Abstract

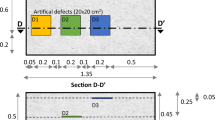

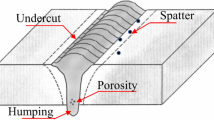

Laser ultrasonics could be an attractive solution for the nondestructive testing of structures in harsh environments. Longitudinal waves generated in the ablation regime are especially well suited to internal defect detection because they provide a higher signal-to-noise ratio in comparison to ultrasonic waves generated under a thermo-elastic regime, while their propagation direction normal to the surface enables the simplified interpretation processing of received signals when the defect echoes are analyzed. The internal defect detection using laser-generated longitudinal waves in the ablation regime was investigated numerically and experimentally, and a numerical model to simulate the generation and propagation of ultrasonic waves in the ablation regime was developed. This model was based on the simulation of ultrasonic generation and propagation caused by the net reaction force that was directly converted from the laser intensity absorbed onto the surface. This model was also extended as a model for internal defect detection. A steel specimen containing artificial internal defects was fabricated and inspected by using the through-transmission (T-scan) and pulse-echo (B-scan) modes. Clear amplitude reduction was observed in the transmitted waves at the defect positions in T-scan images, while B-scan images clearly showed the defect echoes arriving at different times depending on the depth location of internal defects. These results demonstrate that longitudinal waves excited in the ablation regime can be effectively used for internal defect detection.

Similar content being viewed by others

References

C. B. Scruby and L. E. Drain, Laser ultrasonics: Techniques and applications, Adam Hilger, Bristol, UK (1990).

S. Choi, H. Seo and K. Y. Jhang, Noncontact evaluation of acoustic nonlinearity of a laser-generated surface wave in a plastically deformed aluminum alloy, Research in Nondestructive Evaluation, 26 (1) (2015) 13–22.

S. Choi and K. Y. Jhang, Influence of slit width on harmonic generation in ultrasonic surface waves excited by masking a laser beam with a line arrayed slit, NDT&E International, 57 (2013) 1–6.

T. W. Murray, S. Krishnaswamy and J. D. Achenbach, Laser generation of ultrasound in films and coatings, Applied Physics Letters, 74 (1999) 3561–3563.

A. Abbate, S. C. Schroeder, B. E. Knight, F. Yee, J. Frankel and P. Das, Characterization of surfaces and coatings using laser-generated ultrasonic surface waves, Review of Progress in QNDE, 15 (1996) 585–592.

Z. Zhou, K. Zhang, J. Zhou, G. Sun and J. Wang, Application of laser ultrasonic technique for non-contact detection of structural surface breaking cracks, Optics & Laser Technology, 73 (2015) 173–178.

F. Hernandez-Valle, B. Dutton and R. S. Edwards, Laser ultrasonic characterization of branched surface-breaking defects, NDT&E International, 68 (2014) 113–119.

Y. K. An, B. Park and H. Sohn, Complete noncontact laser ultrasonic imaging for automated crack visualization in a plate, Smart Materials and Structures, 22 (2) (2013) 025022.

I. Arias and J. D. Achenbach, A model for the ultrasonic detection of surface-breaking cracks by the scanning laser source technique, Wave Motion, 39 (1) (2004) 61–75.

R. Quintero, F. Simonetti, P. Howard, J. Friedl and A. Sellinger, Noncontact laser ultrasonic inspection of ceramic matrix composites (CMCs), NDT&E International, 88 (2017) 8–16.

N. Hosoya, R. Umino, A. Kanda, I. Kajiwara and A. Yoshinaga, Lamb wave generation using nanosecond laser ablation to detect damage, Journal of Vibration and Control (2017) 1–12.

N. Fuse, K. Kaneshige and H. Watanabe, Development of thickness measurement system for hot steel with laserultrasonic wave technology, Materials Transactions, 55 (7) (2014) 1011–1016.

S. J. Davies, C. Edwards, G. S. Taylor and S. B. Palmer, Laser-generated ultrasound: its properties, mechanisms and multifarious applications, Journal of Physics D: Applied Physics, 26 (3) (1993) 329–348.

R. J. Dewhurst, D. A. Hutchins, S. B. Palmer and C. B. Scruby, Quantitative measurements of laser-generated acoustic waveforms, Journal of Applied Physics, 53 (1982) 4064–4071.

T. W. Murray and J. W. Wagner, Thermoelastic and ablative generation of ultrasound: Source effects, Review of Progress in QNDE, 17 (1998) 619–625.

D. A. Hutchins, R. J. Dewhurst and S. B. Palmer, Directivity patterns of laser-generated ultrasound in aluminum, The Journal of the Acoustical Society of America, 70 (1981) 1362–1369.

S. N. Hopko and I. C. Ume, Laser ultrasonics: simultaneous generation by means of thermoelastic expansion and material ablation, Journal of Nondestructive Evaluation, 18 (3) (1999) 91–98.

S. E. Kruger and M. Lord, Ultrasonic wave generation by lasers on different metal surfaces, AIP Conference Proceedings, 894 (2007) 209–216.

B. Mi and I. C. Ume, Parametric studies of laser generated ultrasonic signals in ablative regime: Time and frequency domains, Journal of Nondestructive Evaluation, 21 (1) (2002) 23–33.

J. Kim and K. Y. Jhang, Non-contact measurement of elastic modulus by using laser ultrasound, International Journal of Precision Engineering and Manufacturing, 16 (5) (2015) 905–909.

D. Lévesque, Y. Asaumi, M. Lord, C. Bescond, H. Hatanaka, M. Tagami and J. P. Monchalin, Inspection of thick welded joints using laser-ultrasonic SAFT, Ultrasonics, 69 (2016) 236–242.

D. Lévesque, G. Rousseau, P. Wanjara, X. Cao and J. P. Monchalin, Laser-ultrasonic inspection of hybrid laser-arc welded HSLA-65 steel, AIP Conference Proceedings, 1581 (1) (2014) 405–411.

M. H. Sadd, Elasticity: Theory, applications, and numerics, Academic Press, Burlington, MA, USA (2009).

V. K. Chillara, B. Ren and C. J. Lissenden, Guided wave mode selection for inhomogeneous elastic waveguides using frequency domain finite element approach, Ultrasonics, 67 (2016) 199–211.

S. Choi and K. Y. Jhang, Thermal damages on the surface of a silicon wafer induced by a near-infrared laser, Optical Engineering, 53 (2014) 017103.

S. Choi and K. Y. Jhang, Influence of repetitive pulsed laser irradiation on the surface characteristics of an aluminum alloy in the melting regime, Journal of Mechanical Science and Technology, 29 (1) (2015) 335–340.

D. Deng and S. Kiyoshima, Numerical simulation of residual stresses induced by laser beam welding in a SUS316 stainless steel pipe with considering initial residual stress influences, Nuclear Engineering and Design, 240 (4) (2010) 688–696.

A. J. Pinkerton and L. Li, An analytical model of energy distribution in laser direct metal deposition, Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 218 (2004) 363–374.

S. Y. Zhang, M. Paul, S. Fassbender, U. Schleichert and W. Arnold, Experimental study of laser-generated shear waves using interferometry, Research in Nondestructive Evaluation, 2 (3) (1990) 143–155.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Tae June Kang

Sungho Choi is currently a Research Professor of mechanical engineering at Hanyang University, Seoul, Korea. He received his B.S. and Ph.D. in mechanical engineering from Hanyang University, Seoul, Korea, in 2010 and 2015, respectively. His research interests include laser-material interactions and ultrasonic nondestructive evaluation.

Kyung-Young Jhang received his B.S. and M.S. in precision mechanical engineering from Hanyang University, Seoul, Korea, in 1983 and 1985, respectively. In 1991, he received his Ph.D. in precision mechanical systems design from the Tokyo Institute of Technology, Yokohama, Japan. He has been a Professor at Hanyang University, Seoul, Korea since 1992. His research interests include experimental mechanics, ultrasonic nondestructive evaluation techniques, optical measuring systems, visual image processing, random signal processing, and lasermaterial interactions.

Rights and permissions

About this article

Cite this article

Choi, S., Jhang, KY. Internal defect detection using laser-generated longitudinal waves in ablation regime. J Mech Sci Technol 32, 4191–4200 (2018). https://doi.org/10.1007/s12206-018-0817-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-018-0817-1