Abstract

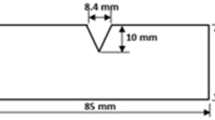

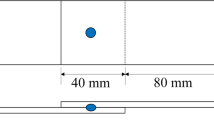

Electric motor industries widely use cold-rolled non-oriented (CRNO) electrical steel sheets (ESSs) as the magnetic core. The sheets are of low carbon–silicon, thin (0.5 mm), and laminated and joined as a stack with gas tungsten arc (GTA) welding. A weld zone is affected by the welding heat and dependent on welding current (30–110 A). The fusion zone (FZ) and heat-affected zone (HAZ) of the weld zone are analyzed for variation in the base metal (BM) and microstructural properties using a scanning electron microscope (SEM) and optical microscope (OM). The effects of weld depth, weld width, stress–strain relationship, filler material, and grain size are investigated with a weld current change. Tensile and micro-hardness testing in FZ and HAZ revealed a change of failure in zones, maximum fracture load, and micro-hardness. The effect of grain size and completely ferritic phases (α-phase and γ-phase) in the weld zone is also studied. All the properties variations are compared and correlated to the input welding heat on the thin–laminated, non-grain-oriented stack on ESS.

Similar content being viewed by others

Abbreviations

- BCC:

-

Body-centered cubic lattice structure

- CRNO:

-

Cold rolled non-grain-oriented electrical steel

- EDS:

-

Energy-dispersive X-ray spectroscopy

- FZ:

-

Fusion zone

- GTA:

-

Gas tungsten arc

- HAZ:

-

Heat-affected zone

- SEM:

-

Scanning electron microscope

- TIG:

-

Tungsten inert gas

- UTS:

-

Ultimate tensile strength

- WEDM:

-

Wire electric discharge machine

- YS:

-

Yield strength

References

Petrovic D S 2010 Non-oriented electrical steel sheets; Materiali in Tehnologije 44 317–325

Lindenmo M, Coombs A and Snell D 2000 Advantages, properties and types of coatings on non-oriented electrical steels; J. Magn. Magn. Mater. 215 79–82

Fischer O and Schneider J 2003 Influence of deformation process on the improvement of non-oriented electrical steel; J. Magn. Magn. Mater. 254 302–306

Schoppa A, Schneider J, Wuppermann C D and Bakon T 2003 Influence of welding and sticking of laminations on the magnetic properties of non-oriented electrical steels; J. Magn. Magn. Mater. 254 367–369

Kurosaki Y, Mogi H, Fujii H, Kubota T and Shiozaki M 2008 Importance of punching and workability in non-oriented electrical steel sheets; J. Magn. Magn. Mater. 320 2474–2480

Vourna P 2016 An accurate method for determining residual stresses with magnetic non-destructive techniques in welded ferromagnetic steels; IOP Conf. Ser.: Mater. Sci. Eng. 108 012017

Zhang Y, Wang H, Chen K and Li S 2017 Comparison of laser and TIG welding of laminated electrical steels; J. Mater. Process. Technol. 247 55–63

ThyssenKrupp India 2017 STABOLIT insulation coatings for NOES. Manual on electrical steel, Catalog Issue-05/2017, version 2

Vourna P, Ktena A, Tsakiridis P E and Hristoforou E 2015 A novel approach of accurately evaluating residual stress and microstructure of welded electrical steels; NDT & E Int. 71 33–42

Senda K, Toda H and Kawano M 2015 Influence of interlocking on core magnetic properties; IEEJ J. Ind. Appl. 4 496–502

Markovits T and Takács J 2010 Edge welding of laminated steel structure by pulsed Nd: YAG laser; Phys. Proc. 5 47–52

Vegelj D, Zajec B, Gregorčič P and Možina J 2014 Adaptive pulsed-laser welding of electrical laminations; Strojniškivestnik—J. Mech. Eng. 60 106–114

Vourna P 2014 Characterization of electron beam welded non-oriented electrical steel with magnetic Barkhausen noise; Key Eng. Mater. 605 39–42

Schade T, Ramsayer R M and Bergmann J P 2014 Laser welding of electrical steel stacks investigation of the weldability. In: Proceedings of the 2014 4th International Electric Drives Production Conference (EDPC), pp. 1–6

Wang H, Zhang Y and Li S 2016 Laser welding of laminated electrical steels; J. Mater. Process. Technol. 230 99–108

Coombs A, Lindenmo M, Snell D and Power D 2001 Review of the types, properties, advantages, and latest developments in insulating coatings on nonoriented electrical steels; IEEE Trans. Magn. 37 544–557

Krings A, Cossale M, Soulard J, Boglietti A and Cavagnino A 2014, Manufacturing influence on the magnetic properties and iron losses in cobalt-iron stator cores for electrical machines. In: Proceedings of the 2014 IEEE Energy Conversion Congress and Exposition (ECCE), pp. 5595–5601

Miyagi D, Aoki Y, Nakano M and Takahashi N 2010 Effect of compressive stress in thickness direction on iron losses of nonoriented electrical steel sheet; IEEE Trans. Magn. 46 2040–2043

Bali M and Muetze A 2017 The influence of cutting on the magnetic properties of electrical steel sheets and its modeling in electric machine design; Elektrotechnik und Informationstechnik 134 185–190

Clerc A J and Muetze A 2012 Measurement of stator core magnetic degradation during the manufacturing process; IEEE Trans. Ind. Appl. 48 1344–1352

Tanaka I and Yashiki H 2010 Magnetic and mechanical properties of newly developed high-strength nonoriented electrical steel; IEEE Trans. Magn. 46 290–293

Krings A, Nategh S, Wallmark O and Soulard J 2013 Influence of the welding process on the performance of slotless PM motors with SiFe and NiFe stator laminations; IEEE Trans. Ind. Appl. 50 296–306

Centner M and Schafer U 2009 Optimized design of high-speed induction motors in respect of the electrical steel grade; IEEE Trans. Ind. Electron. 57 288–295

Emura M, Landgraf F J G, Ross W and Barreta J R 2003 The influence of cutting technique on the magnetic properties of electrical steels; J. Magn. Magn. Mater. 254 358–360

Honda A, Senda K and Sadahiro K 2002 Electrical steel for motors of electric and hybrid vehicles; Kawasaki Steel Giho 34 85–89

ThyssenKrupp India 2007 Power core. Manual on electrical steel, Catalog Issue-12/2007

Moses A J 1990 Electrical steels: past, present and future developments; IEE Proc. A (Phys. Sci., Meas. Instrum., Manag. Educ.) 137 233–245

Takashima M, Morito N, Honda A and Maeda C 1999 Nonoriented electrical steel sheet with low iron loss for high-efficiency motor cores; IEEE Trans. Magn. 35 557–561

Yabumoto M, Kaido C, Wakisaka T, Kubota T and Suzuki N 2003. Electrical steel sheet for traction motor of hybrid/electric vehicles. SHINNITTETSU GIHO, pp. 51–54

ThyssenKrupp India 2012 Power core. Manual on electrical steel, Catalog Issue-09/2012

Dharmik B Y and Lautre N K 2020 Performance assessment of CMT over GTA welding on stacked thin sheets of CRNGO electrical steel; Mater. Lett. 272 127901

Dharmik B Y and Lautre N K 2020 A study on hardness of CRNO electrical sheets for edge joining through TIG welding. In: Advances in Additive Manufacturing and Joining Springer, Singapore, pp. 689–698

Funding

Funding was provided by Science and Engineering Research Board, India (Grant No. CRG/2018/001619).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dharmik, B.Y., Lautre, N.K. Experimental evaluation on weld zone of thin–laminated stacked sheets post-GTA weld of CRNO electrical steel. Sādhanā 46, 71 (2021). https://doi.org/10.1007/s12046-021-01589-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-021-01589-1