 124, 501–512 (2017)

J.H. Li, M. Wiessner, M. Albu, S. Wurster, B. Sartory, F. Hofer, P. Schumacher, Correlative characterization of primary Al3(Sc, Zr) phase in an Al–Zn–Mg based alloy. Mater. Charact. 102, 62–70 (2015)

S. Saumitra, T.Z. Todorova, J.W. Zwanziger, Temperature dependent lattice misfit and coherency of Al3X (X = Sc, Zr, Ti and Nb) particles in an Al matrix. Acta Mater. 89, 109–115 (2015)

T. Dorin, M. Ramajayam, J. Lamb, T. Langan, Effect of Sc and Zr additions on the microstructure/strength of Al–Cu binary alloys. Mater. Sci. Eng. A 707, 58–64 (2017)

H. Hallem, W. Lefebvre, B. Forbord, F. Danoix, K. Marthinsen, The formation of Al3(ScxZryHf1−x−y)-dispersoids in aluminium alloys. Mater. Sci. Eng. A 421, 154–160 (2006)

H. Hallem, B. Forbord, K. Marthinsen, An investigation of dilute Al–Hf and Al–Hf–Si alloys. Mater. Sci. Eng. A 387–389, 940–943 (2004)

A.F. Norman, P.B. Prangnell, R.S. McEwen, The solidification behavior of dilute aluminium–scandium alloys. Acta Mater. 46(16), 5715–5732 (1998)

S. Srinivasan, P.B. Desch, R.B. Schwarz, Metastable phases in the Al3X (X = Ti, Zr, and Hf) intermetallic system. Scripta Metall. Mater. 25(11), 2513–2516 (1991)

I.G. Brodova, I.V. Polents, V.O. Esin, E.M. Lobov, On the formation of the cast structure of supercooled Al–Ti alloys. Phys. Metals Metall. 73(1), 63–67 (1992)

P. Malek, M. Janecek, B. Smola, P. Bartuska, J. Plestil, Structure and properties of rapidly solidified Al–Zr–Ti alloys. J. Mater. Sci. 35, 2625–2633 (2000)

A.F. Norman, P. Tsakiropoulos, Rapid solidification of Al–Hf alloys—solidification, microstructures and decomposition of solid-solutions. Int. J. Rapid Solid 6(3–4), 185–213 (1991)

E.A. Popova, A.B. Shubin, P.V. Kotenkov, E.A. Pastukhov, L.E. Bodrova, O.M. Fedorova, Al–Ti–Zr master alloys: structure formation. Russ. Metall. (Metally) 2012(5), 357–361 (2012)

E.A. Popova, P.V. Kotenkov, E.A. Pastukhov, A.B. Shubin, Master alloys Al–Sc–Zr, Al–Sc–Ti, and Al–Ti–Zr: their manufacture, composition, and structure. Russ. Metall. (Metally) 2013(8), 590–594 (2013)

E.A. Popova, A.B. Shubin, P.V. Kotenkov, L.E. Bodrova, A.V. Dolmatov, E.A. Pastukhov, N.A. Vatolin, Al–Sc–Zr Master alloy and estimation of its modifying capacity. Russ. Metall. (Metally) 2011(8), 715–718 (2011)

E.A. Popova, P.V. Kotenkov, E.A. Pastukhov, Synergetic effect in modifying with master alloys having an aluminide cubic structure. Russ. Metall. (Metally) 2016(2), 189–193 (2016)

J.L. Murray, The Al–Sc (Aluminum–Scandium) system. J. Phase. Equil. 19(4), 380–384 (1998)

K.E. Knipling, D.C. Dunand, D.N. Seidman, Nucleation and precipitation strengthening in dilute Al–Ti and Al–Zr alloys. Metall. Mater. Trans. A 38, 2552–2563 (2007)

J.L. Murray, A.J. McAlister, D.J. Kahan, The Al–Hf (Aluminum–Hafnium) system. J. Phase. Equil. 19(4), 376–379 (1998)

G. Ghosh, M. Asta, First-principles calculation of structural energetics of Al–TM (TM = Ti, Zr, Hf) intermetallics. Acta Mater. 53, 3225–3252 (2005)

K.B. Hyde, A.F. Norman, P.B. Prangnell, The effect of cooling rate on the morphology of primary Al3Sc intermetallic particles in Al–Sc alloys. Acta Mater. 49, 1327–1337 (2001)

A.V. Shubin, E.A. Popova, KYu. Shunyev, E.A. Pastukhov, Slow crystallization Al–Sc alloys: growth of spherical intermetallic particles. Defect Diffus. Forum 326–328, 75–80 (2012)

A.B. Shubin, E.A. Popova, P.V. Kotenkov, E.A. Pastukhov, Crystallization of Al–Sc–Ti alloys at low cooling rates: morphology of intermetallic particles. Melts 5, 3–11 (2015). (In Russian)

K.B. Hyde, A.F. Norman, P.B. Prangnell, The effect of Ti on grain refinement in Al–Sc alloys. Mater. Sci. Forum 396–402, 39–44 (2002)

S.I. Fujikawa, Solid state diffusion in light metals. J. Jpn. Inst. Light Metals 46(4), 202–215 (1996)

X.U. Cong, D.U. Rou, X.J. Wang, S. Hanada, H. Yamagata, W.H. Wang, C.L. Ma, Effect of cooling rate on morphology of primary particles in Al−Sc−Zr master alloy. Trans. Nonferrous Met. Soc. China 24, 2420–2426 (2014)

K.E. Knipling, R.A. Karnesky, C.P. Lee, D.C. Dunand, D.N. Seidman, Precipitation evolution in Al–0.1Sc, Al–0.1Zr and Al–0.1Sc–0.1Zr (at.%) alloys during isochronal aging. Acta Mater. 58, 5184–5195 (2010)

H. Hallem, B. Forbord, K. Marthinsen, An investigation of cast structures in Al–Hf– (Sc)–(Zr) alloys and their subsequent effect on recrystallisation resistance after cold rolling. Mater. Forum 28, 240–245 (2004)

Y. Harada, D.C. Dunand, Microstructure of Al3Sc with ternary transition-metal additions. Mater. Sci. Eng. A 329–331, 686–695 (2002)

Acknowledgments

The work was carried out according to the state assignment for IMET UB RAS. The results were obtained using the equipment of the Ural-M Center for Collective Use.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Popova, E., Kotenkov, P., Shubin, A. et al. Formation of Metastable Aluminides in Al–Sc–Ti (Zr, Hf) Cast Alloys. Met. Mater. Int. 26, 1515–1523 (2020). https://doi.org/10.1007/s12540-019-00397-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00397-x