Abstract

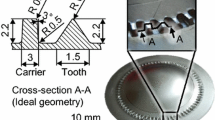

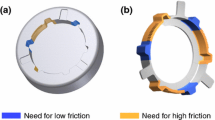

Sheet-bulk metal forming (SBMF) processes are characterized by a successive and/or simultaneous occurrence of different load conditions such as the stress and strain states. These conditions influence the material flow and often lead to a reduced geometrical accuracy of the produced components. To improve the product quality, a control of the material flow is required. One suitable approach, the local adaption of tribological conditions by means of surface modifications of tool or workpiece, so-called tailored surfaces. To control the material flow and thus to improve the component accuracy, methods to reduce and to increase friction are needed. The aim of this study is to determine requirements for necessary adaptions of the friction, the identification of tribological mechanisms for different types of tool-sided tailored surfaces as well as the verification of the effectiveness of these surface modifications to improve the results of a specific SBMF process. The numerical analysis of a combined deep drawing and upsetting process revealed that this process is characterized by two areas of varying tribological load conditions. Using a numerical analysis, the friction factor gradient between these two areas was identified as a main influencing factor on the material flow. Based on this finding, Chromium-based hard coatings for the reduction of the friction and high-feed milled surfaces for an increase of the friction were investigated regarding their frictional behaviour. The results of the ring-compression tests revealed that the carbon content and the post treatment of coated tool surfaces are relevant to reduce the friction. The increased profile depth of the milled surfaces was identified as the main influencing factor on the tribological behaviour of this kind of tailored surfaces. The effectiveness of both types of tailored surfaces was verified for the combined deep drawing and upsetting process.

Similar content being viewed by others

References

Kleiner M, Geiger M, Klaus A (2003) Manufacturing of lightweight components by metal forming. Annals of the CIRP 52(2):521–542

Doege E, Thalemann J (1989) Near net-shape forming in sheet-metal forming and forging. Annals of the CIRP 38:609–616

Merklein M, Allwood JM, Behrens BA, Brosius A, Hagenah H, Kuzman K, Mori K, Tekkaya AE, Weckenmann A (2012) Bulk forming of sheet metal. Annals of the CIRP 61(2):725–745

Mori K (2012) Bulk forming of sheet metals for controlling wall thickness distribution of products. Steelresearch Journal, Weinheim: Wiley-VCH: 17–24

Mori K, Abe Y, Osakada K, Hiramatsu S (2011) Plate forging of tailored blanks having local thickening for deep drawing of square cups. J Mater Process Technol 211(10):1569–1574

Wang ZG, Yoshikawa Y, Osakada K (2013) A new forming method of solid bosses on a cup made by deep drawing. Annals of the Cirp 62(1):291–294

Löffler M, Andreas K, Engel U, Schulte R, Groebel D, Krebs E, Freiburg D, Biermann D, Stangier D, Tillmann W, Weikert T, Wartzack S, Tremmel S, Lucas H, Denkena B, Merklein M (2016) Tribological measures for controlling material flow in sheet-bulk metal forming. Prod Eng 10(4–5):459–470

Klocke F, Dambon O, Behrens B (2011) Analysis of defect mechanisms in polishing of tool steels. Production Engineering Research and Development 5(5):475–483

Lange K (1985) Handbook of Metal Forming. McGraw-Hill, New York

Fontaine J, Donnet C, Erdemir A (2008) Fundamentals of the tribology of DLC coatings. In: Donnet C, Edemir A (ed) Tribology of diamond like carbon films. Springer, New York, pp 139–154

Twardy S (2014) Funktionsgerechte Fertigung von Mikroumformwerkzeugen durch Mikrofräsen. phd thesis, Universität Bremen

Trauth DH (2016) Tribology of machine hammer peened tool surface for deep drawing. phd thesis, RWTH Aachen

Neudecker T (2004) Tribologische Eigenschaften keramischer Blechumformwerkzeuge – Einfluss einer Oberflächenendbearbeitung mittels Excimerlaserstrahlung. phd thesis, Friedrich-Alexander-Universität Erlangen-Nürnberg

Popp U (2006) Grundlegende Untersuchungen zum Lasterstrahlstrukturieren von Kaltmassivumform-werkzeugen. phd thesis, Friedrich-Alexander-Universität Erlangen-Nürnberg

Wagner K (2011) Beanspruchungsangepasste Kaltmassivumformwerkzeuge durch local optimierte Werkzeugoberflächen. phd thesis, Friedrich-Alexander-Universität Erlangen-Nürnberg

Vetter J, Lugscheider E, Guerreiro SS (1998) (Cr:Al)N coatings deposited by the cathodic vacuum arc evaporation. Surf Coat Technol 98:1233–1239

Krawate M, Hashimoto A.K, Suzuki T (2003) Oxidation resistance of Cr1-xAlxN Ti1-xAlxN films. Surf Coat Technol 165(2):163–167

Ding XZ, Zeng XT (2005) Structural, mechanical and tribological properties of CrAlN coatings deposited by reactive unbalanced sputtering. Surf Coat Technol 200(6):1372–1376

Tillmann W, Stangier D, Schröder P (2016) Investigation and optimization of the tribo-mechanical properties of CrAlCN coatings using Design of Experiments. Surf Coat Technol 308:147–157

Ahn S-K, Kwon S-H, Kim K-H (2011) Effect of carbon on microstructure of CrAlCxN1-x coatings by hybrid coating system. Trans Nonferrous Metals Soc China 21:78–82

Sun Z, Ahuja R (2006) Ab initio study of the Cr2AlC (0001) surface. Appl Phys Lett 88:161913

Polcar T, Cvrcek L, Siroky P, Novák R (2005) Tribological characteristics of CrCN coatings at elevated temperature. Vacuum 80(1–3):113–116

Paulo JA (2011) Machining of Hard Materials. Springer, London

Abele E, Dewald M, Heimrich F (2010) Leistungsgrenzen von Hochvorschubstrategien im Werkzeug- und Formenbau. Werkzeug und Formenbau 105:737–743

Lucas H, Denkena B, Grove T, Krebs E, Kersting P, Freiburg D, Biermann D (2015) Analysis of Residual Stress States of Structured Surfaces Manufactured by High-Feed and Micromilling. HTM Journal of Heat Treatment and Materials 70(4):183–189

Zabel A, Surmann T, Peuker A (2008) Surface structuring and tool path planning for efficient milling of dies. In: Abele E (ed) 7th international conference on high speed machining proceedings, Bamberg, pp 155–160

Peuker A (2015) Werkzeugentwicklung für die Transplantation thermisch gespritzter mikrostrukturierter Funktionsschichten auf Druckgusswerkstücke, Vulkan Verlag, Essen

Funding

This work was supported by the German Research Foundation (DFG) within the scope of the Transregional Collaborative Research Centre on Sheet-Bulk metal forming (CRC/TR 73, Subprojects A1, B3, B5 and C1).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Löffler, M., Schulte, R., Freiburg, D. et al. Control of the material flow in sheet-bulk metal forming using modifications of the tool surface. Int J Mater Form 12, 17–26 (2019). https://doi.org/10.1007/s12289-018-1399-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-018-1399-2