Abstract

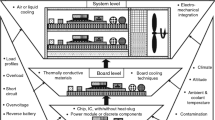

As the cooling capacity of the active cooling devices has reached their allowable heat flux limit, heat spreading technologies are becoming more remarkable in the thermal management of high-power electronics. Flat plate two-phase heat spreaders (FTHSs) are advantageous for the thermal management of electronic devices due to their simplicity, power-free operation, and high reliability. This review is based on understanding the working mechanism and limitations of FTHSs. As the power density of electronic devices increases, researchers focus on performance improvement to overcome their malfunctioned working conditions. This review summarizes the major parameters of FTHS that affect heat transfer performance. Moreover, recent advances in FTHSs suggest that new design concepts can extend the maximum operating heat flux of thermal management devices. This review can establish a direction for studying higher-performance heat spreaders and identifying the latest trends.

Similar content being viewed by others

Abbreviations

- P cap.max :

-

Maximum capillary pressure

- P V :

-

Pressure drop of vapor flow

- P I :

-

Pressure drop of liquid flow

- P g :

-

Hydraulic head

- σ :

-

Surface tension

- θ :

-

Contact angle

- d p :

-

Pore size

- K :

-

Permeablility

- μ :

-

Viscosity

- V :

-

Velocity

- L :

-

Length

- Cu :

-

Copper

- Al :

-

Aluminum

- SS :

-

Stainless steel

- Ni :

-

Nickel

- RU :

-

Recommended by past successful usage

- RL :

-

Recommended by literature

- PC :

-

Probably compatible

- NR :

-

Not recommended

- GNC :

-

Generation of gas at all temperatures

- GNT :

-

Generation of gas at elevated temperatures

References

J. Broughton et al., Review of thermal packaging technologies for automotive power electronics for traction purposes, J. Electron. Packag. Trans. ASME (2018).

C. Qian et al., Thermal management on IGBT power electronic devices and modules, IEEE ACCESS, 6 (2018) 12868–12884.

X. Dai et al., Reliability design of direct liquid cooled power semiconductor module for hybrid and electric vehicles, Microelectron. Reliab., 64(SI) (2016) 474–478.

G. Coquery et al., High temperature reliability on automotive power modules verified by power cycling tests up to 150 degrees C, Microelectron. Reliab., 43(9–11) (2003) 1871–1876.

R. Bayerer, Advanced packaging yields higher performance and reliability in power electronics, Microelectron. Reliab., 50(9–11, SI) (2010) 1715–1719.

M. Ciappa, Selected failure mechanisms of modern power modules, Microelectron. Reliab., 42(4–5) (2002) 653–667.

H. Lee, V. Smet and R. Tummala, A review of sic power module packaging technologies: challenges, advances, and emerging issues, IEEE J. Emerg. Sel. Top. Power Electron., 8(1) (2019) 239–255.

I. Mudawar, Assessment of high-heat-flux thermal management schemes, IEEE Trans. Components Packag. Technol., 24(2) (2001) 122–141.

M. A. Ebadian and C. X. Lin, A review of high-heat-flux heat removal technologies, J. Heat Transfer, 133 (11) (2011).

A. Bar-Cohen and P. Wang, Thermal management of on-chip hot spot, J. Heat Transfer, 134 (5) (2012).

S. Shu et al., Heat dissipation in high-power semiconductor lasers with heat pipe cooling system, J. Mech. Sci. Technol., 31(6) (2017) 2607–2612.

V. Kravets et al., Heat pipes with variable thermal conductance property for space applications, J. Mech. Sci. Technol., 31(6) (2017) 2613–2620.

J. H. Boo and S. Y. Park, Isothermal characteristics of a rectangular parallelepiped sodium heat pipe, J. Mech. Sci. Technol., 19(4) (2005) 1044–1051.

D. A. Reay, P. A. Kew and R. J. McGlen, Heat Pipes: Theory, Design and Applications, Sixth Edition (2013).

J. R. Bose, N. Ahammed and L. G. Asirvatham, Thermal performance of a vapor chamber for electronic cooling applications, J. Mech. Sci. Technol., 31(4) (2017) 1995–2003.

G. Huang et al., A novel ultra-thin vapor chamber for heat dissipation in ultra-thin portable electronic devices, Appl. Therm. Eng., 167 (2020) 114726.

B. Li et al., Heat spreading performance of SiC-based power module with bonded vapour chamber for electric powertrain integration, Appl. Therm. Eng., 181 (2020) 115896.

Y. Tang et al., Thermal management of high-power LEDs based on integrated heat sink with vapor chamber, Energy Convers. Manag. (2017).

J. C. Wang, Thermal investigations on LED vapor chamber-based plates, Int. Commun. Heat Mass Transf., 38(9) (2011) 1206–1212.

M. R. Shaeri, D. Attinger and R. Bonner, Feasibility study of a vapor chamber with a hydrophobic evaporator substrate in high heat flux applications, Int. Commun. Heat Mass Transf. (2017).

B. Zohuri, Heat Pipe Design And Technology: Modern Applications For Practical Thermal Management, Springer (2016).

D. A. Nield and A. Bejan, Convection in Porous Media (2017).

B. Li et al., Optimization design of grooved evaporator wick structures in vapor chamber heat spreaders, Appl. Therm. Eng., 166 (2020) 114657.

Y. Nam et al., Characterization and modeling of the heat transfer performance of nanostructured cu micropost wicks, J. Heat Transfer, 133 (10) (2011).

J. Zeng et al., Fabrication and capillary characterization of micro-grooved wicks with reentrant cavity array, Int. J. Heat Mass Transf., 104 (2017) 918–929.

W. Zhou et al., Effect of the passage area ratio of liquid to vapor on an ultra-thin flattened heat pipe, Appl. Therm. Eng., 162 (2019) 114215.

Y. Li et al., Experimental investigation of vapor chambers with different wick structures at various parameters, Exp. Therm. Fluid Sci., 77 (2016) 132–143.

Y. T. Chen et al., Feasibility study of an aluminum vapor chamber with radial grooved and sintered powders wick structures, Appl. Therm. Eng., 51(1–2) (2013) 864–870.

J. Zeng et al., Experimental investigation on thermal performance of aluminum vapor chamber using micro-grooved wick with reentrant cavity array, Appl. Therm. Eng., 130 (2018) 185–194.

G. Chen et al., Heat transfer characteristic of an ultra-thin flat plate heat pipe with surface-functional wicks for cooling electronics, Int. Commun. Heat Mass Transf., 100 (2019) 12–19.

Y. Peng et al., The performance of the novel vapor chamber based on the leaf vein system, Int. J. Heat Mass Transf., 86 (2015) 656–666.

W. Liu et al., The performance of the vapor chamber based on the plant leaf, Int. J. Heat Mass Transf., 98 (2016) 746–757.

S. S. Hsieh and Y. R. Yang, Design, fabrication and performance tests for a polymer-based flexible flat heat pipe, Energy Convers. Manag., 70 (2013) 10–19.

G. Huang et al., Fabrication and thermal performance of mesh-type ultra-thin vapor chambers, Appl. Therm. Eng., 162 (2019) 114263.

W. Zhou et al., Ultra-thin flattened heat pipe with a novel band-shape spiral woven mesh wick for cooling smartphones, Int. J. Heat Mass Transf., 146 (2020) 118792.

C. Liu, Q. Li and D. Fan, Fabrication and performance evaluation of flexible flat heat pipes for the thermal control of deployable structure, Int. J. Heat Mass Transf., 144 (2019) 118661.

W. Zhou et al., A novel ultra-thin flattened heat pipe with biporous spiral woven mesh wick for cooling electronic devices, Energy Convers. Manag. (2019).

D. Deng et al., Characterization of capillary performance of composite wicks for two-phase heat transfer devices, Int. J. Heat Mass Transf., 56(1–2) (2013) 283–293.

S. C. Wong, J. H. Liou and C. W. Chang, Evaporation resistance measurement with visualization for sintered copper-powder evaporator in operating flat-plate heat pipes, Int. J. Heat Mass Transf., 53(19–20) (2010) 3792–3798.

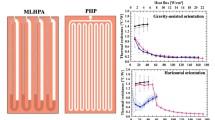

Y. Tang et al., A multi-artery vapor chamber and its performance, Appl. Therm. Eng., 60(1–2) (2013) 15–23.

J. S. Kim et al., Thermal performance of aluminum vapor chamber for EV battery thermal management, Appl. Therm. Eng., 185 (2021) 116337.

Y.-T. Chen et al., Thermal performance of a vapor chamber heat pipe with diamond-copper composition wick structures, 2009 4th Int. Microsystems, Packag. Assem. Circuits Technol. Conf. (2009) 340–343.

S. Sharratt, C. Peng and Y. S. Ju, Micro-post evaporator wicks with improved phase change heat transfer performance, Int. J. Heat Mass Transf., 55(21–22) (2012) 6163–6169.

K. Matin, A. Bar-Cohen and J. J. Maurer, Modeling and simulation challenges in embedded two phase cooling: DARPA’s ICECool program, Proceedings of the ASME 2015 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems collocated with the ASME 2015 13th International Conference on Nanochannels, Microchannels, and Minichannels. Volume 3: Advanced Fabrication and Manufacturing; Emerging Technology Frontiers; Energy, Health and Water- Applications of Nano-, Micro- and Mini-Scale Devices; MEMS and NEMS; Technology Update Talks; Thermal Management Using Micro Channels, Jets, Sprays (2015).

T. Liu et al., Characterization and thermal modeling of a miniature silicon vapor chamber for die-level heat redistribution, Int. J. Heat Mass Transf., 152 (2020) 119569.

Q. Cai, B. Chen and C. Tsai, Design, development and tests of high-performance silicon vapor chamber, J. Micromechanics Microengineering, 22(3) (2012) 35009.

B. He et al., Experiments on the ultrathin silicon vapor chamber for enhanced heat transfer performance, 2016 15th IEEE Intersoc. Conf. Therm. Thermomechanical Phenom. Electron. Syst., IEEE (2016) 569–573.

S. B. Kim et al., Thermal characteristics of silicon wafer-based TVCs (thin vapor chambers) with disk-shape using DI water, Int. J. Heat Mass Transf., 127 (2018) 526–534.

S. Cho and Y. Joshi, Thermal performance of microelectronic substrates with submillimeter integrated vapor chamber, J. Heat Transfer, 141 (5) (2019).

D. Deng et al., Thermal performance of composite porous vapor chambers with uniform radial grooves, Appl. Therm. Eng., 125 (2017) 1334–1344.

A. S. Kousalya et al., Metal functionalization of carbon nanotubes for enhanced sintered powder wicks, Int. J. Heat Mass Transf., 59(1) (2013) 372–383.

C. Byon and S. J. Kim, Effects of geometrical parameters on the boiling limit of bi-porous wicks, Int. J. Heat Mass Transf., 55(25–26) (2012) 7884–7891.

S. Xu et al., Development of ultra-thin thermal ground planes by using stainless-steel mesh as wicking structure, J. Microelectromechanical Syst., 25(5) (2016) 842–844.

J. A. Weibel et al., Experimental characterization of capillary-fed carbon nanotube vapor chamber wicks, J. Heat Transfer, 135 (2) (2012).

F. Zhou, Y. Liu and E. M. Dede, Design, fabrication, and performance evaluation of a hybrid wick vapor chamber, J. Heat Transfer, 141 (8) (2019).

T. E. Tsai et al., Two-phase closed thermosyphon vapor-chamber system for electronic cooling, Int. Commun. Heat Mass Transf., 37(5) (2010) 484–489.

J. Huang, J. Zhang and L. Wang, Review of vapor condensation heat and mass transfer in the presence of non-condensable gas, Appl. Therm. Eng., 89 (2015) 469–484.

K. Hijikata, S. J. Chen and C. L. Tien, Non-condensable gas effect on condensation in a two-phase closed thermosyphon, Int. J. Heat Mass Transf., 27(8) (1984) 1319–1325.

X. M. Wu et al., Approximate equations for film condensation in the presence of non-condensable gases, Int. Commun. Heat Mass Transf., 85 (2017) 124–130.

J. He et al., Effect of non-condensable gas on the operation of a loop heat pipe, Int. J. Heat Mass Transf., 70 (2014) 449–462.

X. Ji, J. Xu and A. M. Abanda, Copper foam based vapor chamber for high heat flux dissipation, Exp. Therm. Fluid Sci., 40 (2012) 93–102.

P. Wallin, Heat pipe, selection of working fluid, Proj. Report, MVK160 Heat Mass Transf. Lund, Sweden (2012).

H. Zhang et al., A study on thermal performance of a pump-assisted loop heat pipe with ammonia as working fluid, Appl. Therm. Eng., 175 (2020) 115342.

A. Basiulis and M. Filler, Operating characteristics and long life capabilities of organic fluidheat pipes, 6th Thermophys. Conf. (1971) 408.

S. C. Wong, S. F. Huang and K. C. Hsieh, Performance tests on a novel vapor chamber, Appl. Therm. Eng., 31(10) (2011) 1757–1762.

K. Baraya, J. A. Weibel and S. V. Garimella, Simultaneous wick and fluid selection for the design of minimized-thermal-resistance vapor chambers under different operating conditions, Int. J. Heat Mass Transf., 136 (2019) 842–850.

S. Wiriyasart and P. Naphon, Fill ratio effects on vapor chamber thermal resistance with different configuration structures, Int. J. Heat Mass Transf., 127 (2018) 164–171.

S. Lips, F. Lefèvre and J. Bonjour, Combined effects of the filling ratio and the vapour space thickness on the performance of a flat plate heat pipe, Int. J. Heat Mass Transf., 53(4) (2010) 694–702.

H. Peng, J. Li and X. Ling, Study on heat transfer performance of an aluminum flat plate heat pipe with fins in vapor chamber, Energy Convers. Manag., 74 (2013) 44–50.

M. C. Tsai, S. W. Kang and K. V. De Paiva, Experimental studies of thermal resistance in a vapor chamber heat spreader, Appl. Therm. Eng., 56(1–2) (2013) 38–44.

W. Li et al., Experimental investigation on the thermal performance of vapor chamber in a compound liquid cooling system, Int. J. Heat Mass Transf., 170 (2021) 121026.

L. Chen et al., Development and thermal performance of a vapor chamber with multi-artery reentrant microchannels for high-power LED, Appl. Therm. Eng., 166 (2020) 114686.

A. Bar-Cohen et al., Two-phase thermal ground planes: technology development and parametric results, J. Electron. Packag. Trans. ASME (2015).

Y. S. Ju et al., Planar vapor chamber with hybrid evaporator wicks for the thermal management of high-heat-flux and high-power optoelectronic devices, Int. J. Heat Mass Transf. (2013).

M. Sigurdson et al., A large scale titanium thermal ground plane, Int. J. Heat Mass Transf., 62(1) (2013) 178–183.

Q. Cai and A. Bhunia, High heat flux phase change on porous carbon nanotube structures, Int. J. Heat Mass Transf., 55(21–22) (2012) 5544–5551.

C. Oshman et al., The development of polymer-based flat heat pipes, J. Microelectromechanical Syst., 20(2) (2011) 410–417.

H. Ma et al., Experimental investigation of a flat-plate oscillating heat pipe during high-gravity loading, ASME 2011 International Mechanical Engineering Congress and Exposition (2011) 627–632.

S. M. Thompson et al., Ultra-high thermal conductivity of three-dimensional flat-plate oscillating heat pipes for electromagnetic launcher cooling, 2012 16th Int. Symp. Electromagn. Launch Technol. (2012) 1–5.

C. J. Oshman et al., Fabrication and testing of a flat polymer micro heat pipe, Transducers 2009–2009 Int. Solid-State Sensors, Actuators Microsystems Conf., IEEE (2009) 1999–2002.

C. Oshman et al., Flat flexible polymer heat pipes, J. Micromechanics Microengineering, 23(1) (2012) 15001.

G. S. Hwang et al., Multi-artery heat pipe spreader: experiment, Int. J. Heat Mass Transf., 53(13–14) (2010) 2662–2669.

R. Ranjan et al., Modeling and design optimization of ultrathin vapor chambers for high heat flux applications, IEEE Trans. Components, Packag. Manuf. Technol., 2(9) (2012) 1465–1479.

D. H. Altman et al., Analysis and characterization of thermal expansion-matched wick-based multi-chip passive heat spreaders in static and dynamic environments, Proceedings of the ASME 2013 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems. Volume 2: Thermal Management; Data Centers and Energy Efficient Electronic Systems (2013).

H. P. J. de Bock et al., On the charging and thermal characterization of a micro/nano structured thermal ground plane, 2010 12th IEEE Intersoc. Conf. Therm. Thermomechanical Phenom. Electron. Syst., IEEE (2010) 1–6.

Q. Cai et al., Studies of material and process compatibility in developing compact silicon vapor chambers, J. Micromechanics Microengineering, 23(6) (2013) 65003.

Q. Cai et al., Development of scalable silicon heat spreader for high power electronic devices, J. Therm. Sci. Eng. Appl., 1 (4) (2010).

C. Ding et al., A flat heat pipe architecture based on nanostructured titania, J. Microelectromechanical Syst., 19(4) (2010) 878–884.

N. S. Dhillon et al., Experimental investigation of thin-film evaporation in an open-loop columnated micro-evaporator, Int. Work. Micro Nanotechnol. Power Gener. Energy Convers. Appl. (PowerMEMS), Seoul, Korea, Nov (2011) 15–18.

J. A. Weibel and S. V. Garimella, Visualization of vapor formation regimes during capillary-fed boiling in sintered-powder heat pipe wicks, Int. J. Heat Mass Transf., 55(13–14) (2012) 3498–3510.

J. H. Moon et al., Boiling-driven, wickless, and orientation-independent thermal ground plane, Int. J. Heat Mass Transf. (2021).

Acknowledgments

This work was supported by the Civil-Military Technology Cooperation Program of the Institute of Civil-Military Technology Cooperation, with a grant funded by the Defense Acquisition Program Administration and the Ministry of Trade, Industry, and Energy (Number 18CM5017) and the National Research Foundation of Korea (NRF) grant funded by the Ministry of Science and ICT, Korea (Number NRF-2020R1A2C3008689).

Author information

Authors and Affiliations

Corresponding author

Additional information

Hyunmuk Lim is a researcher at the Department of Mechanical Engineering, Ajou University, Suwon, Korea and a Ph.D. candidate at the Department of Mechanical and Information Engineering, University of Seoul, Korea. He received his M.S. (2013) in Mechanical and Information Engineering from the University of Seoul, Korea. His research field is related to the thermal management of high-power electronics and two-phase heat spreaders.

Jungho Lee is a Professor at the Department of Mechanical Engineering, Ajou University, Suwon, Korea. He received his M.S. (1994) and Ph.D. (1999) in Mechanical Engineering from POSTECH, Pohang, Korea. He is a member of KSME, ASME, ASM, and AUTSE. His research interests focus on phase-change heat transfer (boiling and condensation), thermal management, development in heat transfer devices such as heat pipe, vapor chamber, and thermal ground plane.

Rights and permissions

About this article

Cite this article

Lim, H., Lee, J. Flat plate two-phase heat spreader on the thermal management of high-power electronics: a review. J Mech Sci Technol 35, 4801–4814 (2021). https://doi.org/10.1007/s12206-021-1042-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-021-1042-x