Abstract

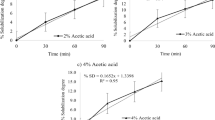

The combination of carbon and nitrogen-rich co-substrates results in a better balance and increases the stability of the anaerobic co-digestion (AcoD) process. In this work, the AcoD process of waste from the leather industry (shavings and sludge) with waste from agriculture (oat straw) was assessed with regard to the energy (biogas production) and waste treatment efficiency (reduction of organic matter). The results indicate that the addition of untreated oat straw improved the AcoD process, increasing biogas production (25.44 mL of cumulative biogas/g of VSS added) by almost 60% when compared to the AcoD of only leather waste (16.17 mL/gVSS). Also, the effect of acid, alkaline, thermal, and the combination of these pretreatment techniques was evaluated on the lignocellulosic composition of oat straw and on methane yields. Pretreatments improved the characteristics and bioavailability of oat straw, particularly in methodologies that use alkali, with a significant increase in cellulose content accompanied by a decrease in hemicellulose and lignin content. However, the possible formation of secondary products or sterilization of important microorganisms did not reflect in a greater production of biogas: 21.06 mL/gVSS for oat straw pretreated only with HCl and 21.91 mL/gVSS for oat straw pretreated with HCl in autoclave; 5.20 mL/gVSS for oat straw pretreated with NaOH; and 3.43 mL/gVSS for oat straw pretreated with NaOH in autoclave; thermal pretreatment probably has generated toxic compounds from hemicellulose and cellulose degradation, which inhibited the AcoD process and, as consequence, virtually no biogas was produced.

Similar content being viewed by others

Data Availability

Not applicable.

Code Availability

Not applicable.

References

Koupaie EH, Dahadha S, Lakeh AAB et al (2019) Enzymatic pretreatment of lignocellulosic biomass for enhanced biomethane production-a review. J Environ Manage 233:774–784. https://doi.org/10.1016/j.jenvman.2018.09.106

U.S. Energy Information Administration (2019) International Energy Outlook 2019. https://www.eia.gov/outlooks/ieo/pdf/ieo2019.pdf. Accessed 2 Jun 2020

Abraham A, Mathew AK, Park H et al (2020) Pretreatment strategies for enhanced biogas production from lignocellulosic biomass. Bioresour Technol 301:122725. https://doi.org/10.1016/j.biortech.2019.122725

Edwiges T, Aline J, Henrique J et al (2019) Comparison of various pretreatment techniques to enhance biodegradability of lignocellulosic biomass for methane production. J Environ Chem Eng 7:103495. https://doi.org/10.1016/j.jece.2019.103495

Fjørtoft K, Morken J, Hanssen JF, Briseid T (2019) Pre-treatment methods for straw for farm-scale biogas plants. Biomass Bioenergy 124:88–94. https://doi.org/10.1016/j.biombioe.2019.03.018

Ferreira LC, Donoso-Bravo A, Nilsen PJ et al (2013) Influence of thermal pretreatment on the biochemical methane potential of wheat straw. Bioresour Technol 143:251–257. https://doi.org/10.1016/j.biortech.2013.05.065

Sabeeh M, Liaquat R, Maryam A (2020) Effect of alkaline and alkaline-photocatalytic pretreatment on characteristics and biogas production of rice straw. Bioresour Technol 309:123449. https://doi.org/10.1016/j.biortech.2020.123449

Patowary D, Baruah DC (2018) Effect of combined chemical and thermal pretreatments on biogas production from lignocellulosic biomasses. Ind Crop Prod 124:735–746. https://doi.org/10.1016/j.indcrop.2018.08.055

Neshat SA, Mohammadi M, Najafpour GD, Lahijani P (2017) Anaerobic co-digestion of animal manures and lignocellulosic residues as a potent approach for sustainable biogas production. Renew Sustain Energy Rev 79:308–322. https://doi.org/10.1016/j.rser.2017.05.137

Patinvoh RJ, Osadolor OA, Chandolias K et al (2017) Innovative pretreatment strategies for biogas production. Bioresour Technol 224:13–24. https://doi.org/10.1016/j.biortech.2016.11.083

Gomez-Tovar F, Celis LB, Razo-Flores E, Alatriste-Mondragón F (2012) Chemical and enzymatic sequential pretreatment of oat straw for methane production. Bioresour Technol 116:372–378. https://doi.org/10.1016/j.biortech.2012.03.109

Wyman V, Henríquez J, Palma C, Carvajal A (2018) Lignocellulosic waste valorisation strategy through enzyme and biogas production. Bioresour Technol 247:402–411. https://doi.org/10.1016/j.biortech.2017.09.055

Zhang L, Loh K, Zhang J (2019) Enhanced biogas production from anaerobic digestion of solid organic wastes: current status and prospects. Bioresour Technol Rep 5:280–296. https://doi.org/10.1016/j.biteb.2018.07.005

Mancini G, Papirio S, Lens PNL, Esposito G (2018) Increased biogas production from wheat straw by chemical pretreatments. Renew Energy 119:608–614. https://doi.org/10.1016/j.renene.2017.12.045

Rajput AA, Zeshan VC (2018) Effect of thermal pretreatment on chemical composition, physical structure and biogas production kinetics of wheat straw. J Environ Manage 221:45–52. https://doi.org/10.1016/j.jenvman.2018.05.011

Chandra R, Takeuchi H, Hasegawa T, Kumar R (2012) Improving biodegradability and biogas production of wheat straw substrates using sodium hydroxide and hydrothermal pretreatments. Energy 43:273–282. https://doi.org/10.1016/j.energy.2012.04.029

Taherdanak M, Zilouei H, Karimi K (2016) The influence of dilute sulfuric acid pretreatment on biogas production from wheat plant. Int J Green Energy 13:1129–1134. https://doi.org/10.1080/15435075.2016.1175356

Kim M, Kim B, Nam K, Choi Y (2018) Effect of pretreatment solutions and conditions on decomposition and anaerobic digestion of lignocellulosic biomass in rice straw. Biochem Eng J 140:108–114. https://doi.org/10.1016/j.bej.2018.09.012

Mao C, Feng Y, Wang X, Ren G (2015) Review on research achievements of biogas from anaerobic digestion. Renew Sustain Energy Rev 45:540–555. https://doi.org/10.1016/j.rser.2015.02.032

Siddique MNI, Wahid ZA (2018) Achievements and perspectives of anaerobic co-digestion: a review. J Clean Prod 194:359–371. https://doi.org/10.1016/j.jclepro.2018.05.155

Hagos K, Zong J, Li D et al (2017) Anaerobic co-digestion process for biogas production: progress, challenges and perspectives. Renew Sustain Energy Rev 76:1485–1496. https://doi.org/10.1016/j.rser.2016.11.184

Agustini C, Da Costa M, Gutterres M (2018) Biogas production from tannery solid wastes–scale-up and cost saving analysis. J Clean Prod 187:158–164. https://doi.org/10.1016/j.jclepro.2018.03.185

Agustini CB, Spier F, Da Costa M, Gutterres M (2018) Biogas production for anaerobic co-digestion of tannery solid wastes under presence and absence of the tanning agent. Resour Conserv Recycl 130:51–59. https://doi.org/10.1016/j.resconrec.2017.11.018

Simioni T, Agustini CB, Dettmer A, Gutterres M (2020) Nutrient balance for anaerobic co-digestion of tannery wastes: energy efficiency, waste treatment and cost-saving. Bioresour Technol 308:123255. https://doi.org/10.1016/j.biortech.2020.123255

Pessuto J, Scopel BS, Perondi D et al (2016) Enhancement of biogas and methane production by anaerobic digestion of swine manure with addition of microorganisms isolated from sewage sludge. Process Saf Environ Prot 104:233–239. https://doi.org/10.1016/j.psep.2016.08.020

Xu R, Zhang K, Liu P et al (2018) A critical review on the interaction of substrate nutrient balance and microbial community structure and function in anaerobic co-digestion. Bioresour Technol 247:1119–1127. https://doi.org/10.1016/j.biortech.2017.09.095

Miron TL, Plaza M, Bahrim G et al (2011) Chemical composition of bioactive pressurized extracts of Romanian aromatic plants. J Chromatogr A 1218:4918–4927. https://doi.org/10.1016/j.chroma.2010.11.055

Li S, Xu S, Liu S et al (2004) Fast pyrolysis of biomass in free-fall reactor for hydrogen-rich gas. Fuel Process Technol 85:1201–1211. https://doi.org/10.1016/j.fuproc.2003.11.043

Agustini CB, Da Costa M, Gutterres M (2020) Tannery wastewater as nutrient supply in production of biogas from solid tannery wastes mixed through anaerobic co-digestion. Process Saf Environ Prot 135:38–45. https://doi.org/10.1016/j.psep.2019.11.037

Priebe GPS, Kipper E, Gusmão AL et al (2016) Anaerobic digestion of chrome-tanned leather waste for biogas production. J Clean Prod 129:410–416. https://doi.org/10.1016/j.jclepro.2016.04.038

Zupančič GD, Jemec A (2010) Anaerobic digestion of tannery waste: semi-continuous and anaerobic sequencing batch reactor processes. Bioresour Technol 101:26–33. https://doi.org/10.1016/j.biortech.2009.07.028

Agustini CB, Meyer M, Da Costa M, Gutterres M (2018) Biogas from anaerobic co-digestion of chrome and vegetable tannery solid waste mixture: influence of the tanning agent and thermal pretreatment. Process Saf Environ Prot 118:24–31. https://doi.org/10.1016/j.psep.2018.06.021

Kalyanaraman C, Kameswari KSB, Rao JR (2015) Studies on enhancing the biodegradation of tannins by ozonation and Fenton’s oxidation process. J Ind Eng Chem 25:329–337. https://doi.org/10.1016/j.jiec.2014.11.012

De Oliveira JP, Bruni GP, Lima KO et al (2017) Cellulose fibers extracted from rice and oat husks and their application in hydrogel. Food Chem 221:153–160. https://doi.org/10.1016/j.foodchem.2016.10.048

Krishania M, Vijay VK, Chandra R (2013) Methane fermentation and kinetics of wheat straw pretreated substrates co-digested with cattle manure in batch assay. Energy 57:359–367. https://doi.org/10.1016/j.energy.2013.05.028

Shen J, Zheng Q, Zhang R et al (2019) Co-pretreatment of wheat straw by potassium hydroxide and calcium hydroxide: methane production, economics, and energy potential analysis. J Environ Manage 236:720–726. https://doi.org/10.1016/j.jenvman.2019.01.046

Ran G, Li D, Zheng T et al (2018) Hydrothermal pretreatment on the anaerobic digestion of washed vinegar residue. Bioresour Technol 248:265–271. https://doi.org/10.1016/j.biortech.2017.06.068

Liu T, Zhou X, Li Z et al (2019) Effects of liquid digestate pretreatment on biogas production for anaerobic digestion of wheat straw. Bioresour Technol 280:345–351. https://doi.org/10.1016/j.biortech.2019.01.147

Morán JI, Alvarez VA, Cyras VP, Vázquez A (2008) Extraction of cellulose and preparation of nanocellulose from sisal fibers. Cellulose 15:149–159. https://doi.org/10.1007/s10570-007-9145-9

Yao Y, David A, Davaritouchaee M (2018) Methane recovery from anaerobic digestion of urea-pretreated wheat straw. Renew Energy 115:139–148. https://doi.org/10.1016/j.renene.2017.08.038

Kumar S, Gandhi P, Yadav M et al (2019) Weak alkaline treatment of wheat and pearl millet straw for enhanced biogas production and its economic analysis. Renew Energy 139:753–764. https://doi.org/10.1016/j.renene.2019.02.133

Yang H, Yan R, Chen H et al (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86:1781–1788

Colom X, Carrillo F, Nogués F, Garriga F (2003) Structural analysis of photodegraded wood by means of FTIR spectroscopy. Polym Degrad Stab 80:543–549

Hu F, Jung S, Ragauskas A (2012) Pseudo-lignin formation and its impact on enzymatic hydrolysis. Bioresour Technol 117:7–12. https://doi.org/10.1016/j.biortech.2012.04.037

Gomes CS, Repke JU, Meyer M (2019) Diauxie during biogas production from collagen-based substrates. Renew Energy 141:20–27. https://doi.org/10.1016/j.renene.2019.03.123

Kim MJ, Kim SH (2017) Minimization of diauxic growth lag-phase for high-efficiency biogas production. J Environ Manage 187:456–463. https://doi.org/10.1016/j.jenvman.2016.11.002

Mirmohamadsadeghi S, Karimi K, Tabatabaei M, Aghbashlo M (2019) Biogas production from food wastes: a review on recent developments and future perspectives. Bioresour Technol Reports 7:100202. https://doi.org/10.1016/j.biteb.2019.100202

Appels L, Baeyens J, Degrève J, Dewil R (2008) Principles and potential of the anaerobic digestion of waste-activated sludge. Prog Energy Combust Sci 34:755–781. https://doi.org/10.1016/j.pecs.2008.06.002

Shetty DJ, Kshirsagar P, Tapadia-maheshwari S et al (2017) Alkali pretreatment at ambient temperature: a promising method to enhance biomethanation of rice straw. Bioresour Technol 226:80–88. https://doi.org/10.1016/j.biortech.2016.12.003

Hierholtzer A, Akunna JC (2012) Modelling sodium inhibition on the anaerobic digestion process. Water Sci Technol 1565–1573. https://doi.org/10.2166/wst.2012.345

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Simioni, T., Agustini, C.B., Dettmer, A. et al. Anaerobic Co-Digestion of Tannery Wastes and Untreated/Pretreated Oat Straw. Bioenerg. Res. 15, 589–601 (2022). https://doi.org/10.1007/s12155-021-10285-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-021-10285-1