Abstract

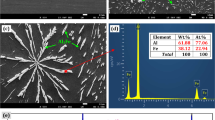

High-hardness materials that are challenging to machine using traditional machining methods are frequently machined using the modern machining technology known as EDM. An exclusive characteristic changing the surface of the workpiece by electrode transfer in EDM with reverse polarity is known as electro discharge coating (EDC). EDC is a cutting-edge method for surface modification that modify surface of any material to enhance existing surface qualities or add new surface functionalities. The present study analyzes the coating characteristics of tungsten disulfide (WS2) and copper (Cu) coated AA7075 by EDC. Coating was carried out based on face-centered central composite design, employed with multiple EDC parameter combinations to assess the output properties such as deposition rate (DR) and micro hardness (MH). According to the experimental findings, the DR and MH rise when the current and pulse length are increased. In contrast, DR increases and MH decreases as pulse off time increases. A scanning electron microscope has examined the surface topography of a coating (SEM). In order to explore the element transfer and diffusion from the electrode onto the substrate, energy dispersive spectroscopy has been used.

Similar content being viewed by others

References

Siddique, A.R., Mohanty, S., Das, A.K.: Micro-electrical discharge coating of titanium alloy using WS2 and Brass P/M electrode. Mater. Manuf. Process 34(15), 1761–1774 (2019)

Samuel, M.P., Philip, P.K.: Powder metallurgy electrodes for electrical discharge machining. J. Mach. Tool. Manuf. 37, 1625–1633 (1996)

Aspinwall, D.K., Dewes, R.C., Lee, H., GandSimao, J.: Electrical discharge surface alloying of Ti and Fe workpiece materials using refractory powder compact electrodes and Cu wire. CIRP Ann. 52(1), 151–156 (2003)

Shunmugan, M.S., Philip, P.K., Gangadhar, A.: A Improvement of wear resistance by EDM with tungsten disulfide P/M electrode. Wear 171, 1–5 (1994)

Lee, H.G., Simao, J., Aspinwall, D.K., Dewes, R.C.: Electrical discharge surface alloying. J. Mater. Process. Tech 149, 334–340 (2014)

Kumar, S., Batra, U.: Surface modification of die steel materials by EDM method using tungsten powder-mixed dielectric. J. Manuf. Process. 14, 35–40 (2012)

Janmanee, P., Muttamara, A.: Surface modification of tungsten carbide by electrical discharge coating (EDC) using a titanium powder suspension. Appl. Surf. Sci. 258(19), 7255–7265 (2012)

Elaiyarasan, U., Satheeshkumar, V., Senthilkumar, C.: Effect of parameters on microstructure of electrical discharge coated ZE41A magnesium alloy with tungsten carbide-copper composite electrode. Surf. Topogr. Metrol. Prop. 9, 025006 (2021)

Elaiyarasan, U., Satheeshkumar, V., Senthilkumar, C.: Effect of sintered electrode on microhardness and microstructure in electro discharge deposition of magnesium alloy. J Mech. Beha. Mater. 29, 69–76 (2020)

Tyagi, R., Mahto, N.K., Das, A.K., Mandal, A.: Preparation of MoS2+Cu coating through the EDC process and its analysis. Sur Engg. 36, 86–93 (2019)

Tyagi, R., Das, A.K., Mandal, A.: Electrical discharge coating using WS2 and Cu powder mixture for solid lubrication and enhanced tribological performance. Trib. Int. 120, 80–92 (2018)

Montgomery, D.C.: Introduction to statistical process control. John Wily & Sons, New York (2001)

Habib, S.S.: Study of the parameters in electrical discharge machining through response surface methodology approach. App. Math. Model. 33, 4397–4407 (2009)

Senthilkumar, C.: Optimisation of EDC parameters using TOPSIS approach. Int. J. Mach. Mach. Mater. 21, 480–492 (2019)

Phan, N.H., Muthuramalingam, T., Minh, N.D., Duc, N.V.: Enhancing surface morphology of machined SKD61 die steel in EDM process using DEAR approach based multi criteria decision making. Int. J. Interact. Des. Manuf. 16(3), 1155–1161 (2022)

ShanmugaElango, K., Senthilkumar, C.: Surface alloying characteristics of WS2/Cu composite electrodes deposited on an aluminum alloy by electrical discharge coating. J. Adh. Sci. Tech. 37(1), 3–15 (2023)

Yap, C.Y., Liew, P.J., Yan, J.: Surface modification of tungsten carbide cobalt by electrical discharge coating with quarry dust suspension. Int. J. Adv. Manuf. Tech. 7–8, 2105–2116 (2020)

Gill, A.S., Kumar, S.: Surface alloying of H11 die steel by tungsten using EDM process. Int. J. Adv. Manuf. Technol. 78(9–12), 1585–1593 (2015)

Rahang, M., Patowari, P.K.: Parametric optimization for selective surface modification in EDM using Taguchi analysis. Mater. Manuf. Process. 31, 422–431 (2016)

Ramdatti, J.L., Gohil, A.V., Dave, K.G.: Experimental investigation on electro-discharge surface modification phenomenon of P20+Ni die steel using green P/M composite electrode. J. Mech. Eng. Sci. 15(3), 8390–8404 (2021)

Chakraborty, S., Kar, S., Dey, V., Ghosh, S.K.: Optimization and surface modification of al-6351 alloy using SiC–cu green compact electrode by electro discharge coating process. Surf. Rev. Lett. 24, 1750007–1750019 (2017)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shanmugaelango, K., Senthilkumar, C. & Arokiadass, R. Parametric study on electrical discharge coating of 7075 aluminium with WS2/Cu electrode. Int J Interact Des Manuf 17, 3059–3067 (2023). https://doi.org/10.1007/s12008-023-01339-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-023-01339-z