Abstract

The recent trend in the machining industry is moving towards dry cutting by considering cost and environmental factors. But the dry cutting of advanced materials results in a higher cutting zone temperature, which causes poor finish, excessive tool wear, and higher power consumption. To overcome these drawbacks, the machining industry expects cutting tools with higher hardness and wear resistance. In order to satisfy the required criteria for a cutting tool, a supplementary process such as cryogenic treatment of the cutting tool is carried out to enhance its mechanical properties and cutting performance.

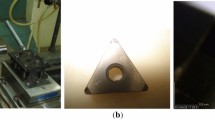

In this deep cryogenic treatment, tungsten carbide (WC) and AlTiN-coated carbide inserts were processed at −196 °C for 24 hours of soaking periods with a cooling/heating rate of 0.25 °C/min and then oil tempering was carried out at 140 °C for 2 hours. The impact of cryo-treatment on the microhardness (HV 1) and X-ray diffraction (XRD) profiles of cutting inserts were evaluated. The micro Vicker hardness of WC and AlTiN-coated inserts was increased by 3.16 % and 5.13 % with cryo-treated over untreated conditions, respectively. From XRD profiles, a small, sharp peak was observed in the 20–30° region with cryo-treated conditions of WC and AlTiN-coated carbide inserts over untreated ones. Hence, a new existence peak of AlTiN2 (Ti0.44 Al0.56) N at 37° and 63° with a cryo-treated AlTiN insert over an untreated one. In addition, a peak of WC; AlTiN2 (Ti0.44 Al0.56) N was observed at 76°. Finally, it was confirmed that there was an increase in hardness with cryo-treatment by the formation of small, sharp peaks, i.e., η-phase carbides, and hard surface coating over untreated conditions.

Similar content being viewed by others

References

H. Lin, C. Wang, Y. Yuan, Z. Chen, Q. Wang and W. Xiong, Tool wear in Ti-6Al-4V alloy turning under oils on water cooling comparing with cryogenic air mixed with minimal quantity lubrication, International Journal Advanced Manufacturing Technology, 81 (2015) 87–101.

M. A. Khan, M. Mia and N. R. Dhar, High-pressure coolant on flank and rake surfaces of tool in turning of Ti-6Al-4V: investigations on forces, temperature, and chips, International Journal Advanced Manufacturing Technology, 90 (2017) 1977–1991.

K. A. Venugopal, S. Paul and A. B. Chattopadhyay, Growth of tool wear in turning of Ti-6Al-4V alloy under cryogenic cooling, Wear, 262 (2007) 1071–1078.

S. S. Gill, H. Singh, R. Singh and J. Singh, Cryoprocessing of cutting tool materials - a review, International Journal Advanced Manufacturing Technology, 48 (2010) 175–192.

C. Y. Nie, Y. Deng, Y. Ding, N. Li, X. G. Zhou and L. D. Wei, Effect of cryogenic treatment on improving the fracture toughness of TiN coated cemented carbide, Advance Materials Research, 415–417 (2012) 1903–1910.

M. R. Kusumba, V. K. Domakonda and S. Balasubramaniyan, Application of cryogenically treated electrode for enhancement of process outcomes during sustainable electric discharge machining, International Journal of Modern Manufacturing Technologies, 12(2) (2020) 86–92.

J. Yong and C. Ding, Effect of cryogenic treatment on WC-Co cemented carbides, Materials Science and Engineering A, 528 (2011) 1735–1739.

S. T. Dhande, V. A. Kane, M. M. Dhobe and C. L. Gogte, Influence of soaking periods in cryogenic treatment of tungsten carbide, Procedia Manufacturing, 20 (2018) 318–328.

M. Padmakumar, J. Guruprasath, P. Achuthan and D. Dinakaran, Investigation of phase structure of cobalt and its effect in WC-Co cemented carbides before and after deep cryogenic treatment, International Journal of Refractory Metals & Hard Materials, 74 (2018) 87–92.

M. Padmakumar and D. Dinakaran, Evaluation of mechanical and metallurgical properties of cryo-treated tungsten carbide with 25 % cobalt, Materials Today: Proceedings, 43(6) (2021) 3463–3469.

S. S. Gill, R. Singh, J. Singh and H. Singh, Investigation on wear behaviour of cryogenically treated TiAlN coated tungsten carbide inserts in turning, International Journal of Machine Tools & Manufacture, 51 (2011) 25–33.

Chetan, S. Ghosh and P. V. Rao, Performance evaluation of deep cryogenic processed carbide inserts during dry turning of Nimonic 90 aerospace grade alloy, Tribology International, 115 (2017) 397–408.

S. Thamizimanii, C. Yuvaraji, J. S. Senthilkumar, I. Arun and Sulaiman, Effect of feed rate on difficult to cut metals on surface roughness and tool wear using surface treated and untreated tools, Procedia Manufacturing, 30 (2019) 216–223.

J. Singh and W. Zaidi, Application of cryo-treatment for improving machining characteristics and reduce manufacturing cost, Materials Today: Proceedings, 33(3) (2020) 1531–1537.

N. A. Özbek, Effects of cryogenic treatment types on the performance of coated tungsten tools in the turning of AISI H11 steel, Journal of Materials Research and Technology, 9(4) (2020) 9442–9456.

P. S. Jadhav, C. P. Mohanty, T. K. Hotta and M. Gupta, An optimal approach for improving the machinability of Nimonic C-263 superalloy during cryogenic assisted turning, Journal of Manufacturing Processes, 58 (2020) 693–705.

G. Akıncıoglu, Investigation of the effect of cryogenic treatment cubic boron nitride turning insert tools, Journal of Materials Engineering and Performance, 30(2) (2021) 1280–1288.

W. J. Liu, J. H. Duan, H. C. Zhao, Y. W. Ye and H. Chen, Effect of cryogenic treatment time on microstructure and tribology performance of TiAlN coating, Surface Topography: Metrology and Properties, 9 (2021) 035055.

M. Dhananchezian, Investigate the comparative performance of dry turning Monel 400 alloy by untreated and cryo-treated AlTiN carbide tools, Advances in Materials and Processing Technologies (2023) DOI: https://doi.org/10.1080/2374068X.2023.2204031.

F. Uny, E. Blanquet, F. Schuster and F. Sanchette, Ti-Al-N-Based hard coatings: thermodynamical background, CVD deposition, and properties, a review, Coatings and Thin-Film Technologies, IntechOpen (2018) DOI: https://doi.org/10.5772/intechopen.79747.

N. A. Özbek, A. Çiçek, M. Gülesin and O. Özbek, Investigation of the effects of cryogenic treatment applied at different holding times to cemented carbide inserts on tool wear, International Journal of Machine Tools & Manufacture, 86 (2014) 34–43.

B. N. Sahoo, A. Mohanty, S. Gangopadhyay and K. Vipindas, An insight into microstructure and machining performance of deep cryogenically treated cemented carbide inserts, Journal of Manufacturing Processes, 58 (2020) 819–831.

C. Yooliengpun, N. Bandasak, K. Tuchinda and O. Diewwanit, Effect of cryogenic treatment of cemented tungsten carbide tools for die application, IOP Conference Series: Materials Science and Engineering, 1048 (2020) 012002.

Acknowledgements

An author has been supported under Internally Funded Project, Sri Sivasubramaniya Nadar College of Engineering, Kalavakkam - 603110.

Author information

Authors and Affiliations

Corresponding author

Additional information

Dhananchezian is an Associate Professor of the Department of Mechanical Engineering, Sri Sivasubramaniya Nadar College of Engineering, OMR, Kalavakkam–603110. He received his Ph.D. in Mechanical Engineering from Anna University, Chennai. His research interests include cryogenic cooling, and metal cutting. He is a fellow member of AICTE (national doctoral fellowship) during the year 2008–2010. He has published 36 international journals in his credits.

Rights and permissions

About this article

Cite this article

Dhananchezian, M. Investigation of cryo-treatment on hardness and XRD profile of WC and AlTiN coated inserts. J Mech Sci Technol 38, 2431–2437 (2024). https://doi.org/10.1007/s12206-024-0421-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-024-0421-5