Abstract

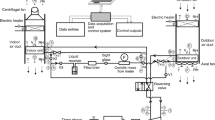

Construction equipment has consumed a lot of energy with a high workload compared to commercial vehicles of the same class. So, fuel efficiency is one of the important indicators of merchantability of the construction equipment. Especially, because forklift has been generally used only when necessary, the work has been carried out without adequate warm-up. So, not only the thermal efficiency of the engine of the construction equipment has deteriorated but also the sufficient fluidity of auto transmission fluid and hydraulic fluid have been hardly able to secure. Therefore, the exhaust heat recovery (EHR) system which consists of exhaust heat recovery unit and auto-transmission fluid (ATF) heater has been developed to improve the fuel economy of forklift by recovering the waste heat of exhaust gas. The performance tests of a 4.5 ton forklift have been carried out to evaluate the effects of exhaust heat recovery system on the fuel economy under the VDI fuel consumption drive cycle. It has found that the fuel consumption of a 4.5 ton forklift can be reduced through the fast warm-up of the auto-transmission fluid by recovering the waste heat of exhaust gas.

Similar content being viewed by others

Abbreviations

- AT:

-

auto transmission

- ATF:

-

auto-transmission fluid

- CFD:

-

computational Fluid Dynamics

- dp :

-

pressure drop

- EG:

-

exhaust gas

- EHR:

-

exhaust heat recovery

- Hc :

-

height of core

- HF:

-

hydraulic fluid

- H F :

-

height of fin

- L O :

-

off-set length of fin

- P F :

-

pitch of fin

- Q :

-

heat transfer

- T F :

-

thickness of fin

- T H :

-

thickness of housing

- T T :

-

thickness of tube

- W C :

-

width of core

- W T :

-

width of tube

- δ S :

-

side gap

- δ T :

-

tube gap

References

Battista, D. D. and Cipollone, R. (2016). Experimental and numerical assessment of methods to reduce warm up time of engine lubricant oil. Applied Energy, 162, 570–580.

Bong, S. W., Lee, H. K., Heo, H. S., Kwon, H. J., Han, J. M. and Jung, J. K. (2017). Performance analysis according to ATF heat exchanger design parameters. Fall Conf. Proc., Korean Society of Automotive Engineers, 13–21.

Graphtec GL820 Data Logger (2005). GL820 midi LOGGER User Manual. Graphtec Corporation.

Heo, H. S., Lee, D. H., Kang, T. G., Lee, H. K. and Kim, T. J. (2012). Effect of fast ATF warm-up on fuel economy using recovery of EGR gas waste heat in a diesel engine. Trans. Korean Society of Automotive Engineers 20, 4, 25–32.

Heo, H. S., Bae, S. J., Hong, S. M. and Park, S. U. (2018). Performance design of an exhaust superheater for waste heat recovery of construction equipment. Int. J. Automotive Technology 19, 2, 221–231.

HYDAC HMG 4000 (2016). Portable Data Recorder HMG 4000 Operating Manual. HYDAC Electronic.

Lee, H. S., Won, J. P., Cho, C. W., Lee, D. H., Heo, H. S. and Kim, Y. C. (2010). A study on analytic approach of powertrain fast warm-up performance characteristics for exhaust heat recovery. Fall Conf. Proc., Korean Society of Automotive Engineers, 1033–1038.

Murtagh, M., Kee, R., McCullough, G., Stuart, C., Bradley, C., Trimble, S., Allen, M., Chen, C., Kolkemo, A. and Reichenbach, D. (2013). Development and validation of a forklift truck powertrain simulation. SAE Int. J. Commercial Vehicles 6, 1, 150–160.

Ryu, H., Heo, H. S., Bae, S. J., Lee, J. Y. and Park, S. U. (2017). Design and performance experimental evaluation of the ATF heater for fast warm-up system of construction equipment. Fall Conf. Proc., Korean Society of Automotive Engineers, 219–225.

Type Sheets for Industrial Trucks (2002). VDI 2198. Verein Deutscher Ingenieure (Association of German Engineers).

Wang, T., Zhang, Y. and Shu, G. (2011). A review of researches on thermal exhaust heat recovery with rankine cycle. Renewable and Sustainable Energy Reviews 15, 6, 2862–2871.

Wenzel, W., Tabares, I. G. and Vecker, M. (2014). Warm-up optimisation by means of exhaust heat recovery. MTZ Worldwide 75, 5, 30–35.

Will, F. and Boretti, A. (2011). A new method to warm up lubricating oil to improve the fuel efficiency during cold start. SAE Int. J. Engines 4, 1, 175–187.

Acknowledgement

The research was supported by a grant (No. 20172020108590) from the Korea Institute of Energy Technology Evaluation and Planning (KETEP), that is funded by the Ministry of Trade, Industry and Energy.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Heo, MW., Bae, SJ., Jeong, JY. et al. Effects of an Exhaust Heat Recovery System on Performance Characteristics of a Forklift Truck. Int.J Automot. Technol. 20, 579–588 (2019). https://doi.org/10.1007/s12239-019-0055-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12239-019-0055-2