Abstract

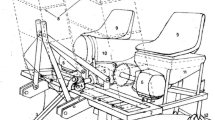

Adopting trash mulch in sugarcane farming encounters challenges attributed to the lack of suitable all-in-one trash management machinery with simultaneous stubble shaving. This limits soil health benefits and impeding advantages such as quick trash decomposition during ratoon crop initiation. Thus, in the present study, a tractor-operated trash mulcher-cum-stubble shaver device for sugarcane ratoon crop was designed and developed at ICAR-Indian Institute of Sugarcane Research (IISR), Lucknow, India. The design of this device includes three major units such as trash mulching, chemical spraying and stubble shaving unit to complete the trash management operations in one go in the manually harvested sugarcane crop field. Based on computer-aided design, the device was developed which is simple in construction and capable of eliminating the manual collection of trash or burning it. It operates with the provision of differential height cutting blades, the trash mulching unit effectively shreds and mulches the trash lying on the ridges as well as in the furrows of sugarcane rows. The liquid trash decomposer is sprayed over the shredded trash with the chemical spraying unit followed by stubble shaver that precisely shaves two rows of harvested stubbles without cane splitting or clogging. Performance evaluation of the developed device was carried out at IISR Research Farm to obtain the best speed ratio (SR) and trash shredding height (TSH). The trash mulcher-cum-stubble shaver device delivers uniform trash shredding (95.8 %) and uniformity of trash spreading (92.6 %) at SR 26 and TSH 25 mm. This device operates at a tractor speed of 2.5 km h−1 consuming 4.5 l h−1 diesel fuel with effective field capacity of 0.3 ha h−1 at 80.0 % field efficiency. The developed technology initiates better ratooning, boosts trash mulching, reduces operational time, dependence on labor and environmental degradation by converting trash indirectly into cash.

Similar content being viewed by others

References

Ali, M., A.K. Dixit, G.S. Manes, R.U. Modi, A. Singh, and A.K. Mahal. 2022. Evaluation of an integral dust separation system based wheat straw combine for improvement in animal feed quality. Animal Nutrition and Feed Technology 22 (3): 641–652. https://doi.org/10.5958/0974-181X.2022.00051.8.

Bairwa, R., C.K. Jha, S.K. Thakur, M. Roy, and D.K. Brajendra. 2023. Carbon pools and indices under activated trash treatments in sugarcane plant–ratoon system grown in calcareous soil of subtropics. Sugar Tech 25: 1433–1444. https://doi.org/10.1007/s12355-023-01280-1.

Basanta, M.V., D. Dourado-Neto, K. Reichardt, O.O.S. Bacchi, J.C.M. Oliveira, P.C.O. Trivelin, L.C. Timm, T.T. Tominaga, V. Correchel, F.A.M. Cássaro, and L.F. Pires. 2003. Management effects on nitrogen recovery in a sugarcane crop grown in Brazil. Geoderma 116: 235–248. https://doi.org/10.1016/S0016-7061(03)00103-4.

Carvalho, J.L.N., R.C. Nogueirol, L.M.S. Menandro, R.D.O. Bordonal, C.D. Borges, H. Cantarella, and H.C.J. Franco. 2017. Agronomic and environmental implications of sugarcane straw removal: A major review. GCB Bioenergy 9: 1181–1195. https://doi.org/10.1111/gcbb.12410.

Choudhary, R.L., G.C. Wakchaure, P.S. Minhas, and A.K. Singh. 2017. Response of ratoon sugarcane to stubble shaving, off-barring, root pruning and band placement of basal fertilisers with a multi-purpose drill machine. Sugar Tech 19: 33–40. https://doi.org/10.1007/s12355-016-0438-x.

Dash, B.S., A. Kumar, R.U. Modi, and S.K. Namdev. 2020. Design and performance evaluation of self-propelled intra-canopy boom spraying system. Journal of Agricultural Engineering 57 (3): 195–209.

Denmead, O.T., C.L. Mayocchi, and F.X. Dunin. 1997. Does green cane harvesting conserve soil water? In Proceedings of the Australian Society of Sugar Cane Technologists 18: 139–146.

FAOSTAT. 2023. Food and Agricultural Organization of the United Nations. http://www.fao.org/faostat/en/#data/QCL/visualize. Accessed 23 Aug 2023.

Fortes, C., P.C.O. Trivelin, and A.C. Vitti. 2012. Long-term decomposition of sugarcane harvest residues in Sao Paulo state, Brazil. Biomass and Bioenergy 42: 189–198. https://doi.org/10.1016/j.biombioe.2012.03.011.

Gomathi, R., P.N.G. Rao, P. Rakkiyappan, B.P. Sundara, and S. Shiyamala. 2013. Physiological studies on ratoonability of sugarcane varieties under tropical Indian condition. American Journal of Plant Sciences 4: 247–281. https://doi.org/10.4236/ajps.2013.42036.

Gómez, O.E., R.T.G.de Souza, G.J.de.M. Rocha, E.de Almeida, and L.A.B. Cortez. 2014. Sugarcane trash as feedstock for second generation processes. In Sugarcane bioethanol—R&D for productivity and sustainability, Luis Augusto Barbosa Cortez, 637–660. https://doi.org/10.5151/BlucherOA-Sugarcane-sugarcanebioethanol_56.

Hemwong, S., B. Toomsan, G. Cadisch, V. Limpinunantana, P. Vityakon, and A. Patanothai. 2009. Sugarcane residue management and grain legume crop effects on N dynamics, N losses and growth of sugarcane. Nutrient Cycling in Agroecosystems 83: 135–151. https://doi.org/10.1007/s10705-008-9209-8.

Hunsigi, G. 2001. Ratoon management. In Sugarcane in agriculture and industry, ed. G. Hunsigi, 217. Bangalore: Prism Books.

Jaiswal, V.P., S.K. Shukla, L. Sharma, and A.D. Pathak. 2023. Crop residue recycling affecting carbon sequestration, nutrients availability and crop yields in rice–wheat and sugarcane–ratoon–wheat system. Sugar Tech 25: 119–140. https://doi.org/10.1007/s12355-022-01157-9.

Kepner, R.A., R. Bainer, and E.L. Barger. 2005. Principles of farm machinery, 3rd ed., 368–382. USA: The AVI Publishing Company Inc.

Maza, M., H.F. Pajot, M.J. Amoroso, and M.G. Yasem. 2014. Post-harvest sugarcane residue degradation by autochthonous fungi. International Biodeterioration and Biodegradation 87: 18–25. https://doi.org/10.1016/j.ibiod.2013.10.020.

Meier, E.A., P.J. Thorburn, M.K. Wegener, and K.E. Basford. 2006. The availability of nitrogen from sugarcane trash on contrasting soils in the wet tropics of North Queensland. Nutrient Cycling in Agroecosystems 75: 101–114. https://doi.org/10.1007/s10705-006-9015-0.

Modi, R.U., K. Manjunatha, P.V. Gautam, T. Nageshkumar, R. Sanodiya, V. Chaudhary, G.R.K. Murthy, I. Srinivas and C.S. Rao. 2020. Climate-smart technology based farm mechanization for enhanced input use efficiency. In Climate Change and Indian Agriculture: Challenges and Adaption Strategies, 325–358. ICAR-National Academy of Agricultural Research and Management, Hyderabad, Telangana, India.

Mukesh, S., and V. Rani. 2017. Performance evaluation of machinery for sugarcane handling and trash management. International Journal of Agricultural Engineering 10: 234–238.

Ng Cheong, L.R., and M. Teeluck. 2015. The practice of green cane trash blanketing in the irrigated zone of Mauritius: Effects on soil moisture and water use efficiency of sugarcane. Sugar Tech 18: 124–133. https://doi.org/10.1007/s12355-015-0374-l.

Olivier, F.C. and A. Singels. 2007. Effect of a trash blanket on irrigation water use efficiency of sugarcane. Proceedings of the International Society of Sugar Cane Technologists 26: 404–408.

de Paula, V.R., and J.P. Molin. 2013. Assessing damage caused by accidental vehicle traffic on sugarcane ratoon. Applied Engineering in Agriculture 29 (2): 161–169.

Robertson, F.A., and P.J. Thorburn. 2007. Management of sugarcane harvest residues: Consequences for soil carbon and nitrogen. Australian Journal of Soil Research 45: 13–23.

Seabra, J.E.A., and I.C. Macedo. 2011. Comparative analysis for power generation and ethanol production from sugarcane residual biomass in Brazil. Energy Policy 39: 421–428. https://doi.org/10.1016/j.enpol.2010.10.019.

Seemakram, W., T. Suebrasri, S. Khaekhum, J. Ekprasert, and S. Boonlue. 2023. Enhancement of integrated sugarcane trash managements by co-inoculation of cellulolytic microorganisms for sustaining soil fertility. Sugar Tech 25: 925–937. https://doi.org/10.1007/s12355-023-01250-7.

Shukla, S.K., R.L. Yadav, P.N. Singh, and I. Singh. 2009. Potassium nutrition for improving stubble bud sprouting, dry matter partitioning, nutrient uptake and winter initiated sugarcane (Saccharum spp. hybrid complex) ratoon yield. European Journal of Agronomy 30: 27–33. https://doi.org/10.1016/j.eja.2008.06.005.

Singh, A.K., and R.U. Modi. 2022. Enhancing income of farmers through engineering interventions in sugarcane based cropping systems. In Proceedings of the 55th Engineers’ Day 2022 Souvenir, The Institution of Engineers (India), U.P. State Centre, 62–67. Lucknow, India.

Singh, A.K., P.R. Singh, and S. Solomon. 2017. Design and development of a tractor-operated disc-type sugarcane ratoon management device. Sugar Tech 19: 501–509. https://doi.org/10.1007/s12355-016-0483-5.

Singh, M.K., and A.K. Singh. 2022. Eco friendly mechanization option for managing sugarcane field trash. RASSA Journal of Science for Society 4: 136–140.

Singh, S.N., A.K. Singh, J.P.S. Malik, R. Kumar, and Sunderpal and M.L. Sharma. 2012. Cultural practice packages and trash management effects on sugarcane ratoons under sub-tropical climatic conditions of India. The Journal of Agricultural Science 150 (2): 237–247. https://doi.org/10.1017/S0021859611000499.

Sood, A., A.K. Dixit, R. Khurana, M. Singh, R.U. Modi, and A. Verma. 2023. Design and development of a tractor operated bund former for mulched field. Agricultural Mechanization in Asia, Africa and Latin America 54 (1): 57–62.

Sood, A., A.K. Dixit, M. Singh, R.U. Modi, A. Singh, and A. Prakash. 2022. Performance assessment of tractor-operated bund former for mulched field. Journal of Agricultural Engineering 59 (1): 1–17. https://doi.org/10.52151/jae2022591.1761.

Sousa, J.G.A., Jr., M.R. Cherubin, C.E.P. Cerri, C.C. Cerri, and B.J. Feigl. 2017. Sugar cane straw left in the field during harvest: decomposition dynamics and composition changes. Soil Research 55: 758–768. https://doi.org/10.1071/SR16310.

Srivastava, A.C. 2003. Energy savings through reduced tillage and trash mulching in sugarcane production. Applied Engineering in Agriculture 19: 13–18. https://doi.org/10.13031/2013.12729.

Sundara, B., and B.K. Tripathi. 1989. Available N changes and N balance under multi ratooning of sugarcane varieties in tropical vertisol. In Proceedings of the International Society of Sugar Cane Technologists 23: 80–88.

Thorburn, P.J., E.A. Meier, K. Collins, and F.A. Robertson. 2012. Changes in soil carbon sequestration, fractionation and soil fertility in response to sugarcane residue retention are site-specific. Soil and Tillage Research 120: 99–111. https://doi.org/10.1016/j.still.2011.11.009.

Vasconcelos, A.L.S., M.R. Cherubin, B.J. Feigl, C.E.P. Cerri, M.R. Gmach, and M. Siqueira-Neto. 2018. Greenhouse gas emission responses to sugarcane straw removal. Biomass and Bioenergy 113: 15–21. https://doi.org/10.1016/j.biombioe.2018.03.002.

Acknowledgements

This study was supported by the ICAR-Indian Institute of Sugarcane Research, Lucknow-226002, Uttar Pradesh, India. The authors acknowledge the help received from technical staff of the Engineering Workshop, Agricultural Engineering Division, ICAR-Indian Institute of Sugarcane Research, Lucknow for fabricating and assembling the designed device and also for conducting field experiments.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All the authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Singh, M.K., Modi, R.U., Singh, A.K. et al. Design and Development of Tractor-Operated Trash Mulcher-Cum-Stubble Shaver Device for Sugarcane Ratoon Crop. Sugar Tech 26, 573–584 (2024). https://doi.org/10.1007/s12355-024-01361-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12355-024-01361-9