Abstract

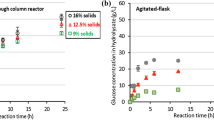

Cellulolytic and hemicellulolytic enzymes are essential to make feasible the fully biochemical route for second-generation ethanol production. Solid-state fermentation figures as a low-cost and sustainable way of obtaining such enzymes by using agro-industrial by-products as substrates. In the current paper, thermal conditions and enzymatic activities from the cultivations of Myceliophthora thermophila, Trichoderma reesei, and Aspergillus niger were evaluated. Mixtures of sugarcane bagasse (SCB) as fibers or powder and wheat bran (WB) were used as substrates within a packed-bed bioreactor with variable packing density, as well as under two fluid flow configurations. Using SCB as fibers and WB 7:3 w/w (packing density 0.1 g/cm3) for M. thermophila, endoglucanase and xylanase activities overcame 850 and 3850 U/g, with temperature rise < 1 °C. Cultivations of M. thermophila and T. reesei in pure WB or with SCB as powder led to temperature rises of 7 to 16 °C, due to lower bed porosity. A. niger cultivations provided endoglucanase activities around 15 U/g under 8 ºC of maximum temperature rise, with no difference among percolating air and jacket water flowing in co- or counter current. The reported results address the importance of a strategic definition of the porous media composition and packing technique for a successful scale-up of the bioprocess, while giving operational flexibility in terms of fluid flow configuration.

Similar content being viewed by others

References

BNEF (2013) Global renewable energy market outlook 2013. In: Bloom. New Energy Financ. http://about.bnef.com/presentations. Accessed 20 Jun 2016

UNICA Final report for the 2020/2021 harvest. http://www.unicadata.com.br. Accessed 30 Mar 2023

Diniz MP, Carreiro SC, Ságio SA et al (2023) Transformation of solid waste into renewable energy: perspectives for the production of 2G biofuels. Eng Agrícola 43:1–9. https://doi.org/10.1590/1809-4430

de Oliveira SP, Rodrigues NA, Casciatori-Frassatto PA, Casciatori FP (2020) Solid-liquid extraction of cellulases from fungal solid-state cultivation in a packed bed bioreactor. Korean J Chem Eng 37:1530–1540

Casciatori FP, Casciatori-Frassatto PA (2018) Enzymes for the Biochemical Route of Second-Generation Ethanol: Production by Solid-State Cultivation as a Feasible and Sustainable Alternative. In: Brienzo M (ed) Bioethanol and Beyond: Advances in Production Process and Future Directions. Nova Science Publishers Inc, Hauppauge, NY, pp 285–314

Reshmy R, Narisetty V, Tarafdar A et al (2022) An overview of cellulase immobilization strategies for biofuel production. Bioenergy Res. https://doi.org/10.1007/s12155-022-10431-3

Diniz da Silva MP, Casciatori FP, Thoméo JC, Grajales LM (2024) Heat analysis of a sugarcane bagasse and wheat bran system in rotating drum bioreactor for cellulase production. In: Grajales Agudelo LM, Serra JCV, Collicchio E (eds) Agroenergy: Renewable and Sustainable Energy, First. Elsevier Ltd. Chapter 19. https://doi.org/10.1016/B978-0-443-21430-1.00008-9

Klein-Marcuschamer D, Oleskowicz-Popiel P, Simmons BA, Blanch HW (2012) The challenge of enzyme cost in the production of lignocellulosic biofuels. Biotechnol Bioeng 109:1083–1087. https://doi.org/10.1002/bit.24370

Perez CL, Casciatori FP, Thoméo JC (2021) Improving enzyme production by solid-state cultivation in packed-bed bioreactors by changing bed porosity and airflow distribution. Bioprocess Biosyst Eng 44:537–548

Grajales Agudelo LM, Serra JCV, Collicchio E (2024) Agroenergy: Renewable and Sustainable Energy. First, Elsevier Ltd, p 400

Tada ÉFR, Agudelo LMG, Thoméo JC (2019) Water holding capacity and heat transfer aspects of a mixture of sugar cane bagasse and wheat bran in a partially filled rotating drum. Brazilian J Chem Eng 36:1131–1141. https://doi.org/10.1590/0104-6632.20190363s20180245

Perez CL, Casciatori FP, Thoméo JC et al (2019) Strategies for scaling-up packed-bed bioreactors for solid-state fermentation: the case of cellulolytic enzymes production by a thermophilic fungus. Chem Eng J 361:1142–1151. https://doi.org/10.1016/j.cej.2018.12.169

Frassatto PAC, Casciatori FP, Thoméo JC et al (2021) β-Glucosidase production by Trichoderma reesei and Thermoascus aurantiacus by solid state cultivation and application of enzymatic cocktail for saccharification of sugarcane bagasse. Biomass Convers Biorefinery 11:503–513. https://doi.org/10.1007/s13399-020-00608-1

Zanelato AI, Shiota VM, Gomes E et al (2012) Endoglucanase production with the newly isolated Myceliophtora sp. I-1D3b in a packed bed solid state fermentor. Brazilian J Microbiol 43:1536–1544

Tada ÉFR, Grajales LM, Lemos YP, Thoméo JC (2017) Mixture and motion of sugar cane bagasse in a rotating drum. Powder Technol 317:301–309. https://doi.org/10.1016/j.powtec.2017.05.006

Pandey A (2003) Solid-state fermentation. Biochem Eng J 13:81–84. https://doi.org/10.1016/S1369-703X(02)00121-3

Pandey A, Selvakumar P, Soccol CR, Nigam P (1999) Solid state fermentation for the production of industrial enzymes. Curr Sci 77:149–162

Dallastra EDG, Dias ACP, de Morais PB et al (2023) Development of a novel pilot-scale tray bioreactor for solid-state fermentation aiming at process intensification. Chem Eng Process - Process Intensif 193:19–21. https://doi.org/10.1016/j.cep.2023.109526

Rodríguez Couto S, Rivela I, Sanromán A (2001) Design of different bioreactor configurations: application to ligninolytic enzyme production in semi-solid-state cultivation. J Chem Technol Biotechnol 76:78–82. https://doi.org/10.1002/1097-4660(200101)76:1%3c78::AID-JCTB326%3e3.0.CO;2-K

Couto SR, Sanromán MÁ (2006) Application of solid-state fermentation to food industry—A review. J Food Eng 76:291–302. https://doi.org/10.1016/j.jfoodeng.2005.05.022

Rodrigues NA, Katayama ET, Casciatori FP (2022) Alternative strategies to perform solid-state cultivation in a multilayer packed-bed bioreactor: Continuous and cyclic operations. Chem Eng J 448:137726. https://doi.org/10.1016/j.cej.2022.137726

Casciatori FP, Bück A, Thoméo JC, Tsotsas E (2016) Two-phase and two-dimensional model describing heat and water transfer during solid-state fermentation within a packed-bed bioreactor. Chem Eng J 287:103–116. https://doi.org/10.1016/j.cej.2015.10.108

Matsumura Y, Sudo K, Shimizu K (1977) Enzymatic hydrolysis of woods. II. Effect of grinding and alkali treatment on hydrolysis of woods by Trichoderma viride cellulase. Mokuzai Gakkaishi 23(11):562–570

Canilha L, Chandel AK, Suzane dos Santos Milessi T et al (2012) Bioconversion of sugarcane biomass into ethanol: An overview about composition, pretreatment methods, detoxification of hydrolysates, enzymatic saccharification, and ethanol fermentation. J Biomed Biotechnol 2012:1–15. https://doi.org/10.1155/2012/989572

Casciatori FP, Laurentino CL, Taboga SR et al (2014) Structural properties of beds packed with agro-industrial solid by-products applicable for solid-state fermentation: Experimental data and effects on process performance. Chem Eng J 255:214–224. https://doi.org/10.1016/j.cej.2014.06.040

Kalogeris E, Christakopoulos P, Katapodis P et al (2003) Production and characterization of cellulolytic enzymes from the thermophilic fungus Thermoascus aurantiacus under solid state cultivation of agricultural wastes. Process Biochem 38:1099–1104. https://doi.org/10.1016/S0032-9592(02)00242-X

dos Santos Gomes AC, Casciatori FP, Gomes E et al (2021) Growth kinetics of Myceliophthora thermophila M.7·7 in solid-state cultivation. J Appl Microbiol 130:90–99. https://doi.org/10.1111/jam.14774

Ghose TK (1987) Measurement of cellulase activities 59:257–268. https://doi.org/10.1351/pac198759020257

Ghose TK, Bisaria VS (1987) Measurement of hemicellulase activities part 1: xylanases. Pure Appl Chem 59:1739–1751. https://doi.org/10.1351/pac198759121739

Miller GL (1959) Use of Dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428. https://doi.org/10.1021/ac60147a030

Pandey A (1991) Effect of particle size of substrate of enzyme production in solid-state fermentation. Bioresour Technol 37:169–172. https://doi.org/10.1016/0960-8524(91)90206-Y

Farinas CS (2015) Developments in solid-state fermentation for the production of biomass-degrading enzymes for the bioenergy sector. Renew Sustain Energy Rev 52:179–188. https://doi.org/10.1016/j.rser.2015.07.092

Rahardjo YSP, Jolink F, Haemers S et al (2005) Significance of bed porosity, bran and specific surface area in solid-state cultivation of Aspergillus oryzae. Biomol Eng 22:133–139. https://doi.org/10.1016/j.bioeng.2005.05.002

Pitol LO, Biz A, Mallmann E et al (2016) Production of pectinases by solid-state fermentation in a pilot-scale packed-bed bioreactor. Chem Eng J 283:1009–1018. https://doi.org/10.1016/j.cej.2015.08.046

Biz A, Finkler ATJ, Pitol LO et al (2016) Production of pectinases by solid-state fermentation of a mixture of citrus waste and sugarcane bagasse in a pilot-scale packed-bed bioreactor. Biochem Eng J 111:54–62. https://doi.org/10.1016/j.bej.2016.03.007

Portilho L, Perpétua F, Valente I et al (2020) Metarhizium anisopliae conidia production in packed-bed bioreactor using rice as substrate in successive cultivations. Process Biochem 97:104–111. https://doi.org/10.1016/j.procbio.2020.07.002

da Cunha LP, Casciatori FP, de Cenço LI, Thoméo JC (2019) Production of conidia of the entomopathogenic fungus Metarhizium anisopliae ICB 425 in a tray bioreactor. Bioprocess Biosyst Eng 42:1757–1768. https://doi.org/10.1007/s00449-019-02172-z

Grajek W (1988) Cooling aspects of solid-state cultures of mesophilic and thermophilic fungi. J Ferment Technol 66:675–679

Saucedo-Castañeda G, Gutierrez-Rojas M, Bacquet G et al (1990) Heat transfer simulation in solid substrate fermentation. Biotechnol Bioeng 35:802–808

Gomes E, Guez MAU, Martin N, Da Silva R (2007) Enzimas termoestáveis: Fontes, produção e aplicação industrial. Quim Nova 30:136–145. https://doi.org/10.1590/S0100-40422007000100025

Casciatori FP, Laurentino CL, Magdaleno Lopes KC et al (2013) Stagnant effective thermal conductivity of agro-industrial residues for solid-state fermentation. Int J Food Prop 16:1578–1593. https://doi.org/10.1080/10942912.2011.603171

Ghildyal NP, Gowthaman MK, Raghava Rao KSMS, Karanth NG (1994) Interaction of transport resistances with biochemical reaction in packed-bed solid-state fermentors: Effect of temperature gradients. Enzyme Microb Technol 16:253–257. https://doi.org/10.1016/0141-0229(94)90051-5

Funding

The authors gratefully acknowledge the funding of this work by the São Paulo Research Foundation (FAPESP) (grants #2018/16689–1; #2018/00996–2; #2016/10636–8), the Brazilian National Council for Scientific and Technological Development (CNPq), grants #2018/430786–2; #448890/2014–3), and the Coordination for the Improvement of Higher Education Personnel (CAPES, Finance Code 001).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and experiments were performed by Fernanda Perpétua Casciatori, Nilton Silva Costa Mafra, Éverton Holanda Sales, and Natalia Alvarez Rodrigues. Processing of figures and graphics and analysis of the results were done by the four authors just mentioned plus Mariana Moreira Sidel Maia, Ana Caroline Pereira Dias, and Lina María Grajales. The first draft of the manuscript was written by Fernanda Perpétua Casciatori, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript for submission, as first version and after major revision.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Casciatori, F.P., Mafra, N.S.C., Rodrigues, N.A. et al. Flow configuration and Packing Density of Sugarcane Bagasse and Wheat Bran Affecting Enzymes Production by Solid-State Fermentation. Bioenerg. Res. 17, 187–197 (2024). https://doi.org/10.1007/s12155-023-10675-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-023-10675-7