Abstract

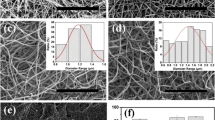

Over the last four decades, additive manufacturing has established itself as a cost-effective, on-demand method for fabricating geometrically complicated structures. Tissue engineering has incited a lot of interest in recent years due to its enormous potential for repairing or replacing damaged tissues. In terms of mechanical and biological properties, creating scaffolds for tissue engineering remains a challenge. The current review concentrates on scaffold manufacturing of PLA nanofibers (NF)-based scaffolds as it is bioresorbable & biocompatible with human body, since they are one of the three most significant components in tissue engineering, along with seed cells, growth regulators, and scaffolds that could be helpful for novice researchers. In addition, the technological aspects of the electrospinning technique are employed to manufacture PLA NF in the case study, and fused filament fabrication (FFF) technology is used to build tensile specimens of PLA/PLA-NF composites. The results of the case study have been supported by tensile testing, X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FTIR), and scanning electron microscopy (SEM).

Similar content being viewed by others

References

Prakash, K.S., Nancharaih, T., Rao, V.V.S.: sciencedirect additive manufacturing techniques in manufacturing—an overview. Mater. Today Proc. 5(2), 3873–3882 (2018). https://doi.org/10.1016/j.matpr.2017.11.642

Tofail, S.A.M., Koumoulos, E.P., Bandyopadhyay, A., Bose, S., O’Donoghue, L., Charitidis, C.: Additive manufacturing: scientific and technological challenges, market uptake and opportunities. Mater. Today 21(1), 22–37 (2018). https://doi.org/10.1016/j.mattod.2017.07.001

DebRoy, T., et al.: Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 92, 112–224 (2018). https://doi.org/10.1016/j.pmatsci.2017.10.001

Herzog, D., Seyda, V., Wycisk, E., Emmelmann, C.: Additive manufacturing of metals. Acta Mater. 117, 371–392 (2016). https://doi.org/10.1016/j.actamat.2016.07.019

Yan, X., Gu, P.: A review of rapid prototyping technologies and systems. CAD Comput. Aided Des. 28(4), 307–318 (1996). https://doi.org/10.1016/0010-4485(95)00035-6

Singh, S., Ramakrishna, S., Singh, R.: Material issues in additive manufacturing: a review. J. Manuf. Process. 25, 185–200 (2017). https://doi.org/10.1016/j.jmapro.2016.11.006

Gao, W., et al.: The status, challenges, and future of additive manufacturing in engineering. CAD Comput. Aided Des. 69, 65–89 (2015). https://doi.org/10.1016/j.cad.2015.04.001

Qu, H.: Additive manufacturing for bone tissue engineering scaffolds. Mater. Today Commun. 24, 101024 (2020). https://doi.org/10.1016/j.mtcomm.2020.101024

Jose, R.R., Rodriguez, M.J., Dixon, T.A., Omenetto, F., Kaplan, D.L.: Evolution of bioinks and additive manufacturing technologies for 3D bioprinting. ACS Biomater. Sci. Eng. 2(10), 1662–1678 (2016). https://doi.org/10.1021/acsbiomaterials.6b00088

Vedadghavami, A., et al.: Manufacturing of hydrogel biomaterials with controlled mechanical properties for tissue engineering applications. Acta Biomater. 62, 42–63 (2017). https://doi.org/10.1016/j.actbio.2017.07.028

Henkel, J., et al.: Bone regeneration based on tissue engineering conceptions-A 21st century perspective. Bone Res. 1, 216–248 (2013). https://doi.org/10.4248/BR201303002

Fomby, P., et al.: Stem cells and cell therapies in lung biology and diseases: conference report. Ann. Am. Thorac. Soc. 12(3), 181–204 (2010). https://doi.org/10.1002/term

J. W. Haycock, Chapter 1 and techniques. 3D Cell Cult. Methods Protoc. Methods Mol. Biol. vol. 695, no. 2, pp. 1–15, (2011) https://doi.org/10.1007/978-1-60761-984-0.

Melchels, F.P.W., Domingos, M.A.N., Klein, T.J., Malda, J., Bartolo, P.J., Hutmacher, D.W.: Additive manufacturing of tissues and organs. Prog. Polym. Sci. 37(8), 1079–1104 (2012). https://doi.org/10.1016/J.PROGPOLYMSCI.2011.11.007

A. D. S. To, Bioactive Peptide Nanofibers for Bone Tissue Regeneration. no. June, (2017).

Rezwan, K., Chen, Q.Z., Blaker, J.J., Boccaccini, A.R.: Biodegradable and bioactive porous polymer/inorganic composite scaffolds for bone tissue engineering. Biomaterials 27(18), 3413–3431 (2006). https://doi.org/10.1016/j.biomaterials.2006.01.039

Marconi, S., et al.: Value of 3D printing for the comprehension of surgical anatomy. Surg. Endosc. 31(10), 4102–4110 (2017). https://doi.org/10.1007/s00464-017-5457-5

Do, A.V., Khorsand, B., Geary, S.M., Salem, A.K.: 3D Printing of Scaffolds for Tissue Regeneration Applications. Adv. Healthc. Mater. 4(12), 1742–1762 (2015). https://doi.org/10.1002/adhm.201500168

Ashammakhi, N., et al.: Bioinks and bioprinting technologies to make heterogeneous and biomimetic tissue constructs. Mater. Today Bio 1, 100008 (2019). https://doi.org/10.1016/j.mtbio.2019.100008

Shahbazi, M., Jäger, H.: Current status in the utilization of biobased polymers for 3D printing process: a systematic review of the materials, processes, and challenges. ACS Appl. Bio Mater. 4(1), 325–369 (2021). https://doi.org/10.1021/acsabm.0c01379

Williams, D., Thayer, P., Martinez, H., Gatenholm, E., Khademhosseini, A.: A perspective on the physical, mechanical and biological specifications of bioinks and the development of functional tissues in 3D bioprinting. Bioprinting 9, 19–36 (2018). https://doi.org/10.1016/j.bprint.2018.02.003

Okamoto, M., John, B.: Synthetic biopolymer nanocomposites for tissue engineering scaffolds. Prog. Polym. Sci. 38(10–11), 1487–1503 (2013). https://doi.org/10.1016/j.progpolymsci.2013.06.001

Roseti, L., et al.: Scaffolds for bone tissue engineering: state of the art and new perspectives. Mater. Sci. Eng. C 78, 1246–1262 (2017). https://doi.org/10.1016/j.msec.2017.05.017

Darie-Niță, R.N., Râpă, M., Frąckowiak, S.: special features of polyester-based materials for medical applications. Polymers (Basel) 14(5), 1–49 (2022). https://doi.org/10.3390/polym14050951

Li, Y., et al.: The effect of mechanical loads on the degradation of aliphatic biodegradable polyesters. Regen. Biomater. 4(3), 179–190 (2017). https://doi.org/10.1093/rb/rbx009

Sabir, M.I., Xu, X., Li, L.: A review on biodegradable polymeric materials for bone tissue engineering applications. J. Mater. Sci. 44(21), 5713–5724 (2009). https://doi.org/10.1007/s10853-009-3770-7

Sakhare, M.S., Rajput, H.H.: Polymer grafting and applications in pharmaceutical drug delivery systems—a brief review. Asian J. Pharm. Clin. Res. 10(6), 59–63 (2017). https://doi.org/10.22159/ajpcr.2017.v10i6.18072

Lao, L.L., Venkatraman, S.S., Peppas, N.A.: Modeling of drug release from biodegradable polymer blends. Eur. J. Pharm. Biopharm. 70(3), 796–803 (2008). https://doi.org/10.1016/j.ejpb.2008.05.024

Rokkanen, P.U., et al.: Bioabsorbable fixation in orthopaedic surgery and traumatology. Biomaterials 21(24), 2607–2613 (2000). https://doi.org/10.1016/S0142-9612(00)00128-9

Murphy, W.L., McDevitt, T.C., Engler, A.J.: Materials as stem cell regulators. Nat. Mater. 13(6), 547–557 (2014). https://doi.org/10.1038/nmat3937

Singh, N., Singh, R., Ahuja, I.P.S., Farina, I., Fraternali, F.: Metal matrix composite from recycled materials by using additive manufacturing assisted investment casting. Compos. Struct. 207, 129–135 (2019). https://doi.org/10.1016/j.compstruct.2018.09.072

Capuana, E., Lopresti, F., Carfì Pavia, F., Brucato, V., La Carrubba, V.: Solution-based processing for scaffold fabrication in tissue engineering applications: a brief review. Polymers (Basel) (2021). https://doi.org/10.3390/polym13132041

Yang, Z., Peng, H., Wang, W., Liu, T.: Crystallization behavior of poly(ε-caprolactone)/layered double hydroxide nanocomposites. J. Appl. Polym. Sci. 116(5), 2658–2667 (2010). https://doi.org/10.1002/app

Perianes-Rodriguez, A., Waltman, L., van Eck, N.J.: Constructing bibliometric networks: a comparison between full and fractional counting. J. Informetr. 10(4), 1178–1195 (2016). https://doi.org/10.1016/j.joi.2016.10.006

Vacanti, J.P., Langer, R.: Tissue engineering: the design and fabrication of living replacement devices for surgical reconstruction and transplantation. Lancet (1999). https://doi.org/10.1016/s0140-6736(99)90247-7

N. Horzum, N. Arik, and Y. B. Truong, Nanofibers for fiber-reinforced composites. Elsevier Ltd, (2017), https://doi.org/10.1016/B978-0-08-101871-2.00012-6.

Agarwal, S., Wendorff, J.H., Greiner, A.: Progress in the field of electrospinning for tissue engineering applications. Adv. Mater. 21(32–33), 3343–3351 (2009). https://doi.org/10.1002/adma.200803092

Gonzales, R.R., Park, M.J., Tijing, L., Han, D.S., Phuntsho, S., Shon, H.K.: Modification of nanofiber support layer for thin film composite forward osmosis membranes via layer-by-layer polyelectrolyte deposition. Membranes (2018). https://doi.org/10.3390/membranes8030070

Hasanzadeh, M., Mottaghitalab, V., Ansari, R., Radavi Moghadam, B., Haghi, A.K.: Issues in production of carbon nanotubes and related nanocomposites: a comprehensive review. Cellul. Chem. Technol. 49(3–4), 237–257 (2015)

Lannutti, J., Reneker, D., Ma, T., Tomasko, D., Farson, D.: Electrospinning for tissue engineering scaffolds. Mater. Sci. Eng. C 27(3), 504–509 (2007). https://doi.org/10.1016/j.msec.2006.05.019

Martins, A., Reis, R.L., Neves, N.M.: Electrospinning: processing technique for tissue engineering scaffolding. Int. Mater. Rev. 53(5), 257–274 (2008). https://doi.org/10.1179/174328008X353547

Rahmati, M., et al.: Electrospinning for tissue engineering applications. Prog. Mater. Sci. (2021). https://doi.org/10.1016/j.pmatsci.2020.100721

Kim, J.E., Kim, S.H., Jung, Y.: Current status of three-dimensional printing inks for soft tissue regeneration. Tissue Eng. Regen. Med. 13(6), 636–646 (2016). https://doi.org/10.1007/s13770-016-0125-8

Caramella, C., et al.: Controlled delivery systems for tissue repair and regeneration. J. Drug Deliv. Sci. Technol. 32, 206–228 (2016). https://doi.org/10.1016/j.jddst.2015.05.015

C. Republic, Synthetic polymer scaffolds for soft tissue engineering department of biological models, institute of macromolecular chemistry of the czech academy. vol. 67, (2018).

Ekiert, M., Mlyniec, A., Uhl, T.: The influence of degradation on the viscosity and molecular mass of poly(lactide acid) biopolymer. Diagnostyka 16(4), 63–70 (2015)

Abdul Khalil, H.P.S., et al.: A review on micro- to nanocellulose biopolymer scaffold forming for tissue engineering applications. Polymers (2020). https://doi.org/10.3390/POLYM12092043

O’Brien, F.J.: Biomaterials & scaffolds for tissue engineering. Mater. Today 14(3), 88–95 (2011). https://doi.org/10.1016/S1369-7021(11)70058-X

Tan, X., Tan, Y.J.: 3D printing of metallic cellular scaffolds for bone implants. 3D 4D Print. Biomed. Appl (2018). https://doi.org/10.1002/9783527813704.ch12

Shadjou, N., Hasanzadeh, M., Khalilzadeh, B.: Graphene based scaffolds on bone tissue engineering. Bioengineered 9(1), 38–47 (2018). https://doi.org/10.1080/21655979.2017.1373539

Li, X., et al.: 3D-printed biopolymers for tissue engineering application. Int. J. Polym. Sci. (2014). https://doi.org/10.1155/2014/829145

Mochane, M.J., Sefadi, J.S., Motsoeneng, T.S., Mokoena, T.E., Mofokeng, T.G., Mokhena, T.C.: The effect of filler localization on the properties of biopolymer blends, recent advances: a review. Polym. Compos. 41(7), 2958–2979 (2020). https://doi.org/10.1002/pc.25590

P. Cite, T. H. E. Published, and R. Record, Fabricating poly ( lactic acid ) and poly ( lactic acid )/ poly ( caprolactone ) blend fibres via electrospinning by. (2019).

Biomaterials and Applications, vol. 506. (2012). https://doi.org/10.1201/9781003049203-9.

Neumann, I.A., Flores-Sahagun, T.H.S., Ribeiro, A.M.: Biodegradable poly (L-lactic acid) (PLLA) and PLLA-3-arm blend membranes: the use of PLLA-3-arm as a plasticizer. Polym. Test. 60, 84–93 (2017). https://doi.org/10.1016/j.polymertesting.2017.03.013

Park, S.H., et al.: Scaffolds for bone tissue engineering fabricated from two different materials by the rapid prototyping technique: PCL versus PLGA. J. Mater. Sci. Mater. Med. 23(11), 2671–2678 (2012). https://doi.org/10.1007/s10856-012-4738-8

E. M. Elmowafy, M. Tiboni, and M. E. Soliman, Biocompatibility, biodegradation and biomedical applications of poly(lactic acid)/poly(lactic-co-glycolic acid) micro and nanoparticles, vol. 49, no. 4. Springer Singapore, 2019. https://doi.org/10.1007/s40005-019-00439-x.

Gentile, P., Chiono, V., Carmagnola, I., Hatton, P.V.: An overview of poly(lactic-co-glycolic) acid (PLGA)-based biomaterials for bone tissue engineering. Int. J. Mol. Sci. 15(3), 3640–3659 (2014). https://doi.org/10.3390/ijms15033640

Ghitman, J., Biru, E.I., Stan, R., Iovu, H.: Review of hybrid PLGA nanoparticles: future of smart drug delivery and theranostics medicine. Mater. Des. (2020). https://doi.org/10.1016/j.matdes.2020.108805

S. K. I. H. Biomaterijala, (2011) Medicinska revija medical review of synthetic biomaterials. vol. 3, no. 1, pp. 51–56.

Primavera, A., Novello, P.: Quantitative EEG findings in patients with subcortical vascular encephalopathy. Eur. Psychiatry 7(3), 121–127 (1992). https://doi.org/10.1017/s0924933800003059

Abudula, T., Saeed, U., Memic, A., Gauthaman, K., Hussain, M.A., Al-Turaif, H.: Electrospun cellulose Nano fibril reinforced PLA/PBS composite scaffold for vascular tissue engineering”. J. Polym. Res. (2019). https://doi.org/10.1007/s10965-019-1772-y

Yin, G.B., Zhang, Y.Z., Wang, S.D., Shi, D.B., Dong, Z.H., Fu, W.G.: Study of the electrospun PLA/silk fibroin-gelatin composite nanofibrous scaffold for tissue engineering. J. Biomed. Mater. Res. Part A 93(1), 158–163 (2010). https://doi.org/10.1002/jbm.a.32496

Wang, W., et al.: 3D printing of PLA/n-HA composite scaffolds with customized mechanical properties and biological functions for bone tissue engineering. Compos. Part B Eng. (2021). https://doi.org/10.1016/j.compositesb.2021.109192

Arastouei, M., Khodaei, M., Atyabi, S.M., Jafari Nodoushan, M.: The in-vitro biological properties of 3D printed poly lactic acid/akermanite composite porous scaffold for bone tissue engineering. Mater. Today Commun. (2021). https://doi.org/10.1016/j.mtcomm.2021.102176

Jammalamadaka, U., Tappa, K.: Recent advances in biomaterials for 3D printing and tissue engineering. J. Funct. Biomater. 9(1), 2018 (2018). https://doi.org/10.3390/jfb9010022

Li, X., et al.: Inkjet bioprinting of biomaterials. Chem. Rev. 120(19), 10793–10833 (2020). https://doi.org/10.1021/acs.chemrev.0c00008

Xu, H., Zhang, Z., Xu, C.: Sedimentation study of bioink containing living cells. J. Appl. Phys. (2019). https://doi.org/10.1063/1.5089245

Liu, Z., Zhang, M., Bhandari, B., Wang, Y.: 3D printing: printing precision and application in food sector. Trends Food Sci. Technol. 69, 83–94 (2017). https://doi.org/10.1016/j.tifs.2017.08.018

Lee Ventola, C.: Medical applications for 3D printing: current and projected uses. P T 39(10), 704–711 (2019)

Han, T., Kundu, S., Nag, A., Xu, Y.: 3D printed sensors for biomedical applications: a review. Sensors (Switzerland) (2019). https://doi.org/10.3390/s19071706

Shaqour, B., et al.: Gaining a better understanding of the extrusion process in fused filament fabrication 3D printing: a review. Int. J. Adv. Manuf. Technol. 114(5–6), 1279–1291 (2021). https://doi.org/10.1007/s00170-021-06918-6

Ozbolat, I.T., Hospodiuk, M.: Current advances and future perspectives in extrusion-based bioprinting. Biomaterials 76, 321–343 (2016). https://doi.org/10.1016/j.biomaterials.2015.10.076

Triyono, J., Alfiansyah, R., Sukanto, H., Ariawan, D., Nugroho, Y.: Fabrication and characterization of porous bone scaffold of bovine hydroxyapatite-glycerin by 3D printing technology”. Bioprinting (2020). https://doi.org/10.1016/j.bprint.2020.e00078

Gupta, S., Bissoyi, A., Bit, A.: A review on 3D printable techniques for tissue engineering. Bionanoscience 8(3), 868–883 (2018). https://doi.org/10.1007/s12668-018-0525-4

Chen, G., Chen, N., Wang, Q.: Fabrication and properties of poly(vinyl alcohol)/β-tricalcium phosphate composite scaffolds via fused deposition modeling for bone tissue engineering. Compos. Sci. Technol. 172, 17–28 (2019). https://doi.org/10.1016/j.compscitech.2019.01.004

Zein, I., Hutmacher, D.W., Tan, K.C., Teoh, S.H.: Fused deposition modeling of novel scaffold architectures for tissue engineering applications. Biomaterials 23(4), 1169–1185 (2002). https://doi.org/10.1016/S0142-9612(01)00232-0

Sano, Y., Matsuzaki, R., Ueda, M., Todoroki, A., Hirano, Y.: 3D printing of discontinuous and continuous fibre composites using stereolithography. Addit. Manuf. 24, 521–527 (2018). https://doi.org/10.1016/j.addma.2018.10.033

Trhlíková, L., Zmeskal, O., Psencik, P., Florian, P.: Study of the thermal properties of filaments for 3D printing. AIP Conf. Proc. (2016). https://doi.org/10.1063/1.4955258

Liu, X., Shao, W., Luo, M., Bian, J., Yu, D.G.: Electrospun blank nanocoating for improved sustained release profiles from medicated gliadin nanofibers. Nanomaterials (2018). https://doi.org/10.3390/nano8040184

Hoque, M.E., et al.: Fabrication using a rapid prototyping system and in vitro characterization of PEG-PCL-PLA scaffolds for tissue engineering. J. Biomater. Sci. Polym. Ed. 16(12), 1595–1610 (2005). https://doi.org/10.1163/156856205774576709

Stout, D.A., Basu, B., Webster, T.J.: Poly(lactic-co-glycolic acid): carbon nanofiber composites for myocardial tissue engineering applications. Acta Biomater. 7(8), 3101–3112 (2011). https://doi.org/10.1016/j.actbio.2011.04.028

Sadeghianmaryan, A., Karimi, Y., Naghieh, S., Alizadeh Sardroud, H., Gorji, M., Chen, X.: Electrospinning of scaffolds from the polycaprolactone/polyurethane composite with graphene oxide for skin tissue engineering. Appl. Biochem. Biotechnol. (2020). https://doi.org/10.1007/s12010-019-03192-x

Jiang, D., Ning, F., Wang, Y.: Additive manufacturing of biodegradable iron-based particle reinforced polylactic acid composite scaffolds for tissue engineering. J. Mater. Process. Technol. (2020). https://doi.org/10.1016/j.jmatprotec.2020.116952

Wibowo, A., et al.: 3D printing of polycaprolactone—polyaniline electroactive scaffolds for bone tissue engineering. Materials (2020). https://doi.org/10.3390/ma13030512

Jiao, Z., Luo, B., Xiang, S., Ma, H., Yu, Y., Yang, W.: 3D printing of HA / PCL composite tissue engineering scaffolds. Adv. Ind. Eng. Polym. Res. 2(4), 196–202 (2019). https://doi.org/10.1016/j.aiepr.2019.09.003

Manzoor, F., et al.: 3D printed PEEK/HA composites for bone tissue engineering applications: effect of material formulation on mechanical performance and bioactive potential. J. Mech. Behav. Biomed. Mater. (2021). https://doi.org/10.1016/j.jmbbm.2021.104601

Kim, M., Kim, G.: Electrospun PCL/phlorotannin nanofibres for tissue engineering: physical properties and cellular activities. Carbohydr. Polym. 90(1), 592–601 (2012). https://doi.org/10.1016/j.carbpol.2012.05.082

N. Maurmann et al., Mesenchymal stem cells cultivated on scaffolds formed by 3D printed PCL matrices , coated with PLGA electrospun nanofibers for use in tissue engineering Mesenchymal stem cells cultivated on scaffolds formed by 3D printed PCL matrices , coated with PLGA el.

DeChen, R., Huang, C.F., hui Hsu, S.: Composites of waterborne polyurethane and cellulose nanofibers for 3D printing and bioapplications. Carbohydr. Polym. (2019). https://doi.org/10.1016/j.carbpol.2019.02.025

Tardajos, M.G., et al.: Chitosan functionalized poly-ε-caprolactone electrospun fibers and 3D printed scaffolds as antibacterial materials for tissue engineering applications. Carbohydr. Polym. 191, 127–135 (2018). https://doi.org/10.1016/j.carbpol.2018.02.060

Ngadiman, N.H.A., Yusof, N.M., Idris, A., Fallahiarezoudar, E., Kurniawan, D.: Novel processing technique to produce three dimensional polyvinyl alcohol/maghemite nanofiber scaffold suitable for hard tissues. Polymers (Basel) (2018). https://doi.org/10.3390/polym10040353

Chen, Y.P., Lo, T.S., Lin, Y.T., Chien, Y.H., Lu, C.J., Liu, S.J.: Fabrication of drug-eluting polycaprolactone/ poly (Lactic-co-glycolic acid) prolapse mats using solution-extrusion 3d printing and coaxial electrospinning techniques. Polymers (Basel). (2021). https://doi.org/10.3390/polym13142295

De Vrieze, S., Van Camp, T., Nelvig, A., Hagström, B., Westbroek, P., De Clerck, K.: The effect of temperature and humidity on electrospinning. J. Mater. Sci. 44(5), 1357–1362 (2009). https://doi.org/10.1007/s10853-008-3010-6

Casasola, R., Thomas, N.L., Trybala, A., Georgiadou, S.: Electrospun poly lactic acid (PLA) fibres: effect of different solvent systems on fibre morphology and diameter. Polymer (Guildf) 55(18), 4728–4737 (2014). https://doi.org/10.1016/j.polymer.2014.06.032

Singh, B., et al.: Investigations on melt flow rate and tensile behaviour of single, double and triple-sized copper reinforced thermoplastic composites. Materials (Basel). (2021). https://doi.org/10.3390/ma14133504

K. Torres-Rivero, J. Bastos-Arrieta, N. Fiol, and A. Florido, Metal and metal oxide nanoparticles: an integrated perspective of the green synthesis methods by natural products and waste valorization: applications and challenges, 1st ed., vol. 94. Elsevier B.V., 2021. doi: https://doi.org/10.1016/bs.coac.2020.12.001.

Acknowledgements

Authors like to thanks Indian Institute of Technology Bombay and Guru Nanak Dev Engineering College Ludhiana.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kour, K., Kumar, R., Singh, G. et al. Additive manufacturing of polylactic acid-based nanofibers composites for innovative scaffolding applications. Int J Interact Des Manuf (2023). https://doi.org/10.1007/s12008-023-01435-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-023-01435-0