Abstract

Chemical treatment is used to improve interfacial bonding of natural fibers to polymers to produce natural fiber reinforced polymer matrix composites with enhanced mechanical properties. In the present study, raffia palm (Raphia farinifera) fibers intended for use in composite manufacture was subjected to chemical treatments with NaOH and H2SO4 solutions. Morphological, thermal, tensile, physical and structural changes in the fibers before and after treatment were investigated using scanning electron microscopy, differential scanning calorimetry, universal testing machine and Fourier transform infrared spectroscopy. Chemical treatment reduced the tensile strength of the fibers. Some non-cellulosic components were partially or fully removed as a result of chemical treatment. There was an increase in the degradation temperature of the fibers due to chemical treatment. Water absorption capacity of the fibers decreased as a results of chemical treatment, which will be beneficial in composite synthesis.

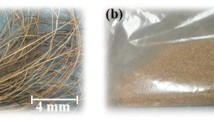

Graphic abstract

Similar content being viewed by others

References

Alemdar A, Sain M (2008) Biocomposites from wheat straw nanofibers: morphology, thermal and mechanical properties. Compos Sci Technol 68:557–565

Ankom Technology (2000) Acid detergent fiber in feeds—filter bag technique. Method 5:6–7

Ankom Technology (2011) Neutral detergent fiber in feeds—filter bag technique. Method 6:10–11

Ankom Technology (2013) Determining acid detergent lignin in beakers. Method 8:11–12

Arias A, Heuzey MC, Huneault MA (2013) Thermomechanical and crystallization behavior of polylactide-based flax fiber biocomposites. Cellulose 20:439–452

Arsène M, Okwo A, Bilba K, Soboyejo ABO, Soboyejo WO (2007) Chemically and thermally treated vegetable fibers for reinforcement of cement-based composites. Mater Manuf Process 22:214–227

ASTM D3822M-14 (2014) Standard test method for tensile properties of single textile fibers. ASTM International USA

ASTM D-15 (2015) Standard practice for calculating yellowness and whiteness indices from instrumentally measured color coordinates. ASTM International USA

ASTM E1164-12 (2017) Standard practice for obtaining spectrometric data for object-color evaluation 1. ASTM International USA

Aziz SH, Ansell MP (2004) The effect of alkalization and fibre alignment on the mechanical and thermal properties of kenaf and hemp bast fibre composites: part 1—polyester resin matrix. Compos Sci Technol 64:1219–1230

Benyahia A, Merrouche A (2014) Effect of chemical surface modifications on the properties of alfa fiber–polyester composites. Polym Plast Technol Eng 53:403–410

Bilba K, Ouensanga A (1996) Fourier transform infrared spectroscopic study of thermal degradation of sugar cane bagasse. J Anal Appl Pyrolysis 38:61–73

Bjerre AB, Olesen AB, Fernqvist T, Plöger AS, Schmidt AS (1996) Pretreatment of wheat straw using combined wet oxidation and alkaline hydrolysis resulting in convertible cellulose and hemicellulose. Biotechnol Bioeng 49:568–577

Bledzki AK, Gassan J (1999) Composites reinforced with cellulose based fibers. Prog Polym Sci 24:221–274

Bonarski JT, Olek W (2011) Application of the crystalline volume fraction for characterizing the ultrastructural organization of wood. Cellulose 18:223–235

Bruno IJ, Cole JC, Edgington PR, Kessler M, Macrae CF, McCabe P, Pearson J, Taylor R (2002) New software for searching the Cambridge structural database and visualizing crystal structures. Acta Crystallogr Sect B 58:389–397

Bryś A, Bryś J, Ostrowska-Ligęza E, Kaleta A, Górnicki K, Głowacki S, Koczoń P (2016) Wood biomass characterization by DSC or FT-IR spectroscopy. J Therm Anal Calorim 126:27–35

Cai M, Takagi H, Nakagaito AN, Li Y, Geoffrey INW (2016) Effect of alkali treatment on interfacial bonding in abaca fiber-reinforced composites. Compos Part A Appl Sci Manuf 90:589–597

Carrillo F, Colom X, Suñol JJ, Saurina J (2004) Structural FTIR analysis and thermal characterisation of lyocell and viscose-type fibres. Eur Polym J 40:2229–2234

Chae DW, Choi KR, Kim BC, Oh YS (2003) Effect of cellulose pulp type on the mercerizing behavior and physical properties of lyocell fibers. Text Res J 73:541–545

Chen Y, Liu C, Chang PR, Cao X, Anderson DP (2009) Bionanocomposites based on pea starch and cellulose nanowhiskers hydrolyzed from pea hull fibre: effect of hydrolysis time. Carbohydr Polym 76:607–615

Chen H, Ferrari C, Angiuli M, Yao J, Raspi C, Bramanti E (2010) Qualitative and quantitative analysis of wood samples by fourier transform infrared spectroscopy and multivariate analysis. Carbohydr Polym 82:772–778

Chen W, Yu H, Liu Y, Hai Y, Zhang M, Chen P (2011) Isolation and characterization of cellulose nanofibers from four plant cellulose fibers using a chemical–ultrasonic process. Cellulose 18:433–442

Chen Z, Xu Y, Shivkumar S (2018) Microstructure and tensile properties of various varieties of rice husk. J Sci Food Agric 98:1061–1070

Cherian BM, Pothan LA, Nguyen-Chung T, Mennig G, Kottaisamy M, Thomas S (2008) A novel method for the synthesis of cellulose nanofibril whiskers from banana fibers and characterization. J Agric Food Chem 56:5617–5627

Chinga-carrasco G, Aslan M, Sørensen BF, Madsen B (2011) Strength variability of single flax fibres. J Mater Sci 46:6344–6354

Cicala G, Cristaldi G, Latteri A (2010) Composites based on natural fibre fabrics. Woven Fabr Eng. https://doi.org/10.5772/10465

Colom X, Carrillo F, Nogués F, Garriga P (2003) Structural analysis of photodegraded wood by means of FTIR spectroscopy. Polym Degrad Stab 80:543–549

Das M, Chakraborty D (2006) Influence of alkali treatment on the fine structure and morphology of bamboo fibers. J Appl Polym Sci 102:5050–5056

de Andrade Silva F, Chawla N, de Toledo Filho D (2008) Tensile behavior of high performance natural (sisal) fibers. Compos Sci Technol 68:3438–3443

Dong Y, Ghataura A, Takagi H, Haroosh HJ, Nakagaito AN, Lau KT (2014) Polylactic acid (PLA) biocomposites reinforced with coir fibres: evaluation of mechanical performance and multifunctional properties. Compos Part A Appl Sci Manuf 63:76–84

Du R, Su R, Qi W, He Z (2018) Enhanced enzymatic hydrolysis of corncob by ultrasound-assisted soaking in aqueous ammonia pretreatment. Biotech 8:1–7

Edeerozey AMM, Akil HM, Azhar AB, Ariffin MIZ (2007) Chemical modification of kenaf fibers. Mater Lett 61:2023–2025

Elenga RG, Dirras GF, Goma Maniongui J, Djemia P, Biget MP (2009) On the microstructure and physical properties of untreated raffia textilis fiber. Compos Part A Appl Sci Manuf 40:418–422

Elenga RG, Djemia P, Tingaud D, Chauveau T, Maniongui JG, Dirras G (2013) Effects of alkali treatment on the microstructure, composition, and properties of the raffia textilis fiber. BioResources 8:2934–2949

Fahma F, Iwamoto S, Hori N, Iwata T, Takemura A (2010) Isolation, preparation, and characterization of nanofibers from oil palm empty-fruit-bunch (OPEFB). Cellulose 17:977–985

Fiore V, Prestipino M, Valenza A, Scalici T, Nicoletti F, Vitale G (2015) A new eco-friendly chemical treatment of natural fibres: effect of sodium bicarbonate on properties of sisal fibre and its epoxy composites. Compos Part B Eng 85:150–160

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896

French AD, Santiago Cintrón M (2013) Cellulose polymorphy, crystallite size, and the Segal crystallinity index. Cellulose 20:583–588

Gonzalez AV, Cervantes-Uc JM, Olayo R, Herrera-Franco PJ (1999) Effect of fiber surface treatment on the fiber-matrix bond strength of natural fiber reinforced composites. Compos Part B Eng 30:309–320

Hao A (2013) Mechanical and thermal properties of kenaf polypropylene nonwoven composites. Ph.D. Thesis; University of Texas, Texas, USA, pp 19–30

Hashim MY, Amin AM, Marwah FMO, Othman HM, Yunus MRM, Huat CN (2017) The effect of alkali treatment under various conditions on physical properties of kenaf fiber. J Phys Conf Ser. https://doi.org/10.1088/1742-6596/914/1/012030

Himmelsbach DS, Akin DE (1998) Near-infrared Fourier-transform raman spectroscopy of flax (Linum usitatissimum L.) stems. J Agric Food Chem 46:991–998

Holbery J, Houston D (2006) Natural-fibre-reinforced polymer composites in automotive applications. JOM 58:80–86

Jacob M, Varughese KT, Thomas S (2005) Water sorption studies of hybrid biofiber-reinforced natural rubber biocomposites. Biomacromolecules 6:2969–2979

Jin W, Singh K, Zondlo J (2013) Pyrolysis kinetics of physical components of wood and wood-polymers using isoconversion method. Agriculture 3:12–32

Jústiz-Smith NG, Virgo GJ, Buchanan VE (2008) Potential of Jamaican banana, coconut coir and bagasse fibres as composite materials. Mater Charact 59:1273–1278

Kabir MM, Wang H, Lau KT, Cardona F (2012) Chemical treatments on plant-based natural fibre reinforced polymer composites: an overview. Compos Part B Eng 43:2883–2892

Kataoka Y, Kondo T (1998) FT-IR microscopic analysis of changing cellulose crystalline structure during wood cell wall formation. Macromolecules 31:760–764

Kaushik VK, Kumar A, Kalia S (2012) Effect of mercerization and benzoyl peroxide treatment on morphology, thermal stability and crystallinity of sisal fibers. Int J Text Sci 1:101–105

Kondo T, Sawatari C (1996) A Fourier transform infra-red spectroscopic analysis of the character of hydrogen bonds in amorphous cellulose. Polymer (Guildf) 37:393–399

Kubo S, Kadla JF (2005) Hydrogen bonding in lignin: a fourier transform infrared model compound study. Biomacromolecules 6:2815–2821

Le Troedec M, Sedan D, Peyratout C, Bonnet JP, Smith A, Guinebretiere R, Gloaguen V, Krausz P (2008) Influence of various chemical treatments on the composition and structure of hemp fibres. Compos Part A Appl Sci Manuf 39:514–522

Lee CM, Kubicki JD, Fan B, Zhong L, Jarvis MC, Kim SH (2015) Hydrogen-bonding network and OH stretch vibration of cellulose: comparison of computational modeling with polarized IR and SFG spectra. J Phys Chem 119:15138–15149

Li Y, Li G, Zou Y, Zhou Q, Lian X (2014) Preparation and characterization of cellulose nanofibers from partly mercerized cotton by mixed acid hydrolysis. Cellulose 21:301–309

Mabrouk AB, Kaddami H, Boufi S, Erchiqui F, Dufresne A (2012) Cellulosic nanoparticles from alfa fibers (Stipa tenacissima): extraction procedures and reinforcement potential in polymer nanocomposites. Cellulose 19:843–853

Macrae CF, Bruno IJ, Chisholm JA, Edgington PR, McCabe P, Pidcock E, Rodriguez-Monge L, Taylor R, van de Streek J, Wood PA (2008) Mercury CSD 2.0—new features for the visualization and investigation of crystal structures. J Appl Crystallogr 41:466–470

Mahjoub R, Yatim JM, Mohd Sam AR, Hashemi SH (2014) Tensile properties of kenaf fiber due to various conditions of chemical fiber surface modifications. Constr Build Mater 55:103–113

Martins MA, Pessoa JDC, Gonçalves PS, Souza FI, Mattoso LHC (2008) Thermal and mechanical properties of the acai fiber/natural rubber composites. J Mater Sci 43:6531–6538

Mohammed L, Ansari MNM, Pua G, Jawaid M, Islam MS (2015) A review on natural fiber reinforced polymer composite and its applications. Int J Polym Sci. https://doi.org/10.1155/2015/243947

Moore AK, Owen NL (2001) Infrared spectroscopic studies of solid wood. Appl Spectrosc Rev 36:65–86

Morán JI, Alvarez VA, Cyras VP, Vázquez A (2008) Extraction of cellulose and preparation of nanocellulose from sisal fibers. Cellulose 15:149–159

Mukhopadhyay S, Fangueiro R, Shivankar V (2009) Variability of tensile properties of fibers from pseudostem of banana plant. Text Res J 79:387–393

Mwaikambo LY, Ansell MP (2002) Chemical modification of hemp, sisal, jute, and kapok fibers by alkalization. J Appl Polym Sci 84:2222–2234

Nam S, French AD, Condon BD, Concha M (2016) Segal crystallinity index revisited by the simulation of X-ray diffraction patterns of cotton cellulose Iβ and cellulose II. Carbohydr Polym 135:1–9

Nayak S, Mohanty JR (2018) Influence of chemical treatment on tensile strength, water absorption, surface morphology, and thermal analysis of areca sheath fibers. J Nat Fibers. https://doi.org/10.1080/15440478.2018.1430650

Nishiyama Y, Langan P, Chanzy H (2002) Crystal structure and hydrogen-bonding system in cellulose Ib from synchrotron X-ray and neutron fiber diffraction. J Am Chem Soc 124:9074–9082

Odera RS, Onukwuli OD, Atuanya CU (2015) Characterization of the thermo-microstructural analysis of raffia palm fibers proposed for roofing sheet production. J Miner Mater Charact Eng 3:335–343

Oliveira AKF, D’Almeida JRM (2014) Characterization of ubuçu (Manicaria saccifera) natural fiber mat. Polym Renew Resour 5:13–28

Ouajai S, Shanks RA (2005) Composition, structure and thermal degradation of hemp cellulose after chemical treatments. Polym Degrad Stab 89:327–335

Panthapulakkal S, Zereshkian A, Sain M (2006) Preparation and characterization of wheat straw fibers for reinforcing application in injection molded thermoplastic composites. Bioresour Technol 97:265–272

Persson J, Chanzy H, Sugiyama J (1991) Combined infrared and electron diffraction study of the polymorphism of native celluloses. Macromolecules 24:2461–2466

Politou AS, Morterra C, Low MJD (1990) Infrared studies of carbons Xiii. The oxidation of polycarbonate chars. Carbon N Y 28:855–865

Ramadevi P, Sampathkumar D, Srinivasa CV, Bennehalli B (2012) Effect of alkali treatment on water absorption of single cellulosic abaca fiber. BioResources 7:3515–3524

Reddy N, Yang Y (2005) Properties and potential applications of natural cellulose fibers from cornhusks. Green Chem 7:190–195

Reddy N, Yang Y (2007) Structure and properties of natural cellulose fibers obtained from sorghum leaves and stems. J Agric Food Chem 55:5569–5574

Rokbi M, Osmani H, Imad A, Benseddiq N (2011) Effect of chemical treatment on flexure properties of natural fiber-reinforced polyester composite. Procedia Eng 10:2092–2097

Ronald Aseer J, Sankaranarayanasamy K, Jayabalan P, Natarajan R, Priya Dasan K (2013) Morphological, physical, and thermal properties of chemically treated banana fiber. J Nat Fibers 10:365–380

Rosa MF, Chiou B, Medeiros ES, Wood DF, Williams TG, Mattoso LHC, Orts WJ, Imam SH (2009) Effect of fiber treatments on tensile and thermal properties of starch/ethylene vinyl alcohol copolymers/coir biocomposites. Bioresour Technol 100:5196–5202

Sampathkumar D, Punyamurth R, Venkateshappa SC (2012) Effect of chemical treatment on water absorption of areca fiber. J Appl Sci Res 8:5298–5305

Sandy M, Bacon L (2001) Tensile testing of raffia. J Mater Sci Lett 20:529–530

Santhosh J, Balanarasimman N, Chandrasekar R, Raja S (2014) Study of properties of banana fiber reinforced composites. Int J Res Eng Technol 3:144–150

Saravanakumar SS, Kumaravel A, Nagarajan T, Sudhakar P, Baskaran R (2013) Characterization of a novel natural cellulosic fiber from Prosopis juliflora bark. Carbohydr Polym 92:1928–1933

Sathishkumar TP, Navaneethakrishnan P, Shankar S, Rajasekar R (2014) Investigation of chemically treated randomly oriented sansevieria ehrenbergii fiber reinforced isophthallic polyester composites. J Compos Mater 48:2961–2975

Sathitsuksanoh N, Zhu Z, Wi S, Percival Zhang YH (2011) Cellulose solvent-based biomass pretreatment breaks highly ordered hydrogen bonds in cellulose fibers of switchgrass. Biotechnol Bioeng 108:521–529

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Shibata S, Cao Y, Fukumoto I (2005) Effect of bagasse fiber on the flexural properties of biodegradable composites. Polym Compos 26:689–694

Soleimani M, Tabil L, Panigrahi S, Opoku A (2008) The effect of fiber pretreatment and compatibilizer on mechanical and physical properties of flax fiber-polypropylene composites. J Polym Environ 16:74–82

Soleimani M, Tabil LG, Oguocha I, Fung J (2017) Interactive influence of biofiber composition and elastomer on physico-mechanical properties of PLA green composites. J Polym Environ. https://doi.org/10.1007/s10924-017-0967-8

Suryanto H, Marsyahyo E, Irawan YS, Soenoko R (2014) Effect of alkali treatment on crystalline structure of cellulose fiber from mendong (Fimbristylis globulosa) straw. Key Eng Mater 594–595:720–724

Symington MC, Banks WM, West OD, Pethrick RA (2009) Tensile testing of cellulose based natural fibers for structural composite applications. J Compos Mater 43:1083–1108

Taha I, Steuernagel L, Ziegmann G (2007) Optimization of the alkali treatment process of date palm fibres for polymeric composites. Compos Interfaces 14:669–684

Thiruchitrambalam M, Athijayamani A, Sathiyamurthy S, Thaheer ASA (2010) A review on the natural fiber-reinforced polymer composites for the development of roselle fiber-reinforced polyester composite. J Nat Fibers 7:307–323

Tibolla H, Pelissari FM, Menegalli FC (2014) Cellulose nanofibers produced from banana peel by chemical and enzymatic treatment. LWT Food Sci Technol 59:1311–1318

Tomczak F, Satyanarayana KG, Sydenstricker THD (2007) Studies on lignocellulosic fibers of Brazil: part III—morphology and properties of Brazilian curaua fibers. Compos Part A Appl Sci Manuf 38:2227–2236

Tsujiyama SI, Miyamori A (2000) Assignment of DSC thermograms of wood and its components. Thermochim Acta 351:177–181

Vardhini KJV, Murugan R, Selvi CT, Surjit R (2016) Optimisation of alkali treatment of banana fibres on lignin removal. Indian J Fibre Text Res 41:156–160

Xu F, Yu J, Tesso T, Dowell F, Wang D (2013) Qualitative and quantitative analysis of lignocellulosic biomass using infrared techniques: a mini-review. Appl Energy 104:801–809

Yan L, Chouw N, Yuan X (2012) Improving the mechanical properties of natural fibre fabric reinforced epoxy composites by alkali treatment. J Reinf Plast Compos 31:425–437

Yang H, Yan R, Chen H, Lee DH, Zheng C (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86:1781–1788

Yue Y, Zhou C, French AD, Xia G, Han G, Wang Q, Wu Q (2012) Comparative properties of cellulose nano-crystals from native and mercerized cotton fibers. Cellulose 19:1173–1187

Zafeiropoulos NE, Williams DR, Baillie CA, Matthews FL (2002) Engineering and characterisation of the interface in flax fibre/polypropylene composite materials. Part I. Development and investigation of surface treatments. Compos Part A Appl Sci Manuf 33:1083–1093

Acknowledgments

The authors hereby acknowledge the technical assistance received from Mr. Jason Maley and Dr. Jianfeng Zhu of the Saskatchewan Structural Sciences Centre (SSSC), University of Saskatchewan, Saskatoon with respect to FTIR and XRD data analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fadele, O., Oguocha, I.N.A., Odeshi, A.G. et al. Effect of chemical treatments on properties of raffia palm (Raphia farinifera) fibers. Cellulose 26, 9463–9482 (2019). https://doi.org/10.1007/s10570-019-02764-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-019-02764-8