Abstract

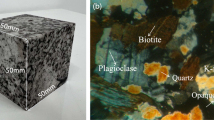

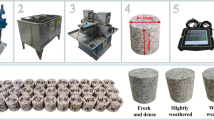

PFC-GBM (Particle Flow Code-Grain Based Model) is the major and fundamental method to simulate rock behaviors in this paper. Geo-materials are composed of micro-grains, the behavior of these grains and the interface between them influence macroscopic behavior of materials. Traditional PFC simulation method could simulate the integral micro-behavior of material, and PFC-GBM simulation focuses on every different grains and interfaces to simulate micro-heterogeneity of material. In this paper, an attempt is made to investigate the strength of rock masses and the development of micro-cracks under thermal-mechanical coupling effect. For this purpose, a numerical model is established based on mineral analysis and pre-existing mechanical experiments of Granite from one of complex tunnels in Yunnan Province. After establishing the model, the specimen were first heated and then compressed according to test sequence of laboratory experiments. The simulation results are calibrated to match the laboratory test results including thermal behaviors and fracture development. The conclusion of simulations show that both of thermal behaviors and fracture development are depended on the micro-heterogeneity of granite in UCS (Unconfined Compressive Strength) experiment, the characteristics of minerals influence the macroscopic fracture mechanism. The simulation reveals that in a certain range of temperature (40°C ~ 90°C), temperature increasing enhance the brittle damage of granite. The situation of 130°C had the obvious thermal-crack before loading and then exhibited a much lower peak strength and failure strain. This numerical observation may guide the underground construction in complex geo-environment.

Similar content being viewed by others

References

Bahrani, N., Potyondy, D. O., and Pierce, M. (2012). “Simulation of brazilian test using PFC2d Grain-Based Model.” Proc. 21st Canadian Rock Mechanics Symposium, Edmonton, Canada, 9p.

Bahrani, N., Valley, B., Kaiser, P. K., and Pierce, M. (2011). “Evaluation of PFC2d grain-based model for simulation of confinement dependent rock strength degradation and failure processes.” Proc. 45 th US Rock Mech. Symp., San Francisco, CA, USA, 10p.

Bewick, R. P., Kaiser, P. K., and Bawden, W. F. (2014). “DEM simulation of direct shear: 2. Grain boundary and mineral grain strength component influence on shear rupture.” Rock Mech Rock Eng, Vol. 47, Issue 5, pp. 1673–1692, DOI: 10.1007/s00603-013-0494-4.

Bewick, R. P., Kaiser, P. K., Bawden, W. F., and Bahrani, N. (2014). “DEM simulation of direct shear: 1. Rupture under constant normal stress boundary conditions.” Rock Mech Rock Eng, Vol. 47, Issue 5, pp. 1647–1671, DOI: 10.1007/s00603-013-0490-8.

Bewick, R. P., Valley, B., and Kaiser, P. K. (2012). “Effect of grain scale geometric heterogeneity on tensile stress generation in rock loaded in compression.” 46 th US Rock Mechanics/Geomechanics Symposium, Chicago, IL, USA, pp. 24–27.

Bock, H., Blumling, P., and Konietzky, H. (2006). “Study of the micromechanical behavior of the Opalinus Clay: An example of cooperation across the ground engineering disciplines.” Bull Eng Geol Env, Vol. 65, Issue 2, pp. 195–207, DOI: 10.1007/s10064-005-0019-9.

Chaki, S., Takarli, W. P., and Agbodjan (2008). “Influence of thermal damage on physical properties of a granite rock: Porosity, permeability and ultrasonic wave evolutions.” Construction and Building Materials, Vol. 22, Issue 7, pp. 1456–1461.

Chen, G. Q., Li, T. B., Zhang, G. F., and Yin, H. Y. (2014). “Temperature effect of rock burst for hard rock in deep-buried tunnel.” Natural Hazards, Vol. 72, No. 2, pp. 915–926.

Chen, Y. F., Li, D. Q., Jiang, Q. H., and Zhou, C. B. (2012). “Micromechanical analysis of anisotropic damage and its influence on effective thermal conductivity in brittle rocks.” International Journal of Rock Mechanics & Mining Sciences, Vol. 50, pp. 102–116.

Clauser, C. and Huenges, E. (1995). “Thermal conductivity of rocks and minerals.” American Geophysical Union: Rock Physics and Phase Relations-a Handbook of Physical Constants, Vol. 3, pp. 106–125.

Coulthard, M. A. (1999). “Applications of numerical modelling in underground mining and construction.” Geotech Geol Eng, Vol. 17, Issues 3–4, pp. 373–385.

Cundall, P. A. and Strack, O. (1979). “A discrete numerical model for granular assemblies.” Geotechnique, Vol. 29, No. 1, pp. 47–65, DOI: 10.1680/geot.1979.29.1.47.

David, C., MeneÂndez, B., and Darot, M. (1999). “Influence of stressinduced and thermal cracking on physical properties and microstructure of La Peyratte granite.” International Journal of Rock Mechanics and Mining Sciences, Vol. 36, Issue 4, pp. 433–448.

Feng, X. T. and Seto, M. (1999). “Fractal structure of the time distribution of microfracturing in rocks.” Geophysical Journal International, Vol. 136, No.1, pp. 275–285.

Ferrero, A. M., Migliazza, M., and Spagnoli, A. (2014). “Micromechanics of intergranular cracking due to anisotropic thermal expansion in calcite marbles.” Engineering Fracture Mechanics, Vol. 130, pp. 42–52.

Frankin, L. O. and Charles, E. H. Jr. (1982). “The specific heat capacity of biotite.” The Journal of Chemical Thermodynamics, Vol. 14, Issue 11, pp. 1029–1034.

Hallbauer, D. K., Wagner, H., and Cook, N. G. W. (1973). “Some observations concerning the microscopic and mechanical behaviour of quartzite specimens in stiff, triaxial compression tests.” Int. J. Mech. Min. Sci. Geomech. Abstr., Vol. 10, Issue 6, pp. 713–726.

Huotari, T. and Kukkonen, L. (2004). Thermal expansion proprieties of rocks: Literature survey and estimation of thermal expansion coefficient for Olkiluoto Mica Gneiss. Geological Survey of Finland.

Itasca Consulting Group, Inc (2004). UDEC — Universal Distinct Element Code, version 4.0. Minneapolis: ICG.

Itasca Consulting Group, Inc (2008). PFC 2d (Particle Flow Code in 2 dimensions), version 4.0. Minneapolis: ICG.

Ivars, D. M. (2010). Bonded particle model for jointed rock mass. Doctoral Thesis, Sweden: KTH.

Ivars, D. M., Potyondy, D. O., Pierce, M., and Cundall, P. A. (2008). The smooth-joint contact model. 8th World Congress on Computationa Mechanics/5th European Congress on Computational Methods in Applied Sciences and Engineering, Venice. Paper No. a2735. B.A. Schrefler and U. Perego, Eds. Barcelona, Spain: CIMNE.

Kranz, R. L. (1983). “Microcracks in rocks: A review.” Tectonophysics, Vol. 100, Issues 1–3, pp. 449–480, DOI: 10.1016/0040-1951(83)90198-1.

Lan, H., Martin, C. D., and Anderson, J. C. (2013). “Evolution of in situ rock mass damage induced by mechanical–thermal loading.” Rock Mech Rock Eng., Vol. 46, Issue 1, pp. 153–168, DOI: 10.1007/s00603-012-0248-8.

Lan, H., Martin, C. D., and Hu, B. (2010). “Effect of heterogeneity of brittle rock on micromechanical extensile behavior during compression loading.” J. Geophys. Res., Vol. 115, Issue B1, B01202, DOI: 10.1029/2009JB006496.

Lee, C., Lee, D., and Jeon, S. (2013). “The Influence of excavation damaged zone on the mechanical and thermal behavior of cement mortar block around an opening.” KSCE Journal of Civil Engineering, Vol. 17, No. 6, pp. 1263–1274, DOI: 10.1007/s12205-013-0206-3.

Lisjak, A. and Grasselli, G. (2014). “A review of discrete modeling techniques for fracturing processes in discontinuous rock masses.” Journal of Rock Mechanics and Geotechnical Engineering, Vol. 6, Issue 4, pp. 301–304.

Liu, J. J. and Liu, H. L. (2009). “Testing and analysis of thermal characteristics of rock.” West-china Exploration Engineering, Vol. 4, pp. 144–148 (in Chinese).

Ma, C. C., Li, T. B., Chen, G. Q., and Chen, Z. Q. (2015). “Micro particle model for hard brittle rock and the effect of unloading rock burst.” Chinese Journal of Rock Mechanics and Engineering, Vol. 34, No. 2, pp. 1–11 (in Chinese).

Mavko, G., Mukerji, T., and Dvorkin, J. (2003). The rock physics handbook: Tools for seismic analysis of porous media. Cambridge Univ. Press, NY.

Olsson, W. A. and Peng, S. S. (1976). “Microcrack nucleation in marble.” Int.J. Rock Mech. Min. Sci., Vol. 13, Issue 2, pp. 53–59.

Penumadu, D., Dutta, A. K., Luo, X., and Thomas, K. G. (2009). “Nano and neutron science applications for geomechanics.” KSCE Journal of Civil Engineering, Vol. 13, No. 4, pp. 233–242, DOI: 10.1007/s12205-009-0233-2.

Potyondy, D. O. (2010). “A grain-based model for rock: Approaching the true microstructure.” Proc. Proceedings of Rock Mechanics, in the Nordic Countries, 10p.

Potyondy, D. O. and Cundall, P. A. (2004). “A bonded-particle model for rock.” Int. J. Rock Mech. Min. Sci., Vol. 41, Issue 8, pp. 1329–1364, DOI: 10.1016/j.ijrmms.2004.09.011.

Wibberley, C. A. J., Petit, J. P., and Rives, T. (2000). “Micromechanics of shear rupture and the control of normal stress.” J. Struct. Geol., Vol. 22, Issue 4, pp. 411–427.

Yavuz, H., Demirdag, S., and Caran, S. (2009). “Thermal effect on the physical properties of carbonate rocks.” International Journal of Rock Mechanics & Mining Sciences, Vol. 47, Issue 1, pp. 94–103.

Zhang, Y. and Wang, Y. L. (2009), “Influence of rock nonhomogeneity on thermal cracking.” Journal of Henan Institute of Engineering, Vol. 21, No. 4, pp. 11–14 (in Chinese).

Zhao, Y. S., Meng, Q. R., Kang, T. H., Zhang, N., and Xi, B. P. (2008). “Micro-CT experimental technology and meso-investigation on thermal fracturing characteristics of granite.” Chinese Journal of Rock Mechanics and Engineering, Vol. 27, No. 1, pp. 28–34 (in Chinese).

Zuo, J. P., Xie, H. P., and Zhou, H. W. (2012). Investigation of mesofailure behavior of rock under thermal-mechanical coupled effects based on high temperature SEM. Science China (Physics, Mechanics & Astronomy), Vol. 55, No. 10, pp. 1855–1862 (in Chinese).

Zuo, J. P., Zhou, H. W., Fang, Y., and Huang, Y. M. (2012). “Experimental research on fracture characteristics of double-noteched Beishan granite under thermal-mechanical coupling effects.” Chinese Journal of Rock Mechanics and Engineering, Vol. 31, No. 4, pp. 738–745 (in Chinese).

Zuo, J. P., Zhou, H. W., Fang, Y., Meng, B. B., and Peng, R. D. (2011). “Experimental research on thermal cracking of deep granite in Beishan region, Gansu Province.” Chinese Journal of Rock Mechanics and Engineering, Vol. 30, No. 6, pp. 1107–1115 (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, Z., Li, T., Chen, G. et al. The Grain-Based Model Numerical Simulation of Unconfined Compressive Strength Experiment Under Thermal-Mechanical Coupling Effect. KSCE J Civ Eng 22, 2764–2775 (2018). https://doi.org/10.1007/s12205-017-1228-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12205-017-1228-z