Abstract

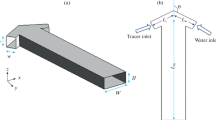

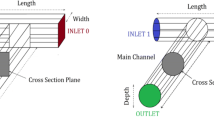

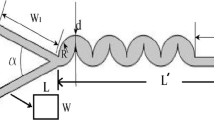

The computational fluid dynamics (CFD) study on micromixers in this paper illustrates the effect of confluence angle on mixing performance at different Reynolds numbers and flow rate ratios. The mixing performance parameters such as mixing quality and effectiveness increases with the increase in Reynolds number for all the micromixer geometries. For any value of Reynolds number, the angle of confluence is found to have a significant effect on flow behavior in the mixing channel and thus on mass transfer. The formation of vortices and the interlacing of fluid streams are identified as the favorable phenomena due to which mass transfer or mixing of fluid streams is enhanced. The mixing effectiveness is mostly observed to be high in case of unequal flow rates in the two feed/inlet channels. The optimum value of confluence angle depends of flow rate ratio. When flow rate ratio is high, T-shaped micromixer (θ = 180°) provides better performance while for other ratios, micromixers with relatively large angles of confluence are found more suitable.

Similar content being viewed by others

Abbreviations

- A :

-

Area

- c :

-

Concentration/mass fraction (kg/kg)

- d :

-

Diameter (m)

- D AB :

-

Diffusion coefficient (m2/s)

- Eu :

-

Euler number

- f :

-

Friction factor

- l :

-

Channel length (m)

- l m :

-

Mixing length (m)

- L :

-

Total length of channels (m)

- \(\Delta p\) :

-

Pressure drop (Pa)

- Q :

-

Volumetric flow rate (m3/s)

- R :

-

Flow rate ratio

- Re :

-

Reynolds number

- \(x\) :

-

Distance from mixing channel inlet

- \(\sigma^{2}\) :

-

Variance of concentration

- \(\alpha\) :

-

Mixing quality

- ρ :

-

Density (kg/m3)

- u av :

-

Average velocity (m/s)

- u :

-

x-Component of velocity (m/s)

- v :

-

y-Component of velocity (m/s)

- w :

-

z-Component of velocity (m/s)

- μ :

-

Viscosity (kg/m·s)

- v :

-

Kinematic viscosity (m2/s)

References

Aoki N, Umei R, Yoshida A, Mae K (2011) Design method for micromixers considering influence of channel confluence and bend on diffusion length. Chem Eng J 167:643–650

Aoki N, Fukuda T, Maeda N, Mae K (2013) Design of confluence and bend geometry for rapid mixing in microchannels. Chem Eng J 227:198–202

Borgogna A, Murmura MA, Annesini MC, Giona M, Cerbelli S (2018) Inertia–driven enhancement of mixing efficiency in microfluidic cross–junctions: a combined Eulerian/Lagrangian approach. Microfuid Nanofuid 22:20

Borgogna A, Murmura MA, Annesini MC, Giona M, Cerbelli S (2019) A hybrid numerical approach for predicting mixing length and mixing time in microfluidic junctions from moderate to arbitrarily large values of the Péclet number. Chem Eng Sci 196:247–264

Cai G, Xue L, Zhang H, Lin J (2017) A review on micromixers. Micromachines 8:274

Capretto L, Cheng W, Hill M, Zhang X (2011) Micromixing within microfluidic devices. Top Curr Chem 304:27–68

Engler M, Kockmann N, Kiefer T, Woias P (2004) Numerical and experimental investigations on liquid mixing in static micromixers. Chem Eng J 101:315–322

Fang Y, Ye Y, Shen R, Zhu P, Guo R, Hu Y, Wu L (2012) Mixing enhancement by simple periodic geometric features in microchannels. Chem Eng J 187:306–310

Garofalo F, Adrover A, Cerbelli S, Giona M (2010) Spectral characterization of static mixers. The S-shaped micromixer as a case study. AIChE J 56(2):318–335

Hossain S, Ansari MA, Kim K (2009) Evaluation of the mixing performance of three passive micromixers. Chem Eng J 150:492–501

Hsieh SS, Lin JW, Chen JW (2013) Mixing efficiency of Y-type micromixers with different angles. Int J Heat Fluid Flow 44:130–139

Jeong GS, Chung S, Kima CB, Lee SH (2010) Applications of micromixing technology. Analyst 135:460–473

Kashid M, Renken A, Kiwi-Minsker L (2011) Mixing efficiency and energy consumption for five generic microchannel designs. Chem Eng J 167:436–443

Kockmann N, Kiefer T, Engler M, Woias P (2006) Convective mixing and chemical reactions in microchannels with high flowrates. Sens Actuators B 117:495–508

Kothare MV (2006) Dynamics and control of integrated microchemical systems with application to micro-scale fuel processing. Comput Chem Eng 30:1725–1734

Lobasov AS, Minakov AV, Kuznetsov VV, Rudyak VY, Shebeleva AA (2018) Investigation of mixing efficiency and pressure drop in T-shaped micromixers. Chem Eng Process 134:105–114

Mouheb NA, Malsch D, Montillet A, Solliec C, Henkel T (2012) Numerical and experimental investigations of mixing in T-shaped and cross-shaped micromixers. Chem Eng Sci 68:278–289

Nguyen NT, Wereley ST (2002) Fundamentals and applications of microfluidics, vol 2. Artech house, Norwood

Nguyen N-T, Wu Z (2005) Micromixers: a review. J Micromech Microeng 15:1–16

Ortega-Casanova J, Lai C-H (2018) CFD study about the effect of using multiple inlets on the efficiency of a micromixer. Assessment of the optimal inlet configuration working as a microreactor. Chem Eng Process 125:163–172

Patankar SV, Spalding DB (1972) A calculation procedure for heat, mass and momentum transfer in three-dimensional parabolic flows. Int J Heat Mass Transfer 15:1787–1805

Rahimi M, Akbari M, Parsamoghadam MA, Alsairafi AA (2015) CFD study on effect of channel confluence angle on fluid flow pattern in asymmetrical shaped microchannels. Comput Chem Eng 73:172–182

Rahimi M, Azimi N, Parsamogadam MA, Rahimi A, Masahy MM (2017) Mixing performance of T, Y and oriented Y-micromixers with spatially arranged outlet channel: evaluation with Villermaux/Dushman test reaction. Microcyst Technol 23:3117–3130

Sarkar S, Singh KK, Shankar V, Shenoy KT (2014) Numerical simulation of mixing at 1–1 and 1–2 microfluidic junctions. Chem Eng Process 85:227–240

Soleymani A, Kolehmainen E, Turunen I (2008) Numerical and experimental investigations of liquid mixing in T-type micromixers. Chem Eng J 135:S219–S228

Vatankhah P, Shamloo A (2018) Parametric study on mixing process in an in-plane spiral micromixer utilizing chaotic advection. Anal Chim Acta 1022:96–105

Zhendong L, Yangcheng L, Jiawei W, Guangsheng L (2012) Mixing characterization and scaling-up analysis of asymmetrical T-shaped micromixer Experiment and CFD simulation. Chem Eng J 181–182:597–606

Acknowledgements

The support provided by NED University of Engineering and Technology, Karachi, Pakistan, is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fatima, U., Shakaib, M. & Memon, I. Analysis of mass transfer performance of micromixer device with varying confluence angle using CFD. Chem. Pap. 74, 1267–1279 (2020). https://doi.org/10.1007/s11696-019-00975-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-019-00975-8