Abstract

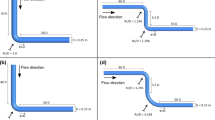

This article presents a numerical analysis of mixing and pressure drop in a spiral micromixer with four different inlet flow path configurations. Micromixers Type 1 and Type 2 (M-Type 1 and M-Type 2) have Y-shaped and T-shaped entry into the main channel with fluid entry into a spiral channel at 90°, whereas, in Micromixers Type 3 and Type 4 (M-Type 3 and M-Type 4), the entries of fluid are in line with spiral channel. The mass fraction contours of the species, velocity vectors, mixing efficiency, and pressure drops are analyzed for Reynolds number in the range 1 ≤ Re ≤ 100. The results show that the mixing efficiency first decreases with the increase in Re and then increases with Re values. In contrast, pressure drops and mixing performance increase with the increase in Re values irrespective of the micromixer design. Higher mixing is observed in micromixers having Y-shaped inlets. The mixing efficiency of 97.2% is observed in M-Type 3, followed by 94% in M-Type 1. In M-Type 2 and M-Type 4, the values of mixing efficiency are 89% and 90.3%, respectively. The mixing performance of micromixers in M-Type 1 and M-Type 3 is lower than M-Type 2 and M-Type 4.

Similar content being viewed by others

Abbreviations

- \({\varvec{V}}\) :

-

Velocity of fluids, ms−1

- \(P\) :

-

Pressure, Nm−2

- \(Re\) :

-

Reynolds number

- \(D\) :

-

Dean number

- \(D_{h}\) :

-

Hydraulic diameter of the micromixer, mm

- \(s\) :

-

Radius of curvature of the convex surface of spiral

- t :

-

Total number of a specimen point

- \(C_{i}\) :

-

Concentration of the species, molm−3

- \( C_{r}\) :

-

Species fraction at specimen point r

- \(\overline{{C_{n} }}\) :

-

Average mixing species fraction

- MP:

-

Mixing performance

- Q :

-

Total flow rate of the fluids

- \(\rho\) :

-

Density of fluid, kgm−3

- \(\alpha\) :

-

Diffusivity of the mixture, m2 s−1

- \(\nu\) :

-

Kinematic viscosity, m2s−1

- \(\chi\) :

-

Standard deviation of species concentration

- \(\overline{\chi }\) :

-

maximum standard deviation

References

Lee C Y, Wang W T, Liu C C and Fu L M 2016 Passive mixers in microfluidic systems: A review. J. Chem. Eng. 288: 146–160 https://doi.org/10.1016/j.cej.2015.10.122

Mondal B, Mehta S K, Patowari P K and Pati S 2019 Numerical study of mixing in wavy micromixers: comparison between raccoon and serpentine mixer. Chemical Engineering and Processing-Process Intensification 136: 44–61

Biswas S K, Das T and Chakraborty S 2012 Nontrivial augmentations in mixing performance through integrated active and passive mixing in serpentine microchannels. Journal of Applied Physics 111(5): 054904

Vasista K N, Mehta S K and Pati S 2022 Electroosmotic mixing in a microchannel with heterogeneous slip dependent zeta potential. Chemical Engineering and Processing-Process Intensification 176: 108940

Mehta S K, Pati S and Mondal P K 2021 Numerical study of the vortex-induced electroosmotic mixing of non-Newtonian biofluids in a nonuniformly charged wavy microchannel: Effect of finite ion size. Electrophoresis 42(23): 2498–2510

Mondal B, Mehta S K, Pati S and Patowari P K 2021 Numerical analysis of electroosmotic mixing in a heterogeneous charged micromixer with obstacles. Chemical Engineering and Processing-Process Intensification 168: 108585

Mehta S K, Mondal B, Pati S and Patowari P K 2022 Enhanced electroosmotic mixing of non-Newtonian fluids in a heterogeneous surface charged micromixer with obstacles. Colloids and Surfaces A: Physicochemical and Engineering Aspects 648: 129215. https://doi.org/10.1016/j.colsurfa.2022.129215

Mehta S K and Pati S 2022 Enhanced Electroosmotic Mixing in a Wavy Micromixer Using Surface Charge Heterogeneity. Industrial & Engineering Chemistry Research 61(7): 2904–2914. https://doi.org/10.1021/acs.iecr.1c04318

Vasista K N, Mehta S K and Pati S 2021 Numerical assessment of hydrodynamic and mixing characteristics for mixed electroosmotic and pressure-driven flow through a wavy microchannel with patchwise surface heterogeneity. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, p. 09544089211051640

Tripathi E and Patowari P K 2020 Design and Computational Analysis of Spiral Microchannel for Mixing of Fluids. In: Techno-Societal 2018, Pawar P, Ronge B, Balasubramaniam R, Vibhute A, Apte S (eds), pp. 305-313 Cham: Springer, DOI: https://doi.org/10.1007/978-3-030-16962-6_31

Mondal B, Pati S and Patowari P K 2021 Serpentine square wave microchannel fabrication with WEDM and soft lithography. Materials Today: Proceedings 46: 8513–8518

Tripathi E, Patowari P K and Pati S 2019 Fabrication of spiral micromixer using mold machined by CO2 assisted laser machine. In: Paper presented at 11th International conference on precision, meso, micro and nano engineering COPEN 11 IIT Indore, 12–14 Dec. 2019

Mariotti A, Galletti C, Mauri R, Salvetti M V and Brunazzi E 2018 Steady and unsteady regimes in a T-shaped micro-mixer: Synergic experimental and numerical investigation. Chemical Engineering Journal 341: 414–431

Mondal B, Pati S and Patowari P K 2020 Numerical analysis of mixing performance in microchannel with different ratio of outlet to inlet width. In: Techno-Societal 2018 (eds) Pawar P, Ronge B, Balasubramaniam R, Vibhute A and Apte S, Springer, Cham, pp 257–266. https://doi.org/10.1007/978-3-030-16962-6_26

Tripathi E, Patowari P K and Pati S 2022 Mixing characteristics and pressure drop analysis in a spiral micromixer. In: Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, p. 09544089221095636. https://doi.org/10.1177/09544089221095636

Borgohain P, Arumughan J and Dalal A 2018 Natarajan G. Design and performance of a three-dimensional micromixer with curved ribs. Chemical Engineering Research and Design 136: 761–75

Mondal B, Pati S and Patowari P K 2019 Analysis of mixing performances in microchannel with obstacles of different aspect ratios. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering 233(5): 1045–1051

Borgohain P, Dalal A, Natarajan G and Gadgil H P 2018 Numerical assessment of mixing performances in cross-T microchannel with curved ribs. Microsystem Technologies 24(4): 1949–63

Sudarsan A P and Ugaz V M 2006 Fluid mixing in planar spiral microchannels. Lab on a Chip 6(1): 74–82

Tripathi E, Patowari P K and Pati S 2021 Comparative assessment of mixing characteristics and pressure drop in spiral and serpentine micromixers. Chemical Engineering and Processing-Process Intensification 162: 108335

Ngo I L, Lai T K, Choi H J, Le H T T, Kim G M and Dang T D 2020 A study on mixing performance of dean flows through spiral micro-channel under various effects. Physics of Fluids 32(2): 022004

Duryodhan V S, Chatterjee R, Singh S G and Agrawal A 2017 Mixing in planar spiral microchannel. Experimental Thermal and Fluid Science 89: 119–127

Vatankhah P and Shamloo A 2018 Parametric study on mixing process in an in-plane spiral micromixer utilizing chaotic advection. Analytica Chimica Acta 1022: 96–105

Balasubramaniam L, Arayanarakool R, Marshall S D, Li B, Lee P S and Chen P C 2017 Impact of cross-sectional geometry on mixing performance of spiral microfluidic channels characterized by swirling strength of Dean-vortices. Journal of Micromechanics and Microengineering 27(9): 095016

Tripathi E, Patowari P K and Pati S 2021 Numerical investigation of mixing performance in spiral micromixers based on Dean flows and chaotic advection. Chemical Engineering and Processing-Process Intensification 169: 108609

Sarma P and Patowari P K 2016 Design and analysis of passive Y-type micromixers for enhanced mixing performance for biomedical and microreactor application. Journal of Advanced Manufacturing Systems 15(03): 161–172

Chen X, Li T and Hu Z 2017 A novel research on serpentine microchannels of passive micromixers. Microsystem Technologies 23(7): 2649–2656

Raza W, Hossain S and Kim K Y 2018 Effective mixing in a short serpentine split-and-recombination micromixer. Sensors and Actuators B: Chemical 258: 381–392

Rahimi M, Akbari M, Parsamoghadam M A and Alsairafi A A 2015 CFD study on effect of channel confluence angle on fluid flow pattern in asymmetrical shaped microchannels. Computers & Chemical Engineering 73: 172–182

Hsieh S S, Lin J W and Chen J H 2013 Mixing efficiency of Y-type micromixers with different angles. International Journal of Heat and Fluid Flow 44: 130–1

Mondal B, Pati S and Patowari P K 2020 Influence of confluence angle between inlets on the mixing performance of micro-mixer with obstacles. In: Techno-Societal 2018 (eds) Pawar P, Ronge B, Balasubramaniam R, Vibhute A and Apte S, Springer, Cham, pp 275–283

Dundi M, Raju V R K and Chandramohan V P 2021 Simple structured and highly efficient passive T-type micromixer with circumferential in-step at entry. Asia-Pacific Journal of Chemical Engineering 16(4): e2667

Fatima U, Shakaib M and Memon I 2020 Analysis of mass transfer performance of micromixer device with varying confluence angle using CFD. Chemical Papers 74(4): 1267–1279

Ansari M A, Kim K Y, Anwar K and Kim S M 2010 A novel passive micromixer based on unbalanced splits and collisions of fluid streams. Journal of Micromechanics and Microengineering 20(5): 055007. https://doi.org/10.1088/0960-1317/20/5/055007

Gao Y, Zhu D F, Han Y and Torrente-Murciano L 2021 Rational design of the inlet configuration of flow systems for enhanced mixing. Journal of Flow Chemistry 11(3): 589–598

Nivedita N, Ligrani P and Papautsky I 2017 Dean flow dynamics in low-aspect ratio spiral microchannels. Scientific Reports 7(1): 1–10

Viktorov V, Mahmud M R and Visconte C 2016 Numerical study of fluid mixing at different inlet flow-rate ratios in Tear-drop and Chain micromixers compared to a new HC passive micromixer. Engineering Applications of Computational Fluid Mechanics 10(1): 182–192

Pati S 2012 A textbook on fluid mechanics and hydraulic machines. McGraw-Hill Education (India) Pvt. Ltd, New Delhi

Solehati N, Bae J and Sasmito A P 2014 Numerical investigation of mixing performance in microchannel T-junction with wavy structure. Computers & Fluids 96: 10–19

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

TRIPATHI, E., PATOWARI, P.K. & PATI, S. Assessment of mixing performance in a spiral micromixer with different inlet path configurations. Sādhanā 47, 240 (2022). https://doi.org/10.1007/s12046-022-02019-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-022-02019-6