Abstract

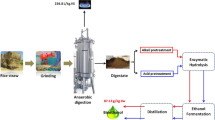

Extrusion, a physical pretreatment, is normally used for the pretreatment of lignocellulosic materials to improve biogas production. Wheat straw (WS) and its solid digestate (digested wheat straw, WSD) were selected to evaluate the effect of extrusion on lignocellulose structure and biogas production from WS and WSD. The WS and WSD were extruded and then were used for biogas production at (37 ± 1) °C in a batch model. The results showed that the cellulose, hemicellulose, and lignin contents of WS and WSD were 28%, 25%, and 14% and 30%, 25%, and 22%, respectively, while the cumulative biogas yields of WS and WSD were 179 and 57 mL/g TSadded (total solid, TS). After extrusion treatment, the cumulative biogas yields of WS and WSD were increased by 23% and 152%, respectively, while the cumulative methane yields of WS and WSD were increased by 27% and 192%, respectively, compared to the unextruded biomass. The results of scanning electron microscope and specific surface area (SSA) indicated that the lignocellulose structure in WSD suffered greater destruction and the increase in the SSA in WSD was 51-percentage points compared to WS pretreated by extrusion. Therefore, it is technically feasible to use extrusion treatment as a pretreatment for the reuse of digested wheat straw for biogas production.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Qian EW (2014) Pretreatment and saccharification of lignocellulosic biomass. Res Approaches Sustain Biomass Syst 181–204

Ministry of Agriculture and Rural Affairs of China (2021) Report on Comprehensive Utilization of Crop Straw in China. http://www.moa.gov.cn/xw/zwdt/202210/t20221010_6412962.htm. Accessed 10 October 2022

Vasco-Correa J, Khanal S, Manandhar A, Shah A (2018) Anaerobic digestion for bioenergy production: global status, environmental and techno-economic implications, and government policies. Bioresource Technol 247:1015–1026. https://doi.org/10.1016/j.biortech.2017.09.004

Soltanian S, Aghbashlo M, Almasi F, Hosseinzadeh-Bandbafha H, Nizami AS, Ok YS, Lam SS, Tabatabaei M (2020) A critical review of the effects of pretreatment methods on the exergetic aspects of lignocellulosic biofuels. Energ Convers Manage 212:112792. https://doi.org/10.1016/j.enconman.2020,112792

Abraham A, Mathew AK, Park H, Choi O, Sindhu R, Parameswaran B, Pandey A, Park JH, Sang BI (2020) Pretreatment strategies for enhanced biogas production from lignocellulosic biomass. Bioresource Technol 301:122725. https://doi.org/10.1016/j.biortech.2019.122725

Shetty DJ, Kshirsagar P, Tapadia-Maheshwari S, Lanjekar V, Singh SK, Dhakephalkar PK (2017) Alkali pretreatment at ambient temperature: a promising method to enhance biomethanation of rice straw. Bioresource Technol 226:80–88. https://doi.org/10.1016/j.biortech.2016.12.003

Hjorth M, Gränitz K, Adamsen AP, Møller HB (2011) Extrusion as a pretreatment to increase biogas production. Bioresource Technol 102(8):4989–4994. https://doi.org/10.1016/j.biortech.2010.11.128

Camire ME (1998) Chemical changes during extrusion cooking: recent advances. In: Shahidi F, Ho C-T, van Chuyen N (eds) Process-Induced Chemical Changes in Food. Plenum Press, New York, pp 109–121

Zheng Y, Zhao J, Xu F, Li Y (2014) Pretreatment of lignocellulosic biomass for enhanced biogas production. Prog Energy Combust Sci 42:35–53. https://doi.org/10.1016/j.pecs.2014.01.001

Karunanithy C, Muthukumarappan K (2010) Influence of extruder temperature and screw speed on pretreatment of corn stover while varying enzymes and their ratios. Appl Biochem Biotechnol 162:264–279

Chen XH, Zhang YL, Gu Y, Liu ZG, Shen Z (2014) Enhancing methane production from rice straw by extrusion pretreatment. Appl Energ 122:34–41. https://doi.org/10.1016/j.apenergy.2014.01.076

Frydendal-Nielsen S, Hjorth M, Baby S, Felby C, Jorgensen U, Gislum R (2016) The effect of harvest time, dry matter content and mechanical pretreatments on anaerobic digestion and enzymatic hydrolysis of miscanthus. Bioresource Technol 218:1008–1015. https://doi.org/10.1016/j.biortech.2016.07.046

Victorin M, Davidsson Å, Wallberg O (2020) Characterization of mechanically pretreated wheat straw for biogas production. BioEnergy Res 13(3):833–844. https://doi.org/10.1007/s12155-020-10126-7

Wahid R, Hjorth M, Kristensen S, Moller HB (2015) Extrusion as pretreatment for boosting methane production: effect of screw configurations. Energ Fuel 29(7):4030–4037. https://doi.org/10.1021/acs.energyfuels.5b00191

Souza MF, Devriendt N, Willems B, Guisson R, Biswas JK, Meers E (2022) Techno-economic feasibility of extrusion as a pretreatment step for biogas production from grass. Bioenerg Res 15(2):1232–1239. https://doi.org/10.1007/s12155-021-10287-z

Chen GY, Chang ZZ, Zheng Z (2014) Feasibility of NaOH-treatment for improving biogas production of digested Spartina alterniflora. Int Biodeter Biodegr 93:131–137. https://doi.org/10.1016/j.ibiod.2014.01.027

Chen GY, Zheng Z, Yang SG, Fang CX, Zou XX, Zhang JB (2010) Improving conversion of Spartina alterniflora into biogas by co-digestion with cow feces. Fuel Process Technol 91(11):1416–1421. https://doi.org/10.1016/j.fuproc.2010.05.015

Van Soest PJ, Robertson JB, Lewis BA (1991) Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J Dairy Sci 74:3583–3597. https://doi.org/10.3168/jds.S0022-0302(91)78551-2

Chen GY, Cao HN, Fan XQ, Sun YC, Wang J, Dong JZ, Wu P (2021) Investigating the effect of compaction on the anaerobic digestion process of rice straw. Bioenerg Res 15:1213–1224. https://doi.org/10.1007/s12155-021-10347-4

Chen GY, Zheng Z, Yang SG, Fang CX, Zou XX, Luo Y (2010) Experimental co-digestion of corn stalk and vermicompost to improve biogas production. Waste Manag 30:1834–1840. https://doi.org/10.1016/j.wasman.2010.03.014

APHA, AWWA, WEF (2012) Standard methods for the examination of water and wastewater. 22nd ed. Washington

Zou SZ, Wang XJ, Chen YL, Wan HW, Feng YZ (2016) Enhancement of biogas production in anaerobic co-digestion by ultrasonic pretreatment. Energy Convers Manage 112:226–235. https://doi.org/10.1016/j.enconman.2015.12.087

Perez-Rodriguez N, Garcia-Bernet D, Dominguez JM (2017) Extrusion and enzymatic hydrolysis as pretreatments on corn cob for biogas production. Renew Energ 107:597–603. https://doi.org/10.1016/j.renene.2017.02.030

Komilis DP, Ham RK (2003) The effect of lignin and sugars to the aerobic decomposition of solid wastes. Waste Manage 23:419–423. https://doi.org/10.1016/S0956-053X(03)00062-X

Kupryaniuk K, Oniszczuk T, Combrzynski M, Czekala W, Matwijczuk A (2020) The influence of corn straw extrusion pretreatment parameters on methane fermentation performance. Materials 13:3003. https://doi.org/10.3390/ma13133003

Raju CS, Ward AJ, Nielsen L, Møller HB (2011) Comparison of near infra-red spectroscopy, neutral detergent fibre assay and in-vitro organic matter digestibility assay for rapid determination of the biochemical methane potential of meadow grasses. Bioresource Technol 102(17):7835–7839. https://doi.org/10.1016/j.biortech.2011.05.049

Menardo S, Cacciatore V, Balsari P (2015) Batch and continuous biogas production arising from feed varying in rice straw volumes following pre-treatment with extrusion. Bioresource Technol 180:154–161. https://doi.org/10.1016/j.biortech.2014.12.104

Witaszek K, Pilarski K, Niedbala G, Pilarska AA, Herkowiak M (2020) Energy efficiency of comminution and extrusion of maize substrates subjected to methane fermentation. Energies 13:1887. https://doi.org/10.3390/en13081887

Pilarski K, Pilarska AA, Witaszek K, Dworecki Z, Zelazinski T, Ekielski A, Makowska A, Michniewicz J (2016) The impact of extrusion on the biogas and biomethane yield of plant substrates. J Ecol Eng 17:264–272. https://doi.org/10.12911/22998993/64563

Kozlowski K, Lewicki A, Czekala W, Wójtowicz A, Kupryaniuk K, Drozdz D (2019) Extrusion pretreatment of maize straw-case study for a Polish biogas plants. Int Agrophys 33(4):527–535. https://doi.org/10.31545/intagr/113548

Sambusiti C, Monlau F, Ficara E, Musatti A, Rollini M, Barakat A, Malpei F (2015) Comparison of various post-treatments for recovering methane from agricultural digestate. Fuel Process Technol 137:359–365. https://doi.org/10.1016/j.fuproc.2015.04.028

Duque A, Manzanares P, Ballesteros M (2017) Extrusion as a pretreatment for lignocellulosic biomass: fundamentals and applications. Renew Energy 114:1427–1441. https://doi.org/10.1016/j.renene.2017.06.050

Panepinto D, Genon G (2016) Analysis of the extrusion as a pretreatment for the anaerobic digestion process. Ind Cro Prod 83:206–212. https://doi.org/10.1016/j.indcrop.2015.12.044

Anderson GK, Yang G (1992) Determination of bicarbonate and total volatile acid concentration in anaerobic digesters using a simple titration. Water Environ Res 64:53–59. https://doi.org/10.2175/WER.64.1.8

Ding JT, Zhang PY, Hua GL, Meng HB, Shen YJ (2018) Running status of large and medium scale biogas project and physical, chemical and biological characteristics of materials before and after fermentation in winter of Beijing. Trans Chin Soc. Agric Eng 34:213–220. https://doi.org/10.11975/j.issn.1002-6819.2018.23.027

Debouba M, Gouia H, Suzuki A, Ghorbel MH (2006) NaCl stress effects on enzymes involved in nitrogen assimilation pathway in tomato Lycopersicon esculentum seedlings. J Plant Physiol 163:1247–1258. https://doi.org/10.1080/01904167.2016.1201495

Fu SF, Wang F, Yuan XZ, Yang ZM, Luo SJ, Wang CS, Guo RB (2016) The thermophilic (55 degrees C) microaerobic pretreatment of corn straw for anaerobic digestion. Bioresource Technol 175:203–208. https://doi.org/10.1016/j.biortech.2016.01.040

Boni MR, D’Amato E, Polettini A, Pomi R, Rossi A (2016) Effect of ultrasonication on anaerobic degradability of solid waste digestate. Waste Manage 48:209–217. https://doi.org/10.1016/j.wasman.2015.10.031

Tuomela M, Vikman M, Hatakka A, Itävaara M (2000) Biodegradation of lignin in a compost environment: a review. Bioresource Technol 72(2):169–183. https://doi.org/10.1016/S0960-8524(99)00104-2

Rasapoor M, Young B, Asadov A, Brar R, Sarmah AK, Zhuang WQ, Baroutian S (2020) Effects of biochar and activated carbon on biogas generation: a thermogravimetric and chemical analysis approach. Energ Convers Manage 203:112221. https://doi.org/10.1016/j.enconman.2019.112221

Bedoic R, Bulatovic VO, Cucek L, Cosic B, Spehar A, Puksec T, Duic N (2019) A kinetic study of roadside grass pyrolysis and digestate from anaerobic monodigestion. Bioresource Technol 292:121935. https://doi.org/10.1016/j.biortech.2019.121935

Yadav M, Paritosh K, Pareek N, Vivekanand V (2019) Coupled treatment of lignocellulosic agricultural residues for augmented biomethanation. J Clean Prod 213:75–88. https://doi.org/10.1016/j.jclepro.2018.12.142

Liang JJ, Lin YQ, Wu SB, Liu C, Lei M, Zeng C (2015) Enhancing the quality of bio-oil and selectivity of phenols compounds from pyrolysis of anaerobic digested rice straw. Bioresource Technol 181:220–223. https://doi.org/10.1016/j.biortech.2015.01.056

Acknowledgements

The authors would like to take this opportunity to express our sincere appreciation for the support of China Scholarship Council.

Funding

This work was supported by The University Synergy Innovation Program of Anhui Province (GXXT-2019–010) and Natural Science Foundation of Anhui Province (1808085ME132).

Author information

Authors and Affiliations

Contributions

Guang-Yin Chen: resource, writing-review and editing, supervision, project administration, funding acquisition. Hai-Nan Cao: investigation, validation, writing-original draft. Chang-ping Zhao: formal analysis, data curation, validation. Wan-rong Zhang: formal analysis, data curation. Jia-wei Zheng: formal analysis, data curation. En-hui Wang: data curation, validation, investigation.

Corresponding author

Ethics declarations

Ethics Approval

Not applicable.

Consent to Participate

Written informed consent for publication was obtained from all participants.

Consent for Publication

All the authors consent to publication.

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, G., Cao, H., Zhao, C. et al. A Comparative Study of the Effects of Extrusion on Lignocellulose Structure and Biogas Production from Wheat Straw and Digested Wheat Straw. Bioenerg. Res. 16, 1939–1949 (2023). https://doi.org/10.1007/s12155-022-10545-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-022-10545-8