Abstract

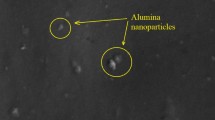

Current research investigates the effect of the core-shell (C/SH) particles in composites manufactured using novel thermoplastic Elium® resin and carbon fiber reinforcement of different areal weights, 200 gsm and 400 gsm bi-angle non-crimp carbon fabrics (NCCFs). The core-shell particles were activated using the ex-situ methodology which involves the activation of particles before the Resin transfer molding (RTM) injection process. Recommended particle activation parameters are established after carrying out a detailed microscopic study to understand the melting and flattening behavior of these particles. Static indentation and damping attributes are studied to understand the influence of C/SH particles added novel carbon/Elium® composite in improving the out-of plane properties and dynamic mechanical attributes respectively. The interply regions were also toughened with the addition of 1% core-shell particles and the intensity of load drop has reduced by 20% while comparing the thick and thin ply NCCF/Elium® composites. Microscopic examination has shown that the core-shell particles helped to spread the damage evenly throughout the specimen and absorbed more energy during the static-indentation. Loss factor or damping for thick ply Elium® composite and thin ply epoxy composite is increased by 19% and 16.4% with the addition of 5% and 1% C/SH particles respectively. The underlying reasons for improvement offered by C/SH particles in quasi-static impact and dynamic mechanical tests are also deliberated in this paper.

Similar content being viewed by others

References

S. K. Bhudolia, S. C. Joshi, A. Bert, G. R. Gohel, and M. Raama, Fiber. Polym., 20, 1716 (2019).

T. J. Kang and S. H. Lee, J. Compos. Mater., 28, 1574 (1994).

K. A. Dransfield, L. K. Jain, and Y.-W. Mai, Compos. Sci. Technol., 58, 815 (1998).

G. L. Farley, B. T. Smith, and J. Maiden, J. Reinf. Plast. Compos., 11, 787 (1992).

Y.-W. M. Amar and C. Garg, Compos. Sci. Technol., 31, 179 (1988).

T. Yokozeki, Y. Aoki, and T. Ogasawara, Compos. Struct., 82, 382 (2008).

S. K. Bhudolia, S. C. Joshi, and Y. D. Boon, Fiber. Polym., 20, 1036 (2019).

V. M. V. Lopresto, C. Leone, and G. Caprino, Compos. Sci. Technol., 66, 206 (2006).

S. Black, “Bi-angle Fabrics Find First Commercial Application”, http://www.compositesworld.com/articles/bi-angle-fabrics-find-first-commercial-application (Accessed June 7, 2020).

P. K. Saha, “Aerospace Manufacturing Processes”, 1st ed. CRC Press, 2016.

V. Dikshit, K. S. Bhudolia, and C. S. Joshi, Fibers, 5, 38 (2017).

K. Mehar, S. K. Panda, and B. K. Patle, Polym. Compos., 39, 3792 (2018).

S. X. Hengshi Zhou, Mater. Lett., 10, 601 (2014).

I. Ozsoy, A. Demirkol, A. Mimaroglu, H. Unal, and Z. Demir, Strojniški vestnik — J. Mech. Eng., 61, 601 (2015).

M. Ali and S. C. Joshi, J. Mater. Sci., 48, 8354 (2013).

M. Ali and S. C. Joshi, Int. J. Damage Mech., 21, 1106 (2012).

W. Wu, Dissertation, Clausthal University of Technology, Clausthal-Zellerfeld, Germany, 2013.

W. Wu, F. Klunker, L. Xie, B. Jiang, and G. Ziegmann, Compos. Part A: Appl. Sci. Manuf., 53, 190 (2013).

C.-Y. Huang and J.-L. Tsai, J. Compos. Mater., 49, 545 (2014).

S. K. Bhudolia, P. Perrotey, and S. C. Joshi, Proceedings of the Institution of Mechanical Engineers, Part P: Journal of Sports Engineering and Technology, 230, 64 (2016).

S. K. Bhudolia, P. Perrotey, and S. C. Joshi, Compos. Struct., 179, 502 (2017).

S. K. Bhudolia, P. Perrotey, and S. C. Joshi, Materials, 10, 293 (2017).

S. K. Bhudolia and S. C. Joshi, Compos. Struct., 203, 696 (2018).

S. K. Bhudolia, P. Perrotey, and S. C. Joshi, Compos. Part B: Eng., 134, 246 (2018).

S. K. Bhudolia, K. K. Kam, and S. C. Joshi, J. Ind. Text., 47, 1887 (2018).

M. E. Kazemi, L. Shanmugam, D. Lu, X. Wang, B. Wang, and J. Yang, Compos. Part A-Appl. Sci. Manuf., 125, 105523 (2019).

P. Khalili, B. Blinzler, R. Kádár, P. Blomqvist, A. Sandinge, R. Bisschop, and X. Liu, Compos. Part A-Appl. Sci. Manuf., 137, 105986 (2020).

P. Khalili, B. Blinzler, R. Kádár, R. Bisschop, M. Försth, and P. Blomqvist, Materials, 12, 2648 (2019).

S. K. Bhudolia, P. Perrotey, and S. C. Joshi, Materials, 10 (2017).

K. van Rijswijk and H. E. N. Bersee, Compos. Part A-Appl. Sci. Manuf., 38, 666 (2007).

W. Wu, “Proceedings of the19th International Conference on Composite Materials”, Canada, Montreal, 2013.

T. S. Lundstrom and M. Zetterberg, “Proceedings of the 5th International Conference on Flow Processes in Composite Materials”, Plymouth, UK, July, 1999.

T. S. Lundström, Compos. Part A-Appl. Sci. Manuf., 31, 1345 (2000).

S. K. Bhudolia, S. C. Joshi, A. Bert, B. Yi Di, R. Makam, and G. Gohel, Compos. Commun., 13, 129 (2019).

ASTM D7028-07, “Standard Test Method for Glass Transition Temperature (DMA Tg) of Polymer Matrix Composites by Dynamic Mechanical Analysis (DMA)”, ASTM International, West Conshohocken, PA, 2015.

S. K. Bhudolia, G. Gohel, S. C. Joshi, and K. F. Leong, Compos. Commun., 21, 100383 (2020).

S. Tsai, S. Sihn, and R. Kim, 46th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Austin, Texas, 2005.

S. Sihn, R. Kim, K. Kawabe, and S. Tsai, Compos. Sci. Technol., 67, 996 (2007).

R. Amacher, J. Cugnoni, J. Botsis, L. Sorensen, W. Smith, and C. Dransfeld, Compos. Sci. Technol., 101, 121 (2014).

M. Ali and S. C. Joshi, Int. J. Damage Mech., 21, 1106 (2012).

J. Chen, A. J. Kinloch, S. Sprenger, and A. C. Taylor, Polymer, 54, 4276 (2013).

R. Matadi Boumbimba, C. Froustey, P. Viot, J. M. Olive, F. Léonardi, P. Gerard, and R. Inoubli, Compos. Struct., 116, 414 (2014).

S. K. Bhudolia, P. Perrotey, and S. C. Joshi, Compos. Struct., 179, 502 (2017).

G. Giannakopoulos, K. Masania, and A. C. Taylor, J. Mater. Sci., 46, 327 (2011).

Acknowledgment

The authors would like to acknowledge the financial support from the Institute for Sports Research, Nanyang Technological University, Singapore. Authors would like to thank Arkema France for providing Elium resin as a part of collaborative projects with Institute for Sports Research, Nanyang Technological University, Singapore.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bhudolia, S.K., Gohel, G., Joshi, S.C. et al. Manufacturing Optimization and Experimental Investigation of Ex-situ Core-shell Particles Toughened Carbon/Elium® Thermoplastic Composites. Fibers Polym 22, 1693–1703 (2021). https://doi.org/10.1007/s12221-021-0819-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-021-0819-y