Abstract

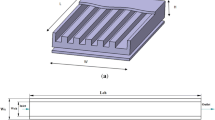

Electronic components used in high power dissipating equipment’s requires superior thermal management and system design should be good enough to serve its promised lifetime without any performance issues/early failures. Prime task for product designers is to keep the electronic devices temperature below threshold limit by dispelling generated heat. Most common and preferred electronics thermal management technique is air-cooled heatsinks with fans because of its heat dissipation range and most reliable simple technique. This review paper specifically aims to understand the recent advancements of air-cooled pin–fin heatsinks for heat transfer applications. This article focuses on available literature only on heatsinks of pin–fin type to explore the results of different types of geometry, orientation, spacing out, perforations on heat transfer performance. In addition to above analytical, numerical, experimental results and heat transfer correlations of different studies are compared and summarized. The outcome of this review article is to provide better understanding on the cooling performance of the pin–fin type heatsink technology and its effective usage towards better thermal management applications.

Similar content being viewed by others

Abbreviations

- η :

-

System performance

- q :

-

Heat flux (W m–2)

- Re:

-

Reynolds number

- ρ :

-

Density (kg m–3)

- V :

-

Average velocity of air inside duct (m s–1)

- D h :

-

Hydraulic diameter (m)

- μ :

-

Dynamic Viscosity of fluid (kg ms–1)

- ν :

-

Kinematic viscosity of the fluid (m2 s–1)

- A d :

-

Cross-section area (m2)

- A s :

-

Total surface area of solid fin array (m2)

- P c :

-

Perimeter of cross-section (m)

- Nu:

-

Nusselt number

- h avg :

-

Average convective heat transfer coefficient (W m–2 °C–1)

- K air :

-

Thermal conductivity of air (W m–1 °C–1)

- K :

-

Thermal conductivity of heat sink (W m–1 °C–1)

- ΔP :

-

Pressure drop (kPa)

- g :

-

Acceleration due to gravity (m s–2)

- Δh :

-

Differential pressure head across the test section (m)

- P in :

-

Pressure at inlet (kPa)

- P out :

-

Pressure at outlet (kPa)

- Q ele :

-

Total electrical energy supplied to heater (W)

- Q cond :

-

Heat energy dissipated from heat sink through conduction (W)

- Q conv :

-

Heat dissipated from heat sink through convection (W)

- Q rad :

-

Heat dissipated from heat sink through radiation (W)

- Q loss :

-

Heat energy loss through insulation (W)

- Q net :

-

Net heat energy supplied to heat sink (W)

- m :

-

Mass flow rate of fluid (m s–1)

- C p :

-

Specific heat capacity of fluid (J kg–1 °C–1)

- T s :

-

Average base plate temperature (°C)

- T bm :

-

Bulk mean temperature (°C)

- T out :

-

Outlet air temperature (°C)

- T in :

-

Inlet air temperature (°C)

- R th :

-

Thermal resistance (°C W–1)

- f :

-

Friction factor

- ε f :

-

Fin effectiveness

- ϵ :

-

Fin efficiency

- Lw:

-

Length of wing

- D :

-

Pin fin diameter

- S :

-

Fin Pinch

- S/D :

-

Pitch to pin fin diameter ratio

- Lw/D :

-

Length of wing to pin fin diameter ratio

- Η :

-

System performance

- NACA:

-

National Advisory Committee for Aeronautics

- GA:

-

Genetic algorithm

- CFD:

-

Computational fluid dynamics

- HTPF:

-

Hydrothermal performance factor

- THP:

-

Thermo hydraulic performance

- PEC:

-

Performance evaluation criteria

- TPI:

-

Aero thermal performance index

- COE:

-

Coefficient of enhancement

- FOM:

-

Factor of merit

- PPFHS:

-

Plate-pin–fin heat sink

- PPFHS-P:

-

Plate-pin–fin heat sink with perforations

- PPFHS-S:

-

Plate-pin–fin heat sink with splitters

- PPFHS-PS:

-

Plate-pin–fin heat sink with perforations and splitters

- SFHSs:

-

Strip fin heat sinks

- MPF:

-

Micro pin fins

- BCC:

-

Body centred cubic

- PF:

-

Profit factor

- PPFI:

-

Percentage of profit factor increment

- C-GPFs:

-

Cylindrical grooved pin-fins

- T-GPFs:

-

Triangular grooved pin-fins

- HPFs:

-

Hexagonal pin fins

- CPFs:

-

Cylindrical pin fins

- Np:

-

Number of perforations

References

Sadique H, Samsher QM. Heat transfer augmentation in microchannel heatsink using secondary flows: a review. Int Jurnal Heat Mass Transf. 2022;194:123063. https://doi.org/10.1016/j.ijheatmasstransfer.2022.123063.

Nafis BM, Whitt R, Iradukunda A-C, Huitink D. Additive manufacturing for enhancing thermal dissipation in heatsink implementation: a review. Heat Transf Eng. 2020. https://doi.org/10.1080/01457632.2020.1766246.

Iradukunda A-C, Huitink DR, Luo F. A review of advanced thermal management solutions and the implications for integration in high-voltage packages. IEEE J Emerg Sel Top Power Electron. 2020;8(1):256–71. https://doi.org/10.1109/JESTPE.2019.2953102.

Smoyer JL, Norris PM. Brief historical perspective in thermal management and the shift toward management at the nanoscale. Heat Transf Eng. 2018. https://doi.org/10.1080/01457632.2018.1426265.

Tong XC. Thermal management fundamentals and design guides in electronic packaging. Adv Mater Thermal Manag Electron Packag Springer Ser Adv Microelectron. 2011. https://doi.org/10.1007/978-1-4419-7759-5_1.

Maji A, Choubey G. Improvement of heat transfer through fins: a brief review of recent developments. Heat Transf. 2020;49(3):1658–85. https://doi.org/10.1002/htj.21684.

Kumar VM, NageswaraRao B, Farooq SK. A detailed review on pin fin heatsink world academy of science engineering and technology. 2016. Int J Energy Power Eng. https://doi.org/10.5281/zenodo.1127134.

Khattak Z, Ali HM. Air cooled heatsink geometries subjected to forced flow: a critical review. Int J Heat Mass Transf. 2019;130:141–61. https://doi.org/10.1016/j.ijheatmasstransfer.2018.08.048.

Nilpueng K, Mesgarpour M, Asirvatham LG, Dalkılıç AS, SeonAhn H, Mahian O, Wongwises S. Effect of pin fin configuration on thermal performance of plate pin fin heatsinks. Case Stud Therm Eng. 2021;27:101269. https://doi.org/10.1016/j.csite.2021.101269.

Yadava S, Pandey KM. A comparative thermal analysis of pin fins for improved heat transfer in forced convection. Mater Today Proc. 2018;5:1711–7. https://doi.org/10.1016/j.matpr.2017.11.268.

Xu J, Yao J, Su P, Lei J, Wu J, Gao T. Heat transfer and pressure loss characteristics of pin-fins with different shapes in a wide channel. In: Proceedings of ASME turbo expo 2017: turbomachinery technical conference and exposition GT2017. https://doi.org/10.1115/GT2017-63761

Jin W, Junmei Wu, Jia N, Lei J, Ji W, Xie G. Effect of shape and distribution of pin-fins on the flow and heat transfer characteristics in the rectangular cooling channel. Int J Therm Sci. 2021;161: 106758. https://doi.org/10.1016/j.ijthermalsci.2020.106758.

Ranjan A, SinghYadav S, Das K. Thermal and flow analysis of split drop-shaped pin fins for improved heat transfer rate. Inst Eng India Ser C. 2020;101(2):375–82. https://doi.org/10.1007/s40032-019-00548-4.

Sakanova A, Tseng KJ. Comparison of pin-fin and finned shape heatsink for power electronics in future aircraft. Appl Therm Eng. 2018. https://doi.org/10.1016/j.applthermaleng.2018.03.020.

Ayoobi A, Ramezanizadeh M, Alhuyi-Nazari M. Optimization of temperature distribution and heat flux functions for cylindrical and conical micro-fins by applying genetic algorithm. J Therm Anal Calorim. 2021;143:4119–30. https://doi.org/10.1007/s10973-020-09293-8.

Turkyilmazoglu M. Thermal management of parabolic pin fin subjected to a uniform oncoming airflow: optimum fin dimensions. J Therm Anal Calorim. 2021;143:3731–9. https://doi.org/10.1007/s10973-020-10382-x.

Niranjan RS, Singh O, Ramkumar J. Numerical study on thermal analysis of square micro pin fins under forced convection. Heat Mass Transf. 2022;58:263–81. https://doi.org/10.1007/s00231-021-03105-x.

Senthil Kumar R, Jayavel S. Forced convective air-cooling effect on electronic components of different geometries and orientations at flow shedding region. IEEE Trans Compon Packag Manuf Technol. 2018;8(4):597–605. https://doi.org/10.1109/TCPMT.2018.2797185.

Alama MW, Bhattacharyya S, Souayeh B, Dey K, Hammami F, Rahimi-Gorji M, Biswas R. CPU heatsink cooling by triangular shape micro-pin-fin: numerical study. Int Commun Heat Mass Transf. 2020;112:104455. https://doi.org/10.1016/j.icheatmasstransfer.2019.104455.

Ahmadian-Elmi M, Mashayekhi A, Nourazar SS, Vafai K. A comprehensive study on parametric optimization of the pin-fin heatsink to improve its thermal and hydraulic characteristics. Int J Heat Mass Transf. 2021;180: 121797. https://doi.org/10.1016/j.ijheatmasstransfer.2021.121797.

Xie G, Song Y, Simon TW. Turbulent flow characteristics and heat transfer enhancement in a rectangular channel with elliptical cylinders and protrusions of various heights. Numer Heat Transf Part A Appl. 2017. https://doi.org/10.1080/10407782.2017.1386507.

Ravi S, Jadhav C. Balaji, Fluid flow and heat transfer characteristics of a vertical channel with detached pin-fin arrays arranged in staggered manner on two opposite endwalls. Int J Therm Sci. 2016;105:57–74. https://doi.org/10.1016/j.ijthermalsci.2016.02.017.

Xie Y, Shi D, Shen Z. Experimental and numericalinvestigation of heat transfer and friction performance for turbine blade tip cap with combined pin-findimple/protrusion structure. Int J Heat Mass Transf. 2017;104:1120–34. https://doi.org/10.1016/j.ijheatmasstransfer.2016.09.032.

Luo L, Du W, Wang S, Sunden B, Zhang X. Flow structure and heat transfer characteristics of a 90°-turned pin-finned wedge duct with dimples at different locations. Numer Heat Transf Part A Appl. 2018. https://doi.org/10.1080/10407782.2017.1421373.

Zhang D, Jing Q, Xie Y, Shen Z. Numerical prediction on turbine blade internal tip cooling with pin-fin and dimple/protrusion structures. Numer Heat Transf Part A Appl. 2016. https://doi.org/10.1080/10407782.2016.1214515.

Du W, Luo L, Wang S, Zhang X. Flow structure and heat transfer characteristics in a 90-deg turned pin fined duct with different dimple/protrusion depths. Appl Therm Eng. 2018. https://doi.org/10.1016/j.applthermaleng.2018.10.052.

Yang L, Wang Q, Rao Y. Searching for irregular pin-fin shapes for high temperature applications using deep learning methods. Int J Therm Sci. 2021;161:106746. https://doi.org/10.1016/j.ijthermalsci.2020.106746.

Turkyilmazoglu M. An optimum profile of a special pin fin: full solutions. Int J Numer Meth Heat Fluid Flow. 2020;30(11):4945–54. https://doi.org/10.1108/HFF-11-2019-0801.

Turkyilmazoglu M. Effective computation of solutions for nonlinear heat transfer problems in fins. ASME J Heat Transf. 2014;136(9):091901. https://doi.org/10.1115/1.4027772.

Haque MR, Hridi TJ, Haque MM. CFD studies on thermal performance augmentation of heatsink using perforated twisted, and grooved pin fins. Int J Therm Sci. 2022;182:107832. https://doi.org/10.1016/j.ijthermalsci.2022.107832.

Niranjan RS, Singh O, Ramkumar J Experimental investigation of forced convection on square micro-pin fins. In: Saha, P., Subbarao, P., Sikarwar, B. (eds) Advances in fluid and thermal engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-13-6416-7_11

Mate DM, Tale VT. Effects of pin fin arrangement its heat transfer characteristics on performance of heatsink. Mater Today Proc. 2021;43:2377–82. https://doi.org/10.1016/j.matpr.2021.01.940.

Chang SW, Cheng TH. Thermal performance of channel flow with detached and attached pin-fins of hybrid shapes under inlet flow pulsation. Int J Heat Mass Transf. 2021;164:120554. https://doi.org/10.1016/j.ijheatmasstransfer.2020.120554.

S Yadav, KA Verma, M Ray, KM Pandey. Thermal analysis of semi circular pin fins for application in electronics cooling. Int J Recent Technol Eng; 2019. https://doi.org/10.35940/ijrte.A1954.078219.

Choudhary V, Kumar M, KumarPatil A. Experimental investigation of enhanced performance of pin fin heatsink with wings. Appl Therm Eng. 2019;155:546–62. https://doi.org/10.1016/j.applthermaleng.2019.03.139.

Chang SW, Wu P-S, Wei BS. Aerothermal performance improvement by array of pin-fins with spiral wings. Int J Therm Sci. 2021;170:107148. https://doi.org/10.1016/j.ijthermalsci.2021.107148.

Khonsue O. Enhancement of the forced convective heat transfer on mini pin fin heatsinks with micro spiral fins. Heat Mass Transfer. 2018;54:563–70. https://doi.org/10.1007/s00231-017-2159-4.

Varakhedkar A, Kumar R. Flow and Heat Transfer Characteristics of Square Cylinder with Protrusions at Different Channel Confinements. Int J Eng Adv Technol. 2019;8:2249–8958. https://doi.org/10.35940/ijeat.D1002.0484S219.

Sajedi R, Osanloo B, Talati F, Taghilou M. Splitter plate application on the circular and square pin fin heatsinks. Microelectron Reliab. 2016;62:91–101. https://doi.org/10.1016/j.microrel.2016.03.026.

Wei Du, Luo L, Wang S, Zhang X. Heat transfer characteristics in a pin finned channel with different dimple locations. Heat Transf Eng. 2019. https://doi.org/10.1080/01457632.2019.1637114.

Adnan M, Ali M. Numerical analysis in enhancement of heat transfer using extended surfaces. In: 2021 International Bhurban conference on applied sciences and technologies (IBCAST), pp 767–773. https://doi.org/10.1109/IBCAST51254.2021.9393211.

El-Said EMS, Abdelaziz GB, Sharshir SW, Elsheikh AH, Elsaid AM. Experimental investigation of the twist angle effects on thermo-hydraulic performance of a square and hexagonal pin fin array in forced convection. Int Commun Heat Mass Transf. 2021;126:105374. https://doi.org/10.1016/j.icheatmasstransfer.2021.105374.

Chang SW, Wu P-S, Cai WL, Yu CH. Experimental heat transfer and flow simulations of rectangular channel with twisted-tape pin-fin array. Int J Heat Mass Transf. 2021;166: 120809. https://doi.org/10.1016/j.ijheatmasstransfer.2020.120809.

Saravanakumar T, SenthilKumar D. Heat transfer study on different surface textured pin fin heatsink. Int Commun Heat and Mass Transf. 2020;119:104902. https://doi.org/10.1016/j.icheatmasstransfer.2020.104902.

Siddiqui JA, Lahane S, Gadekar AV, Lokawar VL. Experimental and computational evaluation of pressure drop and heat transfer characteristics in rectangular channel with helix grooved profile pin fins. Adv Energy Res Springer Proc Energy. 2020. https://doi.org/10.1007/978-981-15-2666-4_69.

Eren M, Caliskan S. Effect of grooved pin-fins in a rectangular channel on heat transfer augmentation and friction factor using Taguchi method. Int J Heat Mass Transf. 2016;102:1108–22. https://doi.org/10.1016/j.ijheatmasstransfer.2016.07.005.

Caliskan S, Dogan A, Kotcioglu I. Experimental investigation of heat transfer from different pin fin in a rectangular channel. Exp Heat Transf. 2018. https://doi.org/10.1080/08916152.2018.1526228.

Jasim HA, Kassim MS, Hussain AA, Habeeb LJ. Investigation of heat transfer enhancement for different shapes pin-fin heatsink. J Mech Eng Res Dev. 2021;44(3):75–89.

Liang D, Chen W, Yinchao Ju, Chyu MK. Comparingendwall heat transfer among staggered pin fin, Kagome and body centered cubic arrays. Appl Therm Eng. 2021;185: 116306. https://doi.org/10.1016/j.applthermaleng.2020.116306.

Ma Y, Yan H, Hooman K, Xie G. Enhanced heat transfer in a pyramidal lattice sandwich panel by introducing pin-fins/protrusions/dimples. Int J Therm Sci. 2020;156: 106468. https://doi.org/10.1016/j.ijthermalsci.2020.106468.

Li Y, Xie G, Boetcher SKS, Yan H. Heat transfer enhancement of X-lattice-cored sandwich panels by introducing pin fins, dimples or protrusions. Int J Heat Mass Transf. 2019;141:627–42. https://doi.org/10.1016/j.ijheatmasstransfer.2019.07.009.

Abadi M, Ranjbar AA, Gorzin M, Bahrampoury R, Hosseini MJ. Effect of splitter angles and orientations attached to pin fin on heat transfer and hydraulic characteristics in a jet impingement rectangular channel. Alex Eng J. 2023;62:475–88. https://doi.org/10.1016/j.aej.2022.07.045.

Wei Du, Luo L, Wang S, Zhang X. Effect of the dimple location and rotating number on the heat transfer and flow structure in a pin finned channel. Int J Heat Mass Transf. 2018;127:111–29. https://doi.org/10.1016/j.ijheatmasstransfer.2018.08.045.

Al-Karagoly MKU, Ayani M, Mamourian M, Bazaz SR. Experimental parametric study of a deep groove within a pin fin arrays regarding fin thermal resistance. Int Commun Heat Mass Transf. 2020;115:104615. https://doi.org/10.1016/j.icheatmasstransfer.2020.104615.

Al-Damook A, Kapur N, Summers JL, HM,. Thompson computational design and optimisation of pin fin heatsinks with rectangular perforations. Appl Therm Eng. 2016. https://doi.org/10.1016/j.applthermaleng.2016.03.070.

KH Dhanawade, HS Dhanawade, A Kashikar, S Matey, M Bhadane, S Sarraf, Thermal Analysis of circular pin-fin with rectangular slot at the center by forced convection. Int J Mech Ind Eng; 2020:14(11). World Academy of Science, Engineering and Technology

Kore SS, Yadav R, Chinchanikar S, Tipole P, Dhole V. Experimental investigations of conical perforations on the thermal performance of cylindrical pin fin heatsink. Int J Ambient Energy. 2020. https://doi.org/10.1080/01430750.2020.1834451.

Sa K-J, Afzal A, Kim K-Y. Performance analysis and design optimization of gapped pin-fin in a cooling channel. Heat Transf Eng. 2017. https://doi.org/10.1080/01457632.2017.1320170.

Gupta D, Saha P, Roy S. Computational analysis of perforation effect on the thermo-hydraulic performance of micro pin-fin heatsink. Int J Therm Sci. 2021;163: 106857. https://doi.org/10.1016/j.ijthermalsci.2021.106857.

Gupta D, Saha P, Roy S. Numerical investigation on heat transfer enhancement with perforated square micro-pin fin heatsink for electronic cooling application. In: 2019 IEEE 21st electronics packaging technology conference (EPTC); 2019, pp 241–246. https://doi.org/10.1109/EPTC47984.2019.9026623

Bhanja MD, Patowari PK. Numerical investigation on heat transfer enhancement of heatsink using perforated pin fins with inline and staggered arrangement. Appl Therm Eng. 2017. https://doi.org/10.1016/j.applthermaleng.2017.07.053.

Maji A, Bhanja D, Patowari PK, Choubey G, Deshamukhya T. Computational investigation of heat transfer analysis through perforated pin fins of different materials. AIP Conf Proc. 2017;1859:020009. https://doi.org/10.1063/1.4990162.

Al-Sallami W, Al-Damook A, Thompson HM. A numerical investigation of thermal airflows over strip fin heatsinks. Int Commun Heat Mass Transf. 2016;75:183–91. https://doi.org/10.1016/j.icheatmasstransfer.2016.03.014.

FarhadIsmail Md, Saha SC. Enhancement of confined air jet impingement heat transfer using perforated pin-fin heatsinks. Appl Thermo-fluid Process Energy Syst Green Energy Technol. 2017. https://doi.org/10.1007/978-981-10-0697-5_10.

Jagannath, R., Muralikrishna, Y. (2021). Numerical Investigation on Heat Transfer Characteristics of a Triangular Slotted Pin Fin Heatsink. In: Palanisamy, M., Ramalingam, V., Sivalingam, M. (eds) Theoretical, Computational, and Experimental Solutions to Thermo-Fluid Systems. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-33-4165-4_1

Cheng WJ, Leng CIM, Jinn FJ. Optimization of pin perforation(s) induced flow dynamic for effective thermal dissipation. Int J Therm Sci. 2020;152:106308. https://doi.org/10.1016/j.ijthermalsci.2020.106308.

Sahel D, Bellahcene L, Yousfi A, Subasi A. Numerical investigation and optimization of a heatsink having hemispherical pin fins. Int Commun Heat Mass Transfer. 2021;122: 105133. https://doi.org/10.1016/j.icheatmasstransfer.2021.105133.

Huang C-H, Huang Y-R. An optimum design problem in estimating the shape of perforated pins and splitters in a plate-pin-fin heatsink. Int J Therm Sci. 2021;170: 107096. https://doi.org/10.1016/j.ijthermalsci.2021.107096.

Tijani AS, Jaffri NB. Thermal analysis of perforated pin-fins heatsink under forced convection condition. Procedia Manuf. 2017. https://doi.org/10.1016/j.promfg.2018.06.025.

Maji A, Deshamukhya T, Choubey G, Choubey A. Performance evaluation of perforated pin fin heatsink using particle swarm optimization and MCDM techniques. J Therm Anal Calorim. 2021. https://doi.org/10.1007/s10973-021-10872-6.

Huang C-H, Chen M-H. An estimation of the optimum shape and perforation diameters for pin fin arrays. Int J Heat Mass Transf. 2019;131:72–84. https://doi.org/10.1016/j.ijheatmasstransfer.2018.11.019.

Chao-Han Wu, Tang H-W, Yang Y-T. Numerical simulation and optimization of turbulent flows through perforated circular pin fin heatsinks. Numer Heat Transf Part A Appl. 2017;71(2):172–88. https://doi.org/10.1080/10407782.2016.1264727.

Maji A, Bhanja D, KumarPatowari P, Kundu B. Thermal analysis for heat transfer enhancement in perforated pin fins of various shapes with staggered arrays. Heat Transf Eng. 2018. https://doi.org/10.1080/01457632.2018.1429047.

Hatem M, Abdellatif H, Hussein W. Enhancement of perforated pin-fins heatsinksunder forced convection. Int Res J Eng Technol. 2020;07(10):1440–5.

Rao CB, Muralikrishna Y. Heat transfer analysis of an equilateral triangular slotted pin fin: an experimental work. In: Palanisamy M, Ramalingam V, Sivalingam M (eds) Theoretical, computational, and experimental solutions to thermo-fluid systems. Lecture notes in mechanical engineering. Springer, Singapore; 2021. https://doi.org/10.1007/978-981-33-4165-4_2

Ranjbar AM, Pouransari Z, Siavashi M. Improved design of heatsink including porous pin fins with different arrangements: a numerical turbulent flow and heat transfer study. Appl Therm Eng. 2021;198:117519. https://doi.org/10.1016/j.applthermaleng.2021.117519.

Lee JS, Ha MY, Min JK. Numerical study on the mixed convection around inclined-pin fins on a heated plate in vertical channels with various bypass ratios. Case Stud Therm Eng. 2021;27:101310. https://doi.org/10.1016/j.csite.2021.101310.

Naratoa P, Wae-hayeea M, Abdullahb MZ, Nuntadusita C. Effect of pin inclination angle on flow and heat transfer characteristics for a row of pins in a flow channel. Int Commun Heat Mass Transf. 2020;110:104396. https://doi.org/10.1016/j.icheatmasstransfer.2019.104396.

Issa J, Saliba N, El Cheikh A. A numerical study of heat transfer and fluid flow in a channel with an array of pin fins in aligned and staggered configurations. In 17th IEEE intersociety conference on thermal and thermomechanical phenomena in electronic systems (ITherm); 2018. https://doi.org/10.1109/ITHERM.2018.8419645

Mandal PK, Sengupta S, Rana SC, Bhanja D. Experimental and numerical investigation of square heatsink having staggered and inline pin fin arrays placed at different orientation. J Mech Sci Technol. 2021;35(11):5187–95. https://doi.org/10.1007/s12206-021-1036-8.

Mandal PK, Sengupta S, Rana SC, Bhanja D. Effect of orientation angle in thermal performance analysis of a horizontal heatsink of perforated pin fins. In: 1st international conference on advances in mechanical engineering and nanotechnology (ICAMEN 2019), AIP Conf Proc 2148, 030003-1–030003-10. https://doi.org/10.1063/1.5123925

Kamde GE, Dingare SV. Experimental and computational investigation of forced convection analysis of plate circular pin fin heatsinksover vertical base. J Inst Eng India Ser C. 2018;99(5):503–12. https://doi.org/10.1007/s40032-017-0363-0.

Chu W-X, Chiou P-H, Wang C-C. Experimental and numerical study upon uniformity of impingement cooling with pin-fin heatsink. IEEE. 2019. https://doi.org/10.1109/TCPMT.2019.2926406.

Xia G, Chen Z, Cheng L, Ma D, Zhai Y, Yang Y. Micro-PIV visualization and numerical simulation of flow and heat transfer in three micro pin-fin heatsinks. Int J Therm Sci. 2017;119:9–23. https://doi.org/10.1016/j.ijthermalsci.2017.05.015.

Ravanji A, Zargarabadi MR. Effects of pin-fin shape on cooling performance of a circular jet impinging on a flat surface. Int J Therm Sci. 2021;161:106684. https://doi.org/10.1016/j.ijthermalsci.2020.106684.

Huang C-H, Chiang P-C. An inverse study to design the optimal shape and position for delta winglet vortex generators of pin-fin heatsinks. Int J Therm Sci. 2016;109:374–85. https://doi.org/10.1016/j.ijthermalsci.2016.06.018.

Yang Xu, Zhu H-R, Wei-jiang Xu, Liu C-L. Effect of pin fin arrangement on the heat transfer characteristics in a convergent channel with impingement. Int J Heat Mass Transf. 2018;125:629–39. https://doi.org/10.1016/j.ijheatmasstransfer.2018.04.111.

Wen M-Y, Yeh C-H. Forced convective performance of perforated circular pin-fin heatsinks. Heat Mass Transf. 2017;53:1713–23. https://doi.org/10.1007/s00231-016-1933-z.

Wen M-Y, Yeh C-H. Numerical study of thermal performance of perforated circular pin fin heatsinks in forced convection. Heat Mass Transf. 2017;53:2031–44. https://doi.org/10.1007/s00231-016-1960-9.

Wen M-Y, Yeh C-H. Impingement thermal performance of perforated circular pin-fin heatsinks. Heat Mass Transf. 2018;54:1009–20. https://doi.org/10.1007/s00231-017-2206-1.

Mohammed AA, Razuqi SA. Effect of air fan position on heat transfer performance of elliptical pin fin heatsink subjected to impinging air flow. J Therm Eng. 2021;6(7):1406–16. https://doi.org/10.18186/thermal.990714.

Li H-Y, Liao W-R, Li T-Y, Chang Y-Z. Application of vortex generators to heat transfer enhancement of a pin-fin heatsink. Int J Heat Mass Transf. 2017;112:940–9. https://doi.org/10.1016/j.ijheatmasstransfer.2017.05.032.

Mohammed AA, Razuqi SA. Performance of rectangular pin-fin heatsink subject to an impinging air flow. J Therm Eng. 2021;7(3):666–76.

Effendi NS, Park JS, Kim BG, Kim KJ (2019) The optimization of hollow hybrid fin heat sinks under impinging airflows. In: 2019 IEEE 21st electronics packaging technology conference (EPTC), 2019, pp 413–416. https://doi.org/10.1109/EPTC47984.2019.9026713

Yan H, Luo L, Zhang J, Wei Du, Wang S, Huang D. Flow structure and heat transfer characteristics of a pin-finned channel with upright/curved/inclined pin fins under stationary and rotating conditions. Int Commun Heat Mass Transf. 2021;127: 105483. https://doi.org/10.1016/j.icheatmasstransfer.2021.105483.

Wang S, Yan H, Luo L, Du W, Sundén B, Zhang X. Heat transfer characteristics of a dimpled/protrusioned pin fin wedge duct with different converging angles for turbine blades. Numer Heat Transf Part A Appl. 2019;76(5):369–92. https://doi.org/10.1080/10407782.2019.1630235.

Bai W, Liang D, Chen W, Chyu MK. Investigation of ribs disturbed entrance effect of heat transfer and pressure drop in pin-fin array. Appl Therm Eng. 2019;162: 114214. https://doi.org/10.1016/j.applthermaleng.2019.114214.

Al-damook A, Alkasmoul FS. Heat transfer and airflow characteristics enhancement of compact plate-pin fins heatsinks a review. Propuls Power Res. 2018;7(2):138–46. https://doi.org/10.1016/j.jppr.2018.05.003.

Deepak Sharma KM, Pandey AjoyDebbarma, Choubey G. Numerical investigation of heat transfer enhancement of SiO2-water based nanofluids in light water nuclear reactor. Mater Today: Proc. 2020;4(9):10118–22. https://doi.org/10.1016/j.matpr.2017.06.332.

Deshamukhya T, Bhanja D, Nath S, Maji A, Choubey G. Analytical study of temperature distribution in a rectangular porous fin considering both insulated and convective tip. AIP Conf Proc. 2017;1859: 020031. https://doi.org/10.1063/1.4990184.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kesavan, D., Senthil Kumar, R. & Marimuthu, P. Heat transfer performance of air-cooled pin–fin heatsinks: a review. J Therm Anal Calorim 148, 623–649 (2023). https://doi.org/10.1007/s10973-022-11691-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11691-z