Abstract

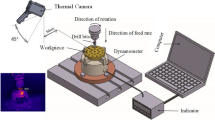

This study focused on using the Taguchi technique to optimize the process parameters in drilling of AISI D2 steel with carbide drills to minimize the surface roughness (Ra) and thrust forces (Ff). The drilling experiments were conducted on a CNC vertical machining centre according to the L18 experimental design. Uncoated drills were classified into three groups: untreated (U), cryo-treated (CT) and cryo-treated and tempered (CTT). The experimental results showed that the CTT drills exhibited the best performance in terms of Ra and Ff due to the improved wear resistance of carbide drills after the cryogenic treatment and tempering. As a result of analysis of variance (ANOVA), it was found that the most influential parameter on both Ra and Ff was the feed rate, with percentage contributions of 66.97% and 80.07%, respectively. The results showed that the Taguchi technique is a powerful method to optimize the process parameters in drilling of tool steel.

Similar content being viewed by others

References

Akıncıoğlu S, Gökkaya H and Uygur İ 2015 A review of cryogenic treatment on cutting tools. Int. J. Adv. Manuf. Technol. 78: 1609–1627

Kıvak T, Samtaş G and Çiçek A 2012 Taguchi method based optimisation of drilling parameters in drilling of AISI 316 steel with PVD monolayer and multilayer coated HSS drills. Measurement 45: 1547–1557

Bal K S 2012 Performance Appraisal of cryo‐treated tool by turnıng operation. National Institute of Technology, Rourkela, pp. 52–80

Thakur D, Ramamoorthy B and Vijayaraghavan L 2008 Influence of different post treatments on tungsten carbide–cobalt inserts. Mater Lett. 62: 4403–4406

Reddy T V S, Sornakumar T, Reddy M V and Venkatram R 2009 Machinability of C45 steel with deep cryogenic treated tungsten carbide cutting tool inserts. Int. J. Refract. Met. H 27: 181–185

Yong A 2006 Cryogenic treatment of cutting tools. National University of Singapore, Singapore

Dogra M, Sharma V S, Sachdeva A, Suri N M and Dureja J S 2011 Performance evaluation of CBN, coated carbide, cryogenically treated uncoated/coated carbide inserts in finish-turning of hardened steel. Int. J. Adv. Manuf. Technol. 57: 541–553

Lal M H, Renganarayanan S and Kalanidhi A 2001 Cryogenic treatment to augment wear resistance of tool and die steel. Cryogenics 41: 149–155

Priyadarshini A 2007 A study of the effect of cryogenic treatment on the performance of high speed steel tools and carbide inserts. National Institute of Technology, Rourkela

Sahoo B N 2011 Effect of cryogenic treatment of cemented carbide inserts on properties & performance evaluation in machining of stainless steel. National Institute of Technology, Rourkela

Çiçek A, Kıvak T, Uygur İ, Ekici E and Turgut Y 2012 Performance of cryogenically treated M35 HSS drills in drilling of austenitic stainless steels. Int. J. Adv. Manuf. Technol. 60: 65–73

Firouzdor V, Nejati E and Khomamizadeh F 2008 Effect of deep cryogenic treatment on wear resistance and tool life of M2 HSS drill. J. Mater. Process. Technol. 206: 467–472

Kumar K V B S K and Choudhury S K 2008 Investigation of tool wear and cutting force in cryogenic machining using design of experiments. J. Mater. Process. Technol. 203: 95–101

Poomari A, Mohan B, Rajadurai A and Senthilkumar A 2012 Study on tool life of coated, cryogenically treated and coated and plain cermet cutting tools while machining steel. Eur. J. Sci. Res. 85: 394–407

Ramji B R, Murthy H N N, Krishna M and Raghu M J 2010a Performance study of cryogenically treated HSS drills in drilling gray cast iron using orthogonal array technique. Res. J. Appl. Sci. 2: 487–491

Ramji B R, Narasimha M H N and Krishna M 2010b Performance analysis of cryogenically treated carbide drills in drilling white cast iron. Int. J. Appl. Eng. Res. 1: 553–560

Thamizhmanii S, Nagib M and Sulaiman H 2011 Performance of deep cryogenically treated and non-treated PVD inserts in milling. J Achiev. Mater. Manuf. Eng. 49: 2

Rumman M R and Hong S J 2011 Optimization of surface roughness by Taguchi design method. Adv. Mater. Resour. 156: 392–395

Zhang J Z, Chen J C and Kirby E D 2007 Surface roughness optimization in an end-milling operation using the Taguchi design method. J. Mater. Process. Technol. 184: 233–239

Asiltürk İ and Akkuş H 2011 Determining the effect of cutting parameters on surface roughness in hard turning using the Taguchi method. Measurement 44: 1697–1704

Göloğlu C and Sakarya N 2008 The effects of cutter path strategies on surface roughness of pocket milling of 1.2738 steel based on Taguchi method. J. Mater. Process. Technol. 206: 7–15

Vijian P and Arunachalam V P 2006 Optimization of squeeze cast parameters of LM6 aluminium alloy for surface roughness using Taguchi method. J. Mater. Process. Technol. 180: 161–166

Tsao C C and Hocheng H 2008 Evaluation of thrust force and surface roughness in drilling composite material using Taguchi analysis and neural network. J. Mater. Process. Technol. 203: 342–348

Silva F J, Franco S D, Machado A R, Ezugwu E O and Souza Jr A M 2006 Performance of cryogenically treated HSS tools. Wear 26: 674–685

Yong A Y L, Seah K H W and Rahman M 2006 Performance evaluation of cryogenically treated tungsten carbide tools in turning. Int. J. Mach. Tools Manuf. 46: 2051–2056

Eşme U 2009 Application of Taguchi Method for the optimization of resistance spot welding process. Arab. J. Sci. Eng. 34: 519–527

Benardos P G and Vosniakos G C 2002 Prediction of surface roughness in CNC face milling using neural networks and Taguchi’s design of experiments. Robot. Comput. Integr. Manuf. 18: 343–354

Akıncıoğlu S, Gökkaya H and Uygur İ 2016 The effects of cryogenic-treated carbide tools on tool wear and surface roughness of turning of Hastelloy C22 based on Taguchi method. Int. J. Adv. Manuf. Technol. 82: 303–314

Çiçek A, Kıvak T and Ekici E 2013 Optimization of drilling parameters using Taguchi technique and response surface methodology (RSM) in drilling of AISI 304 steel with cryogenically treated HSS drills. J. Intell. Manuf. DOI 10.1007/s10845-013-0783-5

Molinari A, Pellizzari M, Gialanella S, Straffelini G and Stiasny K H 2001 Effect of cryogenic treatment on the mechanical properties of tool steels. J. Mater. Process. Technol. 118: 350–355

Singh L P and Singh J 2011 Effects of cryogenic treatment on high-speed steel tools. J. Eng. Technol. 1(2): 88–93. DOI:10.4103/0976-8580.86640

Fang N and Wu Q 2009 A comparative study of the cutting forces in high speed machining of Ti–6Al–4V and Inconel 718 with a round cutting edge tool. J. Mater. Process. Technol. 209: 4385–4389

Guibert N, Paris H, Rech J and Claudin C 2009 Identification of thrust force models for vibratory drilling. Int. J. Mach. Tools Manuf. 49: 730–738

Mauvoisin G, Bartier O, El Abdi R and Nayebi A 2003 Influence of material properties on the drilling thrust to hardness ratio. Int. J. Mach. Tools Manuf. 43: 825–832

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Akıncıoğlu, G., Mendi, F., Çiçek, A. et al. Taguchi optimization of machining parameters in drilling of AISI D2 steel using cryo-treated carbide drills. Sādhanā 42, 213–222 (2017). https://doi.org/10.1007/s12046-017-0598-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12046-017-0598-8