Abstract

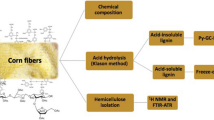

The presence of hemicellulose inhibits the enzymatic hydrolysis of lignocellulosic biomass. The purpose of this study is to investigate the effect of different hemicellulose fractions on the enzymatic hydrolysis and the way to eliminate the inhibiting effect caused by hemicellulose. Four kinds of hemicelluloses, namely, HXF, H15, H30, and H60, were first extracted from corn stover by ethanol fractional precipitation. The structures of hemicellulose samples were analyzed using Fourier transform infrared spectroscopy, 1H and 13C nuclear magnetic resonance, and high-performance ion chromatography. The results show that H30 has the strongest inhibition on the enzymatic hydrolysis of Avicel and corn stover, presenting inhibition ratio of 13.35% and 9.98%, respectively. The inhibition ratios of other hemicelluloses in Avicel and corn stover are 8–12% and 5–9%, respectively. However, the inhibiting effect caused by H30 is removed by adding hemicellulase, which even presents a 4.99% increase in the efficiency of enzymatic hydrolysis of corn stover. The corresponding glucose concentration reached 68.11 g/L. This research could help design effective processes to promote the enzymatic hydrolysis of lignocellulosic biomass.

Similar content being viewed by others

Data Availability

Data will be available on request.

References

Cherubini F, Strømman AH (2010) Production of biofuels and biochemicals from lignocellulosic biomass: estimation of maximum theoretical yields and efficiencies using matrix algebra. Energy Fuels 24:2657–2666. https://doi.org/10.1021/ef901379s

Fatma S, Hameed A, Noman M, Ahmed T, Shahid M, Tariq M, Sohail I, Tabassum R (2018) Lignocellulosic biomass: a sustainable bioenergy source for the future. Protein Pept Lett 25:148–163. https://doi.org/10.2174/0929866525666180122144504

Kubicek CP, Mikus M, Schuster A, Schmoll M, Seiboth B (2009) Metabolic engineering strategies for the improvement of cellulase production by hypocrea jecorina. Biotechnol Biofuels 2:19. https://doi.org/10.1186/1754-6834-2-19

Mateos E, Ormaetxea L (2018) Sustainable renewable energy by means of using residual forest biomass. Energies 12:13. https://doi.org/10.3390/en12010013

Lu X, Wang C, Li X, Zhao J (2017) Temperature and pH influence adsorption of cellobiohydrolase onto lignin by changing the protein properties. Bioresour Technol 245:819–825. https://doi.org/10.1016/j.biortech.2017.08.139

Mou H, Wu S, He M, Liu H, Huang H, Xu C (2018) Study of the difference between enzyme adsorption onto hydrotropic and alkali lignin separated from eucalyptus and bamboo. Bioresources 13:1441–1456. https://doi.org/10.15376/biores.13.1.1441-1456

Hu G, Heitmann JA, Zhong B, Lucia LA, Argyropoulos DS (2015) Quantitative study of the interfacial adsorption of cellullase to cellulose. J Phys Chem C 119:14160–14166. https://doi.org/10.1021/acs.jpcc.5b02011

Chen H, Zhao X, Liu D (2016) Relative significance of the negative impacts of hemicelluloses on enzymatic cellulose hydrolysis is dependent on lignin content: evidence from substrate structural features and protein adsorption. ACS Sustainable Chem Eng 4:6668–6679. https://doi.org/10.1021/acssuschemeng.6b01540

Mussatto SI, Fernandes M, Milagres AMF, Roberto IC (2008) Effect of hemicellulose and lignin on enzymatic hydrolysis of cellulose from brewer’s spent grain. Enzyme Microb Technol 43:124–129. https://doi.org/10.1016/j.enzmictec.2007.11.006

Dien BS, Sarath G, Pedersen JF, Sattler SE, Chen H, Funnell-Harris DL, Nichols NN, Cotta MA (2009) Improved sugar conversion and ethanol yield for forage sorghum (Sorghum bicolor L. Moench) lines with reduced lignin contents. Bioenerg Res 2:153–164. https://doi.org/10.1007/s12155-009-9041-2

Meng X, Wells T, Sun Q, Huang F, Ragauskas A (2015) Insights into the effect of dilute acid, hot water or alkaline pretreatment on the cellulose accessible surface area and the overall porosity of Populus. Green Chem 17:4239–4246. https://doi.org/10.1039/c5gc00689a

Ma J, Zhang X, Zhou X, Xu F (2014) Revealing the changes in topochemical characteristics of poplar cell wall during hydrothermal pretreatment. Bioenerg Res 7:1358–1368. https://doi.org/10.1007/s12155-014-9472-2

Leu SY, Zhu JY (2013) Substrate-related factors affecting enzymatic saccharification of lignocelluloses: our recent understanding. Bioenerg Res 6:405–415. https://doi.org/10.1007/s12155-012-9276-1

Sun SF, Yang HY, Yang J, Shi ZJ (2022) The effect of alkaline extraction of hemicellulose on cocksfoot grass enzymatic hydrolysis recalcitrance. Ind Crops Prod 178:114654. https://doi.org/10.1016/j.indcrop.2022.114654

Wang R, Yue J, Jiang J, Li J, Zhao J, Xia H, Wang K, Xu J (2021) Hydrothermal CO2-assisted pretreatment of wheat straw for hemicellulose degradation followed with enzymatic hydrolysis for glucose production. Waste Biomass Valor 12:1483–1492. https://doi.org/10.1007/s12649-020-01103-4

Qing Q, Yang B, Wyman CE (2010) Xylooligomers are strong inhibitors of cellulose hydrolysis by enzymes. Bioresour Technol 101:9624–9630. https://doi.org/10.1016/j.biortech.2010.06.137

Kumar R, Wyman CE (2009) Effect of xylanase supplementation of cellulase on digestion of corn stover solids prepared by leading pretreatment technologies. Bioresour Technol 100:4203–4213. https://doi.org/10.1016/j.biortech.2008.11.057

Várnai A, Huikko L, Pere J, Siika-Aho M, Viikari L (2011) Synergistic action of xylanase and mannanase improves the total hydrolysis of softwood. Bioresour Technol 102:9096–9104. https://doi.org/10.1016/j.biortech.2011.06.059

Shen L, Wang C, Chen J (2017) Photometric determination of the activity of cellulase and xylanase via measurement of formation of gold nanoparticles. Microchim Acta 184:163–168. https://doi.org/10.1007/s00604-016-1979-0

Wang Q, Wang Z, Shen F, Hu J, Sun F, Lin L, Yang G, Zhang Y, Deng S (2014) Pretreating lignocellulosic biomass by the concentrated phosphoric acid plus hydrogen peroxide (PHP) for enzymatic hydrolysis: evaluating the pretreatment flexibility on feedstocks and particle sizes. Bioresour Technol 166:420–428. https://doi.org/10.1016/j.biortech.2014.05.088

Wang Q, Tian D, Hu J, Shen F, Yang G, Zhang Y, Deng S, Zhang J, Zeng Y, Hu Y (2018) Fates of hemicellulose, lignin and cellulose in concentrated phosphoric acid with hydrogen peroxide (PHP) pretreatment. RSC Adv 8:12714–12723. https://doi.org/10.1039/c8ra00764k

Peng F, Ren JL, Xu F, Bian J, Peng P, Sun RC (2009) Comparative study of hemicelluloses obtained by graded ethanol precipitation from sugarcane bagasse. J Agric Food Chem 57:6305–6317. https://doi.org/10.1021/jf900986b

Ibáñez AB, Bauer S (2014) Downscaled method using glass microfiber filters for the determination of Klason lignin and structural carbohydrates. Biomass Bioenergy 68:75–81. https://doi.org/10.1016/j.biombioe.2014.06.013

Yang Q, Pan X (2016) Correlation between lignin physicochemical properties and inhibition to enzymatic hydrolysis of cellulose. Biotechnol Bioeng 113:1213–1224. https://doi.org/10.1002/bit.25903

Yoo CG, Li M, Meng X, Pu Y, Ragauskas AJ (2017) Effects of organosolv and ammonia pretreatments on lignin properties and its inhibition for enzymatic hydrolysis. Green Chem 19:2006–2016. https://doi.org/10.1039/c6gc03627a

Sun JX, Sun XF, Sun RC, Su YQ (2004) Fractional extraction and structural characterization of sugarcane bagasse hemicelluloses. Carbohydr Polym 56:195–204. https://doi.org/10.1016/j.carbpol.2004.02.002

Morrison IM (1974) Changes in the hemicellulosic polysaccharides of rye-grass with increasing maturity. Carbohydr Res 36:45–51. https://doi.org/10.1016/S0008-6215(00)81991-6

Sun JX, Sun XF, Sun RC, Fowler P, Baird MS (2003) Inhomogeneities in the chemical structure of sugarcane bagasse lignin. J Agric Food Chem 51:6719–6725. https://doi.org/10.1021/jf034633j

Sun RC, Fang JM, Goodwin A, Lawther JM, Bolton AJ (1998) Fractionation and characterization of polysaccharides from abaca fibre. Carbohydr Polym 37:351–359. https://doi.org/10.1016/S0144-8617(98)00046-0

Chaikumpollert O, Methacanon P, Suchiva K (2004) Structural elucidation of hemicelluloses from Vetiver grass. Carbohydr Polym 57:191–196. https://doi.org/10.1016/j.carbpol.2004.04.011

Gruppen H, Hamer RJ, Voragen AGJ (1992) Water-unextractable cell wall material from wheat flour. 2. Fractionation of alkali-extracted polymers and comparison with water-extractable arabinoxylans. J Cereal Sci 16:53–67. https://doi.org/10.1016/S0733-5210(09)80079-9

Sun R, Lawther JM, Banks WB (1996) Fractional and structural characterization of wheat straw hemicelluloses. Carbohydr Polym 29:325–331. https://doi.org/10.1016/S0144-8617(96)00018-5

Gupta SK, Madan RN, Bansal MC (1987) Chemical composition of pinus caribaea hemicellulose. Tappi J 70:113–114. https://doi.org/10.5555/19860612224

Schooneveld-Bergmans MEF, Beldman G, Voragen AGJ (1999) Structural features of (Glucurono)arabinoxylans extracted from wheat bran by barium hydroxide. J Cereal Sci 29:63–75. https://doi.org/10.1006/jcrs.1998.0222

Delcour JA, Van Win H, Grobet PJ (1999) Distribution and structural variation of arabinoxylans in common wheat mill streams. J Agric Food Chem 47:271–275. https://doi.org/10.1021/jf9805294

Xu F, Sun JX, Liu CF, Sun RC (2006) Comparative study of alkali- and acidic organic solvent-soluble hemicellulosic polysaccharides from sugarcane bagasse. Carbohydr Res 341:253–261. https://doi.org/10.1016/j.carres.2005.10.019

Rao MS, Muralikrishna G (2004) Structural analysis of arabinoxylans isolated from native and malted finger millet (Eleusine coracana, ragi). Carbohydr Res 339:2457–2463. https://doi.org/10.1016/j.carres.2004.07.005

Gabrielii I, Gatenholm P, Glasser WG, Jain RK, Kenne L (2000) Separation, characterization and hydrogel-formation of hemicellulose from aspen wood. Carbohydr Polym 43:367–374. https://doi.org/10.1016/S0144-8617(00)00181-8

Imamura T, Watanabe T, Kuwahara M, Koshijima T (1994) Ester linkages between lignin and glucuronic acid in lignin-carbohydrate complexes from Fagus crenata. Phytochemistry 37:1165. https://doi.org/10.1016/S0031-9422(00)89551-5

Izydorczyk MS, Biliaderis CG (1995) Cereal arabinoxylans: advances in structure and physicochemical properties. Carbohydr Polym 28:33–48. https://doi.org/10.1016/0144-8617(95)00077-1

Linder Å, Bergman R, Bodin A, Gatenholm P (2003) Mechanism of assembly of xylan onto cellulose surfaces. Langmuir 19:5072–5077. https://doi.org/10.1021/la0341355

Zhang J, Tang M, Viikari L (2012) Xylans inhibit enzymatic hydrolysis of lignocellulosic materials by cellulases. Bioresour Technol 121:8–12. https://doi.org/10.1016/j.biortech.2012.07.010

Qing Q, Wyman CE (2011) Hydrolysis of different chain length xylooliogmers by cellulase and hemicellulase. Bioresour Technol 102:1359–1366. https://doi.org/10.1016/j.biortech.2010.09.001

Yang B, Wyman CE (2006) BSA treatment to enhance enzymatic hydrolysis of cellulose in lignin containing substrates. Biotechnol Bioeng 94:611–617. https://doi.org/10.1002/bit.20750

Mes-Hartree M, Saddler JN (1983) The nature of inhibitory materials present in pretreated lignocellulosic substrates which inhibit the enzymatic hydrolysis of cellulose. Biotechnol Lett 5:531–536. https://doi.org/10.1007/BF01184944

Funding

This work was financially supported by the National Natural Science Foundation of China (Nos. 22078308 and 22261132515), Young Elite Scientists Sponsorship Program by Henan Association for Science and Technology (No. 2022HYTP018), Innovation Leadership Program in Sciences and Technologies for Central Plains Talent Plan (No. 214200510009), Program for Science & Technology Innovative Research Team in the University of Henan Province (No. 22IRTSTHN007), Key Program of Henan Provincial Science and Technology R&D Plan Joint Fund for Cultivation of Superior Disciplines (No. 222301420008), Innovation Leadership Program in Sciences and Technologies for Zhengzhou Talent Gathering Plan, Innovation Leadership Program in Sciences and Technologies and Local Outstanding Talents for Zhengzhou Talent Gathering Plan (No. 20180400042), Program of Processing and Efficient Utilization of Biomass Resources of Henan Center for Outstanding Overseas Scientists (No. GZS2022007).

Author information

Authors and Affiliations

Contributions

Conceptualization: Jingliang Xu, Wenlong Xiong; methodology: Jingliang Xu, Wenlong Xiong, Zhanqiang Yan; investigation: Jingliang Xu, Wenlong Xiong, Zhanqiang Yan, Md Asraful Alam; supervision: Jingliang Xu, Zili Zhan; writing—original draft: Zhanqiang Yan, Jinfeng Li; writing—review and editing: Jingliang Xu, Wenlong Xiong, Md Asraful Alam, Shen Zhang; funding: Jingliang Xu, Wenlong Xiong.

Corresponding authors

Ethics declarations

Ethics Approval

This article does not contain any studies with humans or animals performed by any of the authors.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yan, Z., Alam, M.A., Li, J. et al. Effect of Hemicelluloses Fractionated by Graded Ethanol Precipitation from Corn Stover on the Enzymatic Hydrolysis of Lignocellulosic Biomass. Bioenerg. Res. (2024). https://doi.org/10.1007/s12155-024-10745-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12155-024-10745-4