Abstract

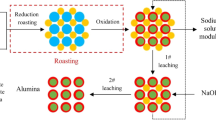

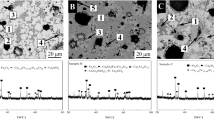

The traditional alumina-silicate raw materials, for example, clays, in the precalcining technique of cement production, have been replaced by low grade and high silica content sandstones, shales, and industrial waste residues, including fly ashes, slag, and others. The results are the change of compositions and characteristics of raw materials applied and a great effect on cement calcination process and clinker formation. In this work, the cement clinker formation process of different alumina-silicate raw materials to replace clay raw material was studied by chemical analysis, X-ray diffraction, differential thermal analysis, and high temperature microscope based on the characteristics of the alumina-silicate raw materials. The formation heat of the clinker was determined by the acid dissolution method. Influence of different alumina-silicate raw materials on the clinker burnability and formation process was studied. The results show that the changing of alumina-silicate raw materials, especially using industrial waste residues, can reduce the formation temperature of high temperature liquid phases, improve the burnability of raw materials, reduce the formation temperature and formation heat of clinker. And this study also observed the formation temperature and transformation of high temperature liquid phases in the heating process of raw materials by high temperature microscope.

Similar content being viewed by others

References

Li B, Xu Y Z. Production of Portland Cement Clinker with Steel Slag in Replacement of Iron Ore Ingredients[J]. Cement, 2008(4): 24–25

Wang Z Y, Zhong W H, Zhang W S, et al. Influences of Steel Slag on the Formation of Portland Cement Clinker[J]. Cement, 2010(3): 10–13

Meng G B, Gu W F, Wang L, et al. Investigation on Applying Steel Slag to Raw Mix Proportioning of Cement[J]. Baosteel. Technol., 2002(2): 31–34

Meng H L, Jiang D, Yan Q, et al. Study of Cement Clinker Production With Fly Ash in Replacement of Silica-Aluminkum Raw Materials[J]. Coal. Ash. Chin., 2001(3): 26–27

Xue F L. Study of Portland Cement Clinker Production With Fly Ash in Replacement of Clay[J]. Cem. Eng., 2007(4): 86–87

Wei D X, Qiao W G, Huang Z Q. Application of Fly Ash Sandshale Instead of Clay Ingredient in Cement Production[J]. Ener. Env. Prot., 2003, 17(3): 57–58

Zhang C H, Gao K Q, Liang G Q, et al. Application of Shale Ingredients in 5 500 t/d Two Short Kiln[J]. Cement, 2013(3): 12–14

SHI Z L, SHI Z Z, LUO Z Y. Applied Research on Utilization of Metallic Tailings as Clay for Cement Production in Dry Rotary Kiln [J]. Acta Scientiae Circumstantiae, 2007, 27(2): 348–352

Zhang H, Xing L. Mineralogical Studies of Steel Residues on a Electric Cooker[J]. Geoin. Jiangsu, 2002(2): 27–28

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the National Basic Research Program of China (“973” Program) (No.2009CB623102) and the National High Technology Research and Development Program of China (“863” Program) (No.2013AA031602)

Rights and permissions

About this article

Cite this article

Wang, Y., Cui, S., Lan, M. et al. Influence of characteristics of alumina-silicate raw materials on the formation process of clinker. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 29, 966–971 (2014). https://doi.org/10.1007/s11595-014-1029-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-014-1029-x