Abstract

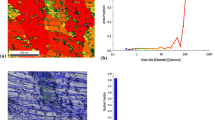

The goal of ECAP method to resolve the issue of estimating the size of the thermal effect that develops in an AA5083 system during the deformation process. In order to do this, the process based on the mechanical and physical characteristics of metal subjected to upsetting and its temperature were analyzed using the Gleeble 3500 physical modelling complex. A database for modelling in the Deform-3D system was built based on the results. Additionally, the ECAP process was modelled, and thermal fields and the stress–strain state were examined. The difference in heating temperatures, while considering the sample's heat transfer to the tooling and when not, is no greater than eight percent. The complex strain-stressed situation can be simulated using this deformation scheme. Tests were performed on specimens that had been heated in a solution in water as well as specimens that had undergone extrusion and homogenizing processes, respectively. The solution treatment method does not affect the plasticity of the under examination alloy in the analyzed range of deformation parameters, but it does affect the hardness, microhardness distribution, and grain size of the alloy. TEM and electron backscattered diffraction analyses were used to explain the evolution of microstructure. The mechanical characteristics deteriorate and soften as a consequence of a rise in the deformation temperature. With equal channel angular pressing (ECAP) innovation, the AA5083 quality is being improved.

Similar content being viewed by others

References

Aksenov, D.A., et al.: The thermal effect of deformation during the ECAP processing of the Cu-0.6 Cr alloy. Lett. Mater. 11(1), 95–99 (2011). https://doi.org/10.22226/2410-3535-2021-1-95-99

Gupta, A., et al.: Influence of ECAP processing temperature and number of passes on hardness and microstructure of Al-6063. Adv. Mater. Process. Technol. 8, 1635–1646 (2021)

Segal, V.M.: Materials processing by simple shear. Mater. Sci. Eng. A 197(2), 157–164 (1995). https://doi.org/10.1016/0921-5093(95)09705-8

El Aal, A., Ibrahim, M., et al.: Microstructure evolution and mechanical properties of pure aluminum deformed by equal channel angular pressing and direct extrusion in one step through an integrated die. Mater. Sci. Eng. A 625, 252–263 (2015). https://doi.org/10.1016/j.msea.2014.11.089

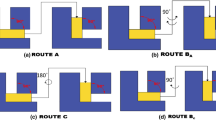

Xu, S., et al.: Numerical studies on processing routes and deformation mechanism of multi-pass equal channel angular pressing processes. J. Mater. Process. Technol. 176(1–3), 251–259 (2006). https://doi.org/10.1016/j.jmatprotec.2006.03.167

Abbasi-Baharanchi, M., Karimzadeh, F., Enayati, M.H.: Mechanical and tribological behavior of severely plastic deformed Al6061 at cryogenic temperatures. Mater. Sci. Eng. A 683, 56–63 (2017). https://doi.org/10.1016/j.msea.2016.11.099

Fang, D.R., et al.: Effect of equal channel angular pressing on tensile properties and fracture modes of casting Al–Cu alloys. Mater. Sci. Eng. A 426(1–2), 305–313 (2006). https://doi.org/10.1016/j.msea.2006.04.044

Rahimi, H.R., Sedighi, M., Hashemi, R.: Forming limit diagrams of fine-grained Al 5083 produced by equal channel angular rolling process. Proc. Instit. Mech. Eng. Part L J. Mater. Des. Appl. 232(11), 922–930 (2018). https://doi.org/10.1177/1464420716655560

Mallikarjuna, C., Shashidhara, S.M., Mallik, U.S.: Evaluation of grain refinement and variation in mechanical properties of equal-channel angular pressed 2014 aluminum alloy. Mater. Des. 30(5), 1638–1642 (2009). https://doi.org/10.1016/j.matdes.2008.07.036

Ramu, G., Bauri, R.: Effect of equal channel angular pressing (ECAP) on microstructure and properties of Al–SiCp composites. Mater. Des. 30(9), 3554–3559 (2009). https://doi.org/10.1016/j.matdes.2009.03.001

Tham, Y.W., et al.: Bulk nanostructured processing of aluminum alloy. J. Mater. Process. Technol. 192, 575–581 (2007). https://doi.org/10.1016/j.jmatprotec.2007.04.076

Pürçek, G.: Improvement of mechanical properties for Zn–Al alloys using equal-channel angular pressing. J. Mater. Process. Technol. 169(2), 242–248 (2005). https://doi.org/10.1016/j.jmatprotec.2005.03.012

Saray, O., Purcek, G.: Microstructural evolution and mechanical properties of Al–40 wt.% Zn alloy processed by equal-channel angular extrusion. J. Mater. Process. Technol. 209(5), 2488–2498 (2009). https://doi.org/10.1016/j.jmatprotec.2008.05.043

Tolaminejad, B., Dehghani, K.: Microstructural characterization and mechanical properties of nanostructured AA1070 aluminum after equal channel angular extrusion. Mater. Des. 34, 285–292 (2012). https://doi.org/10.1016/j.matdes.2011.08.003

Valiev, R.Z., Langdon, T.G.: Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater Sci. 51(7), 881–981 (2006). https://doi.org/10.1016/j.pmatsci.2006.02.003

Kadiyan, S., Dehiya, B.S.: Evaluating the influence of various routes on micro-structure and mechanical properties of AA-6063 after equal channel angular pressing. Mater. Res. Exp. 6(8), 0865f9 (2019). https://doi.org/10.1088/2053-1591/ab2618

Iqbal, U.M., Muralidharan, S.: Optimization of die design parameters and experimental validation on twist channel angular pressing process of AA6061-T6 aluminium alloy. Mater. Res. Exp. 6(8), 0865f2 (2019). https://doi.org/10.1088/2053-1591/ab25b2

Croeni, J.G., Howe, J.S., Katō, H.: High Energy-rate Forging and Extrusion and the Effect on Structure and Properties, vol. 6757. US Department of the Interior, Bureau of Mines, Washington, DC (1966)

Krolo, J., et al.: Statistical analysis of the combined ECAP and heat treatment for recycling aluminum chips without remelting. Metals 9(6), 660 (2019). https://doi.org/10.3390/met9060660

Semenova, I.P., Valiev, R.Z., Langdon, T.G.: High-pressure torsion and equal-channel angular pressing. Nanocryst. Titanium (2019). https://doi.org/10.1016/B978-0-12-814599-9.00001-8

Soni, A., Gupta, S.K.: Finite element analysis of aluminum alloy at many die channel angles using DEFORM-3D. Int. J. Recent Technol. Eng. 8(2), 58–61 (2019). https://doi.org/10.35940/ijrte.A1330.078219

Sulaiman, S., et al.: Experimental and numerical study of high strain rate property of pure copper processed by ECAE method. Adv. Mater. Process. Technol. 5(3), 386–393 (2019). https://doi.org/10.1080/2374068X.2019.1616416

Gal, J.: Melting curves of Al, Cu, U and Fe metals utilizing the Lindemann-Gilvarry criterion and parameterization of the equations of state. arXiv preprint arXiv:1912.06182 (2019)

Agarwal, K.M., et al.: Comparison of different methods of severe plastic deformation for grain refinement. IOP Conf. Ser. Mater. Sci. Eng. (2019). https://doi.org/10.1088/1757-899X/691/1/012074

Viceré, A., et al.: Corrosion behavior of AA6012 aluminum alloy processed by ECAP and cryogenic treatment. Metals 9(4), 408 (2019). https://doi.org/10.3390/met9040408

Baig, M., et al.: Effect of microstructure and mechanical properties of Al5083 alloy processed by ECAP at room temperature and high temperature. Crystals 11(6), 683 (2021). https://doi.org/10.3390/cryst11060683

Dalan, F.C., et al.: Effect of ECAP processing on distribution of second phase particles, hardness and electrical conductivity of Cu−0.81 Cr−0.07 Zr alloy. Trans. Nonferr. Metals Soc. China 32(1), 217–232 (2022). https://doi.org/10.1016/S1003-6326(21)65789-8

Medvedev, A., et al.: On the effect of ECAP and subsequent cold rolling on the microstructure and properties of electromagnetically cast Al-Fe alloys. Int. J. Lightweight Mater. Manuf. (2022). https://doi.org/10.1016/j.ijlmm.2022.06.001

Palanivel, R., et al.: Effect of machining process parameters and number of pass on compaction behaviour of commercially pure aluminium chips consolidated by equal channel angular pressing (ECAP) using response surface methodology. Arch. Metall. Mater. (2022). https://doi.org/10.24425/amm.2022.137766

Heydarinia, A., et al.: Free volume formation and the high strength of pure Mg after room temperature core-sheath ECAP passes. J. Mater. Res. Technol. 18, 147–158 (2022). https://doi.org/10.1016/j.jmrt.2022.02.061

Ciemiorek, M., et al.: Ductility and formability of ultrafine-grained 5754 aluminium alloy under various strain rates and temperatures. Mater. Sci. Eng. A (2022). https://doi.org/10.1016/j.msea.2022.143375

Hashemi, P.M., Borhani, E., Nourbakhsh, M.S.: Commercially pure titanium modification to enhance corrosion behavior and osteoblast response by ECAP for biomedical applications. J. Appl. Biomater. Functional Mater. 20, 22808000221095230 (2022). https://doi.org/10.1177/22808000221095234

Ciemiorek, M., et al.: Microstructural changes and formability of Al–Mg ultrafine-grained aluminum plates processed by multi-turn ECAP and upsetting. Mater. Sci. Eng. A 831, 142202 (2022). https://doi.org/10.1016/j.msea.2021.142202

Klu, E.E., et al.: Influence of equal channel angular pressing on mechanical properties of Mg-Li alloys mechanical properties of Mg-Li alloys: an overview. Rare Metal Mater. Eng. 51(2) (2022)

Oliveira, P., et al.: Tailoring the microstructure of a Cu-0.7 cr-0.07 zr alloy submitted to ecap at cryogenic temperature for improved thermal stability. https://doi.org/10.2139/ssrn.4048844.

Silva, W.B., et al.: Magnesium alloys for hydrogen storage processed by ECAP followed by low temperature rolling. Mater. Res. (2022). https://doi.org/10.1590/1980-5373-MR-2021-0214

Namur, R.S., et al.: Cryogenic and room temperature ECAP consolidation of blended elemental powders of aluminum and copper. Mater. Res. (2022). https://doi.org/10.1590/1980-5373-MR-2021-0414

Sureshkumar, P., et al.: Electrochemical corrosion and tribological behaviour of AA6063/Si3N4/Cu (NO3) 2 composite processed using single-pass ECAPA route with 120 die angle. J. Market. Res. 16, 715–733 (2022). https://doi.org/10.1016/j.jmrt.2021.12.020

Huang, Y., Robson, J.D., Prangnell, P.B.: The formation of nanograin structures and accelerated room-temperature theta precipitation in a severely deformed Al–4 wt% Cu alloy. Acta Mater. 58(5), 1643–1657 (2010). https://doi.org/10.1016/j.actamat.2009.11.008

Estrin, Y., Vinogradov, A.: Extreme grain refinement by severe plastic deformation: a wealth of challenging science. Acta Mater. 61(3), 782–817 (2013). https://doi.org/10.1016/j.actamat.2012.10.038

Huang, J., et al.: Development of repetitive corrugation and straightening. Mater. Sci. Eng. A 371(1–2), 35–39 (2004). https://doi.org/10.1016/S0921-5093(03)00114-X

Thangapandian, N., Prabu, S.B., Padmanabhan, K.A.: Effects of die profile on grain refinement in Al–Mg alloy processed by repetitive corrugation and straightening. Mater. Sci. Eng. A 649, 229–238 (2016). https://doi.org/10.1016/j.msea.2015.09.051

Mazurina, I., et al.: Effect of deformation temperature on microstructure evolution in aluminum alloy 2219 during hot ECAP. Mater. Sci. Eng. A 486(1–2), 662–671 (2008). https://doi.org/10.1016/j.msea.2007.09.070

Goloborodko, A., et al.: Effect of pressing temperature on fine-grained structure formation in 7475 aluminum alloy during ECAP. Mater. Sci. Eng. A 381(1–2), 121–128 (2004). https://doi.org/10.1016/j.msea.2004.04.049

Verma, D., et al.: Ultra-high-strength interstitial-free steel processed by equal-channel angular pressing at large equivalent strain. Metall. Mater. Trans. A 47(4), 1803–1817 (2016)

Kulakowska, A., et al.: Effect of initial state and processing temperature on structure and properties under hot torsion of AA5754 alloy. Lett. Mater. 11(3), 233–238 (2021). https://doi.org/10.22226/2410-3535-2021-3-233-238

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Singh, N., Agrawal, M.K., Saxena, K.K. et al. Advancement and influence of designing of ECAP on deformation and microstructure properties of the AA5083 under thermal effects. Int J Interact Des Manuf 18, 1809–1827 (2024). https://doi.org/10.1007/s12008-023-01213-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-023-01213-y