Abstract

Fruit juices are traditionally processed thermally to avoid microorganisms’ growth and increase their shelf-life. The concentration of juices by thermal evaporation is carried out to reduce their volume and consequently the storage and transportation costs. However, many studies revealed that the high-temperature operation destroys many valuable nutrients and the aroma of the juice. Currently, membrane technology has emerged as an alternative to conventional processes to clarify and concentrate fruit juices due to its ability to improve juices’ safety, quality, and nutritional values. Low-cost, low-energy requirement, and minimal footprint make membrane technology an attractive choice for industrial adoption. The low-temperature operation that preserves the nutritional and sensorial quality of the juice can fulfill the market demand for healthy juice products. In this review, the pressure-driven membrane processes, including microfiltration, ultrafiltration, and reverse osmosis; osmotic distillation; membrane distillation; and forward osmosis that have been widely investigated in recent years, are discussed.

Similar content being viewed by others

Introduction

Fruit juice processing involves the transformation of fruit into juice, practically to prolong its shelf-life without compromising the fruit’s original taste and chemical composition. Today, the juice industry produces some of the most popular beverages in the world due to their tastiness and high nutritional values like vitamins, minerals, protein, and fibers, a wide range of health-boosting antioxidants, and calorific content for energy.

Consumers are showing an increased interest in juices high in nutritional ingredients that improve health. This is evident in a recent study by Heng et al. [1] which sees nearly 40% of consumers increase their purchase of orange juice in response to the COVID-19 pandemic. The consumption of fruit juice that is high in vitamin C and nutrients to boost the immune system are prevalent during the flu or cold season. The growing demand for orange juice during the outbreak of COVID-19 shows that consumers are willing to increase their fruit juice consumption to help their bodies receive nutrients essential to keep them healthy. The World Health Organization (WHO) also listed nutritional advice as a response to the pandemic, which included consuming fresh fruits and unsweetened fruit juices to incorporate into daily nutrition [2].

The global fruit juice market reached USD103.5 billion in revenue in 2022 and is expected to grow annually at a compound annual growth rate (CAGR) of 6.97% from 2022 to 2026 [3]. This has pushed the juice industry to produce high-quality products that are nutritious and minimally processed to preserve their health benefits to keep up with the demands. Various types of research are performed to come up with methods that can [4] minimize the effects of treatments and processing on the sensorial and nutritional properties of foods and [5] enhance the shelf-life of foods without damaging the qualities of natural foods [6].

The conventional techniques to process fruit juice use thermal technologies, especially in the clarification and concentration processes, to gain a longer shelf-life, avoid the growth of microorganisms, and reduce storage and transportation costs. Furthermore, this method is cost-effective for ensuring microbial safety and enzyme deactivation. However, thermal processing is known to cause negative impacts on the nutritional (vitamins, phenolic compounds, anthocyanins, and carotenoids) as well as the sensory (flavor, color, aroma, appearance, and texture) qualities of the fruit juice [7,8,9]. This situation has triggered a need for alternative processes in the fruit juice industry, such as freeze concentration, aroma recovery, and sublimation concentration, to preserve the product’s qualities. Nonetheless, these methods did not considerably improve the quality of the products [9].

Preserving the organoleptic scores of foods is a crucial goal of the juice industry. As a result, membrane technology has gained significant attention as an alternative to conventional thermal concentration and clarification processes. In the last 20 years, the application of membrane technology in the food industry has increased. The global membrane market for the food and beverage processing industry is estimated to grow at a CAGR of 6.53%, equivalent to USD2.14 billion for 2021–2025 based on 2020 [10]. Membrane technology is more favorable in the food industry as it requires fewer operating expenses, is more efficient, and has a shorter processing time than traditional filtration [11].

Microfiltration (MF), ultrafiltration (UF), reverse osmosis (RO), forward osmosis (FO), membrane distillation (MD), and osmotic distillation (OD) are the commonly used membrane processes in juice industries as they have immediate application to juice processing. Recently, FO has been gaining considerable popularity as a single-step process to concentrate juices. Many researchers reported positive results on the practicality of FO for juice concentration. However, the juice industry has yet to implement this process due to limitations on replicating the results for a scale-up process. Thus, further research is still needed as most published researchers are limited to small-scale production of either laboratory-scale or pilot-scale projects.

This paper aims to review the recent developments of membrane technology in clarifying and concentrating fruit juice. We have covered the overview of fruit juice production and recent membrane developments in fruit juice processing reported in the literature in the last 3 years, including MF, UF, RO, FO, MD, and OD. Although several reviews on the membrane operation for fruit juice processing have been published previously [12,13,14,15], we provide the latest studies in the last 3 years published in the literature and can be regarded as the continuation of the previous works.

Overview of the Fruit Juice Production

The making of juices from fruits precedes agriculture itself. Fruits soften during the ripening process and produce pulpy liquids. Hunter-gatherers consumed this pseudo juice straightforwardly or collected it for later consumption. Fruit juices that were easily perishable during the premodern era, especially in warm climates, commanded immediate consumption within a day or risk fermentation that changes the characteristics of the juice [16]. Humans have learned to develop methods through trial and error to extract fruit juices for thousands of years. Tool-making abilities furthered the mechanization of devices for extracting the juices. Furthermore, the invention of collecting vessels from local materials enables the juices to be stored. The evolution of technology kickstarted by the industrial revolutions further developed the methods to produce fruit juices. The health trends that emerged in the modern era led to higher consumption and demand for juices. The market is urging high-quality juices that are fresh, healthy, loaded with nutrients, and have a minimal footprint.

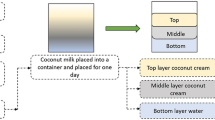

Now, fruit juice is generally available as an unfermented liquid extracted from the edible portion of ripe fruits. The processing of fruit juice can be divided into three main steps: extraction of juice from the edible part of the fruit, clarification of juice, and concentration of juice. Typically, clarified juice is consumed as a ready-to-drink beverage. In contrast, concentrated juice is reconstituted for beverage consumption or can be used as a flavoring in many products such as ice cream and jam. The overall process flow of juice processing is depicted in Fig. 1. The Codex Alimentarius Commission has classified the different categories of fruit juices: single fruit juice from one type of fruit; mixed juice, which is a mixture of two or more juices, concentrated fruit juices; water extracted fruit juice; fruit puree; and concentrated fruit puree [17].

General fruit juice processing flow chart [adapted from [18]]

Extraction of Juice from Fruit Flesh

The recovery of liquid juice from the solid part of the fruit involves simple operations of pressing, squeezing, and screening, but the process is somewhat more challenging. This is because each step during the juice extraction influences the product’s yield, quality, flavor, and composition. The handling involved during fruit harvesting, storage, delivery, fruit selection, screening, washing, drying, peeling, cutting, and pulping (Fig. 2) to extract the juice directly affects the overall quality of fruit juice. Furthermore, the juice should be able to preserve its chemical, physical, sensory, nutritional, and organoleptic properties after being subjected to all these processes.

Typical steps involved in fruit juice extraction [adapted from [19]]

According to Mushtaq [19], the primary extraction process of fruit juices includes mechanical pressers, rack and cloth press, hydraulic press, screw-type press, belt press, hydrodiffusion extractors, and spiral filter pressers. The methods and principles used to extract the juice from the fruit flesh differ from one type of fruit to another. For example, the juice from citrus pulp can be easily extracted by pressing, whereas juices from apples and pineapples are recovered by first crushing them into pulp before the juices are pressed out. Most juice extraction equipment applies pressure on the pulp, but some juice extracting units use centrifugal force and diffusion.

Clarification of Fruit Juice

The extracted juices from the previous steps are further prepared to undergo filtration and clarification to produce a clarified single-strength juice (Fig. 3). The general steps involved in conventional fruit juice processing to make a clarified juice are suspended solids removal (centrifugation), pectin/starch hydrolysis (enzyme treatment), colloid and haze removal (fining treatment), fining agent removal (diatomaceous earth filtration), and final filtration. These multiple-step procedures are typically labor- and time-consuming as many steps are involved [20]. Hence, membrane filtration technologies can replace conventional processing as it can be used as a single step to produce a higher quality clarified juice in a shorter time.

Conventional versus ultrafiltration membrane in fruit juice processing [adapted from [20]]

Microfiltration (MF) and ultrafiltration (UF) are the most widely employed membrane filtration process to clarify fruit juices. In some cases, enzyme pretreatment is carried out before membrane filtration for fruit juices containing a high amount of pectin, as it can cause high fouling intensity and reduce membrane flux [21]. Nonetheless, replacing the conventional method with membrane technology has many advantages, as it eliminates the need for centrifugation, most enzymes, fining agents, and diatomaceous earth filtration. Furthermore, the process times are lowered by 83–89%. Higher juice output is obtained by 2–15% and improved product quality [20]. Membrane technology clarifies various fruit juice types, including pomegranate, apple, citrus, tomato, guava, dragon fruit, banana, cashew apple, and prickly pear.

The Concentration of Fruit Juice

The concentration of fruit juices is carried out to extend the shelf-life of products by reducing microbial activities (low water activity) and costs (volume for storage and transportation). The concentration of fruit juices was traditionally carried out at a high temperature which ultimately evaporates the water molecules, leaving a juice concentrate. This process is known as thermal drying or concentrating, which has been applied since ancient times to preserve juice for long-term storage and transport. Thermal treatments can be categorized by the heat treatment intensity, heating duration, and the methods employed. The typical means of thermal treatments of fruit juices include the conventional techniques of a high-temperature long time (HTLT), high-temperature short time (HTST), medium-temperature long time (MTLT), medium-temperature short time (MTST), and the non-conventional methods of microwave heating and Ohmic heating [8].

However, thermal drying has always been associated with adverse effects on fruit juices’ quality, antioxidant activities, shelf-life, and nutritional attributes. For example, orange, lemon, grapefruit, and lime juices heated at 74–88 °C will experience cloud stabilization through complete or partial inactivation of pectic enzymes. The heating of fruit juices also leads to the escape of flavors and aromas, which are volatile in nature [19].

To prevent the loss of valuable contents in the juice, membrane filtration can be used to concentrate fruit juices at a low operating temperature. Currently, forward osmosis (FO), reverse osmosis (RO), osmotic distillation (OD), and membrane distillation (MD) are broadly used to concentrate various types of prefiltered fruit juices such as apple, pomegranate, grape, watermelon, citrus, date, and orange.

Composition of Fruit Juice

The composition of fruit juice is affected by the structure and functional features of the fruit. In general, the composition of fruit juices is presented in Table 1 [16], the range of values is affected by the type of fruit, cultivar, cultivation, and maturity.

The major component in fruit is water which is required for metabolic processes and to maintain cell turgor. Water content can range from 85 to 93% in citrus fruit juices. The solids are a mixture of hundreds of identified components composed of natural and/or polymer sugars such as glucose, fructose, starch, cellulose, pectin, and hemicellulose, representing a large portion of the total solids. The solid contents are classified into soluble and non-soluble. Soluble solids refer to the solids readily presented in the juice, whereas non-soluble solids are mainly the residues obtained after pressing, such as the pulps. Nutrients like protein, fats, vitamins, and minerals vary significantly between the types of fruit. Fruit acids are present in some fruits, especially citrus, which cause a sour taste and low pH. The protein content in fruit juice is generally lower than 1% but higher in oily fruits and fruit seeds. Lipid percentage in fruit juice usually accounts for less than 0.5%, except in olive, oil palm, avocado, and fruit seeds. The very low lipid contents are responsible for the low calorific amount of fruit juice [16].

Parameters of Membrane Technology Affecting the Clarification and Concentration of Fruit Juice Performance

Pressure-driven membrane processes are one of the most popular membrane technologies used in fruit juice clarification due to their higher efficiency than conventional clarification techniques. Pressure-driven membrane processes allow the fruit juice industry to eliminate several processes from the multi-step traditional approach, such as cooling, flocculation, and centrifugation, which reduce operation time. Furthermore, pressure-driven membrane processes are environmentally friendly since it does not use clarifying agents that could lead to environmental pollution when disposed of [22]. Microfiltration (MF) and ultrafiltration (UF) are the two most versatile pressure-driven membrane processes used as a single-step clarification of fruit juices.

MF is a membrane process that efficiently removes the juice’s components to haze appearances. The resulting juice is typically clear and free of pulps or suspended solids [7]. Furthermore, the retention barrier produced by the MF membrane also filtered bacteria on the membrane surface for sterilization of the fruit juice (Singh [15]. UF is also becoming a more attractive technology for clarification of fruit juices over the traditional ways of using fining agents and diatomaceous earth. Compared to MF, UF can filter finer particle sizes. The retention capacity of UF is generally measured in molecular weight cut-off (MWCO), which translates to the lowest molecular weight of particles that is 90% retained by the membrane. MWCO is a vital indicator in UF as it determines the size of materials that can pass through the membrane; the size exclusion in UF allows only molecules smaller than the cut-off value to pass through the membrane. Therefore, the suitable cut-off value depends on the feed’s properties and the separation goal, which needs to be established before the operation as it will determine the particle transport, separation efficiency, and juice quality. The MWCO of the UF membrane is typically between 300 and 500,000 Da, which can filter colloids, polymers, lipids, proteins, and biomolecules. The membrane pores typically allow water, vitamins, sugars, and salts to pass through. Hence, the chances for permeate stream contamination are reduced, and since no heat treatment is required, the loss of volatile aromas is prevented [15].

The transmembrane pressure (TMP) plays a vital role in pressure-driven membrane processes, acting as the driving force for separation. Higher TMP generally results in higher permeate flux up to a threshold, above which the fouling phenomenon occurs and significantly reduce the filtration efficiency.

The permeate flux (\({J}_{P}\)) is measured as the volume or weight of permeate produced per unit of time per unit of membrane area. Permeate flux is used interchangeably as water flux or evaporation flux in the concentration of fruit juices.

where \({V}_{P}\) is the permeate volume, \({W}_{P}\) is the permeate weight, \({A}_{m}\) is the effective membrane area, and \(t\) is the time. The quality and flux yield of clarified fruit juices are highly influenced by the operating parameters of the membrane process, such as the TMP, temperature, crossflow velocity (CFV), feed flow rate; and membrane characteristics such as pore size, MWCO, hydrophilicity, and membrane material and structure. Many studies have investigated the optimum operating conditions that produce the highest permeate flux and fruit juice quality during clarification.

TMP can be calculated as the difference between the feed-retentate average to the permeate:

where \({P}_{F}\), \({P}_{R}\), and \({P}_{P}\) are the feed, retentate, and permeate pressures, respectively.

Permeate recovery (PR) is the amount of liquid permeated across the membrane. It is a measure of the extent of separation in a membrane process. The higher the permeate recovery, the more concentrated the components collected in the retentate stream. PR is calculated in both volumetric and weight ratios:

where \({V}_{P}\) and \({V}_{F}\) are the volumes of permeate and feed, respectively, while \({W}_{P}\) and \({W}_{F}\) are the weight of permeate and feed, respectively.

The volume reduction factor (VRF) or weight reduction factor (WRF) is the ratio between the initial feed volume or weight and the volume or weight of the resulting retentate according to the following equations:

where \({V}_{F}\) and \({V}_{R}\) are the volumes of feed and retentate, respectively, while \({W}_{F}\) and \({W}_{R}\) are the weight of feed and retentate, respectively. In the juice concentration process, the reduction factor is also commonly known as the concentration factor and can be calculated similarly.

Rejection (R) of the membrane towards a specific compound is a measure of the percentage of the compound retained by the membrane.

where \({C}_{P}\) and \({C}_{F}\) are the concentration of a specific compound in permeate and feed, respectively. During the concentration of fruit juices, the ability of the membrane to retain the nutritional (vitamins, proteins, bioactive components, etc.) and sensorial features (color, aroma, etc.) of the juice are essential to preserving its quality. High retention of bioactive components such as anthocyanins, phenolic, lycopene, and flavonoid content is desired for health benefits.

The driving force of the forward osmosis (FO) process is the difference in osmotic pressure between the feed solution (FS) and draw solution (DS). DS is also used interchangeably as an osmotic agent or stripping solution. The osmotic pressure of the FS and DS can be calculated according to the following equations:

where \({\pi }_{FS}\) and \({\pi }_{DS}\) are the osmotic pressures of FS and DS, respectively, \(R\) is the universal gas constant, \(T\) is the temperature, \(\overline{V }\) is the molar volume of water, \({a}_{W}\) is the water activity, \(i\) is the Van’t Hoff factor of dissociation, and \({C}_{DS}\) is the concentration of the osmotic solution.

The membrane distillation (MD) process is driven by the vapor pressure difference produced by the temperature difference through the membrane surface. The water vapor flux (\({J}_{\mathrm{vap}}\)) in MD is calculated by:

where \(c\) is the mass transfer coefficient, while \({p}_{F,m}\) and \({p}_{P,m}\) are the vapor pressures on the feed-membrane interface and permeate-membrane interface, respectively

The main challenges of MD process are temperature polarization, concentration polarization, and membrane fouling. Temperature polarization is a significant issue in MD and occurs when a temperature difference arises between the bulk feed and membrane surface at the liquid/vapor interface. Vaporization of a component leads to a decrease in liquid bulk temperature and an increase in vapor temperature, reducing the temperature difference and causing a drop in permeate flux. The temperature polarization coefficient (TPC) is calculated as the ratio of boundary layer resistance to the overall heat transfer resistance.

where \({T}_{F,m}\) and \({T}_{P,m}\) are the temperatures on feed-membrane and permeate-membrane interfaces and \({T}_{F}\) and \({T}_{P}\) are the feed temperature and permeate temperature.

Concentration polarization is another challenge that affects the MD and FO processes. Evaporation causes the concentration near the membrane surface to become higher than that of the bulk feed, which also causes reduced permeate flux. The concentration polarization coefficient (CPC) is the ratio of the solute concentration at the feed-membrane interface (\({C}_{F,m}\)) and the concentration of bulk feed (\({C}_{F}\)).

Fouling is a phenomenon that occurs on the boundary layer and pores of the membrane that reduces the permeate flux and efficiency of the membrane. It involves concentration polarization or temperature polarization, which leads to gel layer formation and attachment of solute or solid on the membrane surface and pores. High fouling intensity may lead to cake layer formation and pore blocking. Fouling can be affected by the feed properties (concentration, viscosity, etc.), membrane properties (pore size, material, structure, etc.), and operating conditions (TMP, temperature, flow rate, etc.). Various solutes and solids, either soluble or suspended in fruit juices, are potential foulants that can readily cause membrane fouling during the operation. Nevertheless, the propensity of fouling can be controlled by optimizing the process that improves the membrane performance.

Membrane Technology for the Clarification of Fruit Juice

Pressure-Driven Membrane Processes

Consumer preferences for clear juices have caused clarified juices to be considerably more popular than unclarified juices. Clear juices are produced when the suspended matter in the juice is removed, and no turbidity sediments are formed after bottling [23]. Freshly extracted fruit juices contain suspended solids that contribute to the cloudiness and haze-like appearance. These materials are removed in the clarification process. Traditionally, fruit juices are clarified in a series of steps, including enzyme treatment, the addition of fining agent, and filtration, which are energy- and time-consuming [20]. These steps can be reduced to a single-step process by using membrane technologies.

Different membrane materials were used to perform clarification of fruit juices. There are mainly two types of membrane material used: polymeric and ceramic. Polymeric membranes such as polyvinylidene difluoride (PVDF) and polysulfone (PSF) are extensively used in the microfiltration (MF) and ultrafiltration (UF) processes as they are relatively cheaper and easier to fabricate. Ceramic membranes are more robust and resistant to fouling and chemical attack, but they are primarily found in niche applications due to their higher cost. Many studies explored a hybrid type of membrane called a composite membrane; an essential membrane fabricated using several layers made from different materials.

The nutritional and chemical properties’ comparison between clarified juice and natural or commercial juice has been studied by different authors. Morittu et al. [24] investigated the physicochemical, antioxidant, and hypoglycemic properties of clarified and natural pomegranate juice. The pomegranate juice was purified using a hollow fiber PVDF membrane module at a temperature of 25 °C, a TMP of 60 kDa, and a feed flow rate of 30 L/h. Under this condition, the suspended solids were removed from the fresh juice, and very low retention of phenols, flavonoids, and anthocyanins (between 3.5 and 4.0%) was evaluated. However, a significant ascorbic acid reduction was measured in the clarified juice at around 30% less than in the natural juice. Nonetheless, the membrane clarification process showed positive results in the antioxidant activity despite the lower phenols, flavonoids, and anthocyanins content in pomegranate juice, which the authors inferred was caused by the elimination of the antagonisms between antioxidants and other components.

Severcan et al. [25] compared the physicochemical properties of clarified pomegranate juice using 0.01–0.05 wt% TiO2 and Al2O3 incorporated in PSF/PEI (17/2 wt%) nanocomposite MF membranes and commercial clarified pomegranate juice by Döhler Inc. The authors found that the clarified juice using nanocomposite MF membranes has better quality than the commercial clarified juice in terms of its color properties, turbidity removal, total soluble solids content, and antioxidant activity. However, the MF membranes exhibit specific retention of phenols and anthocyanins. In particular, the phenols’ content in the clarified juice was reduced by 30–48%, while the anthocyanins’ content was decreased by 3.6–28%. Phenols’ compounds give the juice its color, acidity, bitterness, and antioxidant activity. In contrast, anthocyanins are a group of red, purple, and blue pigments that contribute to antioxidant activity and total phenolic content. Overall, the 0.05 wt% Al2O3 incorporated MF membrane performed the best among the membranes, as it showed the lowest retention of phenols and anthocyanins, the highest color value, total soluble solid content, and antioxidant activity as a result of its greater porosity with negligible effect on turbidity.

Severcan et al. [26] also investigated the effect of membranes on apple juice quality using a similar type of membrane. The apple juice was clarified using PSF/PEI (20/2 wt%) nanocomposite UF membranes with 0.01–0.05 wt% TiO2 and Al2O3 at 540 kPa, and the resulting quality of clarified apple juice was compared with commercial clarified apple juice. Because of the addition of nanoparticles increased the membrane’s porosity, hydrophilicity, and anti-fouling property significantly, the highest flux (44.6 L/m2h) was obtained using the membrane prepared with 0.01 wt% TiO2. This membrane also had the highest porosity and hydrophilicity. Also, the clarified apple juice obtained using the membranes incorporated with TiO2 and Al2O3 nanoparticles had better quality than the commercial ones in terms of color, turbidity, total soluble solids, phenolic content, and antioxidant activity.

Le et al. [27] studied the effect of membrane pore size and transmembrane (TMP) on the ultrafiltration of red-flesh dragon fruit juice. Three membranes made of PES polymer with different pore sizes were used to find the optimum membrane molecular weight cut-off (MWCO). The highest permeate flux (7.9 kg/m2h) was obtained using a membrane with 10 kDa MWCO and 300 kPa TMP. Finding the optimum MWCO is essential for membrane filtration operation, as a membrane with a cut-off value higher or lower than the suspended particle sizes tends to have reduced performance due to the fouling mechanisms such as the formation of the gel layer and pore blocking. The experiment under this operating condition resulted in the membrane’s lowest retention of phenolic compounds (11.3%) and betacyanins (30.6%).

In addition, Mejia and Yáñez-Fernandez [28] examined the effect of TMP on the quality of microfiltered orange prickly pear juice. The experiments were performed at a temperature of 20 °C, a TMP of 34–138 kPa, a volumetric flux of 77.8 L/h, and a volume reduction factor (VRF) of 5.9. The optimum TMP was achieved at 69 kPa, under which the limiting flux was obtained. Increasing the pressure above 69 kPa did not cause any significant increase in the flux yield. In terms of quality, the MF membrane showed almost complete rejection of turbidity (99.77%) and low rejection of total soluble solids (TSS) (5.26%). However, the MF membrane also showed high retention of antioxidant capacity and mild retention for betalains content despite having a molecular weight much lower than the membrane pore size. The authors concluded that this might be attributed to the bioactive compounds’ tendency to undergo degradation and fouling that reduced the membrane permeability. Nonetheless, the MF process is recommended for its ability to improve physicochemical properties and conserve bioactive compounds while reducing energy and cost consumption.

A study by Alaei et al. [29] was carried out to investigate the immediate effect of fluid and vacuum pressure on both sides of the ceramic membrane during the MF of tomato juice on the permeate flux, energy consumption, and physicochemical properties of the juice. The optimum operating conditions at 26 °C feed temperature, 200 kPa pressure, and 5 kPa vacuum pressure yielded high permeate flux (12.9 L/m2h), low-energy consumption (0.044 kW.h), and high preservation of nutrients (lycopene and vitamin C) in the tomato juice. In addition, the clarified juice achieved 98% turbidity reduction, giving it a clear appearance, while there were no apparent changes in pH, TSS, viscosity, and density.

Omar et al. [30] studied the clarification of guava juice using a PES UF membrane with 100 kDa MWCO. This research investigated the effect of operating pressure (100–250 kPa) on the permeate flux and fouling. The authors found that the limiting flux (17.22 kg/m2h) occurred at 200 kPa, whereby increasing the pressure above it does not constitute an increase in flux. Compared with fresh guava juice, the clarified guava juice displayed improved quality in the turbidity, color, pH stability (3.8), and TSS recovery (83–93%). The clarified juice, however, experienced some reduction in the total phenolics content and ascorbic acid content at 19–27% and 18–22%, respectively.

Recently, some researchers reported hybrid clarification of fruit juices using non-membrane pretreatment coupled with membrane filtration and assisted membrane operation such as magnetic field and laser to improve membrane performance. Singh and Das [31] studied the effect of pretreatment on the transient flux decline and quality of vitamin C-rich mosambi juice by using two different pretreatments—centrifugation and fining agents (gelatin, bentonite, and combined) addition before subjecting each pretreated juice to 2.5-µm PA membrane filtration. The pretreated juices using centrifugation and combined gelatin-bentonite showed the least flux decline with time, whereas rapid flux decline was observed in raw (unpretreated) juice filtration. While adding fining agents showed no significant improvement in the clarity of pretreated juice (1.4–3.1%) compared to the raw juice (0.6%), the centrifugated juice demonstrated excellent clarity improvement at 65.2%. Subsequent membrane filtration of the pretreated juice yielded 98.4% clarity and alcohol-insoluble solids and viscosity reduction of 98% and 70.4%, respectively. The maximum removal of alcohol-insoluble solids by membrane improved the clarified juice’s shelf-life when stored in a suitable environment.

In another study, the effect of pretreatment using 0.1–0.5% pectinase enzyme on the permeate flux, fouling, and juice quality during the ultrafiltration of banana juice using 100 kDa PES UF membrane was analyzed by Yee et al. [32]. The pectinase treatment before UF to hydrolyze pectin has reduced fouling formation since pectin is the major component to cause fouling during the UF operation. The pretreated banana juice showed a significant reduction of viscosity (50–55%) and 1.65 times higher flux yield (24 kg/m2h) compared to the raw juice (14.5 kg/m2h). Meanwhile, the banana juice treated with the combination of pectinase and UF produced a clarified juice with low turbidity (98% reduction) and TSS (35% reduction), better color properties, and maintained pH. Some apparent decrease in total phenolics content (21.7%) was identified due to oxidation and solute interactions. However, the overall quality of UF-filtered pretreated juice was higher compared to the filtered raw juice.

Abdullah et al. [5] used centrifugation (optimum parameter at 7532 rpm for 52.6 min) as pretreatment to reduce tannin content in cashew apple juice which is undesirable as it contributes to astringency. Consequently, the centrifuged cashew apple juice was subjected to microfiltration using PSF hollow fiber membrane to investigate the effect of TMP and membrane pore size on the flux yield and juice quality. The optimum operating conditions for microfiltration were achieved at 138 kPa TMP and 0.2-µm membrane pore size, which resulted in permeate yield of 74.87 L/m2h. Also, the clarified juice reduced 88% of tannin, 97% of turbidity, 51% of total polyphenol content, and 95% of color and preserved 87% of ascorbic acid content and 97% of TSS.

Salehinia et al. [33] incorporated laser into the PVDF membrane filtration operation of pomegranate juice to study its effect on clarification efficiency. Four variables were manipulated: operating pressure, flow rate, direction of the laser, and laser exposure surface to study the response of the permeate flux, fouling mechanism, and juice characteristic. Optimum operating parameters were obtained at a pressure of 50 kPa,a flow rate of 0.6 L/h and vertical mode laser radiation exposure over a large surface showed reduced fouling and increased permeate yield. Moreover, laser-coupled MF produced a high-quality clarified juice, such as reduced turbidity by 99%, reduced acidity by 11%, and total recovery of phenolic content. Some reduction in TSS, total anthocyanin content, antioxidant activity, density, and color properties is more apparent in the clarified juice in the presence of a laser compared to the absence of a laser.

Likewise, Zarouk et al. [34] studied the effect of using a magnetic field on the efficiency and fouling phenomenon during the microfiltration of pomegranate juice using a cellulose ester membrane. The clarification performed best at high magnetic field intensity in the direction from feed to permeate (vertical mode) using a minimum feed flow rate, which halved the total resistance and consequently increased the permeate flux. The physicochemical characteristics of the clarified juice were improved,for instance, the total anthocyanin content of the clarified juice increased after clarification due to the magnetic field reaction that converted polymeric anthocyanins to their monomers. In contrast, the clarification without the magnetic field showed no significant reduction or increment of anthocyanins. Because of that, the magnetic field reaction caused a potential increase in the antioxidant activity of pomegranate juice which is a desirable quality in its market. Nevertheless, the extent of turbidity reduction was reduced by the magnetic field, though it imposed no destructive behavior on the membrane structure and the quality of clarified pomegranate juice.

Although these researches showed improvement in membrane clarification processes in terms of clarified juice quality and membrane fouling, further research is needed to analyze their effects on cost and energy requirements for industrial adoption. The recent applications of MF and UF processes in clarifying fruit juices are summarized in Table 2.

Table 3 shows the percentage of turbidity removal and some bioactive components (i.e., phenol, anthocyanin, and ascorbic acid) recovery in the clarified fruit juices. Most of these juices registered more than 96% of turbidity removal by the membrane. However, some retention of valuables TSS and bioactive components, like phenols, anthocyanin, vitamin C, tannin, flavonoid, betacyanin, betalain, and lycopene, are expected in membrane operations in most studies. The nutritional losses occurred due to several factors like oxidation and interaction with other components that are retained by the membranes [32].

Membrane Technology for the Concentration of Fruit Juice

Various methods are used in the fruit juice industry to concentrate and preserve the physicochemical components of the fruit juice. This is because non-concentrated juices are vulnerable to nutritional and sensory deterioration due to high water activity, and their bulky volume makes them hard to store, pack, and transport [36]. Therefore, juice concentrates are produced mainly to overcome the issues that single-strength juices face. Juice concentration is preserved by removing most of the water contents of the juice for long-term storage and easier transportation. This was initially achieved by heating the juice to evaporate the water content. Traditional thermal processing at high temperatures has been used until recently to concentrate juice. However, concentrating fruit juices at high temperatures is not desirable since it alters various physical and chemical characteristics affecting the juice’s nutritional, organoleptic, and sensorial properties. This is especially unbeneficial for fruit juices rich in antioxidants and bioactive components that are sensitive to high temperatures.

Presently, the utilization of membrane technologies such as reverse osmosis (RO), osmotic distillation (OD), and membrane distillation (MD) makes it possible for the process to be conducted at low temperatures. Fruit juice concentration using membrane technology removes maximum water and low molecular weight particles while retaining other components such as vitamins, antioxidants, proteins, color, high molecular weight particles, and turbid elements. Table 4 shows the key advantages and disadvantages of membrane concentration processes compared to the conventional evaporation method [37], while the recent applications of ultrafiltration (UF), RO, OD, and MD in fruit juice concentration are summarized in Table 5.

Pressure-Driven Processes and Osmotic Distillation

Membrane processing has grown significantly in recent years as a potential alternative to thermal processing due to its low-temperature operation and low-energy requirements. Pressure-driven membrane processes such as ultrafiltration (UF) and reverse osmosis (RO) are recently used to concentrate fruit juices like watermelon and pomegranate juices [38, 40], in which the retentate of the membrane operation is recovered as the juice concentrate. Other membrane processes that are driven by vapor pressure difference, partial pressure difference, and osmotic pressure difference, like membrane distillation (MD), osmotic distillation (OD), and forward osmosis (FO), respectively, are widely explored for their potentials and advantages.

Bhattacharjee et al. [38] evaluated the concentration of watermelon juice using a 3 kDa UF membrane to preserve the bioactive components, i.e., the ascorbic acid, lycopene, flavonoid, and total phenolic content. By studying the effect of temperature, pressure, and volumetric concentration factor (VCF) on the UF operation, they found that the optimum operating conditions were 23 °C, 300 kPa, and 1.5, respectively. At about 1.1-fold concentration, the UF successfully retained a high percentage of the bioactive components in juice concentrate, especially flavonoid and total phenolic content. Subsequent experiments to study the watermelon concentrate storage ability revealed that the frozen storage method effectively preserved the bioactive compounds for up to 1 month. However, vitamin C loss was relatively high. Ascorbic acid is a powerful antioxidant that makes it sensitive to temperature and will decrease in amount when exposed to unfavorable surroundings.

Bagci et al. [40] found that the concentration of pomegranate juice can be increased by fourfold, from 15.6 to 65°Brix, by integrating RO and OD processes with improved performance. In this study, the authors used a low-pressure nitrogen plasma (LPNM)-modified commercial thin-film composite membrane in the RO process as the preconcentration step before a subsequent concentration by OD. The performance of the LPNM-modified RO membrane was compared with the commercial RO membrane. While there was no apparent difference in the operating time to achieve a concentration of 65°Brix when using commercial RO membrane with OD process as opposed to stand-alone concentration by OD, the LPNM-modified commercial RO membrane performed excellently with the OD by shortening the duration of concentration process by 36% while also retaining the juice aroma which is typically lost when OD is used alone. The chemical content of the juice was well-preserved. Still, lower malic acid, gallic acid, glucose, and fructose retention were observed due to increased membrane permeability following LPNM modification compared to OD and commercial RO-OD concentration processes.

Kumar et al. [42] also studied the potential of hybrid membrane processes of RO and OD to concentrate mandarin juice. Clarified Nagpur mandarin by UF was preconcentrated using polyamide (PA) spiral-wound RO membrane at a low temperature of 10.4 °C, after which the RO retentate was further concentrated using PP hollow fiber OD at 25.4 °C using 56.9 w/w% calcium chloride dihydrate (CaCl2H4O2) (weight ratio of 2 draw solutions (DS) to 1 feed solution (FS)) as the DS. The result for the final concentration of clarified Nagpur mandarin after 16 h of operation was 60.4°Brix or a 6.7-fold concentration factor. The OD has an initial evaporation flux of 0.1 kg/m2h, which decreased as the concentration progressed due to the dilution effect of the DS; restoring the DS to its initial concentration will increase the flux back to its initial range, but as the concentration gets higher, the flux decline became more pronounced. The impact of this study on the ascorbic acid content and antioxidant activity of the juice concentrate revealed that the nutrients were retained due to the low operating temperature.

Rehman et al. [43] performed the concentration of pomegranate juice to investigate the potential of a two-layered hierarchical fibrous composite (HFC) membrane in OD operation. The flat sheet polyvinylidene difluoride-hexafluoropropylene (PVDF-HFP) membrane with polyethylene terephthalate (PET) support layer has an excellent performance by registering a high transmembrane water flux of 8.621 kg/m2h at a low operating temperature of 25 °C, which was about four times higher than most reported studies. The membrane analysis showed well resistance towards membrane wetting because only a tiny drop was measured in the membrane contact angle and liquid entry pressure at the end of the OD process. The pomegranate juice with an initial concentration of 10.4°Brix was concentrated by 4.9-fold to a final concentration of 51.3°Brix in 25.5 h.

Membrane Distillation

Julian et al. [44] employed a membrane distillation (MD) process to concentrate apple juice using hydrophobic polypropylene (PP) membrane. Among the four MD configurations, i.e., direct contact membrane distillation (DCMD), vacuum membrane distillation (VMD), air gap membrane distillation (AGMD), and sweeping gas membrane distillation (SGMD), submerged DCMD (SDCMD) was used to study the effect of feed solution (FS), temperature (30–50 °C), draw solution (DS) flow rate (7.2–14.4 L/h), and DS concentration (545–630 g/L) on the permeate flux and juice quality. Conventional DCMD operation has two separate feed and draws streams that are circulated, each in direct contact with one side of the membrane. In this experiment, SDCMD, which involved the submersion of a membrane module in the feed tank, eliminates the need for feed recirculation to reduce energy requirements and ensure an even feed temperature. However, critical temperature polarization appeared as stagnant feed induced poor feed hydrodynamic and mixing conditions.

Consequently, a reduction in driving force occurred, negatively affecting the permeate flux. The experiments revealed that permeate flux increased at increased feed temperature, DS flow rate, and DS concentration. However, despite the high flux and rapid juice concentration observed at high feed temperatures, high losses in the apple juice nutrients such as phenolic content (14% loss) and vitamin C (15% loss) were measured after only 1-h operation. Assessment of the DS at the end found no trace of the phenolic compound or vitain C, showing that the losses are solely contributed by heat degradation. As such, optimization of apple juice concentration using SDCMD was carried out at 30 °C FS temperature, 14 °C DS temperature, and 630 g/L K4P2O7 as DS for 2 h, resulting in twofold concentration with excellent nutrient preservation.

In a study by Criscuoli and Drioli [45], date juices (clear and dark variations) were concentrated using VMD. Two PP membranes with pore sizes of 0.2 and 0.45 μm at a low temperature of 28 °C were used to investigate the effect of pore size on the transmembrane flux. The results were observed for juice variations in the lower concentration range (18–36°Brix) and upper concentration range (36–70°Brix). The lower concentration range showed that the transmembrane fluxes in both clear and dark juice were similar, but the 0.45-μm membrane obtained higher fluxes. Conversely, the transmembrane fluxes of clear juice were higher than the dark juice in the upper concentration range, while 0.2-μm membrane led to higher fluxes in both juices as transport resistance was magnified in the FS since the concentration took place faster using 0.45-μm membrane. The 0.45-μm membrane achieved 14% and 15% faster concentrations to ~ 70°Brix than the 0.2-μm membrane for both clear and dark juices. Analysis of the permeate showed no solid presence, indicating no solute intrusion occurred across the membranes. This proved that the membranes had good stability for this type of feed and were suitable to be reused.

Forward Osmosis

Recently, forward osmosis (FO) has gained considerable attention as a novel membrane process and the most promising alternative to fruit juice processing. The pioneering research of FO in fruit juice processing dates back to 1966 by Popper et al., who managed to concentrate grape juice to a considerable degree of concentration. Despite the success, a salt intrusion that affected the final product’s quality hinders further research on this particular study. A few decades later, this field continued using better membranes, resulting in higher quality products. Since then, the research of FO for liquid food processing has emerged as a field of interest for many researchers. Table 6 presents the advantages and disadvantages associated with the FO process [46].

One major challenge in FO is the high reverse salt flux from the draw solution (DS) to the feed solution (FS) [47]. Many types of research have been conducted to minimize this effect since high reverse salt flux across the membrane layer increases the salinity of the final product and deteriorates its quality. Reverse salt flux measures osmotic agent (or DS) leakage into the FS due to diffusion, which is measured by increased feed conductivity. Sodium chloride (NaCl) is the most widely used DS for the FO process, as it is easy to obtain and available in large amounts at a low price. However, because the associated ions have small sizes and high mobility, they tend to permeate across the membrane layer, causing undesirable salt intrusion in the FS. Thus, recent efforts were made to develop alternative DS for FO or membrane with high rejection and less susceptibility for reverse salt flux.

Nijmeijer et al. [48] evaluated the concentration of apple juice using polyamide (PA) membrane on electrospun nanofiber thin-film composite (NF-TFC) support with a pore size of 2.9 μm in a flat sheet module. A high initial water flux value of 9.5 L/m2h was obtained using 3.6 M NaCl as the DS at ambient temperature. A concentration factor of 2.1 (50% volume reduction) was achieved after 24 h with a still high water flux (4.5 L/m2h). The membrane was found to have a very low reverse salt flux at 0.29 g/L, which is 4–12 times less than the commercial membrane. As the concentration of FS increased, the DS became diluted as a result of water permeating from the FS to DS due to the osmotic pressure difference between both solutions, reducing the driving force for water permeation. The water flux decreased due to the increased osmotic pressure of the concentrated FS and the occurrence of membrane fouling. Maintaining a suitable osmotic pressure difference between the FS and DS is essential to drive the FO process. Thus, a method of replacing the used DS with a new solution was employed upon reaching a concentration factor of 1.8 to recover the declining water flux over time since water flux is inversely proportional to the concentration factor.

Wang et al. [49] studied the effect of various process parameters (membrane property, crossflow velocity, DS type, and DS concentration) on the concentration of apple juice with an initial concentration of 11°Brix using FO. Based on the performance of the FO membrane, the optimum operating conditions were found using the cellulose triacetate (CTA) membrane. The crossflow velocities (0.267, 0.536, 0.805 m/s) used in the experiment showed no significant influence on the flux profile. On the other hand, the difference of flux obtained between the DS solutes was slight despite the higher flux observed using magnesium chloride (MgCl2) compared to NaCl and glucose. Thus, NaCl was chosen as the optimum DS due to its efficiency and economic benefit. The trend showed that DS with higher osmotic pressure (i.e., concentration) leads to higher water flux. Evidently, the concentration of apple juice using 4 M NaCl as the DS produced the highest water flux of 17.4 L/m2h. After 48 h of operation, the water flux decreased to 8.1 L/m2h with a final juice concentration of 60°Brix.

Variations in flow rate (60 and 120 L/h) of FS and DS, DS concentration (0.2, 0.5, and 1.0 M NaCl), and operating time (1–10 h) were used to study their effect on the concentration of watermelon juice by FO [50]. Based on the results, Vani et al. found that the FO performed well at higher flow rates, higher DS concentration, and longer operating times. Lycopene, a vital bioactive component of watermelon juice that is important in tackling cancer and heart illness risks, is of interest in this study. The experimental results revealed a 4.14-fold increase in the concentration of lycopene, while the juice concentration increased from 7.77 to 9.42°Brix.

The concentration of grape juice using FO, thermal evaporation (TE), and combined FO-TE was compared by Tavares et al. [51]. In the FO process, the juice concentration was performed using a commercial CTA membrane to investigate the effects of three variables, i.e., the osmotic pressure of DS, the temperature of FS, and flow velocity on the water flux and reverse solute flux. The FO experiments were conducted using DS to FS volume ratio of 10:1 to counter the dilution effect of DS that can affect the process efficiency. The results indicated that the higher the osmotic pressure of DS and flow velocity, the higher the water flux and final juice concentration. Furthermore, the lowest value of reverse salt flux was attained under these operating conditions. Since the feed tank capacity limits the experiment, the concentration by FO was conducted for only 5 h, which resulted in a final juice concentration of 41.7°Brix. Conversely, final juice concentrations obtained from TE (90 °C for 55 min) and combined process (FO followed by TE at 90 °C for 30 min) were 66.5 and 65.7°Brix, respectively. In future research, a bigger feed tank should be employed to increase the duration of FO to obtain higher concentration so that a fair comparison can be drawn for all three processes.

A comparison between FO and TE was also investigated by Trishitman et al. [52] to study the shelf-life of pomegranate juice concentrate from both processes. The concentration using FO was carried out at a temperature of 25 °C until the final total soluble solids (TSS) reached ~ 60°Brix, which took 18 h using 6 M NaCl as the DS with a volume ratio of 10 DS to 1 FS to hinder the effect of osmotic agent dilution. For concentration by thermal evaporation, the juice was evaporated by heating at a temperature of 55 °C until the final TSS reached ~ 60°Brix. The concentration of both TE and FO juice concentrates was returned to the fresh juice concentration by reconstitution to analyze their physicochemical properties. The results indicated that the FO reconstituted juice properties, such as the pH, titratable acidity, TSS, anthocyanins, and polyphenols content, were similar to the fresh juice, indicating FO’s ability to maintain the original properties of the pomegranate juice. By comparison, the TE reconstituted juice registered a 15% loss of valuable anthocyanin content that may be degraded during the thermal processing due to its temperature sensitivity. Based on the shelf-life study, the juice concentrates’ storage ability at ambient (25 °C) and accelerated (37 °C) was found to be ~ 101 and ~ 66 days for FO concentrate and ~ 31 and ~ 3 days for TE concentrate, respectively, which showed FO superiority in extending the shelf-life of the juice concentrate.

In a study by Zhao et al. [53], hybrid membrane processes using microfiltration (MF) and ultrafiltration (UF) as pretreatment (clarification and sterilization) and FO for apple juice concentration were investigated. Experimental results indicated that effective pretreatment that gave optimum permeate flux, degree of sterilization, and preservation of the juice quality was achieved using a 0.22-μm MF membrane. The extent of UF retention was more significant than MF due to its smaller pore size, which was most evident for macromolecule compounds like protein. A subsequent FO process was conducted using 4 M NaCl as the DS with a volume ratio of 2 DS to 1 FS until reaching a final concentration of 65°Brix. Besides, the apple juice was separately concentrated by vacuum TE to a final concentration of 65°Brix at 60 °C to compare the quality between FO concentrate and TE concentrate. The analyses showed that the overall quality of raw apple juice in terms of nutritional and volatile components was retained in the FO concentrate. At the same time, apparent protein, phenolic, and flavone losses were found in the TE concentrate, indicating degradation at high temperatures.

So far, table salt or NaCl is extensively used as the DS in many studies of the FO concentration of fruit juices. The high osmotic pressure, low price, and wide availability of NaCl make it desirable for DS application. However, the reverse salt flux is unavoidable due to the property of the salt ions, making the final juice concentrate undesirable from a sensory perspective due to salt intrusion. Other types of DS were explored using food preservatives as an alternative to the common salt [54, 55]. Zhang et al. [55] evaluated several potential food preservatives to be used as DS for the FO concentration of grape juice. They found that 4 M sodium diacetate (SDA) is the most suitable since maximum water flux was observed when using it as the DS. At the end of a 72-h FO concentration process, the grape juice obtained a final concentration of 54°Brix. Nonetheless, SDA accumulation in the juice concentrate was 2.0 g/kg, higher than the 0.5 g/kg safety limit imposed by the Food and Agriculture Organization (FAO). Dilution of the juice concentrate was required to reduce the preservative concentration below the limit to 0.39 g/kg.

Xiao et al. [54] analyzed the potential of sodium lactate (NaLA) food preservative as the DS for the FO concentration of orange juice using cellulose triacetate-polyester (CTA-ES) membrane. Analyses of DS concentration, membrane orientation, and temperature were conducted. The FO experiment for orange juice concentration was performed using 7.1 M NaLA at 25 °C with DS to FS weight ratio of 4:1 until a twofold concentration was achieved to investigate the effect of CTA membrane active layer orientation on the TSS and water flux. They found that using membrane active layer mode facing the FS improved the FO performance by shortening the concentration duration by more than half and higher water flux.

According to [56], the minimum acceptable FO flux for commercial purposes should be at least 5–6 L/m2h (measured at initial juice concentration). These recent studies showed that FO possesses the advantage of high flux. These recent records indicate that FO displays significant advantages such as higher concentration attainable while preserving the bioactive components and fewer operational constraints than the thermal treatments and conventional membrane technologies.

Based on these recent studies, the operating conditions contributing to a higher concentration of fruit juices are a longer operating time, a higher flow rate of FS and DS, and a higher concentration of DS. Crossflow velocity greatly influences the polarization effect and behavior of the boundary layer on both sides of the membrane; high crossflow velocity minimizes the polarization effect, but very high velocity can affect the structure of the membrane. Membrane properties, such as the material used, porosity, and pore size, also affected the FO performance. The DS to FS volume ratio impacts the osmotic solution’s dilution effect. Instead of using a very high DS concentration, increasing DS to FS volume ratio will also significantly improve the FO performance by minimizing the dilution effect.

Table 7 lists the recent studies of concentration by FO for various fruit juices.

Conclusion and Future Direction of Membrane Technology for Industrial Adoption

Membrane technology encompasses the engineering and scientific approaches towards separating component(s) in a gas or liquid mixture. Because of its versatility and many applications, it is used in various industries like water treatment, food processing, and pharmaceutical processing. This paper review mentions of membrane technology in the clarification and concentration of fruit juices in recent years. Membrane technology is vital in improving the quality and warranting the biosafety of fruit juices.

Most studies reported in the literature are carried out at a small scale in the laboratory to optimize the membrane operation that can improve the juice products’ quality and reduce the cost and energy requirements. Several novel membranes were fabricated to clarify and concentrate fruit juices that exhibited superior performance compared to the commercial and conventional membranes used in most studies. In addition, process modifications such as hybrid membrane processes and integration of membrane processes with non-conventional techniques are undertaken by many researchers to improve membrane performance further. Though these researches showed excellent capabilities of membrane technology in clarification and concentration of fruit juices, some limitations are deterrents to industrialization.

Most membrane separations, like pressure-driven processes, operate based on size exclusion, where only molecules smaller than the membrane pore size can pass through. Because the characteristics of fruit juice vary for each type of fruit, the specific compounds that need to be retained or removed may have different sizes, requiring a membrane with specific pore size. Membrane fabrication can be costly as they are tailor-made to suit the specific application. Various factors during the operation can limit the lifespan of the membrane by which systematic degradation would require the membrane to be replaced often, which is costly and not sustainable; this is why optimization of process parameters is essential in these studies.

Membranes behaved differently with different types of fruit because of the composition and properties of the juice (e.g., pH, viscosity). Hence, optimizing even one type of juice requires multiple extensive studies because membrane technology is relatively new in the industry compared to conventional thermal processing. These multiple studies are costly but necessary for adopting membrane technology in the juice industry. Proper approaches towards the engineering processes, including pretreatment, choice of membrane material and configuration, and optimization of process parameters, are fundamental to deter the limitations of membrane technology. Modeling studies and process optimization tools are few in the current literature. Such methods are fast and efficient for accurately analyzing the membrane optimization performance needed to upscale the operation. Various engineering models, such as process parameters, costing, and energy, can now be simultaneously optimized using optimization tools with reasonable accuracy. It can be expected that the efficiency of clarification and concentration by membrane can be significantly enhanced.

References

Heng Y, Zansler M, House L (2020) Orange juice consumers’ response to the COVID-19 pandemic. https://edis.ifas.ufl.edu

World Health Organization (2022) Nutrition and COVID-19. Nutrition. Retrieved October 8, 2022, from https://www.emro.who.int/nutrition/covid-19/index.html

Statista (2022) Juices - worldwide. https://www.statista.com/outlook/cmo/non-alcoholic-drinks/juices/worldwide

Abd El-Salam MH (2003) Membrane techniques/applications of reverse osmosis. In Encyclopedia of Food Sci Nutr (Second Edition) (1997)3833–3837

Abdullah S, Karmakar S, Pradhan RC, Mishra S (2022) Pressure-driven crossflow microfiltration coupled with centrifugation for tannin reduction and clarification of cashew apple juice: modeling of permeate flux decline and optimization of process parameters. J Food Proc Preser 46(6). https://doi.org/10.1111/jfpp.16497

Sant’Anna, V., Marczak, L. D. F., & Tessaro, I. C. (2012) Membrane concentration of liquid foods by forward osmosis: process and quality view. J Food Eng 111(3):483–489. https://doi.org/10.1016/j.jfoodeng.2012.01.032

Ghosh P, Rana SS, Kumar S, Pradhan RC, Mishra S (2015) Membrane filtration of fruit juice - an emerging technology. International Journal of Food and Nutritional Sciences 4(4):47–57

Petruzzi L, Campaniello D, Speranza B, Corbo MR, Sinigaglia M, Bevilacqua A (2017) Thermal treatments for fruit and vegetable juices and beverages: a literature overview. Comprehensive Reviews in Food Science and Food Safety 16(4):668–691. https://doi.org/10.1111/1541-4337.12270

Rastogi NK (2018) Reverse osmosis and forward osmosis for the concentration of fruit juices. In G. Rajauria & B. K. Tiwari (Eds.), Fruit Juices: Extraction, Composition, Quality and Analysis (pp. 241–259). Elsevier Inc. https://doi.org/10.1016/B978-0-12-802230-6.00013-8

Technavio (2021) Membrane market for food and beverage processing industry by filtration process and geography - forecast and analysis 2021–2025. https://www.technavio.com/report/membrane-market-for-food-and-beverage-processing-industry-analysis?utm_source=prnewswire&utm_medium=pressrelease&utm_campaign=temp31jan_rep1_wk5_2022_007&utm_content=IRTNTR45400

Echavarría AP, Torras C, Pagán J, Ibarz A (2011) Fruit juice processing and membrane technology application. Food Engineering Reviews 3(3–4):136–158. https://doi.org/10.1007/s12393-011-9042-8

Bhattacharjee C, Saxena VK, Dutta S (2017) Fruit juice processing using membrane technology: a review. Innov Food Sci Emerg Technol 43:136–153. https://doi.org/10.1016/j.ifset.2017.08.002

Conidi C, Castro-Muñoz R, Cassano A (2020) Membrane-based operations in the fruit juice processing industry: a review. Beverages 6(1):18. https://doi.org/10.3390/beverages6010018

Ilame SA, Singh S, v. (2015) Application of membrane separation in fruit and vegetable juice processing: a review. Crit Rev Food Sci Nutr 55(7):964–987. https://doi.org/10.1080/10408398.2012.679979

Singh R (2015) Introduction to membrane technology. In Membrane Technology and Engineering for Water Purification: Application, Systems Design and Operation (2nd ed., pp. 1–80). Butterworth-Heinemann. https://doi.org/10.1016/B978-0-444-63362-0.00001-X

Bates RP, Morris JR, Crandall PG (2001) Principles and practices of small- and medium-scale fruit juice processing

Codex General Standard for Fruit Juices and Nectars (2005)

Garcia CA (2018) Application of enzymes for fruit juice processing. In: Rajauria G, Tiwari BK (eds) Fruit Juices: Extraction, Composition, Quality and Analysis. Academic Press, pp 201–216

Mushtaq M (2018) Extraction of fruit juice: an overview. In: Rajauria G, Tiwari BK (eds) Fruit Juices: Extraction, Composition, Quality and Analysis. Academic Press, pp 131–160

Cheryan M (1995) FOOD TECHNOLOGY / Membrane Separations. In Encyclopedia of Separation Science (pp. 2849–2855). Academic Press

Garcia-Castello EM, McCutcheon JR (2011) Dewatering press liquor derived from orange production by forward osmosis. J Membr Sci 372(1–2):97–101. https://doi.org/10.1016/j.memsci.2011.01.048

Vaillant F, Pérez AM, Acosta O, Dornier M (2008) Turbidity of pulpy fruit juice: a key factor for predicting cross-flow microfiltration performance. J Membr Sci 325(1):404–412. https://doi.org/10.1016/j.memsci.2008.08.003

Kilara A, van Buren JP (1989) Clarification of Apple Juice. In D. L. Downing (Ed.), Processed apple products (pp. 83–96). Van Nostrand Reinhold. https://doi.org/10.1007/978-1-4684-8225-6

Morittu VM, Mastellone V, Tundis R, Loizzo MR, Tudisco R, Figoli A, Cassano A, Musco N, Britti D, Infascelli F, Lombardi P (2020) Antioxidant, biochemical, and in-life effects of Punica granatum L. natural juice vs. clarified juice by polyvinylidene fluoride membrane. Foods 9(2). https://doi.org/10.3390/foods9020242

Severcan SS, Uzal N, Kahraman K (2020) Clarification of pomegranate juice using PSF microfiltration membranes fabricated with nano TiO2 and Al2O3. J Food Process Preserv 44(8). https://doi.org/10.1111/jfpp.14559

Severcan SS, Uzal N, Kahraman K (2020) Clarification of apple juice using new generation nanocomposite membranes fabricated with TiO2 and Al2O3 nanoparticles. Food Bioprocess Technol 13(3):391–403. https://doi.org/10.1007/s11947-019-02373-0

Le TTH, Vu LTK, Le NL (2021) Effects of membrane pore size and transmembrane pressure on ultrafiltration of red-fleshed dragon fruit (Hylocereus polyrhizus) juice. J Chem Technol Biotechnol 96(6):1561–1572. https://doi.org/10.1002/jctb.6672

Mejia JAA, Yáñez-Fernandez J (2021) Clarification processes of orange prickly pear juice (Opuntia spp.) by microfiltration. Membranes 11(5). https://doi.org/10.3390/membranes11050354

Alaei B, Amiri Chayjan R, Ali Zolfigol M (2021) Tomato juice microfiltration process assisted with pressure-vacuum combination condition: a physicochemical investigation and optimization. Biosys Eng 212:62–76. https://doi.org/10.1016/j.biosystemseng.2021.10.005

Omar JM, Nor MZM, Basri MSM, Che Pa, NF (2020) Clarification of guava juice by an ultrafiltration process: analysis on the operating pressure, membrane fouling and juice qualities. Food Res 4, 85–92. https://doi.org/10.26656/fr.2017.4(S1).S30

Singh V, Das C (2021) Clarification of Citrus fruit (Mosambi) juice by hybrid (Pretreatment and Membrane) process. Materials Today: Proceedings 47:1384–1388. https://doi.org/10.1016/j.matpr.2021.02.435

Yee WP, Nor MZM, Basri MSM, Roslan J (2021) Membrane-based clarification of banana juice: pre-treatment effect on the flux behaviour, fouling mechanism and juice quality attributes. Food Res 5, 57–64. https://doi.org/10.26656/fr.2017.5(S1).046

Salehinia S, Mirsaeedghazi H, Khashehchi M (2021) The effect of laser on the efficiency of membrane clarification of pomegranate juice. J Food Sci Technol 58(5):1682–1692. https://doi.org/10.1007/s13197-020-04678-x

Zarouk S, Mirsaeedghazi H, Massah J (2022) The effect of magnetic field on efficiency and fouling mechanisms during membrane clarification of pomegranate juice. Iran J Chem Chem Eng 41(2):595–606

Akhtar A, Subbiah S, Mohanty K, Sundar R, Unnikrishnan R, Hareesh US (2020) Sugarcane juice clarification by lanthanum phosphate nanofibril coated ceramic ultrafiltration membrane: PPO removal in absence of lime pre-treatment, fouling and cleaning studies. Separ Purific Technol 249. https://doi.org/10.1016/j.seppur.2020.117157

Adnan A, Mushtaq M, Ul-Islam T (2018) Fruit juice concentrates. In G. Rajauria & B. J. Tiwari (Eds.). Fruit Juices: Extraction, Composition, Quality and Analysis 217–240. Academic Press. https://doi.org/10.1016/C2014-0-02764-5

Jiao B, Cassano A, Drioli E (2004) Recent advances on membrane processes for the concentration of fruit juices: a review. J Food Eng 63(3):303–324

Bhattacharjee C, Saxena VK, Dutta S (2020) Insights into effectiveness of tight ultrafiltration and frozen storage in bioactive compound retention in watermelon juice concentrate. J Food Proc Eng 43(10). https://doi.org/10.1111/jfpe.13492

Bagci PO, Akbas M, Gulec HA, Bagci U (2019) Coupling reverse osmosis and osmotic distillation for clarified pomegranate juice concentration: use of plasma modified reverse osmosis membranes for improved performance. Innov Food Sci Emerg Technol 52:213–220. https://doi.org/10.1016/j.ifset.2018.12.013

Bagci PO, Kahvecioglu H, Gulec HA, Bagci U (2020) Pomegranate juice concentration through the consecutive application of a plasma modified reverse osmosis membrane and a membrane contactor. Food Bioprod Process 124:233–243. https://doi.org/10.1016/j.fbp.2020.09.003

Yilmaz E, Bagci PO (2018) Production of phytotherapeutics from broccoli juice by integrated membrane processes. Food Chem 242:264–271. https://doi.org/10.1016/j.foodchem.2017.09.056

Kumar D, Ladaniya MS, Gurjar M, Mendke S, Kumar S (2020) Osmotic membrane distillation for retention of antioxidant potential in Nagpur mandarin (Citrus reticulata Blanco) fruit juice concentrate. J Food Proc Eng 43(1). https://doi.org/10.1111/jfpe.13096

Rehman WU, Khan A, Mushtaq N, Younas M, An X, Saddique M, Farrukh S, Hu Y, Rezakazemi M (2020) Electrospun hierarchical fibrous composite membrane for pomegranate juice concentration using osmotic membrane distillation. J Environ Chem Eng 8(6). https://doi.org/10.1016/j.jece.2020.104475

Julian H, Yaohanny F, Devina A, Purwadi R, Wenten IG (2020) Apple juice concentration using submerged direct contact membrane distillation (SDCMD). J Food Eng 272. https://doi.org/10.1016/j.jfoodeng.2019.109807

Criscuoli A, Drioli E (2020) Date juice concentration by vacuum membrane distillation. Separ Puri Technol 251. https://doi.org/10.1016/j.seppur.2020.117301

Rastogi NK (2016) Opportunities and challenges in application of forward osmosis in food processing. Crit Rev Food Sci Nutr 56(2):266–291. https://doi.org/10.1080/10408398.2012.724734

Ang WL, Wahab Mohammad A, Johnson D, Hilal N (2019) Forward osmosis research trends in desalination and wastewater treatment: a review of research trends over the past decade. J Water Proc Eng 31, 100886. https://doi.org/10.1016/j.jwpe.2019.100886

Nijmeijer K, Oymaci P, Lubach S, Borneman Z (2022) Apple juice, manure and whey concentration with forward osmosis using electrospun supported thin-film composite membranes. Membranes 12(5). https://doi.org/10.3390/membranes12050456

Wang H, Zhang Y, Ren S, Pei J, Li Z (2022) Athermal concentration of apple juice by forward osmosis: process performance and membrane fouling propensity. Chem Eng Res Des 177:569–577. https://doi.org/10.1016/j.cherd.2021.11.023

Vani B, Kalyani S, Pabba M, Sridhar S (2021) Forward osmosis aided concentration of lycopene carotenoid from watermelon juice. J Chem Technol Biotechnol 96(7):1960–1973. https://doi.org/10.1002/jctb.6720

Tavares HM, Tessaro IC, Cardozo NSM (2022) Concentration of grape juice: combined forward osmosis/evaporation versus conventional evaporation. Innov Food Sci Emerg Technol 75. https://doi.org/10.1016/j.ifset.2021.102905

Trishitman D, Negi PS, Rastogi NK (2023) Concentration of pomegranate juice by forward osmosis or thermal evaporation and its shelf-life kinetic studies. Food Chem 399. https://doi.org/10.1016/j.foodchem.2022.133972

Zhao S, Li S, Pei J, Meng H, Wang H, Li Z (2022) Evaluation of hybrid pressure-driven and osmotically-driven membrane process for non-thermal production of apple juice concentrate. Innov Food Sci Emerg Technol 75. https://doi.org/10.1016/j.ifset.2021.102895

Xiao S, Li Z, Xiong Q, Wu C, Huang J, Zhou R, Jin Y (2021) Exploration of sodium lactate as the draw solute of forward osmosis for food processing. J Food Eng 296. https://doi.org/10.1016/j.jfoodeng.2020.110465

Zhang K, An X, Bai Y, Shen C, Jiang Y, Hu Y (2021) Exploration of food preservatives as draw solutes in the forward osmosis process for juice concentration. J Membrane Sci 635. https://doi.org/10.1016/j.memsci.2021.119495

Herron JR, Beaudry EG, Jochums CE, Medina LE (1994) Osmotic concentration apparatus and method for direct osmotic concentration of fruit juices (patent no. US Patent 5,281,430)

Funding

This research was supported by the Ministry of Higher Education Malaysia through the research grant code PRGS/2/2019/TK02/UMS/01/1 and the Universiti Malaysia Sabah Internal Funds.

Author information

Authors and Affiliations

Contributions

Rosalam Sarbatly: Conceptualization; Writing-review and editing; Supervision. Jamilah Sariau: Visualization; Writing-original draft preparation, review and editing. Duduku Krishnaiah: Visualization; Writing-review and editing.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sarbatly, R., Sariau, J. & Krishnaiah, D. Recent Developments of Membrane Technology in the Clarification and Concentration of Fruit Juices. Food Eng Rev 15, 420–437 (2023). https://doi.org/10.1007/s12393-023-09346-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12393-023-09346-2