Abstract

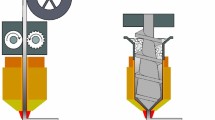

Additive Manufacturing (AM), commonly known as 3D printing, is transforming the manufacturing industry with rapid product development. With the new technological transformation comes new issues and challenges in the manufacturing industry. Additive manufacturing technique with large build volume is costlier compared to smaller ones. Therefore, CNC-assisted material extrusion-based additive manufacturing system has been developed by the FFF laboratory in PDPM IIITDM Jabalpur using an existing Computer Numerical Control (CNC) machine. Using the developed system, large-sized parts can be easily fabricated on the CNC machine platform. The developed system requires setting up new process parameters values to fabricate large-sized parts compared to fused filament fabrication process system. However, the developed system also generates new possibilities such as composite material product development for various industries. Most of the constraints of fused filament fabrication process parameters still apply to this system. Beyond those constraints, new issues and challenges exist because the CNC-assisted material extrusion-based additive manufacturing system significantly changes the properties associated with the fused filament fabrication process. The research article presents the working of the developed system and issues associated with the fabricated parts. The capabilities and challenges in the fabrication of large-sized parts using the developed AM system are also presented.

Similar content being viewed by others

References

Kumar, N., Jain, P.K., Tandon, P., Pandey, P.M.: Additive manufacturing of flexible electrically conductive polymer composites via CNC-assisted fused layer modeling process. J. Brazilian Soc. Mech. Sci. Eng. 40, 1–13 (2018). doi:https://doi.org/10.1007/s40430-018-1116-6

Pignatelli, F., Percoco, G.: An application- and market-oriented review on large format additive manufacturing, focusing on polymer pellet-based 3D printing. Prog Addit. Manuf. (2022). doi:https://doi.org/10.1007/s40964-022-00309-3

Tagscherer, N., Bär, A.M., Zaremba, S., Drechsler, K.: Mechanical Analysis of Parameter Variations in Large-Scale Extrusion Additive Manufacturing of Thermoplastic Composites. J. Manuf. Mater. Process. 6 (2022). doi:https://doi.org/10.3390/jmmp6020036

Francis, V., Jain, P.K.: A filament modification approach for in situ ABS / OMMT nanocomposite development in extrusion-based 3D printing. J. Brazilian Soc. Mech. Sci. Eng. 6 (2018). doi:https://doi.org/10.1007/s40430-018-1282-6

Taufik, M., Jain, P.K.: Part surface quality improvement studies in fused deposition modelling process: a review. Aust J. Mech. Eng. 20, 527–551 (2022). doi:https://doi.org/10.1080/14484846.2020.1723342

Gawali, S.K., Pandey, G.C., Jain, P.K.: Experimental investigations on effect of graphite loading on melt flow behaviour of ABS-Gr composite for fused filament fabrication (FFF) process. Adv. Mater. Process. Technol. 0, 1–11 (2022). doi:https://doi.org/10.1080/2374068X.2022.2093004

Hassen, A.A., Dinwiddie, R.B., Kim, S., Tekinap, H.L., Kumar, V., Lindahl, J., Yeole, P., Duty, C., Vaidya, U., Wang, H., Kunc, V.: Anisotropic thermal behavior of extrusion-based large scale additively manufactured carbon-fiber reinforced thermoplastic structures. Polym. Compos. 43, 3678–3690 (2022). doi:https://doi.org/10.1002/pc.26645

Bi, M., Xia, L., Tran, P., Li, Z., Wan, Q., Wang, L., Shen, W., Ma, G., Xie, Y.M.: Continuous contour-zigzag hybrid toolpath for large format additive manufacturing. Addit. Manuf. 55, 102822 (2022). doi:https://doi.org/10.1016/j.addma.2022.102822

Cleeman, J., Bogut, A., Mangrolia, B., Ripberger, A., Kate, K., Zou, Q., Malhotra, R.: Scalable, flexible and resilient parallelization of fused filament fabrication: Breaking endemic tradeoffs in material extrusion additive manufacturing. Addit. Manuf. 56, 102926 (2022). doi:https://doi.org/10.1016/j.addma.2022.102926

Farahbakhsh, M., Rybkowski, Z.K., Zakira, U., Kalantar, N., Onifade, I.: Impact of robotic 3D printing process parameters on interlayer bond strength. Autom. Constr. 142, 104478 (2022). doi:https://doi.org/10.1016/j.autcon.2022.104478

Roschli, A., Gaul, K.T., Boulger, A.M., Post, B.K., Chesser, P.C., Love, L.J., Blue, F., Borish, M.: Designing for Big Area Additive Manufacturing. Addit. Manuf. 25, 275–285 (2019). doi:https://doi.org/10.1016/j.addma.2018.11.006

Landi, D., Zefinetti, F.C., Spreafico, C., Regazzoni, D.: Comparative life cycle assessment of two different manufacturing technologies: Laser additive manufacturing and traditional technique. Procedia CIRP. 105, 700–705 (2022). doi:https://doi.org/10.1016/j.procir.2022.02.117

Gawali, S.K., Kumar, N., Jain, P.K.: Additive Manufacturing of Large Size Parts Through Retrofitment of Three-Axes CNC Machining Centre. In: Pratap Singh, R., Tyagi, D.M., Panchal, D., and Davim, J.P. (eds.) Proceedings of the International Conference on Industrial and Manufacturing Systems (CIMS-2020). Springer International Publishing, Cham (2022) pp. 421–437

Gawali, S.K., Kumar, N., Jain, P.K.: Investigations on the Development of Heated Build Platform for Additive Manufacturing of Large-Size Parts. In: Sharma, V.S., Dixit, U.S., Sørby, K., Bhardwaj, A., Trehan, R. (eds.) Manufacturing Engineering, pp. 1–17. Springer Singapore, Singapore (2020)

Taufik, M., Jain, P.K.: CNC-assisted selective melting for improved surface finish of FDM parts. Virtual Phys. Prototyp. 11, 319–341 (2016). doi:https://doi.org/10.1080/17452759.2016.1245943

Taufik, M., Jain, P.K.: Thermally assisted finishing of fused deposition modelling build part using a novel CNC tool. J. Manuf. Process. 59, 266–278 (2020). doi:https://doi.org/10.1016/j.jmapro.2020.09.060

Heller, B.P., Smith, D.E., Jack, D.A.: Planar deposition flow modeling of fiber filled composites in large area additive manufacturing. Addit. Manuf. 25, 227–238 (2019). doi:https://doi.org/10.1016/j.addma.2018.10.031

Pappas, J.M., Thakur, A.R., Leu, M.C., Dong, X.: A comparative study of pellet-based extrusion deposition of short, long, and continuous carbon fiber-reinforced polymer composites for large-scale additive manufacturing. J. Manuf. Sci. Eng. Trans. ASME. 143, 1–12 (2021). doi:https://doi.org/10.1115/1.4049646

Akbari, S., Johansson, J., Johansson, E., Tönnäng, L., Hosseini, S.: Large-Scale Robot-Based Polymer and Composite Additive Manufacturing: Failure Modes and Thermal Simulation. (2022)

Wang, Z., Liu, R., Sparks, T., Liou, F.: Large-scale deposition system by an Industrial Robot (I): Design of fused pellet modeling system and extrusion process analysis. 3D Print. Addit. Manuf. 3, 39–47 (2016). doi:https://doi.org/10.1089/3dp.2015.0029

Liu, X., Chi, B., Jiao, Z., Tan, J., Liu, F., Yang, W.: A large-scale double-stage-screw 3D printer for fused deposition of plastic pellets. J. Appl. Polym. Sci. 134, 1–9 (2017). doi:https://doi.org/10.1002/app.45147

Duty, C.E., Kunc, V., Compton, B., Post, B., Erdman, D., Smith, R., Lind, R., Lloyd, P., Love, L.: Structure and mechanical behavior of Big Area Additive Manufacturing (BAAM) materials. Rapid Prototyp. J. 23, 181–189 (2017). doi:https://doi.org/10.1108/RPJ-12-2015-0183

Moreno Nieto, D., Casal López, V., Molina, S.I.: Large-format polymeric pellet-based additive manufacturing for the naval industry. Addit. Manuf. 23, 79–85 (2018). doi:https://doi.org/10.1016/j.addma.2018.07.012

Du, J., Wei, Z., Wang, X., Wang, J., Chen, Z.: An improved fused deposition modeling process for forming large-size thin-walled parts. J. Mater. Process. Technol. 234, 332–341 (2016). doi:https://doi.org/10.1016/j.jmatprotec.2016.04.005

Kumar, N., Jain, P.K., Tandon, P., Pandey, P.M.: Investigation on the effects of process parameters in CNC assisted pellet based fused layer modeling process. J. Manuf. Process. 35, 428–436 (2018). doi:https://doi.org/10.1016/j.jmapro.2018.08.029

Kumar, N., Jain, P.K., Tandon, P., Pandey, P.M.: Extrusion-based additive manufacturing process for producing flexible parts. J. Brazilian Soc. Mech. Sci. Eng. 40, 1–12 (2018). doi:https://doi.org/10.1007/s40430-018-1068-x

Kumar, N., Jain, P.K., Tandon, P., Pandey, P.M.: Toolpath Generation for Additive Manufacturing Using CNC Milling Machine. In: Kumar, L.J., Pandey, P.M., Wimpenny, D.I. (eds.) 3D Printing and Additive Manufacturing Technologies, pp. 73–82. Springer Singapore, Singapore (2019)

Crisp, T.G., Weaver, J.M.: Review of Current Problems and Developments in Large Area Additive Manufacturing (LAAM) Tyler G. Crisp and Jason M. Weaver Department of Manufacturing Engineering, Brigham Young University, Provo, UT 84602. Solid Free. Fabr. 2021 Proc. 32nd Annu. Int. Solid Free. Fabr. Symp. - An Addit. Manuf. Conf. SFF 1539–1548 (2021)

Moreno, D., De, M., Javier, F., Casal, V., Ignacio, S.: Development of carbon fi ber acrylonitrile styrene acrylate composite for large format additive manufacturing. Mater. Des. 191, 108577 (2020). doi:https://doi.org/10.1016/j.matdes.2020.108577

Messman, J., Advincula, R.C.: Advances in 3D printing of thermoplastic polymer composites and nanocomposites. Prog Polym. Sci. (2019). https://doi.org/10.1016/j.progpolymsci.2019.101162

Nycz, A., Noakes, M., Post, B.K., Roschli, A., Babu, S., Love, L.J.: Development and demonstration of large scale metal additive manufacturing for military vehicle applications - Final Report. (2017)

Love, L.J., Noakes, M.W., Post, B.K., Rhyne, B.J., Gaul, K.T.: Feasibility of using additive manufacturing to produce automotive tooling. (2018)

Post, B.K., Richardson, B., Lind, R., Love, L.J., Lloyd, P., Kunc, V., Rhyne, B.J., Roschli, A., Hannan, J., Nolet, S., Veloso, K., Kurup, P., Re, T., Jenne, D.: Solid Freeform Fabrication 2017: Proceedings of the 28th Annual International Solid Freeform Fabrication Symposium - An Additive Manufacturing Conference, SFF 2017. Solid Free. Fabr. 2017 Proc. 28th Annu. Int. Solid Free. Fabr. Symp. - An Addit. Manuf. Conf. SFF, pp. 2430–2446 (2020)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gawali, S.K., Pandey, G.C., Bajpai, A. et al. Large-part manufacturing using CNC-assisted material extrusion-based additive manufacturing: issues and challenges. Int J Interact Des Manuf 17, 1185–1197 (2023). https://doi.org/10.1007/s12008-022-01097-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-022-01097-4