Abstract

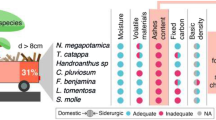

The multiple-species raw material and the poorly controlled carbonization in brick kilns are drawbacks for producing homogeneous and high-quality charcoal with the wood wastes derived from the sustainable forest management plans in Amazon. How much improvement is possible with the previous grouping of woods with similar properties is still unknown. Thus, the objective of this work was to compare the quality of charcoals derived from previously segregated into four distinct groups and non-segregated (traditional carbonization) wood wastes of 23 Amazon species carbonized in brick kilns. Charcoals were characterized by apparent relative density (ARD), moisture content (MC), friability (F), fixed carbon content (FC), volatile matter content (VM), ash content (AC), higher heating value (HHV), and energy density (ED). The group formed by the species Dinizia excelsa provided charcoals with the best quality (ARD = 0.737 g/cm3, AC = 1.20%, HHV = 28.9 MJ/kg, and ED = 21.3 MJ/m3). In contrast, traditional carbonization generated highly heterogeneous and friable charcoals. The segregation promoted average improvements of 22.0, 9.4, 2.0, 2.3, 1.0, and 23.6% in ARD, AC, FC, F, HHV, and ED of the charcoals, respectively. These results encourage the steel industry since it requires high-quality charcoal from legal sources for iron ore reduction.

Similar content being viewed by others

Data Availability

Datasets related to this article can be found at http://dx.doi.org/10.17632/rhznzkmb5z.1, an open-source online data repository hosted by Mendeley Data.

References

Surup GR, Trubetskaya A, Tangstad M (2020) Charcoal as an alternative reductant in ferroalloy production: a review. Processes 8:1432. https://doi.org/10.3390/pr8111432

Rodrigues T, Braghini Junior A (2019) Charcoal: a discussion on carbonization kilns. J Anal Appl Pyrolysis 143:104670. https://doi.org/10.1016/j.jaap.2019.104670

Surup GR, Trubetskaya A, Tangstad M (2021) Life cycle assessment of renewable reductants in the ferromanganese alloy production: a review. Processes 9:185. https://doi.org/10.3390/pr9010185

IBÁ - Brazilian Tree Industry (2022) IBÁ annual report 2022. IBÁ, São Paulo

Menucelli JR, Amorim EP, Freitas MLM et al (2019) Potential of Hevea brasiliensis clones, Eucalyptus pellita and Eucalyptus tereticornis wood as raw materials for bioenergy based on higher heating value. Bioenergy Res 1–8. https://doi.org/10.1007/s12155-019-10041-6

Chen Y, Tshabalala MA, Gao J et al (2014) Thermal behavior of extracted and delignified pine wood flour. Thermochim Acta 591:40–44. https://doi.org/10.1016/j.tca.2014.06.012

Lima MDR, Simetti R, Assis MRD et al (2020) Charcoal of logging wastes from sustainable forest management for industrial and domestic uses in the Brazilian Amazonia. Biomass Bioenergy 142:105804. https://doi.org/10.1016/j.biombioe.2020.105804

Pereira BLC, Carneiro ACO, Carvalho AMML et al (2013) Influence of chemical composition of Eucalyptus wood on gravimetric yield and charcoal properties. Bioresources 8:4574–4592. https://doi.org/10.15376/biores.8.3.4574-4592

Lima MDR, Patrício EPS, Barros Junior UO et al (2020) Logging wastes from sustainable forest management as alternative fuels for thermochemical conversion systems in Brazilian Amazon. Biomass Bioenergy 140:105660. https://doi.org/10.1016/j.biombioe.2020.105660

Lima MDR, Patrício EPS, Barros Junior UO et al (2021) Colorimetry as a criterion for segregation of logging wastes from sustainable forest management in the Brazilian Amazon for bioenergy. Renew Energy 163:792–806. https://doi.org/10.1016/j.renene.2020.08.078

Lima MDR, Ramalho FMG, Trugilho PF et al (2022) Classifying waste wood from Amazonian species by near-infrared spectroscopy (NIRS) to improve charcoal production. Renew Energy 12:3224. https://doi.org/10.1016/j.renene.2022.05.048

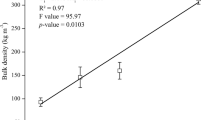

Lima MDR, Massuque J, Bufalino L et al (2022) Clarifying the carbonization temperature effects on the production and apparent density of charcoal derived from Amazonia wood wastes. J Anal Appl Pyrolysis 166:105636. https://doi.org/10.1016/j.jaap.2022.105636

Lima MDR, Trugilho PF, Bufalino L et al (2022) Efficiency of near-infrared spectroscopy in classifying Amazonian wood wastes for bioenergy generation. Biomass Bioenergy 166:106617. https://doi.org/10.1016/j.biombioe.2022.106617

Castro J, Nobre J, Napoli A et al (2019) Massaranduba sawdust: a potential source of charcoal and activated carbon. Polymers (Basel) 11:1276. https://doi.org/10.3390/polym11081276

Santos SFOM, Piekarski CM, Ugaya CML et al (2017) Life cycle analysis of charcoal production in masonry kilns with and without carbonization process generated gas combustion. Sustainability 9:1558. https://doi.org/10.3390/su9091558

Surup G, Kaffash H, Ma Y et al (2022) Life cycle based climate emissions of charcoal conditioning routes for the use in the ferro-alloy production. Energies (Basel) 15:3933. https://doi.org/10.3390/en15113933

Abreu Neto R, Assis AA, Ballarin AW, Hein PRG (2018) Dynamic hardness of charcoal varies according to the final temperature of carbonization. Energy Fuels 32:9659–9665. https://doi.org/10.1021/acs.energyfuels.8b02394

García R, Pizarro C, Lavín AG, Bueno JL (2014) Spanish biofuels heating value estimation. Part II: Proximate Analysis Data Fuel 117:1139–1147. https://doi.org/10.1016/j.fuel.2013.08.049

Gahane D, Biswal D, Mandavgane SA (2022) Life cycle assessment of biomass pyrolysis. Bioenergy Res 15:1387–1406. https://doi.org/10.1007/s12155-022-10390-9

Zimroz R, Bartkowiak A (2013) Two simple multivariate procedures for monitoring planetary gearboxes in non-stationary operating conditions. Mech Syst Signal Process 38:237–247. https://doi.org/10.1016/j.ymssp.2012.03.022

Mingoti SA (2005) Data analysis through multivariate statistical methods: an applied approach. Editora UFMG, Minas Gerais

Martínez MG, Floquet P, Dupont C et al (2020) Assessing the impact of woody and agricultural biomass variability on its behaviour in torrefaction through Principal Component Analysis. Biomass Bioenergy 134:105474. https://doi.org/10.1016/j.biombioe.2020.105474

Dufourny A, van de Steene L, Humbert G et al (2019) Influence of pyrolysis conditions and the nature of the wood on the quality of charcoal as a reducing agent. J Anal Appl Pyrolysis 137:1–13. https://doi.org/10.1016/j.jaap.2018.10.013

Silva FTM, Ataíde CH (2019) Valorization of Eucalyptus urograndis wood via carbonization: product yields and characterization. Energy 172:509–516. https://doi.org/10.1016/j.energy.2019.01.159

Soares JD, Paula MO, Carneiro ACO et al (2021) Parameters to determine mechanical strength of charcoal in a hydraulic press. Braz J Agric Sci 16:1–6. https://doi.org/10.5039/agraria.v16i4a9096

American Society for Testing and Materials (2013) D1762–84: Standard test method for chemical analysis of wood charcoal. ASTM International, Philadelphia

Cordero T, Marquez F, Rodriguez-Mirasol J, Rodriguez JJ (2001) Predicting heating values of lignocellulosics and carbonaceous materials from proximate analysis. Fuel 80:1567–1571. https://doi.org/10.1016/S0016-2361(01)00034-5

Assis MR, Brancheriau L, Napoli A, Trugilho PF (2016) Factors affecting the mechanics of carbonized wood: literature review. Wood Sci Technol 50:519–536. https://doi.org/10.1007/s00226-016-0812-6

Silva MRS, Ribeiro EAS, Barbosa JP et al (2018) Quality attributes of commercial charcoals produced in Amapá, a Brazilian state located in the Amazonia. Environ Dev Sustain. https://doi.org/10.1007/s10668-018-0216-x

Perdigão CRV, Júnior MMB, Gonçalves TAP et al (2020) Forestry control in the Brazilian Amazon I: wood and charcoal anatomy of three endangered species. IAWA J 41:490–509. https://doi.org/10.1163/22941932-bja10016

Braga Júnior MM, Souza FIB, Melo LEL (2021) Forestry control in the Brazilian Amazon II: charcoal anatomy of 21 species. IAWA J 42:299–321. https://doi.org/10.1163/22941932-bja10058

Braga Junior MM, Matos TS, Andrade GM et al (2021) Forestry control in the Brazilian Amazon: charcoal anatomy of tree species from protected areas. Aust J Bot 70:13–31. https://doi.org/10.1071/BT21062

Protásio TP, Lima MDR, Scatolino MV et al (2021) Charcoal productivity and quality parameters for reliable classification of Eucalyptus clones from Brazilian energy forests. Renew Energy 164:34–45. https://doi.org/10.1016/j.renene.2020.09.057

Protásio TP, Lima MDR, Teixeira RAC et al (2020) Influence of extractives content and lignin quality of Eucalyptus wood in the mass balance of pyrolysis process. Bioenergy Res. https://doi.org/10.1007/s12155-020-10166-z

Silva MG, Numazawa S, Araujo MM et al (2007) Charcoal from timber industry residues of three tree species logged in the municipality of Paragominas, PA. Acta Amazon 37:61–70. https://doi.org/10.1590/s0044-59672007000100007

Zainuddin MF, Rosnah S, Noriznan MM, Dahlan I (2014) Effect of moisture content on physical properties of animal feed pellets from pineapple plant waste. Agric Agric Sci Procedia 2:224–230. https://doi.org/10.1016/j.aaspro.2014.11.032

Canal WD, Carvalho AMM, Figueiró CG et al (2020) Impact of wood moisture in charcoal production and quality. Floresta e Ambiente 27:1–7. https://doi.org/10.1590/2179-8087.099917

Ramos DC, Carneiro ACO, Tangstad M et al (2019) Quality of wood and charcoal from Eucalyptus clones for metallurgical use. Floresta e Ambiente 26:e20180435. https://doi.org/10.1590/2179-8087.043518

Silva LFF, Castro ARS, Oliveira RS et al (2020) Selection of species and carbonization parameters of waste wood in Amazon. Pesqui Florest Bras 40:1–11. https://doi.org/10.4336/2020.pfb.40e201801737

Pereira BLC, Carvalho AMML, Oliveira AC et al (2016) Effect of wood carbonization in the anatomical structure and density of charcoal from Eucalyptus. Ciência Florestal 26:545–557. https://doi.org/10.5902/1980509822755

Hara K, Hayashi M, Sato M, Nagata K (2011) Continuous pig iron making by microwave heating with 12.5 kW at 2.45 GHz. J Microw Power Electromagn Energy 45:137–147. https://doi.org/10.1080/08327823.2011.11689808

Simetti R, Bonduelle GM, Silva DA (2018) Wood quality of five Eucalyptus species planted in Rio Grande do Sul, Brazil for charcoal production. J Trop For Sci 30:175–181. https://doi.org/10.26525/jtfs2018.30.2.175181

Sheng C, Azevedo JLT (2005) Estimating the higher heating value of biomass fuels from basic analysis data. Biomass Bioenergy 28:499–507. https://doi.org/10.1016/j.biombioe.2004.11.008

Pereira AKS, Júnior DL, Silva ÁM et al (2021) Understanding the impacts of pyrolysis temperature on the energy performance of Eucalyptus spp. charcoal. Environ Sci Proceed 13:25. https://doi.org/10.3390/IECF2021-10794

Ahmad M, Subawi H (2013) New Van Krevelen diagram and its correlation with the heating value of biomass. Res J Agric Environ Manag 2:295–301

Souza JFT, Pacca SA (2021) Carbon reduction potential and costs through circular bioeconomy in the Brazilian steel industry. Resour Conserv Recycl 169:105517. https://doi.org/10.1016/j.resconrec.2021.105517

Acknowledgements

The authors are grateful for the support of the Laboratory for Technology of Forest Products of the Federal Rural University of Amazonia (UFRA, Brazil), the Multiuser Laboratory of Biomaterials and Biomass Energy of the Federal University of Lavras (UFLA, Brazil), and Embrapa Eastern Amazon. We would like to especially thank the following people who played an important role in the laboratory stages of this project: Eidy Regina Oliveira da Silva, Eliana Martins de Sousa, Sindy Daniela Ferreira Sozinho, and Raimunda Marcia Souza dos Santos.

Funding

This work was supported by the National Council for Scientific and Technological Development (CNPq—process no. 306793/2019–9), Coordination for the Improvement of Higher Education Personnel (CAPES—finance code 001), Banco da Amazonia (financial support contract no. 2018/193), and Keilla Group.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Barros, D.d., Lima, M.D.R., Dias Junior, A.F. et al. Does the Segregation of Wood Waste from Amazonia Improve the Quality of Charcoal Produced in Brick Kilns?. Bioenerg. Res. 16, 1604–1617 (2023). https://doi.org/10.1007/s12155-022-10551-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-022-10551-w