Abstract

Purpose

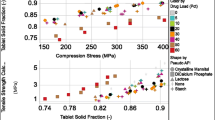

Understanding and predicting the flow of bulk pharmaceutical materials could be key in enabling pharmaceutical manufacturing by continuous direct compression (CDC). This study examines whether, by taking powder and bulk measurements, and using statistical modelling, it would be possible to predict the flow of a range of materials likely to be used in CDC.

Methods

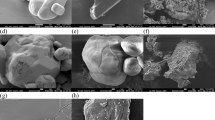

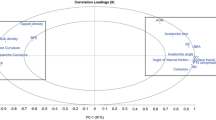

More than 100 materials were selected for study, from four pharmaceutical companies. Particle properties were measured by static image analysis, powder surface area and surface energy techniques, and flow by shear cell measurements. The data was then analysed, and a range of statistical modelling techniques were used to build predictive models for flow.

Results

Using the results from static image analysis, a model could be built which allowed the prediction of likely flow in a shear cell, which can be related to performance in a CDC system. Only a small amount of powder was required for the image analysis. Surface area did not add to the precision of the model, and the available surface energy technique did not correlate with flow.

Conclusions

A small sample of powder can be examined by static image analysis, and this data can be used to give an early read on likely flow of a material in a CDC system or other pharmaceutical process, allowing early intervention (if necessary) to improve the characteristics of a material, early in development.

Similar content being viewed by others

References

Chattoraj S, Sun CC. Crystal and particle engineering strategies for improving powder compression and flow properties to enable continuous tablet manufacturing by direct compression. J Pharm Sci. 2018;107(4):968–74.

Galbraith SC, Liu H, Cha B, Park S-Y, Huang Z, Yoon S. Modeling and simulation of continuous powder blending applied to a continuous direct compression process. Pharmaceutical Development and Technology. 2018;23(10):1097–1107. https://doi.org/10.1080/10837450.2018.1425429.

Gouveia FF, Felizardo PM, Menezes JC. Chapter 14 - Lifecycle Management of PAT Procedures: Applications to Batch and Continuous Processes, Editor(s): Ana Patricia Ferreira, José C. Menezes, Mike Tobyn, Multivariate Analysis in the Pharmaceutical Industry, Academic Press, 2018:323–345. https://doi.org/10.1016/B978-0-12-811065-2.00016-3.

Lakio S, Ervasti T, Tajarobi P, Wikström H, Fransson M, Karttunen AP, et al. Provoking an end-to-end continuous direct compression line with raw materials prone to segregation. Eur J Pharm Sci. 2017;109:514–24.

Moghtadernejad S, Escotet-Espinoza MS, Oka S, Singh R, Liu Z, Román-Ospino AD, et al. A training on: continuous manufacturing (direct compaction) of solid dose pharmaceutical products. J Pharm Innov. 2018;13(2):155–87.

Roth WJ, Almaya A, Kramer TT, Hofer JD. A demonstration of mixing robustness in a direct compression continuous manufacturing process. J Pharm Sci. 2017;106(5):1339–46.

Alam MA, Shi Z, Drennen JK, Anderson CA. In-line monitoring and optimization of powder flow in a simulated continuous process using transmission near infrared spectroscopy. Int J Pharm. 2017;526(1–2):199–208.

Hanson J. Control of a system of loss-in-weight feeders for drug product continuous manufacturing. Powder Technol. 2018;331:236–43.

Burcham CL, Florence AJ, Johnson MD. Continuous manufacturing in pharmaceutical process development and manufacturing. Annual Review of Chemical and Biomolecular Engineering. 2018;9:253–81.

Yadav IK, Holman J, Meehan E, Tahir F, Khoo J, Taylor J, et al. Influence of material properties and equipment configuration on loss-in-weight feeder performance for drug product continuous manufacture. Powder Technol. 2019;348:126–37.

Shah UV, Wang Z, Olusanmi D, Narang AS, Hussain MA, Tobyn MJ, et al. Effect of milling temperatures on surface area, surface energy and cohesion of pharmaceutical powders. Int J Pharm. 2015;495(1):234–40.

Leung LY, Mao C, Srivastava I, Du P, Yang CY. Flow function of pharmaceutical powders is predominantly governed by cohesion, not by friction coefficients. J Pharm Sci. 2017;106(7):1865–73.

Nakamura S, Otsuka N, Yoshino Y, Sakamoto T, Yuasa H. Predicting the occurrence of sticking during tablet production by shear testing of a pharmaceutical powder. Chem Pharm Bull. 2016;64(5):512–6.

Swize T, Osei-Yeboah F, Peterson ML, Boulas P. Impact of shear history on powder flow characterization using a ring shear tester. J Pharm Sci. 2019;108(1):750–754. https://doi.org/10.1016/j.xphs.2018.07.003.

Wang Y, Snee RD, Meng W, Muzzio FJ. Predicting flow behavior of pharmaceutical blends using shear cell methodology: a quality by design approach. Powder Technol. 2016;294(Supplement C):22–9.

Koynov S, Glasser B, Muzzio F. Comparison of three rotational shear cell testers: powder flowability and bulk density. Powder Technol. 2015;283:103–12.

Karttunen A-P, Wikström H, Tajarobi P, Fransson M, Sparén A, Marucci M, et al. Comparison between integrated continuous direct compression line and batch processing – the effect of raw material properties. Eur J Pharm Sci. 2019;133:40–53.

Fu X, Huck D, Makein L, Armstrong B, Willen U, Freeman T. Effect of particle shape and size on flow properties of lactose powders. Particuology. 2012;10(2):203–8.

Yu W, Muteki K, Zhang L, Kim G. Prediction of bulk powder flow performance using comprehensive particle size and particle shape distributions. J Pharm Sci. 2011;100(1):284–93.

Samiei L, Kelly K, Taylor L, Forbes B, Collins E, Rowland M. The influence of electrostatic properties on the punch sticking propensity of pharmaceutical blends. Powder Technol. 2017;305:509–17.

Engisch WE, Muzzio FJ. Feedrate deviations caused by hopper refill of loss-in-weight feeders. Powder Technol. 2015;283:389–400.

Engisch WE, Muzzio FJ. Loss-in-weight feeding trials case study: pharmaceutical formulation. J Pharm Innov. 2014;10(1):56–75.

Ferreira AP, Olusanmi D, Sprockel O, Abebe A, Nikfar F, Tobyn M. Use of similarity scoring in the development of oral solid dosage forms. Int J Pharm. 2016;514(2):335–40.

Escotet-Espinoza MS, Moghtadernejad S, Scicolone J, Wang Y, Pereira G, Schäfer E, et al. Using a material property library to find surrogate materials for pharmaceutical process development. Powder Technol. 2018;339:659–76.

Leane M, Pitt K, Reynolds GK, Dawson N, Ziegler I, Szepes A, et al. Manufacturing classification system in the real world: factors influencing manufacturing process choices for filed commercial oral solid dosage formulations, case studies from industry and considerations for continuous processing. Pharm Dev Technol. 2018;23(10):964–77.

Sandler N, Wilson D. Prediction of granule packing and flow behavior based on particle size and shape analysis. J Pharm Sci. 2010;99(2):958–68.

Wilson D, Bunker M, Milne D, Jawor-Baczynska A, Powell A, Blyth J, et al. Particle engineering of needle shaped crystals by wet milling and temperature cycling: optimisation for roller compaction. Powder Technol. 2018;339:641–50.

Hildebrandt C, Gopireddy SR, Fritsch AK, Profitlich T, Scherließ R, Urbanetz NA. Evaluation and prediction of powder flowability in pharmaceutical tableting. Pharm Dev Technol. 2019;24(1):35–47.

Ferreira AP, Gamble JF, Leane MM, Park H, Olusanmi D, Tobyn M. Enhanced understanding of pharmaceutical materials through advanced characterisation and analysis. AAPS PharmSciTech. 2018;19(8):3462–80.

Stauffer F, Vanhoorne V, Pilcer G, Chavez PF, Rome S, Schubert MA, et al. Raw material variability of an active pharmaceutical ingredient and its relevance for processability in secondary continuous pharmaceutical manufacturing. Eur J Pharm Biopharm. 2018;127:92–103.

Gamble JF, Tobyn M, Hamey R. Application of image-based particle size and shape characterization systems in the development of small molecule pharmaceuticals. J Pharm Sci. 2015;104(5):1563–74.

Shah UV, Olusanmi D, Narang AS, Hussain MA, Tobyn MJ, Hinder SJ, et al. Decoupling the contribution of surface energy and surface area on the cohesion of pharmaceutical powders. Pharm Res. 2015;32(1):248–59.

Clarke J, Gamble JF, Jones JW, Tobyn M, Greenwood R, Ingram A. Alternative approach for defining the particle population requirements for static image analysis based particle characterization methods. Adv Powder Technol. 2019;30(5):920–9.

Gamble JF, Chiu W-S, Tobyn M. Investigation into the impact of sub-populations of agglomerates on the particle size distribution and flow properties of conventional microcrystalline cellulose grades. Pharm Dev Technol. 2011;16(5):542–8.

Santos B, Carmo F, Schlindwein W, Muirhead G, Rodrigues C, Cabral L, Westrup J, Pitt K. Pharmaceutical excipients properties and screw feeder performance in continuous processing lines: a Quality by Design (QbD) approach. Drug Development and Industrial Pharmacy. 2018;44(12):2089-2097. https://doi.org/10.1080/03639045.2018.1513024.

Shah UV, Olusanmi D, Narang AS, Hussain MA, Gamble JF, Tobyn MJ, et al. Effect of crystal habits on the surface energy and cohesion of crystalline powders. Int J Pharm. 2014;472(1–2):140–7.

Gamble JF, Leane M, Olusanmi D, Tobyn M, Šupuk E, Khoo J, et al. Surface energy analysis as a tool to probe the surface energy characteristics of micronized materials - a comparison with inverse gas chromatography. Int J Pharm. 2012;422(1–2):238–44.

Gamble JF, Dawson N, Murphy D, Theophilus A, Kippax P. A proposal for an alternative approach to particle size method development during early-stage small molecule pharmaceutical development. J Pharm Sci. 2019;108(11):3515–3520. https://doi.org/10.1016/j.xphs.2019.08.007.

Gamble JF, Dennis AB, Hutchins P, Jones J, Musembi P, Tobyn M. Determination of process variables affecting drug particle attrition withinmulti-component blends during powder feed transmission. Pharm Dev Technol. 2017;22(7):904–909. https://doi.org/10.1080/10837450.2016.1200616.

Gamble JF, Ferreira AP, Tobyn M, DiMemmo L, Martin K, Mathias N, et al. Application of imaging based tools for the characterisation of hollow spray dried amorphous dispersion particles. Int J Pharm. 2014;465(1–2):210–7.

Gamble JF, Hoffmann M, Hughes H, Hutchins P, Tobyn M. Monitoring process induced attrition of drug substance particles within formulated blends. Int J Pharm. 2014;470(1–2):77–87.

Hughes H, Leane MM, Tobyn M, Gamble JF, Munoz S, Musembi P. Development of a material sparing bulk density test comparable to a standard USP method for use in early development of API’s. AAPS PharmSciTech. 2014;16(1):165–70.

Gamble JF, Davé RN, Kiang S, Leane MM, Tobyn M, Wang SSY. Investigating the applicability of inverse gas chromatography to binary powdered systems: an application of surface heterogeneity profiles to understanding preferential probe-surface interactions. Int J Pharm. 2013;445(1–2):39–46.

Dorris GM, Gray DG. Adsorption of n-alkanes at zero surface coverage on cellulose paper and wood fibers. J Colloid Interface Sci. 1980;77(2):353–62.

Panaretos VM, Zemel Y. Statistical aspects of Wasserstein distances. Annual Review of Statistics and Its Application. 2019;6:405–31.

Vapnik V. Statistical learning theory. New York: Wiley; 1998.

Zeileis A, Hornik K, Smola A, Karatzoglou A. kernlab-an S4 package for kernel methods in R. J Stat Softw. 2004;11(9):1–20.

Rubner Y, Tomasi C, Guibas LJ. The earth mover’s distance as a metric for image retrieval. Int J Comput Vis. 2000;40(2):99–121.

Tange O, others. Gnu parallel-the command-line power tool. The USENIX Magazine. 2011;36(1):42–7.

Cyran KA, Kawulok J, Kawulok M, Stawarz M, Michalak M, Pietrowska M, Widłak P, Polańska J. Support vector machines in biomedical and biometrical applications. Smart Innovation, Systems and Technologies. 2013;13:379–417 https://doi.org/10.1007/978-3-642-28699-5_15.

Olusanmi D, Jayawickrama D, Bu D, McGeorge G, Sailes H, Kelleher J, et al. A control strategy for bioavailability enhancement by size reduction: effect of micronization conditions on the bulk, surface and blending characteristics of an active pharmaceutical ingredient. Powder Technol. 2014;258:222–33.

Mullarney MP, Leyva N. Modeling pharmaceutical powder-flow performance using particle-size distribution data. Pharm Technol. 2009;33(3):126–34.

Bonakdar T, Ali M, Dogbe S, Ghadiri M, Tinke A. A method for grindability testing using the Scirocco disperser. Int J Pharm. 2016;501(1–2):65–74.

Acknowledgements

We are grateful for the helpful comments of Bruno Hancock, Dan Blackwood, Conrad Davies and Martyn Ticehurst (Pfizer), and useful insights were provided by Stefan Lines, James Clarke and Khezia Asamoah (Bristol-Myers Squibb).

Funding

This work was carried out as part of the ADDoPT Consortium (www.addopt.org), which received funding from Finance Birmingham (UK) as part of the AMSCI initiative.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Barjat, H., Checkley, S., Chitu, T. et al. Demonstration of the Feasibility of Predicting the Flow of Pharmaceutically Relevant Powders from Particle and Bulk Physical Properties. J Pharm Innov 16, 181–196 (2021). https://doi.org/10.1007/s12247-020-09433-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12247-020-09433-5