Abstract

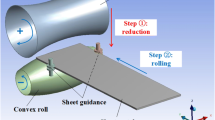

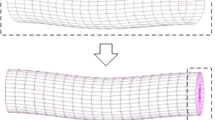

The corrugated sheet is a crucial component of the metal honeycomb structure. This study investigates the size effects on the deformation behavior of ultra-thin-walled corrugated sheets in the roll bending process using experimental and simulation methods. A precision roll bending device was developed, which incorporated a specifically designed eccentric fine-tuning module and a pneumatic module to prevent the distortion and insufficient deformation of the ultra-thin-walled corrugated sheets. The experimental results showed that micro-scratches and orange peel phenomenon appeared in the bending region of ultra-thin-walled corrugated sheets due to the lack of grain deformation coordination. Decreasing the ratio of foil thickness to grain diameter (t/d value) resulted in a slight increase in edge lengths, but a sharp decrease in the thickness of the bending region of ultra-thin-walled corrugated sheets. For the ultra-thin-walled corrugated sheet with a t/d value of 1.2, its thickness was reduced by 14%, leading to a high risk of rupture. Consequently, a finite element model of the roll bending process was established with consideration of the heterogeneity of grain shape and grain orientation. The simulation results indicate that the prediction error of the model for the springback angle was less than 15%. The random distribution of elastic deformation and plastic penetration zones is responsible for the great scatter of the springback angle of ultra-thin-walled corrugated sheets. This research provides a theoretical foundation for the precision manufacturing of ultra-thin-walled corrugated sheets.

Similar content being viewed by others

Data availability

Data will be made available on request.

References

Qiu K, Ming W, Shen L, An Q, Chen M (2017) Study on the cutting force in machining of aluminum honeycomb core material. Compos Struct 164:58–67. https://doi.org/10.1016/j.compstruct.2016.12.060

Ismail Z, Ong ZC (2012) Honeycomb damage detection in a reinforced concrete beam using frequency mode shape regression. Measurement 45(5):950–959. https://doi.org/10.1016/j.measurement.2012.01.049

Eichenhueller B, Egerer E, Engel U (2007) Microforming at elevated temperature - forming and material behaviour. Int J Adv Manuf Technol 33(1–2):119–124. https://doi.org/10.1007/s00170-006-0731-z

Zheng W, Wang G, Zhao G, Wei D, Jiang Z (2013) Modeling and analysis of dry friction in micro-forming of metals. Tribol Int 57:202–209. https://doi.org/10.1016/j.triboint.2012.06.031

Lai X, Peng L, Hu P, Lan S, Ni J (2008) Material behavior modelling in micro/meso-scale forming process with considering size/scale effects. Comput Mater Sci 43(4):1003–1009. https://doi.org/10.1016/j.commatsci.2008.02.017

Chan WL, Fu MW, Lu J, Liu JG (2010) Modeling of grain size effect on micro deformation behavior in micro-forming of pure copper. Mater Sci Eng A 527(24):6638–6648. https://doi.org/10.1016/j.msea.2010.07.009

Mahabunphachai S, Koç M (2008) Investigation of size effects on material behavior of thin sheet metals using hydraulic bulge testing at micro/meso-scales. Int J Mach Tools Manuf 48(9):1014–1029. https://doi.org/10.1016/j.ijmachtools.2008.01.006

Janssen PJM, Hoefnagels JPM, de Keijser TH, Geers MGD (2008) Processing induced size effects in plastic yielding upon miniaturisation. J Mech Phys Solid 56(8):2687–2706. https://doi.org/10.1016/j.jmps.2008.03.008

Fu MW, Chan WL (2013) Micro-scaled progressive forming of bulk micropart via directly using sheet metals. Mater Des 49:774–783. https://doi.org/10.1016/j.matdes.2013.02.045

Liu JG, Fu MW, Chan WL (2012) A constitutive model for modeling of the deformation behavior in microforming with a consideration of grain boundary strengthening. Comp Mater Sci 55:85–94. https://doi.org/10.1016/j.commatsci.2011.11.018

Cao J, Zhuang W, Wang S, Lin J (2010) Development of a VGRAIN system for CPFE analysis in micro-forming applications. Int J Adv Manuf Technol 47(9–12):981–991. https://doi.org/10.1007/s00170-009-2135-3

Ma Z, Peng X, Wang C, Cao Z (2020) Modeling of material deformation behavior in micro-forming with consideration of individual grain heterogeneity. T Nonferr Metal Soc 30(11):2994–3005. https://doi.org/10.1016/S1003-6326(20)65437-1

Funding

This work was supported by financial support from the Jiangsu Graduate Scientific Research and Innovation Program (grant No. KYCX23_3308), State Administration of Science, Technology and Industry for National Defense (No. JCKY2020203B056), the Natural Science Foundation of Jiangsu Province (BK20222010, BK20220636), the National Natural Science Foundation of China (No. 51875128 and No. 51905362), Six Talent Peaks in Jiangsu Province (GDZB-069), and the Natural Science Foundation of Jiangsu Higher Education Institutions of China (No. 20KJA460003).

Author information

Authors and Affiliations

Contributions

JY: writing—original, draft, and analysis. QM: investigation, methodology, and analysis. YZ: original draft and analysis. BZ: supervision and analysis. CW: investigation. ZM: analysis and investigation.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ye, J., Ma, Q., Zhang, Y. et al. Size effects on deformation behavior of ultra-thin-walled corrugated sheets in roll bend forming process. Int J Adv Manuf Technol 130, 1749–1758 (2024). https://doi.org/10.1007/s00170-023-12791-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12791-2