Abstract

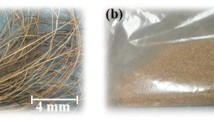

This work aims to reveal how the alkali influences the mechanical behavior and structural stability of palm fiber. First, palm fiber samples were treated with 20% and 40% NaOH solutions separately for approximately 1, 2, 3, and 4 h at room temperature. Then the samples were characterized using tensile testing, Fourier transform infrared spectroscopy, X-ray diffraction, and thermogravimetric analysis. Results showed the tensile properties of alkali-treated fibers exceeded those of untreated fibers. Notably, the fibers treated with 40% NaOH for 1 h yielded the most significant improvements. The tensile strength, elongation at break, Young’s modulus, and yield point increased by 28.8%, 38%, 52.1%, and 64.7%, respectively, compared with the untreated fibers. The increase appeared to be due to the removal of non-cellulosic materials and rearrangement of the cellulose chains.

Similar content being viewed by others

References

T. Sullins, S. Pillay, A. Komus, and H. Ning, Composites Part B, 114, 15 (2017).

H. Takagi and A. Asano, Composites Part A, 39, 685 (2008).

Y. Li, Q. Li, and H. Ma, Composites Part A, 72, 40 (2015).

I. Spiridon, R. N. Darie, and H. Kangas, Composites Part B, 92, 19 (2016).

M. Cai, H. Takagi, A. N. Nakagaito, Y. Li, and G. I. N. Waterhouse, Composites Part A, 90, 589 (2016).

D. Ray and B. K. Sarkar, J. Appl. Polym. Sci., 80, 1013 (2001).

L. Y. Mwaikambo and M. P. Ansell, J. Mater. Sci., 41, 2483 (2006).

M. A. Sawpan, K. L. Pickering, and A. Fernyhough, Composites Part A, 42, 888 (2011).

P. Saha, S. Manna, S. R. Chowdhury, R. Sen, D. Roy, and B. Adhikari, Bioresour. Technol., 101, 3182 (2010).

T. Zhang, M. Guo, L. Cheng, and X. Li, Cellulose, 22, 1039 (2015).

Z. T. Cheng Lan, M. Guo, and X. Li, Wood Fiber Sci., 46, 2701 (2014).

A. K. M. M. Alam, M. D. H. Beg, D. M. R. Prasad, M. R. Khan, and M. F. Mina, Composites Part A, 43, 1921 (2012).

M. N. K. Chowdhury, M. D. H. Beg, M. R. Khan, and M. F. Mina, Cellulose, 20, 1477 (2013).

L. Boopathi, P. S. Sampath, and K. Mylsamy, Composites Part B, 43, 3044 (2012).

K. O. Reddy, C. U. Maheswari, M. Shukla, J. I. Song, and A. V. Rajulu, Composites Part B, 44, 433 (2013).

M. Aydin, H. Tozlu, S. Kemaloglu, A. Aytac, and G. Ozkoc, J. Polym. Environ., 19, 11 (2011).

R. A. S. Chakraborty, S. P. Kundu, R. K. Basak, S. B. Majumder, and B. Adhikari, Bioresour. Technol., 107, 222 (2012).

I. Taha, L. Steuernagel, and G. Ziegmann, Compos. Interfaces, 14, 669 (2007).

M. Cai, H. Takagi, A. N. Nakagaito, M. Katoh, T. Ueki, G. I. N. Waterhouse, and Y. Li, Ind. Crops Prod., 65, 27 (2015).

L. Cheng, T. Zhang, M. Guo, and X. Li, Wood Fiber Sci., 46, 270 (2014).

A. Duval, A. Bourmaud, L. Augier, and C. Baley, Mater. Lett., 65, 797 (2011).

P. R. Blakey, J. Text. Inst., 70, 452 (1979).

V. Fiore, T. Scalici, F. Nicoletti, G. Vitale, M. Prestipino, and A. Valenza, Composites Part B, 85, 150 (2016).

Y. Cao, S. Shibata, and I. Fukumoto, Composites Part A, 37, 423 (2006).

M. M. Kabir, H. Wang, K. T. Lau, and F. Cardona, Composites Part B, 53, 362 (2013).

H. Chen, Y. Yu, T. Zhong, Y. Wu, Y. Li, Z. Wu, and B. Fei, Cellulose, 24, 1 (2016).

C. Albano, J. González, M. Ichazo, and D. Kaiser, Polym. Degrad. Stab., 66, 179 (1999).

F. Yao, Q. Wu, Y. Lei, W. Guo, and Y. Xu, Polym. Degrad. Stab., 93, 90 (2008).

H. Yang, R. Yan, H. Chen, H. L. Dong, and C. Zheng, Fuel, 86, 1781 (2007).

I. M. D. Rosa, J. M. Kenny, D. Puglia, C. Santulli, and F. Sarasini, Compos. Sci. Technol., 70, 116 (2010).

V. Fiore, T. Scalici, and A. Valenza, Carbohydr. Polym., 106, 77 (2014).

A. Orue, A. Jauregi, C. Peña-Rodriguez, J. Labidi, A. Eceiza, and A. Arbelaiz, Composites Part B, 73, 132 (2015).

K. Obi Reddy, M. Shukla, C. Uma Maheswari, and A. Varada Rajulu, J. Forest. Res., 23, 667 (2012).

K. O. Reddy, B. R. Guduri, and A. V. Rajulu, J. Appl. Polym. Sci., 114, 603 (2009).

P. Sudhakara, D. Jagadeesh, Y. Wang, C. V. Prasad, A. P. Devi, G. Balakrishnan, B. S. Kim, and J. I. Song, Carbohydr. Polym., 98, 1002 (2013).

W. Liu, A. K. Mohanty, L. T. Drzal, P. Askel, and M. Misra, J. Mater. Sci., 39, 1051 (2004).

I. M. D. Rosa, J. M. Kenny, M. Maniruzzaman, M. Moniruzzaman, M. Monti, D. Puglia, C. Santulli, and F. Sarasini, Compos. Sci. Technol., 71, 246 (2011).

Y. Liu and H. Hu, Fiber. Polym., 9, 735 (2008).

S. Ouajai and R. A. Shanks, Polym. Degrad. Stab., 89, 327 (2005).

K. L. Pickering, G. W. Beckermann, S. N. Alam, and N. J. Foreman, Composites Part A, 38, 461 (2007).

L. Y. Mwaikambo and M. P. Ansell, J. Mater. Sci., 41, 2497 (2006).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, Y., Deng, P., Jing, L. et al. Tensile Properties and Structure Characterization of Palm Fibers by Alkali Treatment. Fibers Polym 20, 1029–1035 (2019). https://doi.org/10.1007/s12221-019-7841-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-019-7841-3