Abstract

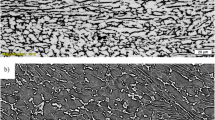

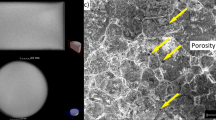

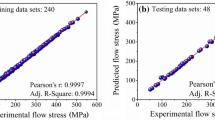

Titanium alloy Ti6Al4V has been recognized for its high strength-to-weight ratio. Extensive deformation study has been conducted; however, defects like strain-induced porosities, non-uniform microstructure, etc., are observed during thermomechanical processing. So, optimization of thermomechanical processing parameters is highly essential to avoid the recurrence of these kinds of defects. Characterization of defects noticed in hot-rolled ring sample was carried out and a detailed deformation study has been conducted to understand the generation of such defects to avoid their occurrence. The study has been conducted in the temperature range of 800-1050 °C and strain rate of 0.001 to 10 s−1 using a Gleeble 3800 thermomechanical simulator. Microstructural mapping of the deformed Ti6Al4V is carried out. Workability by hot deformation is explained through processing maps. As per the efficiency of power dissipation maps, the maximum efficiency of 65-70 % is obtained in the temperature range of 825-900 °C and strain rate 10−3 to 10 −2.5 s−1 up to 0.4 strains. Arrhenius equations are used to calculate the activation energy of hot deformation and an average of 620.62 kJ/mol was obtained for the temperature range of 750-950 ºC. Prediction capability of constitutive models like the modified Johnson–Cook (m-JC) model and artificial neural network (ANN) was verified for deformation behavior. ANN model is found to give the best fit with an absolute average error (AARE) of 0.0417 and correlation coefficient (R) 0.9985. Hot rolling was also conducted at different temperatures of 800-950 °C in the intervals of 50 °C up to 50 % reduction. Microstructure obtained through hot compression and hot rolling is discussed. Specimen hot compressed at 800 °C and strain rates of 0.001, 0.01, 0.1, 1 and 10 s−1 showed strain-induced porosities along the grain boundaries. Similarly, hot-rolled samples at 800 °C showed the presence of strain-induced porosities.

Similar content being viewed by others

References

M. Peters and C. Leyens, Aerospace and Space Materials, Materials Science and Engineering – vol. III

E.B. Shell and S.L. Semiatin, Effect of Initial Microstructure on Plastic Flow and Dynamic Globularization during Hot Working of Ti-6Al-4V, Metall. Mater. Trans. A, 1999, 30, p 3219–3229.

Z.X. Zhang, S.J. Qu, A.H. Feng, and J. Shen, Achieving Grain Refinement and Enhanced Mechanical Properties in Ti-6Al-4V Alloy Produced by Multidirectional Isothermal Forging, Mater. Sci. Eng. A, 2017, 692, p 127–138.

S.L. Semiatin, V. Seetharaman, and I. Weiss, The Thermomechanical Processing of alpha/beta Titanium Alloys, J. Mater. Sci., 1997, 49, p 33–39.

C. Leyens and M. Peters, The metallurgy of titanium alloys Titanium and Titanium Alloys: Fundamentals and Applications, Wiley-VCH GmbH Germany, Germany, 2003, p 4–5

M. Peters, A. Gysler, G. Liitjering, Titanium 80, 4th International Conference on Titanium, Kyoto, Japan, 1980, pp. 1777-86.

T. Seshacharyulu, S.C. Medeiros, W.G. Frazier, and Y.V.R.K. Prasad, Microstructural Mechanisms during Hot Working of Commercial Grade Ti–6Al–4V with Lamellar Starting Structure, Mater. Sci. Eng. A, 2002, 325, p 112–125.

J. Cai, K. Wang, P. Zhai, F. Li, and J. Yang, A Modified Johnson-Cook Constitutive Equation to Predict Hot Deformation Behavior of Ti-6Al-4V Alloy, J. Mater. Eng. Perform., 2015, 24, p 32–44. https://doi.org/10.1007/s11665-014-1243-x

T. Sheppard and J. Norley, Deformation Characteristics of Ti-6AI-4V, Mater. Sci. Technol., 1988, 4, p 903–908.

W. Zhang, H. Ding, J. Zhao, B. Yang, W. Yang, and I. Introduction, Hot Deformation Behavior and Processing Maps of Ti-6Al-4V Alloy with Starting Fully Lamellar Structure, J. Mater. Res., 2018 https://doi.org/10.1557/jmr.2018.331

P.M. Souza, H. Beladi, B. Rolfe, R. Singh, and P.D. Hodgson, Softening Behavior of Ti6Al4V Alloy During Hot Deformation, Mater. Sci. Form, 2015, 829, p 407–412. https://doi.org/10.4028/www.scientific.net/MSF.828-829.407

P.M. Souza, J. Mendiguren, Q. Chao, H. Beladi, P.D. Hodgson, and B. Rolfe, A Microstructural Based Constitutive Approach for simulating Hot Deformation of Ti6Al4V Alloy in the α + β Phase Region, Mater. Sci. Eng. A, 2019, 748, p 30–37. https://doi.org/10.1016/j.msea.2019.01.081

Y.C. Lin, C.Y. Zhao, M.S. Chen, and D.D. Chen, A Novel Constitutive Model for Hot Deformation Behaviors of Ti-6Al-4V Alloy Based on Probabilistic Method, Appl. Phys. A, 2016, 122, p 71.

Y.C. Lin, Q. Wu, G.D. Pang, X.Y. Jiang, and D.G. He, Hot Tensile Deformation Mechanism and Dynamic Softening Behavior of Ti-6Al-4V Alloy with Thick Lamellar Microstructures, Adv. Eng. Mater., 2020, 22, p 1901193.

N. Nayan, R.K. Gupta, V. AnilKumar, Y. Maruti Prasad, and S.V.S.N. Murty, Metallurgical Investigation and Root Cause Analysis of Defects in a Ti Alloy (Ti6Al4V) Propellant Tank Ring, J. Preven. Fail. Anal., 2023 https://doi.org/10.1007/s11668-023-01712-w

M.M. Uz, A.B. Hazar Yoruç, O. Cokgunlu, C.S. Aydo˘gan, and G.G. Yapici, A Comparative Study on Phenomenological and Artificial Neural Network Models for High Temperature Flow Behavior Prediction in Ti6Al4V Alloy, Mater. Today Commun., 2022, 33, p 104933. https://doi.org/10.1016/j.mtcomm.2022.104933

H. Ming, L. Dong, Z. Zhang, X. Lei, R. Yang, and Y. Sha, Correction of Flow Curves and Constitutive Modelling of a Ti-6Al-4V Alloy, Metals, 2018, 8, p 256. https://doi.org/10.3390/met8040256

I. Weiss, R. Srinivasan, P.J. Bania, D. Eylon, and S.L. Semiatin, Advances in the Science and Technology of Titanium Alloy Processing, TMS, Warrendale, Pennsylvania, 1996, p 349–367

E.W. Collings, G. Welsch, and R. Boyer, Materials Properties Handbook: Titanium Alloys, ASM International, Detroit, 1994.

T. Seshacharyulu, S.C. Medeiros, W.G. Frazier, and Y.V.R.K. Prasad, Hot Working of Commercial Ti-6Al-4V with an Equiaxed a–b Microstructure: Materials Modeling Considerations, Mater. Sci. Eng. A, 2000, 284, p 184–194.

H. Margolin and P. Cohen, Titanium '80, 4th International Conference on Titanium, Kyoto, Japan, 1980, pp. 1555-61.

Y.V.R.K. Prasad and S. Sasidhara Eds., Hot Working Guide: A Compendium of Processing Maps, ASM International, Materials Park, OH, 1997

Y.C. Lin, X.Y. Jianga, C.J. Shuaib, C.Y. Zhaoa, D.G. Hea, M.S. Chenb, and C. Chend, Effects of Initial Microstructures on Hot Tensile Deformation Behaviors and Fracture Characteristics of Ti-6Al-4V Alloy, Mater. Sci. Eng. A, 2018, 711, p 293–330.

S.L. Semiatin, R.L. Goetz, E.B. Shell, V. Seetharaman, and A.K. Ghosh, Cavitation and Failure during Hot Forging of Ti-6Al-4V, Metall. Mater. Trans. A, 1999, 30A, p 1411–1424.

R.K. Gupta, S.V.S. Narayana Murty, B. Pant, V. Agarwala, and P.P. Sinha, Hot Workability of γ+α2 Titanium Aluminide: Development of Processing Map and Constitutive Equations, Mater. Sci. Eng. A, 2012, 551, p 169–186.

M. Hu, L. Dong, Z. Zhang, X. Lei, R. Yang, and Y. Sha, Correction of Flow Curves and Constitutive Modelling of a Ti-6Al-4V Alloy, Metals, 2018, 8, p 1–15. https://doi.org/10.3390/met8040256

G.R. Johnson, A Constitutive Model and Data for Materials Subjected to Large Strains, High Strain Rates, and High Temperatures, Proc. 7th Inf. Sympo. Ballist. (1983) 541–547.

H. Zhang, W. Wen, and H. Cui, Behaviors of IC10 Alloy Over a Wide Range of Strain Rates and Temperatures: Experiments and Modeling, Mater. Sci. Eng. A, 2009, 504, p 99–103. https://doi.org/10.1016/j.msea.2008.10.056

Q.Y. Hou and J.T. Wang, A Modified Johnson-Cook Constitutive Model for Mg-Gd-Y Alloy Extended to a Wide Range of Temperatures, Comput. Mater. Sci., 2010, 50, p 147–152. https://doi.org/10.1016/j.commatsci.2010.07.018

Y.C. Lin, X.M. Chen, and G. Liu, A Modified Johnson-Cook Model for Tensile Behaviors of Typical High-strength Alloy Steel, Mater. Sci. Eng. A, 2010, 527, p 6980–6986. https://doi.org/10.1016/j.msea.2010.07.061

D. Samantaray, S. Mandal, A.K. Bhaduri, and P.V. Sivaprasad, An Overview on Constitutive Modelling to Predict Elevated Temperature Flow Behaviour of Fast Reactor Structural Materials, Trans. Indian Inst. Met., 2010, 63, p 823–831. https://doi.org/10.1007/s12666-010-0126-6

L. Yumeng, L. Jinxu, L. Shukui, and C. Xingwang, Effect of Hot-rolling Temperature on Microstructure and Dynamic Mechanical Properties of Ti-6Al-4V Alloy, Rare Metal Mater. Eng., 2018, 47(5), p 1333–1340.

Y.C. Lin, J. Huang, D.G. He, X.Y. Zhang, Q. Wu, L.H. Wang, C. Chen, and K.C. Zhou, Phase Transformation and Dynamic Recrystallization Behaviors in a Ti55511 Titanium Alloy during Hot Compression, J. Alloys Compd., 2019, 795, p 471–482.

Y.Q. Jianga, Y.C. Lin, X.Y. Jianga, D.G. Hea, X.Y. Zhangc, and N. Kotkunde, Hot Tensile Properties, Microstructure Evolution and Fracture Mechanisms of Ti-6Al-4V Alloy with Initial Coarse Equiaxed Phases, Mater Charact, 2020, 163, p 110272.

Acknowledgments

Authors wish to express their deep sense of gratitude to Group Director, Materials and Metallurgy Group and Deputy Director, Materials and Mechanical Entity for their encouragement and support during this work. Authors are thankful to Aerospace materials lab team, LPSC, for the support provided for the isothermal compression test carried out in Gleeble thermomechanical simulator.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dhanya, M.S., Anoop, S., Manwatkar, S.K. et al. Hot Workability and Microstructure Control of Ti6Al4V Alloy. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09228-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09228-6