Abstract

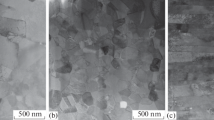

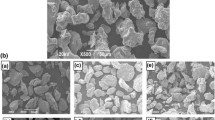

The influence of titanium alloying (Ti content of 0, 0.2, 0.3, and 0.4 wt %) on the nanostructure of yttrium oxide (Y2O3) dispersion strengthened steel with a composition Fe-13.5% Cr-2% W-0.3% Y2O3 is investigated. The spatial distribution of chemical elements is analyzed in the investigated volumes. The matrix composition and average size and concentration of nanoscale clusters are compared for different samples. It is shown that the average nanocluster size (∼3 nm) is almost unchanged with increasing Ti concentration, while the cluster concentration grows from ∼1 × 1023 m−3 (for Ti-free steel) to ∼1.5 × 1024 m−3 (for 0.4 wt % Ti alloy).

Similar content being viewed by others

References

Klueh, R.L. and Harris, D.R., High-Chromium Ferritic and Martensitic Steels for Nuclear Application, ASTM stock Number: MONO3, 2001, p. 220.

Hirata, A., Fujita, T., Wen, Y.R., Schneibel, J.H., Liu, C.T., and Chen, M.W., Atomic structure of nanoclusters in oxide dispersion strengthened steels, Nat. Mater., 2011, vol. 10, pp. 922–926.

Ukai, S., Nishida, T., Okada, H., Okuda, T., Fujiwara, M., and Asabe, K., Development of oxide dispersion strengthened ferritic steels for FBR core application, (I) Improvement of mechanical properties by recrystallization processing, J. Nucl. Sci. Technol., 1997, vol. 34, pp. 256–263.

Cho, H.S., Kimura, A., Ukai, S., and Fujiwara, M., Corrosion properties of oxide dispersion strengthened steels in supercritical water environment, J. Nucl. Mater., 2004, vol. 329–333, pp. 387–391.

Cho, H.S., Kasada, R., and Kimura, A., Effects of neutron irradiation on the tensile properties of high-Cr oxide dispersion strengthened ferritic steels, J. Nucl. Mater., 2007, vol. 367–370, pp. 239–243.

Klueh, R.L., Shingledecker, J.P., Swindeman, R.W., and Hoelzer, D.T., Oxide dispersion-strengthened steels: A comparison of some commercial and experimental alloys, J. Nucl. Mater., 2005, vol. 341, pp. 103–114.

Ukai, S. and Fujiwara, M., Perspective of ODS alloys application in nuclear environments, J. Nucl. Mater., 2002, vol. 307–311, pp. 749–757.

Ukai, S., Harada, M., Okada, H., Inoue, M., Nomura, S., Shikakura, S., Nishida, T., Fujiwara, M., and Asabe, K., Tube manufacturing and mechanical properties of oxide dispersion strengthened ferritic steel, J. Nucl. Mater., 1993, vol. 204, pp. 74–82.

Rogozhkin, S.V., Nikitin, A.A., Aleev, A.A., Germanov, A.B., and Zaluzhnyi, A.G., Atom probe study of radiation induced precipitates in Eurofer97 ferriticmartensitic steel irradiated in BOR60 reactor, Inorg. Mater.: Appl. Res., 2013, vol. 4, pp. 112–118.

He, P., Klimenkov, M., Lindau, R., and Möslang, A., Characterization of precipitates in nano structured 14% Cr ODS alloys for fusion application, J. Nucl. Mater., 2012, vol. 428, pp. 131–138.

He, P., Liub, T., Möslang, A., Lindau, R., Ziegler, R., Hoffmann, J., Kurinskiy, P., Commin, L., Vladimirov, P., Nikitenko, S., and Silveir, M., XAFS and TEM studies of the structural evolution of yttrium-enriched oxides in nanostructured ferritic alloys fabricated by a powder metallurgy process, Mater. Chem. Phys., 2012, vol. 136, pp. 990–998.

Klueh, R.L., Maziasz, P.J., Kim, I.S., Heatherly, L., Hoelzer, D.T., Hashimoto, N., Kenik, E.A., and Miyahara, K., Tensile and creep properties of an oxide dispersion-strengthened ferritic steel, J. Nucl. Mater., 2002, vol. 307–311, pp. 773–777.

Rogozhkin, S.V., Ageev, V.S., Aleev, A.A., Zaluzhnyi, A.G., Leont’eva-Smirnova, M.V., and Nikitin, A.A., Tomographic atom-probe analysis of temperature-resistant 12%-chromium ferritic-martensitic steel EK-181, Phys. Met. Metallogr., 2009, vol. 108, pp. 579–585.

Miller, M.K., Atom Probe Tomography: Analysis at the Atomic Level, New York: Kluwer Academic, 2000.

Aleev, A.A., Iskandarov, N.A., Klimenkov, M., Lindau, R., Möslang, A., Nikitin, A.A., Rogozhkin, S.V., Vladimirov, P., and Zaluzhnyi, A.G., Investigation of oxide particles in unirradiated ODS Eurofer by tomographic atom probe, J. Nucl. Mater., 2011, vol. 409, pp. 65–71.

Rogozhkin, S.V., Bogachev, A.A., Kirillov, D.I., Nikitin, A.A., Orlov, N.N., Aleev, A.A., Zaluzhnyi, A.G., and Kozodaev, M.A., Effect of alloying with titanium on the microstructure of an oxide dispersion strengthened 13.5% Cr steel, Phys. Met. Metallogr., 2014, vol. 115, pp. 1259–1266.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © S.V. Rogozhkin, N.N. Orlov, A.A. Nikitin, A.A. Aleev, A.G. Zaluzhnyi, M.A. Kozodaev, R. Lindau, A. Möslang, P. Vladimirov, 2014, published in Perspektivnye Materialy, 2014, No. 12, pp. 38–44.

Rights and permissions

About this article

Cite this article

Rogozhkin, S.V., Orlov, N.N., Nikitin, A.A. et al. Nanoscale characterization of 13.5% Cr oxide dispersion strengthened steels with various titanium concentrations. Inorg. Mater. Appl. Res. 6, 151–155 (2015). https://doi.org/10.1134/S2075113315020136

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113315020136