Abstract

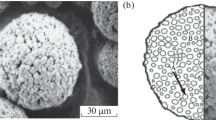

Co-based alloys are promising to offer high-temperature corrosion resistance under extreme environmental conditions. Here, we report a novel approach that exploits the characteristics of the oxidation scale by making the specimens ground at three different levels to compare the effects of surface roughness in the presence and absence of external pressure. At a constant pressure of 2.5 MPa, the influence of surface roughness on the oxidation behaviour at an elevated temperature of 1050°C for 430 h has been investigated via scanning electron microscopy coupled with an energy-dispersive X-ray spectrometer and X-ray diffraction. The results have revealed that for rough surfaces the thickness of the oxide scale with Ra = 76.0 nm is significantly higher compared to a smooth surface with Ra = 13.0 nm. Furthermore, the oxide scale on the rough surface has some micro defects and protrusion compared to smooth surfaces. Besides that, under the applied external pressure and surface roughness, more pressure- and roughness-induced cracks and discontinuity have been observed on the oxide scale.

Graphical Abstract

Similar content being viewed by others

References

Agarwal S and Ocken H 1990 Wear 140 223

Aykut S, Golcu M, Semiz S and Ergur H 2007 Mater. Process. Technol. 190 199

Berthod P 2005 Oxid. Met. 64 235

Oliveira A S C, Villar M and Feder C G 2002 Appl. Surface Sci. 201 154

Song P, Subanovic M, Toscano J, Naumenko D and Quadakkers W J 2011 Mater. Corros. Werkst. Korros. 62 699

Huang T, Bergholz J, Mauer G, Vassen R, Naumenko D and Quadakkers W J 2018 Mater. High Temp. 35 97

Li C, Huang T, Song P, Yuan X, Feng J, Lü K et al 2019 Corros. Sci. 163 108240

Aykut S, Bagci E, Kentli A and Yazıcıoglu O 2007 Mater. Design 28 1880

Shokrani A, Dhokia V and Newman S T 2012 Int. J. Mach. Tools Manuf. 57 83

Akhtar A, Hook M and Reed R 2005 Metall. Mater. Trans. A 36 3001

Raffaitin A, Monceau D, Andrieu E and Crabos F 2006 Acta Mater. 54 4473

Ali S, Lü J, Song P, Ali R and Lu J 2019 Mater. Res. Express 6 1265b2

Xavior M A and Adithan M 2009 J. Mater. Process. Technol. 209 900

Bagci E and Aykut S 2006 J. Adv. Manuf. Technol. 29 940

Wang X, Zhang X, Mu J, Liu H and Li J 2006 Shanghai J. Stomatol. 15 641

Pei H, Wen Z, Li Z, Zhang Y and Yue Z 2018 Appl. Surf. Sci. 440 790

Uran S, Veal B, Grimsditch M, Pearson J and Berger A 2000 Oxid. Met. 54 73

Zhang Z, Hou P, Gesmundo F and Niu Y 2006 Appl. Surf. Sci. 253 881

Huang T, Naumenko D, Song P, Lu J and Quadakkers W J 2018 Oxid. Met. 90 671

Chao J and González-Carrasco J L 1997 Mater. Sci. Eng. A 230 39

Messaoudi K, Huntz A and Lesage B 1998 Mater. Sci. Eng. A 247 248

Mougin J, Lucazeau G, Galerie A and Dupeux M 2001 Mater. Sci. Eng. A 308 118

Huntz A M, Lefevre B and Cassino F 2000 Mater. Sci. Eng. A 290 190

Song P and Lu J S 2013 Adv. Mater. Res. 662 383

Nowak W 2018 Appl. Syst. Innov. 1 32

Calvarin-Amiri G and MolinsR and Huntz A, 2000 Oxid. Met. 53 399

Song P, Naumenko D, Vassen R, Singheiser L and Quadakkers W J 2013 Surf. Coat. Technol. 221 207

Zang J J, Song P, Feng J, Xiong X, Chen R, Liu G L et al 2016 Corros. Sci. 112 170

Madi Y, Salhi E, Charlot F, Galerie A and Wouters Y 2011 Oxid. Met. 75 167

Müller F, Gorr B, Christ H J, Müller J, Butz B, Chen H et al 2019 Corros. Sci. 159 108161

Baufeld B and Schmücker M 2005 Surf. Sci. 199 49

Limarga A M and Wilkinson D S 2007 Acta Mater. 55 189

Evans H 1995 Int. Mater. Rev. 40 1

Jiang S, Li H, Ma J, Xu C, Gong J and Sun C 2010 Corros. Sci. 52 2316

Mohsen S, Abbas A and Akira K 2007 Trans. J. W. R. I. 36 41

Rapp R 1961 Acta Metal. 9 730

Salam S, Hou P, Zhang Y D, Wang H F, Zhang C and Yang Z G 2015 Corros. Sci. 95 143

Takei A and Nii K 1984 Trans. Jpn. Inst. 25 561

Wagner C 1959 J. Electrochem. Soc. 63 772

Yan K, Guo H and Gong S 2014 Corros. Sci. 83 335

Evans H 1983 Corros. Sci. 23 495

Li Z, Qian S and Wang W 2011 Appl. Surf. Sci. 257 10414–10420

Ostwald C and Grabke H J 2004 Corros. Sci. 46 1113

Li C, Song P, Chen K, He X, Yu X and Lu J 2018 Coatings 8 332

Mrowec S 1967 Corros. Sci. 7 563

Zhou C H, Zhang Y and Pan R Y 2019 Key Eng. Mater. 793 67

Li C, Song P, Feng J, Huang T, Lu K, Li Q et al 2019 Appl. Surf. Sci. 479 1178

Platt P, Allen V, Fenwick M, Gass M and Preuss M 2015 Corros. Sci. 98 1

Wang L, Jiang W G, Li X W, Dong J S, Zheng W, Feng H et al 2015 Acta Metall. Sin. Engl. Lett. 28 381

Matsunaga K, Yoshiya M, Shibata N, Ohta H and Mizoguchi T 2022 J. Ceram. Soc. Jpn. 130 648

Gibbs G and Hales R 1977 Corros. Sci. 17 487

Taylor M, Evans H, Busso E and Qian Z 2006 Acta Mater. 54 3241

Taylor M, Evans H, Ponton C and Nicholls J 2000 Surf. Coat Tech. 124 13

Gaillet L, Benmedakhne S, Laksimi A and Moulin G 2003 J. Mater. Sci. 38 1479

Nagl M and Evans W 1993 J. Mater. Sci. 28 6247

Zhou C, Ma H and Wang L 2008 Oxid. Met. 70 287

Wen Z, Zhao Y, Hou H, Tian J and Han P 2017 Superlattice Microst. 103 9

Li C, Song P, Khan A, Feng J, Chen K, Zang J et al 2018 J. Alloys Compd. 739 690

Brister K 1997 Rev. Sci. Instrum. 68 1629

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China under Grant No. 51961019, and the Yunnan Province Science Technology Major Project No. 2019ZE001.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ali, S., Ali, R., Khan, M. et al. Effect of surface roughness at elevated temperature and pressure on the oxidation behaviour of co-based alloy. Bull Mater Sci 47, 55 (2024). https://doi.org/10.1007/s12034-023-03114-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-023-03114-y