Abstract

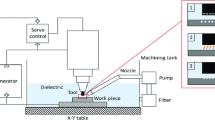

A dielectric fluid plays a significant role on the machining efficiency of Electric discharge machining (EDM). Two phase (liquid-air) dielectric medium was utilized in near-dry (EDM). It is an environmentally friendly process. The present article reports the effect of different dielectric mediums on responses of near-dry EDM. Dielectric mediums used for experimentation were water-air, EDM oil-air and glycerin-air mixtures. The process parameters selected for experimentation were current, duty factor, flushing pressure and lift. Material removal mechanism of near-dry EDM is investigated using imaging techniques. Dielectric fluid with higher viscosity and higher Prandtl number provided better results than fluids with lower viscosity. The results reveal that the Material removal rate (MRR) with glycerin-air dielectric medium is about three-times higher than other dielectric medium used with negligible recast layer. The tool wear rate is negligible in near-dry EDM in relation to all the dielectric mediums.

Similar content being viewed by others

References

M. A. Norliana, G. S. Darius and M. F. Bahari, A review on current research trends in electrical discharge machining (EDM), Int. J. of Machine Tools & Manufacture, 47 (7-8) (2007) 1214–1228.

A. Pandey and S. Singh, Current research trends in variants of electrical discharge machining a review, Int. J. of Engineering Science and Technology, 2 (6) (2010) 2172–2191.

B. C. Nader, C. Antonio, O. Nasreddine and L. Taieb, Threedimensional study of heat and fluid flow of air and dielectric liquids filling containers partially heated from below and entirely cooled from above, International Communications in Heat and Mass Transfer, 37 (5) (2010) 449–456.

C. C. Kao, J. Tao and A. J. Shih, Near dry electrical discharge machining, Int. J. of Machine Tools & Manufacture, 47 (15) (2007) 2273–2281.

M. Kunieda and M. Yoshida, Electrical discharge machining in gas, CIRP Ann., 46 (1) (1997) 143–146.

M. L. Jeswani, Electrical discharge machining in distilled water, Wear, 72 (1) (1981) 81–88.

S. T. Jilani and P. C. Pandey, Experimental investigations into the performance of water as dielectric in EDM, Int. J. of Machine Tool Design and Research, 24 (1) (1984) 31–43.

L. Tang and Y. T. Du, Experimental study on green electrical discharge machining in tap water of Ti-6Al-4V and parameters optimization, Int. J. of Advanced Manufacturing Technology, 70 (1-4) (2013) 469–475.

S. L. Chen, B. H. Yan and F. Y. Huang, Influence of kerosene and distilled water as dielectrics on the electric discharge machining characteristic of Ti-6Al-4V, J. of Material Processing Technology, 87 (1-3) (1999) 107–111.

T. Masuzawa, K. Tanaka and Y. Nakamura, Water-based dielectric solution for EDM, Ann. CIRP, 32 (1) (1983) 119–122.

W. Koenig and L. Joerres, An aqueous solutions of organic compounds as dielectric for EDM sinking, CIRP Ann.-Manufacturing Technology, 36 (1) (1987) 105–109.

T. Tanimura, K. Isuzugawa, I. Fujita, A. Iwamoto and T. Kamitani, Development of EDM in the mist, Proc. of Ninth International Symposium of Electro Machining (ISEM IX), Nagoya, Japan (1989) 313–316.

J. Tao, A. J. Shih and N. Jun, Near-dry EDM milling of mirror-like surface finish, Int. J. of Electrical Machining, 13 (2008) 29–33.

J. Tao, Investigation of dry and near-dry electrical discharge milling processes, A Dissertation, The University of Michigan (2008).

K. Dhakar and A. Dvivedi, Parametric evaluation on neardry electric discharge machining, Materials and Manufacturing Processes (2015).

B. K. Bhuyan and V. Kumar, Experimental modeling and multi-objective optimization of traveling wire electrochemical spark machining (TW-ECSM) process, JMST, 27 (8) (2013) 2467–2476.

K. H. Grote and E. K. Antonsson, Handbook of mechanical engineering, 28th Ed., Springer (2009).

V. L. Streeter, Handbook of fluid dynamics, First Ed., McGraw-Hill, New York (1961).

S. N. Jayasinghe and M. J. Edirisinghe, Effect of viscosity on the size of relics produced by electrostatic atomization, Aerosol Science, 33 (10) (2002) 1379–1388.

C. C. Kao, J. Tao, S. W. Lee and A. J. Shih, Dry wire electrical discharge machining of thin workpiece, Trans. NAMRI/SME, 34 (2006) 253–260.

M. Kunieda, B. Lauwers, K. P. Rajurkar and B. M. chumacher, Advancing EDM through fundamental insight into the process, CIRP Ann.-Manufacturing Technology, 54 (2) (2005) 64–87.

J. Tao, A. J. Shih and N. Jun, Experimental study of the dry and near-dry electrical discharge milling processes, J. of Manufacturing Science and Engineering, 130 (1) (2008) 011002–1-011002-8.

J. P Kruth, L. L. Stevens, B. L. Froyen and K. U. Leuven, Study of the white layer of a surface machined by diesinking electrodischarge machining, Ann. CIRP, 44 (1) (1995) 169–172.

N. Pragadish and M. Pradeep Kumar, Surface characteristics analysis of dry EDMed AISI D2 steel using modified tool design, JMST, 29 (4) (2015) 1737–1743.

J. C. Rebelo, A. M. Dias, D. Kremer and J. L. Lebrun, Influence of EDM pulse energy on the surface integrity of martensitic steels, J. of Materials Processing Technology, 84 (1-3) (1998) 90–96.

S. Kumar, A. Batish, R. Singh and T. P. Singh, A hybrid Taguchi-artificial neural network approach to predict surface roughness during electric discharge machining of titanium alloys, JMST, 28 (7) (2014) 2831–2844.

G. K. M. Rao, S. Satyanarayan and M. Praveen, Influence of machining parameters on electric discharge machining of maraging steels an experimental investigation, Proc. of the World Congress on Engineering, 2 (2008) 1536–1541.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Hyung Wook Park

Krishnakant Dhakar is a Research Scholar in Mechanical and Industrial Engineering Department, IIT Roorkee, India. He obtained his M.E. in Production Engineering from PEC University of Technology, Chandigarh, India in 2009. In 2007, he completed his B.E. in Industrial and Production Engineering from Jabalpur Engineering College, Jabalpur Madhya Pradesh, India. His area of research is advanced manufacturing processes.

Akshay Dvivedi is an Associate Professor in Mechanical and Industrial Engineering, IIT Roorkee, India. He received his Ph.D. and M.Tech. in Mechanical Engineering from IIT Roorkee, India. His interests include quality engineering, advanced manufacturing processes, automobile engineering, robotics, advanced manufacturing processes and CAD/CAM/CAE.

Amit Kumar Dhiman is an Associate Professor of Chemical Engineering, Indian Institute of Technology Roorkee, India. He received his Ph.D. in Chemical Engineering from IIT Kanpur, India. His areas of interest are fluid mechanics, CFD, non-Newtonian fluids, bluff body flow and heat transfer, FVM and FDM Solvers.

Rights and permissions

About this article

Cite this article

Dhakar, K., Dvivedi, A. & Dhiman, A. Experimental investigation on effects of dielectric mediums in near-dry electric discharge machining. J Mech Sci Technol 30, 2179–2185 (2016). https://doi.org/10.1007/s12206-016-0425-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-016-0425-x