Abstract

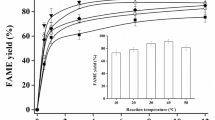

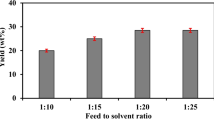

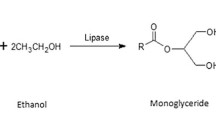

The chemo-enzymatic epoxidation of Lallemantia iberica seed oil (LISO), a novel plant oil characterized by its exceptional high content of alpha-linolenic acid (> 60%), was developed using an immobilized lipase from Pseudozyma antarctica and hydrogen peroxide as oxidant. A statistical approach was used to study the effect of enzyme amount, temperature, time, and solvent amount on the oxirane oxygen content obtained during epoxidation. An oxirane oxygen content of 8.6 ± 0.2% corresponding to a yield of 82% was obtained under optimized conditions that were identified to be at an enzyme load of 8.2 g/mol of double bonds, a solvent amount of 56.4 wt.%, a temperature of 33 °C, and an incubation time of 17 h. In addition, the experimental investigation was combined with a techno-economic and ecological assessment gaining detailed information regarding cost structure and environmental impact for the chemo-enzymatic epoxidation of the novel plant oil.

Similar content being viewed by others

References

Metzger, J. O. (2009). Fats and oils as renewable feedstock for chemistry. European Journal of Lipid Science and Technology, 111, 865–876.

Xia, Y., & Larock, R. C. (2010). Vegetable oil-based polymeric materials: synthesis, properties, and applications. Green Chemistry, 12, 1893–1909.

Niederhauser, W. D. (1951). Chlorinated Rubber and epoxidized oils. ed Company, R. H.), pp. 3.

Gan, L. H., Ooi, K. S., Goh, S. H., Gan, L. M., & Leong, Y. C. (1995). Epoxidized esters of palm olein as plasticizers for poly(vinyl chloride). European Polymer Journal, 31, 719–724.

Al-Mulla, E., Yunus, W., Ibrahim, N., & Rahman, M. (2010). Properties of epoxidized palm oil plasticized polytlactic acid. Journal of Materials Science, 45, 1942–1946.

Campanella, A., Rustoy, E., Baldessari, A., & Baltanás, M. A. (2010). Lubricants from chemically modified vegetable oils. Bioresource Technology, 101, 245–254.

Salimon, J., Salih, N., & Abdullah, B. M. (2012). Production of chemoenzymatic catalyzed monoepoxide biolubricant: optimization and physicochemical characteristics. Journal of Biomedicine and Biotechnology, 2012, 11.

Crivello, J. V., & Narayan, R. (1992). Epoxidized triglycerides as renewable monomers in photoinitiated cationic polymerization. Chemistry of Materials, 4, 692–699.

Overeem, A., Buisman, G. J. H., Derksen, J. T. P., Cuperus, F. P., Molhoek, L., Grisnich, W., & Goemans, C. (1999). Seed oils rich in linolenic acid as renewable feedstock for environment-friendly crosslinkers in powder coatings. Industrial Crops and Products, 10, 157–165.

Dinda, S., Patwardhan, A. V., Goud, V. V., & Pradhan, N. C. (2008). Epoxidation of cottonseed oil by aqueous hydrogen peroxide catalysed by liquid inorganic acids. Bioresource Technology, 99, 3737–3744.

Rüsch gen. Klaas, M., & Warwel, S. (1999). Complete and partial epoxidation of plant oils by lipase-catalyzed perhydrolysis. Industrial Crops and Products, 9, 125–132.

Cai, C., Dai, H., Chen, R., Su, C., Xu, X., Zhang, S., & Yang, L. (2008). Studies on the kinetics of in situ epoxidation of vegetable oils. European Journal of Lipid Science and Technology, 110, 341–346.

Prileschajew, N. (1909). Oxydation ungesättigter Verbindungen mittels organischer Superoxyde. Berichte der Deutschen Chemischen Gesellschaft, 42, 4811–4815.

Bartlett, P. D. (1950). Recent work on the mechanisms of peroxide reactions. Record of Chemical Progress, 11, 47–50.

Swern, D. (1947). Electronic interpretation of the reaction of olefins with organic peracids. Journal of the American Chemical Society, 69, 1692–1698.

Rios, L. A., Weckes, P., Schuster, H., & Hoelderich, W. F. (2005). Mesoporous and amorphous Ti–silicas on the epoxidation of vegetable oils. Journal of Catalysis, 232, 19–26.

Rangarajan, B., Havey, A., Grulke, E., & Culnan, P. (1995). Kinetic parameters of a two-phase model for in situ epoxidation of soybean oil. Journal of the American Oil Chemists’ Society, 72, 1161–1169.

Björkling, F., Godtfredsen, S. E., & Kirk, O. (1990). Lipase-mediated formation of peroxycarboxylic acids used in catalytic epoxidation of alkenes. Journal of the Chemical Society, Chemical Communications, 1301–1303.

Björkling, F., Frykman, H., Godtfredsen, S. E., & Kirk, O. (1992). Lipase catalyzed synthesis of peroxycarboxylic acids and lipase mediated oxidations. Tetrahedron, 48, 4587–4592.

Rüsch gen. Klaas, M., & Warwel, S. (1996). Chemoenzymatic epoxidation of unsaturated fatty acid esters and plant oils. Journal of the American Oil Chemists’ Society, 73, 1453–1457.

Sun, S., Ke, X., Cui, L., Yang, G., Bi, Y., Song, F., & Xu, X. (2011). Enzymatic epoxidation of Sapindus mukorossi seed oil by perstearic acid optimized using response surface methodology. Industrial Crops and Products, 33, 676–682.

Sun, S., Yang, G., Bi, Y., & Liang, H. (2011). Enzymatic epoxidation of corn oil by perstearic acid. Journal of the American Oil Chemists’ Society, 1–5.

Vlček, T., & Petrović, Z. (2006). Optimization of the chemoenzymatic epoxidation of soybean oil. Journal of the American Oil Chemists’ Society, 83, 247–252.

Ulber, R., Sell, D., & Hirth, T. (2011). Renewable raw materials: new feedstocks for the chemical (industry. ed.). John Wiley & Sons.

BMELV, BMBF, BMU and BMWi. (2012) Roadmap Bioraffinerien. ed.

Chauvel, A., Fournier, G., & Raimbault, C. (2003). Manual of process economic evaluation. Editions Technip.

Peters, M. S., Timmerhaus, K. D., & West, R. E. (2003) Plant design and economics for chemical engineering.

(DIN EN ISO 14040, 2006). Umweltmanagement-Ökobilanz-Grundsätze und Rahmenbedingungen (ISO 14040: 2006);. Deutsches Institut für Normung eV.

(DIN EN ISO 14044, 2006) Umweltmanagement; Ökobilanz; Anforderungen und Anleitungen (ISO 14044: 2006). Beuth Verlag, Berlin.

(VDI 6310, 2014) Classification and quality criteria of biorefineries.

Engel, P., Fliedner, E., Fröhling, M., Haase, M., Laure, S., Meier, E., Schultmann, F., Schweinle, J., Susanto, A., & Zeigler, L. (2014), in Lignocellulose-Bioraffinerie - Aufschluss lignocellulosehaltiger Rohstoffe und vollständige stoffliche Nutzung der Komponenten (Phase 2).

Michels, J. (2009) Pilotprojekt" Lignocellulose-Bioraffinerie. Gemeinsamer Schlussbericht zu den wissenschaftlich-technischen Ergebnissen aller Teilvorhaben.

Trippe, F., Fröhling, M., Schultmann, F., Stahl, R., & Henrich, E. (2010). Techno-economic analysis of fast pyrolysis as a process step within biomass-to-liquid fuel production. Waste Biomass Valoriz, 1, 415–430.

Trippe, F., Fröhling, M., Schultmann, F., Stahl, R., & Henrich, E. (2011). Techno-economic assessment of gasification as a process step within biomass-to-liquid (BtL) fuel and chemicals production. Fuel Processing Technology, 92, 2169–2184.

Moncada, J., Tamayo, J., & Cardona, C. A. (2014). Evolution from biofuels to integrated biorefineries: techno-economic and environmental assessment of oil palm in Colombia. Journal of Cleaner Production, 81, 51–59.

Sánchez, M., Marchetti, J. M., El Boulifi, N., Martínez, M., & Aracil, J. (2014) Jojoba oil biorefinery using a green catalyst. Part II: Feasibility study and economical assessment. Biofuels, Bioproducts and Biorefining, n/a-n/a.

West, A. H., Posarac, D., & Ellis, N. (2008). Assessment of four biodiesel production processes using HYSYS.Plant. Bioresource Technology, 99, 6587–6601.

Siebertz, K., van Bebber, D., & Hochkirchen, T. (2010). Statistische Versuchsplanung - Design of Experiments (DoE). Berlin Heidelberg: Springer-Verlag.

Khataee, A. R., Dehghan, G., Ebadi, E., & Pourhassan, M. (2010). Central composite design optimization of biological dye removal in the presence of macroalgae Chara sp. Clean–Soil, Air, Water, 38, 750–757.

Biertümpfel, A., Graf, T., Reinhold, G., & Schmatz, R. (2005) Leitlinie zur effizienten und umweltverträglichen Erzeugung von Iberischem Drachenkopf. Thüringer Landesanstalt für Landwirtschaft.

Richter, R., Graf, T., & Reinhold, G. (2008) Betriebswirtschaftliche Betrachtung der dezentralen Ölsaatenverarbeitung. Thüringer Landesanstalt für Landwirtschaft.

Michels, J., Bäcker, W., Becker, K., Susanto, A., Unkelbach, G., Leschinsky, M., Fliedner, E., Engel, P., Rainer, S., Pohsner, U., Böringer, S., Zibek, S., Naundorf, M., Küstermann, E., Föhling, M., Haase, M., Laure, S., Ziegler, L., Schweinle, J., Meier, E., Tippkötter, N., Duwe, A., Sieker, T., Zorn, H., Imami, A., Riemer, S., Saake, B., Lehnen, R., Meier, D., Kühnel, I., Podschun, J., Strüven, J.-O., Stücker, A., & Amann, M. (2014) Lignocellulose-Bioraffinerie - Aufschluss lignocellulosehaltiger Rohstoffe und vollständige stoffliche Nutzung der Komponenten (Phase 2).

Warwel, S., & Rüsch gen. Klaas, M. (1995). Chemo-enzymatic epoxidation of unsaturated carboxylic acids. Journal of Molecular Catalysis B: Enzymatic, 1, 29–35.

Suh, S., Lenzen, M., Treloar, G. J., Hondo, H., Horvath, A., Huppes, G., Jolliet, O., Klann, U., Krewitt, W., Moriguchi, Y., Munksgaard, J., & Norris, G. (2004). System boundary selection in life-cycle inventories using hybrid approaches. Environmental Science & Technology, 38, 657–664.

Giwa, A. (2017) Comparative cradle-to-grave life cycle assessment of biogas production from marine algae and cattle manure biorefineries. Bioresource Technology.

VCI. (2017) Chemiewirtschaft in Zahlen. 59.

EcoinventCentre. (2010). Ecoinvent data v2.2. Final report ecoinvent v2.2 No. 3. Dübendorf: Swiss Centre for Life Cycle Inventories.

Guinee, J. B. (2002) Handbook on life cycle assessment: operational guide to the ISO standards.

Goud, V. V., Patwardhan, A. V., & Pradhan, N. C. (2006). Studies on the epoxidation of mahua oil (Madhumica indica) by hydrogen peroxide. Bioresource Technology, 97, 1365–1371.

Törnvall, U., Orellana-Coca, C., Hatti-Kaul, R., & Adlercreutz, D. (2007). Stability of immobilized Candida antarctica lipase B during chemo-enzymatic epoxidation of fatty acids. Enzyme and Microbial Technology, 40, 447–451.

Acknowledgements

We like to thank Dr. J. Gottfriedsen (DRACOSA AG) for the supply of Lallemantia iberica seed oil and Novozymes A/S Denmark for the gift of Novozym® 435. We gratefully acknowledge the support of this work by BMEL represented by FNR within the joint research project »Integrated BioProduction« (FKZ of KIT IIP 22001909 and Fraunhofer IGB 22027407).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Haitz, F., Radloff, S., Rupp, S. et al. Chemo-Enzymatic Epoxidation of Lallemantia IbericaSeed Oil: Process Development and Economic-Ecological Evaluation. Appl Biochem Biotechnol 185, 13–33 (2018). https://doi.org/10.1007/s12010-017-2630-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-017-2630-1