Abstract

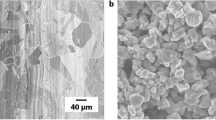

In this paper, coated micro-grinding tools with high wear resistance are successfully manufactured by vacuum multi-arc ion plating method, aiming at improving the grinding performance and prolonging the service life of micro-grinding tools. The principle of vacuum multi-arc ion plating is analyzed. Single factor coating experiment is conducted on the surface of specimens to investigate the effect of different preparation parameters on coating properties. It demonstrated during the present research that the interfacial reaction between metal titanium coating and diamond abrasive particles produces metallurgical bond. Meanwhile, the interpenetration between titanium coating and cobalt and nickel binder layer improves the binding force of the coating, which can firmly wrap diamond particles and slow down the shedding of diamond abrasive particles. When the arc current is 100 A, the voltage of the electromagnetic coil is 20 V and the deposition time is 2.5 h, coating properties with high wear resistance can be obtained.

Similar content being viewed by others

Abbreviations

- J e :

-

Current density

- E :

-

Field intensity

- R v :

-

Coating formation rate

- ρ :

-

Material density

- M :

-

Molar mass

- N a :

-

Avogadro constant

- I :

-

Arc current

- A :

-

Unit of arc current

- U :

-

Coil voltage

- V :

-

Unit of coil voltage

References

Y. Wang, B. Zou, Z. Wang, C. Huang and Z. Liu, Analyzing the performance of self-developed cermet micro end mills in machining of TC4 alloy micro-grooves, Procedia CIRP, 71 (2018) 424–428.

A. Pratap, K. Patra and A. A. Dyakonov, A comprehensive review of micro-grinding: emphasis on toolings, performance analysis, modeling techniques, and future research directions, International Journal of Advanced Manufacturing Technology, 104 (2019) 63–102.

W. Li, Y. Ren, C. Li, Z. Li and M. Li, Investigation of machining and wear performance of various diamond micro-grinding tools, International Journal of Advanced Manufacturing Technology, 106 (2020) 921–935.

T. Wang, X. Zha, F. Chen, J. Wang, Y. Li and F. Jiang, Mechanical impact test methods for hard coatings of cutting tools: a review, International Journal of Advanced Manufacturing Technology, 115 (2021) 1367–1385.

H. B. He, H. Y. Li, X. Y. Zhang, Q. B. Yue, J. Zhang, L. Ma and Y. M. Li, Research on the cutting performances and wear mechanisms of TiAlCrN coated tools during dry turning, J. International Journal of Precision Engineering and Manufacturing, 20 (2) (2019) 201–207.

A. A. Vereschaka, S. N. Grigoriev, N. N. Sitnikov, G. V. Oganyan and A. Batako, Working efficiency of cutting tools with multilayer nano-structured Ti-TiCN-(Ti,Al)CN and Ti-TiCN-(Ti,Al,Cr) CN coatings: analysis of cutting properties, wear mechanism and diffusion processes, J. Surface and Coatings Technology, 332 (2017) 198–213.

C. Sateesh Kumar, H. Majumder, A. Khan and S. K. Patel, Applicability of DLC and WC/C low friction coatings on Al2O3/TiCN mixed ceramic cutting tools for dry machining of hardened 52100 steel, Ceramics International, 46 (8) (2020) 11889–11897.

T. Hao, J. Du, G. Su, P. Zhang, Y. Sun and J. Zhang, Mechanical and cutting performance of cemented carbide tools with Cr/x/DLC composite coatings, International Journal of Advanced Manufacturing Technology, 106 (11–12) (2020) 5241–5254.

Q. Yan, Z. Kuang and J. Lu, Effect of AlTiN-coating oblique guillotine tools on their performance when shearing electrical steel sheets, J. International Journal of Advanced Manufacturing Technology, 99 (2018) 819–831.

C. Dai, W. Ding, J. Xu, Y. Fu and T. Yu, Influence of grain wear on material removal behavior during grinding nickelbased superalloy with a single diamond grain, International Journal of Machine Tools and Manufacture, 113 (2017) 49–58.

R. H. Fowler and L. Nordheim, Electron emission in intense electric fields, Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences, 119 (781) (1928) 173–181.

Y. C. Zhang, Lecture 20: vacuum Ion coating, J. Chinese Journal of Vacuum, 55 (3) (2018) 70–72.

X. Wang, G. Zhou, Y. Men, S. Q. Zhang, H. Y. Zhang, F. Li and L. J. Chen, Superplastic deformation behaviors and power dissipation rate for fine-grained Ti-6Al-4V titanium alloy processed by direct rolling, Crystals, 12 (2) (2022) 270.

J. Cheng, Y. D. Gong, Z. Z. Wu, C. Wang, Z. X. Cao and Y. M. Liu, Experimental study on the micro-grinding surface formation mechanism of hard and brittle materials, Chinese Journal of Mechanical Engineering, 4811 (11) (2012) 190–198.

X. L. Wen, Y. D. Gong, J. Cheng and D. C. Ba, Analysis and experimental research on the wear mechanism of electroplated diamond micro-grinding tools, Chinese Journal of Mechanical Engineering, 51 (11) (2015) 177–185.

J. C. Pang, Research on synthesis mechanism of TiAl-based composite plates based on SiC p/Al-Ti system, Doctoral Dissertation, Harbin Institute of Technology, China (2013).

X. A. Zeng, H. Huang, W. Zhang, H. R. Wang, Z. Liu and C. J. Qiu, The influence of arc current on the microstructure and properties of multi-arc ion plating pure Cr coating, Rare Metals and Cemented Carbides, 45 (5) (2017) 53–56+62.

Acknowledgments

The authors would like to thank the support of National Natural Science Foundation of China (U1908230) and Fundamental Research Funds for the Central Universities (No. N2103023).

Author information

Authors and Affiliations

Corresponding author

Additional information

Xuelong Wen received his Ph.D. degree from Northeastern University in China in 2014. Dr. Wen is currently an Associate Professor and a Master Instructor at the School of Mechanical Engineering and Automation, Northeastern University, China. His research interests include precision machining and grinding, microscale processing, metal 3D printing and addition and subtraction hybrid manufacturing.

Rights and permissions

About this article

Cite this article

Wen, X., Han, F. & Gong, Y. Experimental research on preparation of TiC coated micro-grinding tools and influencing factors of coating properties. J Mech Sci Technol 36, 4171–4183 (2022). https://doi.org/10.1007/s12206-022-0735-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-022-0735-0