Abstract

The purpose of this study is to find out if there is a correlation between material clogging on refractory bricks and the mineralogical composition of the materials that form. For this reason, samples were taken from different points in the burner zone (16 m, 22 m, and at burner) of the rotary kiln during maintenance stops in order to investigate their specificities in terms of mineralogical composition and geochemical composition. A chemical composition analysis was carried out using X-ray fluorescence (XRF). The X-ray powder diffraction (Rietveld method) was used to determine the mineralogical composition of collected samples. The burning material morphologies were also assessed by scanning electron microscopy (SEM). The studied samples show a highly variable mineralogical and geochemical composition. The mineralogical investigation showed the emergence of additional high-temperature resistant phases as well as a percentage drop in the major phases that constitute the final product. All of these findings support the idea that temperature (beyond that necessary for clinkerization processes) has an effect on the mineralogy of the final product. This crust acted as a real membrane, maintaining the refractory brick’s stability by lowering the rate of alteration and degradation.

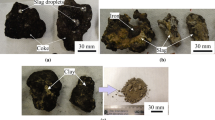

taken from position 22 m of the final combination zone (formulation of C3S)

taken from burner

Similar content being viewed by others

References

Alsop PA (1998) Cement plant operations handbook; for dry process plant. David Hargreaves International Cement Review, Port smouth/UK, p 264

Belgacem S, Galai H, Tiss H (2016) Qualitative and quantitative investigation of post–mortem cement refractory: the case of mag22nesia–spinel bricks. Ceram Int 42(16):19147–19155

Ben Addi K, Diouri A, Khachani M (2014) Degradation of Alumina and Magnesia Chrome refractory bricks in Portland cement kiln. Corrected Version, MATECWeb of Conferences 11(01):048

Benmohamed M, Alouani R, Jmayai A, Ben Haj Amara A, Ben Rhaiem H (2016) Morphological analysis of white cement clinker minerals: discussion on the crystallization-related defects. Int J Anal Chem 1259094:10

Benmohamed M, Galai H, Alouani R, Béjaoui M, Ben Haj Amara A, Ben Rhaiem H (2017) Inter-comparative study of quantitative methods of industrial clinker. Journal of Wuhan University of Technology-Mater. Science Edition 32:1250–1260

Bensted J (2007)Special Cements, In Lea’s Chemistry of Cement and Concrete, 4th ed.; Hewlett, P. C., Ed.; Butterworth-Heinemann: Oxford, Burlington 783

Chaix-Pluchery O, Pannetier J, Bouillot J, Niepce JC (1987) Structural prereactional transformations in Ca(OH)2. J Solid State Chem 67(2):225–234

Chen JH, Yu LY, Sun JL, Li Y, Xue WD (2011) Synthesis of hercynite by reaction sintering. J Eur Ceram Soc 31(3):259–263

Colville AA, Geller S (1972) The crystal structure of Ca2Fe1.43Al0.57O5 and Ca2Fe1.28Al0.72O5. Acta Crystallographica Section B28:3196–3200

De la Torre AG, Morsli K, Zahir M, Aranda MAG (2007) In situ synchrotron powder diffraction study of active belite clinker. J Appl Crystallogr 40:999–1007

De Noirfontaine MN, Dunstetter F, Courtial M, Gasecki G, Signes-Frehel M (2006) Polymorphism of tricalcium silicate, the major compound of Portland cement clinker: 2. Modelling alite for Rietveld analysis, an industrial challenge. Cem Concr Res 36(1):54–64

De Noirfontaine M-N, Dunstetter F, Courtial M, Signes-Frehel M, Wang G, Gorse- DP (2016) A transmission electron microscopy study of radiation damages to b-dicalcium (Ca2SiO4) and M3-tricalcium (Ca3SiO5) orthosilicates. J Nucl Mater 468:113–123

Downs RT, Palmer DC (1994) The pressure behavior of alpha cristobalite. Am Miner 79(1–2):9–14

Fayos J, Glasser FP, Howie RA, Lachowski E, Perez-Mendez M (1985) Structureofdodecacalcium potassium fluoride dioxide tetrasilicatebis(sulphate), KF.2[Ca6(SO4)(SiO4)2O]: a fluorine-containig phase encountered incement clinker production process. Acta Crystallogr A C41:814–816

Guangping L, Nan L, Wen Y, Changhe G, Zhou WY, Uanyuan L (2013) Composition and microstructure of a periclase–composite spinel brick used in the burning zone of a cement rotary kiln. Ceram Int 40(6):8149–8155

Grice JD (2005) The structure of spurrite, tilleyite and scawtite, and relationships toothersilicate-carbonate minerals. Can Mineral 43:1489–1500

Harrison A (2010) Free Lime: The Fifth Phase. ICR Journal 59

Hills LM, Johansen V, MacGregor Miller F (2002) Solving Raw Materials Challenges, Conference Record of IEEEIAS/PCA 2002 Cement Industry Technical Conference, pp 139–151

Hiragushi K, Shikano H, Ohishi M (1989) Cement clinker sticking properties of basic bricks in cement kilns. Taikabutsu Overseas 9(4):15–9

Honda T, Ohta S (1997) Evaluation techniques for refractories used in rotary cement kilns. Taikabutsu Overseas 17(4):50–58

Huang O, Chmaissem JJ, Caponi C, Chaillout M, Marezio JL, Tholence (1994) Neutron powder diffraction study of the crystal structure of HgBa2Ca4Cu5O12 +dat room temperature and at 10 K. Physica C 227(1–2):1–9

Igawa T, Yamamoto H, Komatsu H, Hayashi Y, Matsuzuru M, Ukawa S (1995) Chrome-free bricks with good adhesion of coating in cement rotary kiln. Taikabutsu Overseas 15(3):36–40

Kaur RR, Swinbourne DR, Wadsley MW, Nexhip C (2011) Comparison of ferrous calcium silicate slag and calcium ferrite slag interactions withmagnesia–chromerefractories. Metall Mater Trans B 42B:451–459

Klauss J (2000) Burning cement clinker under reducing conditions in a rotary kiln – one way of lowering the NOx emission. ZKG-International 53:132

Kozuka H, Kajita Y, Tuchiya Y, Honda T, Ohta S (1993) New kind of chrome-free (MgO–CaO–ZrO2) bricks for burning zone of rotary cement kiln. In Proceedings of Third UNITECR’ 93. ALAFAR — AsociacionLatinoamericana de Fabricantesde Refractories, Sao Paulo, Brazil 1021–37

Kozuka H, Kajita Y, Tokunaga K, Sakakibara K, Ohta S (1995) Further improvements of MgO–CaO–ZrO2 for burning zone of rotary cement kiln;’’ In Proceedings ofFourth UNITECR’95, Vol. 1. The Technical Association of Refractories–Japan, Kyoto, Japan 256–63

Lavina B, Princivalle F, Giusta AD (2005) Controlledtime–temperature oxidation reaction in a synthetic Mg-hercynite. Phys Chem Min 32(2):83–88

Lea’s (2007) Chemistry of Cement and Concrete, 4th edn. Oxford, Burlington, Hewlett P C, EdButterworth-Heinemann

Levien L, Prewitt CT, Weidner DJ (1980) Structure and elastic properties of quartz at pressure. Am Miner 65:920–930

Levien L, Prewitt CT (1981) High-pressure crystal structure and compressibility of coesite. Am Miner 66:324–333

Lewis J, Schwarzenbach D, Flack HD (1982) Electric field gradients and charge densityin corundum alpha-Al2O3. Acta Crystallogr A A38:733–739

Liu GP, Li N, Yan W, Gao CH, Zhou W, Li Y (2014) Composition and microstructure of a periclase–composite spinel brick used in the burning zone of a cement rotary kiln. Ceram Int 40(6):8149–8155

Louisnathan SJ (1971) Refinement of the crystal structure of a naturalgehlenite, Ca2Al(Al, Si)2O7. Can Mineral 10(5):822–837

Mazzi F, Galli E, Gottardi G (1976) The crystal structure of tetragonal leucite. Am Miner 61(1–2):108–115

McGinnety JA (1972) Redetermination of the structures of potassium sulfate and potassium chromate: the effect of electrostatic crystal forces upon observed bondlengths. Acta Crystallogr B Struct 28:2845–2852

Mondal P, Jeffery JW (1975) The cristal structure of tricalcium aluminate Ca3Al2O6. Actacristallographica B31:689–697

Mumme WG, Hill RJ, Bushnell-Wye G, Segnit ER (1995) Rietveld crystal structure refinement, crystal chemistry and calculated powder diffraction data for the polymorphs of dicalcium silicate and related phases. Neues Jahrbuchfür Mineralogie-Abhandlungen 169:35–68

Nishi F, Takeuchi Y (1975) The Al6O18 rings of tetrahedra in the structure of Ca8.5NaAl6O18. Acta Crystallogr Struct Sci Cryst Eng Mater 31:1169–1173

Nishi F, Takeuchi Y (1984) The rhombohedral structure of tricalcium silicate at 1200 C. Zeitschrift Fur Kristallographie 168:197–212

Petkov V, Jones PT, Boydens E, Blanpain B, Wollants P (2007) Chemical corrosion mechanisms of magnesia–chromite and chrome-free refractory bricks by copper metal and anode slag. J Eur Ceram Soc 27(6):2433–2444

Poirier J, Qafssaoui F, Ildefonse JP, Bouchetou ML (2008) Analysis and interpretation of refractory microstructures in studies of corrosion mechanisms by liquid oxides. J Eur Ceram Soc 28:1557–1568

Prange R, Bongers J, Hartenstein J, Stradtmann J (1995) Present state and future trends in the use of basic refractories in cement and lime kilns: in Proceedings ofFourth UNITECR’ 95, Vol. 1, The Technical Association of Refractories–Japan, Kyoto, Japan 248–55

Rietveld HMA (1969) A profile refinement method for nuclear and magnetic structures. J Appl Crystallogr 2:65–71

Saalfeld H, Depmeier W (1972) Silicon-free compounds with sodalite structure. Cryst Res Technol 7(1–3):229–233

Sasaki S, Fujino K, Takeuchi Y (1979) X-ray determination of electron-density distribution in oxides, MgO, MnO, CoO, and NiO, and atomic scattering factors of their constituent atoms. Proc Jpn Acad 55(2):43–48

Scheunis L, Fehrjardi FA, Campforts M, Jones PT, Blanpain B, Jak E (2014) The effect of phase formation during use on the chemical corrosion of magnesia–chromite refractories in contact with a non-ferrous PbO– SiO2based slag. J Eur Ceram Soc 34(6):1599–1610

Taylor HFW (1997) Cement Chemistry, 2nd edn. London, Academic Press Thomas Telford

Telschow S, Frandsen F, Theisen K, Dam-Johansen K (2012) Cement formation–a success story in a black box: high temperature phase formation of Portland cement clinker. Ind Eng Chem Res 51(34):10983–11004

Tsurumi T, Hirano Y, Kato H, Kamiya T, Daimon M (1994) Crystal structure and hydration of belite. Ceram Trans 40:19–25

Vazquez TF (1982) Study of stabilized phases in high alumina cement mortars Part I Hydration at elevated temperatures followed by carbonation. Cem Concr Res 12: 485–496

Zhang S, Sarpoolaky H, Marriott NJ, Lee WE (2000) Penetration and corrosion ofmagnesia grain by silicate slags. Br Ceram Trans 99(6):248–255

Acknowledgements

The author would like to thank C-B laboratory team and all employees and personnel involved in this study for their support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Responsible Editor: Domenico M. Doronzo

This paper was selected from the 3rd Conference of the Arabian Journal of Geosciences (CAJG), Tunisia 2020.

Rights and permissions

About this article

Cite this article

Mohamed, B., Marouene, B., Slim, A.M. et al. Mineralogical and geochemical study of industrial clinker: material behavior in the burning zone. Arab J Geosci 15, 1170 (2022). https://doi.org/10.1007/s12517-022-10431-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-022-10431-9