Abstract

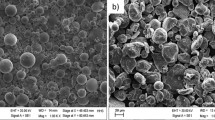

This study investigated the feasibility of a direct energy deposition process for fabrication of oxide dispersion strengthened steel cladding. The effect of the laser working power and scan speed on the microstructural stability of oxide nanoparticles in the deposition layer was examined. Y-Ti-O type oxide nanoparticles with a mean diameter of 45 nm were successfully dispersed by the laser deposition process. The laser working power significantly affected nanoparticle size and number density. A high laser power with a low scan speed seriously induced particle coarsening and agglomeration. Compared with bulk oxide dispersion strengthened steel, the hardness of the laser deposition layer was much lower because of a relatively coarse particle and grain size. Formation mechanism of nanoparticles during laser deposition was discussed.

Similar content being viewed by others

References

X. Boulnat, M. Perez, D. Fabrègue, S. Cazottes, and Y. De Carlan, Acta Mater. 107, 390 (2016).

I. Hilger, F. Bergner, A. Ulbricht, A. Wagner, T. Weißgärber, B. Kieback, et al. J. Alloy. Compd. 685, 927 (2016).

L. Barnard, N. Cunningham, G. R. Odette, I. Szlufarska, and D. Morgan, Acta Mater. 91, 340 (2015).

T. K. Kim, G. E. Kim, Y. Do Kim, and S. Noh, Korean J. Met. Mater. 54, 533 (2016).

M. Ohnuma, J. Suzuki, S. Ohtsuka, S. W. Kim, T. Kaito, M. Inoue, et al. Acta Mater. 57, 5571 (2009).

T. S. Byun, J. H. Yoon, D. T. Hoelzer, Y. B. Lee, S. H. Kang, and S. A. Maloy, J. Nucl. Mater. 449, 290 (2014).

J. H. Kim, J.-B. Seol, and K. M. Kim, Korean J. Met. Mater. 54, 171 (2016).

J. H. Kim, T. S. Byun, E. Shin, J. B. Seol, S. Young, and N. S. Reddy, J. Alloy. Compd. 651, 363 (2015).

T. K. Kim, J.-E. Choi, S.-I. Hong, B. K. Choi, S. Noh, and G. E. Kim, Korean J. Met. Mater. 53, 529 (2015).

T. Liu, L. Wang, C. Wang, H. Shen, and H. Zhang, Mater. Design 88, 862 (2015).

A. J. London, S. Santra, S. Amirthapandian, B. K. Panigrahi, R. M. Sarguna, S. Balaji, et al. Acta Mater. 97, 223 (2015).

X. Mao, K. H. Oh, S. H. Kang, T. K. Kim, and J. Jang, Acta Mater. 89, 141 (2015).

R. M. Hunt, K. J. Kramer, and B. El-Dasher, J. Nucl. Mater. 464, 80 (2015).

J. S. Park, M.-G. Lee, Y.-J. Cho, J. H. Sung, M.-S. Jeong, D. H. Kim, et al. Met. Mater. Int. 22, 143 (2016).

J. C. Walker, K. M. Berggreen, A. R. Jones, and C. J. Sutcliffe, Adv. Eng. Mater. 11, 541 (2009).

T. Boegelein, E. Louvis, K. Dawson, G. J. Tatlock, and A. R. Jones, Mater. Charact. 112, 30 (2016).

T. Boegelein, S. N. Dryepondt, A. Pandey, K. Dawson, and G. J. Tatlock, Acta Mater. 87, 201 (2015).

S. M. Thompson, L. Bian, N. Shamsaei, and A. Yadollahi, Addit. Manuf. 8, 36 (2015).

L. E. Murr, E. Martinez, K. N. Amato, S. M. Gaytan, J. Hernandez, D. A. Ramirez, et al. J. Mater. Res. Technol. 1, 42 (2012).

N. Shamsaei, A. Yadollahi, L. Bian, and S. M. Thompson, Addit. Manuf. 8, 12 (2015).

H. Kim, I. Kim, Y. Jung, D. Park, J. Park, and Y. Koo, Nucl. Eng. Technol. 46, 521 (2014).

J. H. Schneibel, C. T. Liu, M. K. Miller, M. J. Mills, P. Sarosi, M. Heilmaier, et al. Scripta Mater. 61, 793 (2009).

S. Noh, B. K. Choi, S. H. Kang, and T. K. Kim, Nucl. Eng. Technol. 46, 857 (2014).

A. Hirata, T. Fujita, C. T. Liu, and M. W. Chen, Acta Mater. 60, 5686 (2012).

H. J. Chang, H. Y. Cho, and J. H. Kim, J. Alloy. Compd. 653, 528 (2015).

S. Liang, Y. Lei, and Q. Zhu, J. Nucl. Mater. 456, 206 (2015).

L. Barnard, G. R. Odette, I. Szlufarska, and D. Morgan, Acta Mater. 60, 935 (2012).

D. H. Kim, Y. H. Lee, and J. H. Kim, Korean J. Met. Mater. 667, 311 (2016).

F. Bergner, I. Hilger, J. Virta, J. Lagerbom, G. Gerbeth, S. Connolly, et al. Metall. Mater. Trans. A 47, 5313 (2016).

M. Nagini, R. Vijay, M. Ramakrishna, A. V. Reddy, and G. Sundararajan, Mat. Sci. Eng. A 620, 490 (2014).

K. D. Zilnyk, H. R. Z. Sandim, R. E. Bolmaro, R. Lindau, A. Möslang, A. Kostka, et al. J. Nucl. Mater. 448, 33 (2014).

K. Verhiest, S. Mullens, I. De Graeve, N. De Wispelaere, S. Claessens, A. De Bremaecker, et al. Ceram. Int. 40, 14319 (2014).

E. A. Jägle, Z. Sheng, L. Wu, L. Lu, J. Risse, A. Weisheit, et al. JOM 68, 943 (2016).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Euh, K., Arkhurst, B., Kim, I.H. et al. Stability of Y-Ti-O nanoparticles during laser deposition of oxide dispersion strengthened steel powder. Met. Mater. Int. 23, 1063–1074 (2017). https://doi.org/10.1007/s12540-017-6832-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-017-6832-4