Abstract

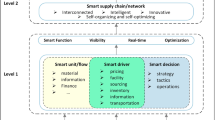

Quality control plays a pivotal role within the Indian textile sector, guaranteeing the alignment of products with customer expectations and industry benchmarks. This study delves into the progression of design models for quality control within the Indian textile industry, with the aim of fostering more eco-conscious manufacturing processes. It scrutinizes the constraints associated with initial quality control methods, underscoring the necessity for more all-encompassing and forward-looking models. The investigation assesses an array of pre-existing quality control frameworks, encompassing the likes of International Quality Standards Models, Structured Quality Control Models, Technological Quality Control Models, and Integrated Quality Control Models. Each model is subject to a comprehensive evaluation based on its strengths, constraints, and applicability in the context of the Indian textile industry. Informed by this analysis, the research advocates for the fusion of Lean, Six Sigma, and Industry 4.0 (LSS 4.0) as a potent quality control paradigm for the Indian textile domain. The LSS 4.0 framework harnesses Lean and Six Sigma principles to optimize processes and curtail defects, while seamlessly incorporating Industry 4.0 innovations for real-time monitoring, data analysis, and automation. While acknowledging the sector's limitations and hurdles like resource scarcity and cultural resistance to change, the study underscores the potential gains of adopting the LSS 4.0 model. In essence, the research lays out a roadmap for industry stakeholders, delineating essential steps such as investing in technology, training, and transforming organizational culture to embrace and implement this integrated model. Succinctly put, the research underscores the significance of advancing quality control models within the Indian textile industry to meet evolving market requisites. The proposed LSS 4.0 model introduces a holistic and technologically sophisticated approach to quality control, fostering sustainable expansion, heightened product quality, and enhanced competitiveness within the industry.

Graphical abstract

Similar content being viewed by others

References

Barrientos, S., Gereffi, G., Rossi, A.: Economic and social upgrading in global production networks: a new paradigm for a changing world. Int. Labour Rev. 150(3–4), 319–340 (2011)

Aremu, M.A., Adeyemi, S.L.: Small and medium scale enterprises as a survival strategy for employment generation in Nigeria. J. Sustain. Dev. 4(1), 200–210 (2011)

Carswell, G., De Neve, G.: Labouring for global markets: conceptualising labour agency in global production networks. Geoforum 44, 62–70 (2013)

Kabeer, N., & Mahmud, S.: Rags, riches and women workers: export-oriented garment manufacturing in Bangladesh. Chains of fortune: linking women producers and workers with global markets, pp. 133–164 (2004)

Ministry of Textiles, Annual Report 2019–20. Retrieved from http://www.textilescommittee.gov.in/Writereaddata/A3%2020190%20Annual%20Report%20English.pdf

Central Statistics Office, Government of India. Retrieved from https://mospi.gov.in/sites/default/files/publication_reports/Economic_Survey_2020-21.pdf

Verma, S., & Mishra, N.: Recognition and marketing opportunities of a "GI" tag in handloom product: a study of Banaras brocades and sarees (2018)

Dahlman, C.: Technology, globalization, and international competitiveness: challenges for developing countries. Industrial development for the 21st century: sustainable development perspectives, pp. 29–83 (2007)

Bag, S., Gupta, S., Kumar, S.: Industry 4.0 adoption and 10R advance manufacturing capabilities for sustainable development. Int. J. Prod. Econ. 231, 1078 (2021)

Nadvi, K., Schmitz, H.: Industrial Clusters in Less Developed Countries Review of Experiences and Research Agenda. Brighton, Institute of Development Studies (1994)

KPMG India: Indian Textiles and Apparel Industry: Stepping onto a higher growth trajectory. Retrieved from https://home.kpmg/in/en/home/insights/2018/05/indian-textiles-pparel-industry.html (2018)

Mandarić, D., Hunjet, A., Vuković, D.: The impact of fashion brand sustainability on consumer purchasing decisions. J. Risk Financ. Manag. 15(4), 176 (2022)

Masoudipour, E., Amirian, H., Sahraeian, R.: A novel closed-loop supply chain based on the quality of returned products. J. Clean. Prod. 151, 344–355 (2017)

Dhakad, M. S.: Bachelor of Fashion Technology (Apparel Production) (Doctoral dissertation, National Institute of Fashion Technology, Mumbai).

Pal, R., Harper, S., Vellesalu, A.: Competitive manufacturing for reshoring textile and clothing supply chains to high-cost environment: a Delphi study. Int. J. Logist. Manag. 29(4), 1147–1170 (2018)

Frederick, S., Gereffi, G.: Upgrading and restructuring in the global apparel value chain: why China and Asia are outperforming Mexico and Central America. Int. J. Technol. Learn. Innov. Dev. 4(1–3), 67–95 (2011)

Zhu, F., Zhang, X.: Impact of online consumer reviews on sales: the moderating role of product and consumer characteristics. J. Mark. 74(2), 133–148 (2010)

Mouttham, L., Garrison, S.J., Archer, D.L., Castelhano, M.G.: A biobank’s journey: Implementation of a quality management system and accreditation to ISO 20387. Biopreserv. Biobank. 19(3), 163–170 (2021)

Jones, E.: Quality Management for Organizations Using Lean Six Sigma Techniques. CRC Press, London (2014)

Kikuchi, M.: Export-oriented garment industries in the rural Philippines. Toward the Rural-based Development of Commerce and Industry: Selected Experiences in East Asia, pp. 89–129 (1998)

Ghobadian, A., Gallear, D.N.: Total quality management in SMEs. Omega 24(1), 83–106 (1996)

Mehta, P. V., & Bhardwaj, S. K.: Managing Quality in the Apparel Industry. New Age International (1998)

Megaw, E.D., Richardson, J.: Eye movements and industrial inspection. Appl. Ergon. 10(3), 145–154 (1979)

Lord, E.: 2—Air flow through plugs of textile fibres: part II. The micronaire test for cotton. J. Text. Inst. Trans. 47(1), 16–47 (1956)

Garvin, D.A.: Managing Quality: The Strategic and Competitive Edge. Simon and Schuster, New York (1988)

Chavan, R. B.: Indian textile industry-environmental issues (2001)

Anderson, J.C., Narus, J.A.: Business marketing: understand what customers value. Harv. Bus. Rev. 76, 53–67 (1998)

Langfield-Smith, K., Greenwood, M.R.: Developing co-operative buyer–supplier relationships: a case study of Toyota. J. Manage. Stud. 35(3), 331–353 (1998)

Bair, J., Gereffi, G.: Local clusters in global chains: the causes and consequences of export dynamism in Torreon’s blue jeans industry. World Dev. 29(11), 1885–1903 (2001)

Knoll, J.S., Rowell, S.L.: Clinical hematology: in-clinic analysis, quality control, reference values, and system selection. Vet. Clin. Small Anim. Pract. 26(5), 981–1002 (1996)

Kolbe, R.H., Burnett, M.S.: Content-analysis research: an examination of applications with directives for improving research reliability and objectivity. J. Consum. Res. 18(2), 243–250 (1991)

Lakhe, R.R., Mohanty, R.P.: Total quality management: concepts, evolution and acceptability in developing economies. Int. J. Qual. Reliab. Manag. 11(9), 9–33 (1994)

Robinson, C.J., Malhotra, M.K.: Defining the concept of supply chain quality management and its relevance to academic and industrial practice. Int. J. Prod. Econ. 96(3), 315–337 (2005)

Marcus, P.A., Willig, J.T. (eds.): Moving Ahead with ISO 14000: Improving Environmental Management and Advancing Sustainable Development, vol. 4. Wiley, London (1997)

Rondinelli, D.A., Vastag, G.: International environmental standards and corporate policies: an integrative framework. Calif. Manage. Rev. 39(1), 106–122 (1996)

Waddock, S.A., Bodwell, C., Graves, S.B.: Responsibility: the new business imperative. Acad. Manag. Perspect. 16(2), 132–148 (2002)

Nayak, R., Akbari, M., Far, S.M.: Recent sustainable trends in Vietnam’s fashion supply chain. J. Clean. Prod. 225, 291–303 (2019)

Partzsch, L., Kemper, L.: Cotton certification in Ethiopia: can an increasing demand for certified textiles create a ‘fashion revolution’? Geoforum 99, 111–119 (2019)

Bacoup, P., Michel, C., Habchi, G., Pralus, M.: From a quality management system (QMS) to a lean quality management system (LQMS). TQM J. 30(1), 20–42 (2018)

Ministry of Textiles, Government of India: Annual Report 2019–2020. Retrieved from http://www.textilescommittee.gov.in/Writereaddata/A3%202019-20%20Annual%20Report%20English.pdf (2020)

Bhat, S., Gijo, E.V., Rego, A.M., Bhat, V.S.: Lean Six Sigma competitiveness for micro, small and medium enterprises (MSME): an action research in the Indian context. TQM J. 33(2), 379–406 (2021)

Patel, P.M., Deshpande, V.A.: Application of plan-do-check-act cycle for quality and productivity improvement-a review. Studies 2(6), 23–34 (2015)

Stauffer, J.: SQC before deming: the works of Walter Shewhart. J. Appl. Manag. Entrep. 8(4), 86 (2003)

Sashkin, M., & Kiser, K. J.: Putting total quality management to work: what TQM means, how to use it, & how to sustain it over the long run. Berrett-Koehler Publishers (1993)

Leitner, P.M.: Japan’s post-war economic success: deming, quality, and contextual realities. J. Manag. Hist. 5(8), 489–505 (1999)

Sá, J.C., Vaz, S., Carvalho, O., Lima, V., Morgado, L., Fonseca, L., Santos, G.: A model of integration ISO 9001 with Lean six sigma and main benefits achieved. Total Qual. Manag. Bus. Excell. 33(1–2), 218–242 (2022)

Schonberger, R.J.: Japanese production management: an evolution—with mixed success. J. Oper. Manag. 25(2), 403–419 (2007)

Humphrey, J.: Industrial reorganization in developing countries: from models to trajectories. World Dev. 23(1), 149–162 (1995)

Wani, I.A., Mehraj, H.K.: Total quality management in education: an analysis. Int. J. Hum. Soc. Sci. Invent. 3(6), 71–78 (2014)

D’Costa, A.P.: An alternative model of development? Co-operation and flexible industrial practices in India. J. Int. Dev. J. Dev. Stud. Assoc. 10(3), 301–321 (1998)

Demirbag, M., Tatoglu, E., Tekinkus, M., Zaim, S.: An analysis of the relationship between TQM implementation and organizational performance: evidence from Turkish SMEs. J. Manuf. Technol. Manag. 17(6), 829–847 (2006)

Pham, H. C., Ulhaq, I., Yeow, P., & Akbari, M.: Other lean tools in fashion and textile manufacturing. In: Lean Supply Chain Management in Fashion and Textile Industry, pp. 199–218. Singapore: Springer Nature Singapore (2022)

Madanhire, I., Mbohwa, C.: Application of statistical process control (SPC) in manufacturing industry in a developing country. Procedia Cirp 40, 580–583 (2016)

Berengueres, J.: The Toyota production system re-contextualized. Lulu.com (2007)

Panizzolo, R., Garengo, P., Sharma, M.K., Gore, A.: Lean manufacturing in developing countries: evidence from Indian SMEs. Prod. Plan. Control 23(10–11), 769–788 (2012)

Wickramasinghe, G.L.D., Wickramasinghe, V.: Implementation of lean production practices and manufacturing performance: the role of lean duration. J. Manuf. Technol. Manag. 28(4), 531–550 (2017)

Gijo, E. V., Antony, J., Hernandez, J., & Scaria, J.: Reducing patient waiting time in a pathology department using the Six Sigma methodology. Leadership in Health Services (2013)

Hsu, C.W., Kuo, T.C., Chen, S.H., Hu, A.H.: Using DEMATEL to develop a carbon management model of supplier selection in green supply chain management. J. Clean. Prod. 56, 164–172 (2013)

Nayak, R., & Padhye, R.: Introduction to automation in garment manufacturing. In Automation in Garment Manufacturing, pp. 1–27. Woodhead Publishing (2018)

Venkatachalam, L.: Environmental implications of the manufacturing sector: a case study of textile manufacturing in Tiruppur, TamilNadu, India. Rev. Dev. Change 20(2), 165–175 (2015)

Rao, S.K., Prasad, R.: Impact of 5G technologies on industry 4.0. Wirel. Pers. Commun. 100, 145–159 (2018)

Ding, K., Jiang, P.: RFID-based production data analysis in an IoT-enabled smart job-shop. IEEE/CAA J. Automatica Sinica 5(1), 128–138 (2017)

Nayak, R., Padhye, R. (eds.): Automation in Garment Manufacturing. Woodhead Publishing, Sawston (2017)

Dwivedi, A., Dwivedi, A.: Role of computer and automation in design and manufacturing for mechanical and textile industries: CAD/CAM. Int. J. Innov. Technol. Explor. Eng. (IJITEE) 3(3), 8 (2013)

Liu, M., Fang, S., Dong, H., Xu, C.: Review of digital twin about concepts, technologies, and industrial applications. J. Manuf. Syst. 58, 346–361 (2021)

Shafiq, M., Lasrado, F., Hafeez, K.: The effect of TQM on organisational performance: empirical evidence from the textile sector of a developing country using SEM. Total Qual. Manag. Bus. Excell. 30(1–2), 31–52 (2019)

Chatterjee, S., Chaudhuri, R., Vrontis, D., & Papadopoulos, T.: Examining the impact of deep learning technology capability on manufacturing firms: moderating roles of technology turbulence and top management support. Ann. Oper. Res. 1–21 (2022)

Ahmad, S., Miskon, S., Alabdan, R., Tlili, I.: Towards sustainable textile and apparel industry: exploring the role of business intelligence systems in the era of industry 4.0. Sustainability 12(7), 2632 (2020)

Kumar, R., Rani, S., Awadh, M.A.: Exploring the application sphere of the internet of things in industry 4.0: a review, bibliometric and content analysis. Sensors 22(11), 4276 (2022)

Arnold, C.E.: Labour recruitment systems in global production networks: the ruralisation of labour regimes in South India’s garment and textile industries. J. Contemp. Asia 52(5), 737–759 (2022)

Sanz-Calcedo, J.G., González, A.G., López, O., Salgado, D.R., Cambero, I., Herrera, J.M.: Analysis on integrated management of the quality, environment and safety on the industrial projects. Proc. Eng. 132, 140–145 (2015)

Patel, A. S., & Patel, K. M.: Status of Lean Six Sigma implementation in Indian industries: a cross-sectional national survey. Int. J. Lean Six Sigma (ahead-of-print) (2022)

Madhani, P.M.: Performance optimisation of retail industry: lean six sigma approach. ASBM J. Manag. 13(1), 74–91 (2020)

Núñez-Merino, M., Maqueira-Marín, J.M., Moyano-Fuentes, J., Martínez-Jurado, P.J.: Information and digital technologies of Industry 4.0 and lean supply chain management: a systematic literature review. Int. J. Prod. Res. 58(16), 5034–5061 (2020)

Skalli, D., Charkaoui, A., Cherrafi, A., Garza-Reyes, J.A., Antony, J., Shokri, A.: Industry 4.0 and lean six sigma integration in manufacturing: a literature review, an integrated framework and proposed research perspectives. Qual. Manag. J. 30(1), 16–40 (2023)

Novak, A., Bennett, D., Kliestik, T.: Product decision-making information systems, real-time sensor networks, and artificial intelligence-driven big data analytics in sustainable industry 4.0. Econ. Manag. Financ. Mark. 16(2), 62–72 (2021)

Chen, C.L.: Value creation by SMEs participating in global value chains under industry 4.0 trend: case study of textile industry in Taiwan. J. Glob. Inf. Technol. Manag. 22(2), 120–145 (2019)

Wang, F.K., Rahardjo, B., Rovira, P.R.: Lean six sigma with value stream mapping in industry 4.0 for human-centered workstation design. Sustainability 14(17), 11020 (2022)

Tissir, S., Cherrafi, A., Chiarini, A., Elfezazi, S., Bag, S.: Lean Six Sigma and industry 4.0 combination: scoping review and perspectives. Total Qual. Manag. Bus. Excell. 34(3–4), 261–290 (2023)

Citybabu, G., Yamini, S.: The implementation of Lean Six Sigma framework in the Indian context: a review and suggestions for future research. TQM J. 34(6), 1823–1859 (2022)

Kwon, O., Lee, N., Shin, B.: Data quality management, data usage experience and acquisition intention of big data analytics. Int. J. Inf. Manage. 34(3), 387–394 (2014)

Schoonahd, J.W., Gould, J.D., Miller, L.A.: Studies of visual inspection. Ergonomics 16(4), 365–379 (1973)

Swanson, R. G.: Sample examination manual (p. 117). Tulsa, Ok, USA: American Association of Petroleum Geologists (1981)

Phase, A. D., & QA, C. T.: Quality Assurance/Quality Control (2002)

Voss, C.A., Roth, A.V., Rosenzweig, E.D., Blackmon, K., Chase, R.B.: A tale of two countries’ conservatism, service quality, and feedback on customer satisfaction. J. Serv. Res. 6(3), 212–230 (2004)

Ting, S.C., Cho, D.I.: An integrated approach for supplier selection and purchasing decisions. Supply Chain Manag. Int. J. 13, 116–127 (2008)

Robinson, L.E., Goodway, J.D.: Instructional climates in preschool children who are at-risk. Part I: object-control skill development. Res. Q. Exerc. Sport 80(3), 533–542 (2009)

Hoyle, D.: ISO 9000 Quality Systems Handbook: Using the Standards as a Framework for Business Improvement. Routledge, London (2009)

Alper, M.M.: Experience with ISO quality control in assisted reproductive technology. Fertil. Steril. 100(6), 1503–1508 (2013)

Rodríguez, G., Alegre, F.J., Martínez, G.: Evaluation of environmental management resources (ISO 14001) at civil engineering construction worksites: a case study of the community of Madrid. J. Environ. Manage. 92(7), 1858–1866 (2011)

Orzes, G., Jia, F., Sartor, M., Nassimbeni, G.: Performance implications of SA8000 certification. Int. J. Oper. Prod. Manag. 37, 1625–1653 (2017)

Nemčić, I.: Importance of Oeko-tex standard for textile industry (Doctoral dissertation, University of Zagreb. Faculty of Textile Technology) (2017)

Ye, S., Wang, Y., Huang, D., Li, J., Gong, Y., Xu, L., Liu, L.: Genetic purity testing of F1 hybrid seed with molecular markers in cabbage (Brassica oleracea var. capitata). Sci. Hortic. 155, 92–96 (2013)

Chojnacka-Komorowska, A., & Kochaniec, S.: Improving the quality control process using the PDCA cycle. Prace Naukowe Uniwersytetu Ekonomicznego we Wrocławiu, 63(4) (2019)

Wang, L.R., Wang, Y., Lou, Y., Li, Y., Zhang, X.G.: The role of quality control circles in sustained improvement of medical quality. Springerplus 2, 1–5 (2013)

Kumar, R.: Kaizen a tool for continuous quality improvement in Indian manufacturing organization. Int. J. Math. Eng. Manag. Sci. 4(2), 452 (2019)

Chen, C.K., Reyes, L., Dahlgaard, J., Dahlgaard-Park, S.M.: From quality control to TQM, service quality and service sciences: a 30-year review of TQM literature. Int. J. Qual. Serv. Sci. 14(2), 217–237 (2022)

Nafiu, M. O., Hamid, A. A., Muritala, H. F., & Adeyemi, S. B.: Preparation, standardization, and quality control of medicinal plants in Africa. In: Medicinal Spices and Vegetables from Africa, pp. 171–204 (2017)

Rosato, D. V., & Rosato, M. G.: Statistical process control and quality control. In: Injection Molding Handbook, pp. 1127–1162 (2000)

Sundar, R., Balaji, A.N., Kumar, R.S.: A review on lean manufacturing implementation techniques. Proc. Eng. 97, 1875–1885 (2014)

Ishak, A., Siregar, K., Naibaho, H.: Quality control with Six Sigma DMAIC and grey failure mode effect analysis (FMEA): a review. IOP Conf. Ser. Mater. Sci. Eng. 505(1), 012057 (2019)

Chen, C., Zhang, J., Delaurentis, T.: Quality control in food supply chain management: an analytical model and case study of the adulterated milk incident in China. Int. J. Prod. Econ. 152, 188–199 (2014)

Parkot, K., & Sioma, A.: Development of an automated quality control system of confectionery using a vision system. In: Photonics Applications in Astronomy, Communications, Industry, and High-Energy Physics Experiments, vol. 10808, pp. 343-351 (2018)

Gibson, N.M., Dudley, N.J., Griffith, K.: A computerized quality control testing system for B-mode ultrasound. Ultrasound Med. Biol. 27(12), 1697–1711 (2001)

Balasubramaniyan, C., Manivannan, D.: IoT enabled air quality monitoring system (AQMS) using Raspberry Pi. Indian J. Sci. Technol. 9(39), 1–6 (2016)

Herakovic, N.: Robot Vision in Industrial Assembly and Quality Control Processes. INTECH Open Access Publisher, London, UK (2010)

González-Lluch, C., Company, P., Contero, M., Camba, J.D., Plumed, R.: A survey on 3D CAD model quality assurance and testing tools. Comput. Aid. Des. 83, 64–79 (2017)

Hazen, B.T., Boone, C.A., Ezell, J.D., Jones-Farmer, L.A.: Data quality for data science, predictive analytics, and big data in supply chain management: an introduction to the problem and suggestions for research and applications. Int. J. Prod. Econ. 154, 72–80 (2014)

Fahle, S., Prinz, C., Kuhlenkötter, B.: Systematic review on machine learning (ML) methods for manufacturing processes: identifying artificial intelligence (AI) methods for field application. Procedia CIRP 93, 413–418 (2020)

Sariyer, G., Mangla, S. K., Kazancoglu, Y., Ocal Tasar, C., & Luthra, S.: Data analytics for quality management in industry 4.0 from a MSME perspective. Ann. Oper. Res. 1–29 (2021)

Sodhi, H.S., Singh, D., Singh, B.J.: An empirical analysis of critical success factors of Lean Six Sigma in Indian SMEs. Int. J. Six Sigma Compet. Adv. 11(4), 227–252 (2019)

Labodová, A.: Implementing integrated management systems using a risk analysis-based approach. J. Clean. Prod. 12(6), 571–580 (2004)

Muruganandham, R., Venkatesh, K., Devadasan, S.R., Harish, V.: TQM through the integration of blockchain with ISO 9001:2015 standard-based quality management system. Total Qual. Manag. Bus. Excell. 34(3–4), 291–311 (2023)

Sodhi, H.S., Singh, D., Singh, B.J.: A conceptual examination of Lean, Six Sigma and Lean Six Sigma models for managing waste in manufacturing SMEs. World J. Sci. Technol. Sustain. Dev. 17(1), 20–32 (2020)

Kaswan, M. S., Rathi, R., Cross, J., Garza-Reyes, J. A., Antony, J., & Yadav, V.: Integrating green Lean Six Sigma and industry 4.0: a conceptual framework. J. Manuf. Technol. Manag. (ahead-of-print) (2022)

Shahin, M., Chen, F.F., Bouzary, H., Krishnaiyer, K.: Integration of Lean practices and industry 4.0 technologies: smart manufacturing for next-generation enterprises. Int. J. Adv. Manuf. Technol. 107, 2927–2936 (2020)

Chiarini, A., Kumar, M.: Lean Six Sigma and Industry 4.0 integration for operational excellence: evidence from Italian manufacturing companies. Prod. Plan. Control 32(13), 1084–1101 (2021)

Sodhi, H.S., Singh, D., Singh, B.J.: Lean Six Sigma practices a competitive priority in SME’s: a critical review. Int. J. Agile Syst. Manag. 13(1), 60–78 (2020)

Sharma, A., & Singh, B. J.: Understanding lean six sigma 4.0 through golden circle model. EasyChair Preprint, 3314 (2020)

Sodhi, H.S., Singh, D., Singh, B.J.: Implementation of Lean Six Sigma model for scrap reduction in machining sector. Int. J. Bus. Excell. 27(1), 110–124 (2022)

Sharma, A., Singh, B.J.: Understanding LSS 4.0 through golden circle model and reviewing its scope in Indian textile industry. Int. J. Six Sigma Compet. Adv. 14(1), 120–137 (2022)

Sodhi, H.S., Singh, B.J., Singh, D.: SWOT analysis of Lean Six Sigma: a review. Int. J. Bus. Excell. 29(2), 162–184 (2023)

Adin, M. Ş.: Investigation of mechanical properties of composites obtained from textile wastes. Batman Energy Summit, 30 June-02 July 2022, Batman, Turkey (2022)

Funding

The authors did not receive support from any organization for the submitted work. No funding was received to assist with the preparation of this manuscript. The authors have no relevant financial or non-financial interests to disclose.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is not any conflict of interest of any kind.

Ethical approval

All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sharma, A., Singh, B.J. Evolution of modified LSS 4.0 model for sustainable Indian textile industry: a narrative review. Int J Interact Des Manuf (2023). https://doi.org/10.1007/s12008-023-01534-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-023-01534-y