Abstract

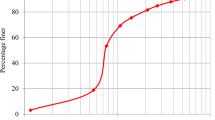

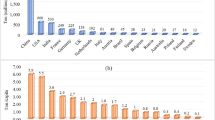

India will generate about 283,470 MW of electricity by 2022. Seventy percent of the proposed energy demand is fulfilled by fossil fuel, out of which 54 % of demand is contributed by coal as reported by Krishna (2001). The coal production would be 850 Mt per year to fulfil the demand. Opencast mining plays a major role in meeting the demand of coal for thermal power generation leading to the use of large-capacity haul trucks. Carrying capacity of trucks/dumpers used in opencast mines has grown from 30 to 250 t in recent years. These ultra-capacity trucks/dumpers need well-designed haul roads. At present, design of new haul roads is based on past experience and empirical methods. The sub-grade, sub-base and/or base of haul road typically uses the overburden (O/B) materials which could be replaced by composite material at a particular layer for better performance. There are more than 165 opencast coal mines and many are near to thermal power stations. Present-generation fly ash (FA) from coal-based thermal power plants in India is 135 Mt/year and it is expected to increase to 300–400 Mt/year by 2016–2017 as reported by Çimento (2004). The usage percentage of fly ash is about 60 % leaving the rest as plant waste occupying a huge land area and creating environmental problems. The investigation has characterised fly ash (FA), mine overburden material (O/B) and lime (L). Geotechnical properties of untreated fly ash, mine overburden, fly ash–mine overburden mixes and lime-treated fly ash–mine overburden mixes were investigated using response surface methodology (RSM). Design-Expert software was used to establish the design matrix and to analyse the experimental data. The relationships between the percentage parameters (%FA + %O/B + %L) and experimentally obtained three responses (California bearing ratio (CBR), unconfined compressive strength (UCS) and BTS) were established. RSM was performed to optimize the interactions of input parameter which showed the best conditions for preparation of composite material. According to the obtained results, the model was developed and further analysis was conducted. The experimental values agreed with the predicted ones, thus indicating suitability of the model employed and the success of RSM in optimizing the composite material. Lime percentage, curing period was observed to have strong influences on the strength parameters of the developed FCMs. The best composite material obtained with highest CBR and UCS values.

Similar content being viewed by others

References

Ali Sadollah, Mohsen Naeim, Hassan Mohamed, Ardeshir Bahreininejad (2013) Optimum culture conditions for 1,3-propanediol production from crude glycerol using metaheuristic algorithms, An Int J Appl Math Inf Sci Lett 1, 1-8

ASTM (2008) Specification for coal fly ash and raw or calcined natural pozzolan for use in concrete. In: Annual book of ASTM standards, concrete and aggregates, American Society for Testing Materials, Philadelphia, vol 04.02.

Barbuta M, Lepadatu D (2008) Mechanical characteristics investigation of polymer concrete using mixture design of experiment and response surface method. J Appl Sci 8(12):2242–2249

BS (1990) Liquid limit—cone penetrometer, BS: 1377 (Part 2)

IS (1972) Indian standard methods of test for soils, determination of shrinkage factors, IS: 2720 (Part VI)

IS (1980) Indian standard methods of test for soils, determination of specific gravity, IS: 2720 (Part III/Set 2)

IS (1985) Indian standard methods of test for soils, grain size analysis, IS: 2720 (Part 4) – 1985

IS (1985) Indian standard methods of test for soils, determination of liquid and plastic limit, IS: 2720 (Part 5)

IS classification and identification of soils for general engineering purposes, IS: 1498 – 1970

IS methods of test for pozzolanic materials, IS: 1727 – 1967

Marcia J. Simon, Concrete mixture optimization using statistical mixture design method, international symposium of high performance concrete, new Orleans Louisiana, oct, 20-22 1997

Tannant DD, Kumar V (2000) Properties of fly ash stabilized haul road construction Materials. Int J Surf Mining Reclamation Environ 14:121–135

Thompson RJ, Visser AT (2003) Mine haul road maintenance management systems, Journal of The South African Institute of Mining and Metallurgy, ISSN 0038- 223X/3.00 + 0.00, pp 303–312

Timur Cihan M, Abdurrahman G, Nabi Y, Namik C (2013) Response surfaces for compressive strength of concrete. Constr Build Mater 40:763–774

Acknowledgements

The authors acknowledge the financial assistance from FAO and DST to carry out the experimental investigation reported here.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, H., Mishra, M.K. Optimization and evaluation of fly ash composite properties for geotechnical application. Arab J Geosci 8, 3713–3726 (2015). https://doi.org/10.1007/s12517-014-1502-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12517-014-1502-z