Abstract

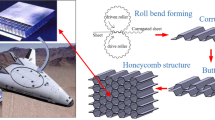

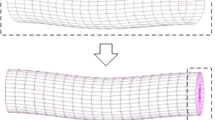

This paper focuses on the corrugated thin-walled sheet metal in the roll bending process. The main defect that appears in corrugated panels subjected to high amounts of bending deformation is a wavy edge. Edge defects are caused by excessive longitudinal stress and strain near the edge of the plate, and local edge buckling may occur when some critical value of the bending radius is exceeded. This paper proposes two different approaches to avoid a wavy edge for a formed panel: excessive stress on the edge region is restrained by controlling the length of the cross-sectional end of the corrugated panel while considering the stress distribution, and the bending radius in each forming step is determined by considering the strain limit at which the initial edge waviness occurs to avoid excessive compression at particular steps. The experimental and numerical results indicated that the two proposed design strategies can minimize wavy edges in the formed shape.

Similar content being viewed by others

References

Liu JH, Westhoff B, Ahmetoglu MA, Altan T (1996) Application of viscous pressure forming (VPF) to low volume stamping of difficult-to-form alloys-results of preliminary FEM simulations. J Mater Process Tech 29:1–9

Wang ZJ, Wang XY, Wang ZR (2004) Viscous pressure forming (VPF) of corrugated thin-walled sheet part with small radius. J Mater Process Tech 145:345–351

Yang M, Shima S (1988) Simulation of pyramid type three roller bending process. Int J Mech Sci 30:877–886

Hua M, Sansome DH, Baines K (1995) Mathematical modeling of the internal bending moment at the top roll contact in multi-pass four-roll thin-plate bending. J Mater Process Tech 52:425–459

Shin JG, Park TJ, Yim H (2001) Kinematics based determination of the rolling region in roll bending for smoothly curved plates. J Manuf Sci Eng 123:284–290

Gandhi AH, Raval HK (2006) Analytical modeling of top roller position for multiple pass (3-roller) cylindrical forming of plates. In: International mechanical engineering congress and exposition, Chicago, IL; Paper no. IMECE2006–14279:107–116

Kajrup G, Flamholz A (2003) Bending the wind-roll bending challenges in fabricating conical cylinder wind towers. The Fabricator.

Rasmussen KJR, Hancock GJ (1998) Deformations and residual stresses induced in channel section columns by presetting and welding. J Constr Steel Res 11:175–204

Landolfo R, Mazzolani FM (1991) The influence of the variation through the thickness of residual stresses in tubular columns. J Constr Steel Res 19:49–57

Farzin M, Tehrani MS, Shameli E (2002) Determination of buckling limit of strain in cold roll forming by the finite element analysis. J Mater Process Tech 125:626–632

Tehrani MS, Naeini HM, Hartley P, Khademizadeh H (2006) Localized edge buckling in cold roll-forming of circular tube section. J Mater Process Tech 177:617–620

Shim DS, Yang DY, Chung SW, Han MS (2010) Optimization of forming steps in the incremental forming of twisted shapes using a line array roll set (LARS). Int J Precis Eng Man 11:715–723

ABAQUS Inc. (2004) ABAQUS 6.12 User’s Manual

Lange K (1998) Handbook of metal forming. McGraw-Hill

Halmos GT (2006) Roll forming handbook. Taylor & Francis

Marciniak Z, Duncan JL (1992) The mechanics of sheet metal forming. Edward Arnold

Acknowledgments

This work is supported by the Korea Institute of Industrial Technology (KITECH) under Grant Number ER150020 and by the Ministry of Strategy and Finance (MOSF). The authors express their sincere gratitude to the MOSF for providing financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Shim, DS., Son, JY., Lee, EM. et al. Improvement strategy for edge waviness in roll bending process of corrugated sheet metals. Int J Mater Form 10, 581–596 (2017). https://doi.org/10.1007/s12289-016-1303-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-016-1303-x