Abstract

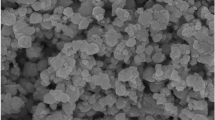

Aluminium Hybrid Metal Matrix Composites (AHMMC) outperformed traditional materials in a variety of engineering fields such as aerospace, marine, and automobile parts due to improved properties such as strength and hardness. The reinforcements which will be added in the AHMMC will make significant contributions for improving the desired material properties. An exploratory study was conducted in this investigation on the development of aluminum-based (LM 26) hybrid metal matrix composites with reinforcements of Graphite and fly-ash. The composite is fabricated using the stir casting approach with various reinforcement combinations by different weight proportions (LM 26 85% and 15% Graphite + fly-ash). The fabricated composites are tested to determine their mechanical properties in accordance with ASTM standards. A comparative analysis was performed to determine the significance of reinforcement as well as the properties of composites at various weight percentages. The reinforcement combinations (LM 26 85% and 7.5% Graphite + 7.5% fly-ash) offers comparatively better mechanical properties with tensile strength 238 N/mm2 and micro hardness 163.3 HV than the remaining combinations which are considered in this investigation. Microstructural analysis was also carried out to reveal the distributions of reinforcement and the nature of fractured surfaces. Wear behavior of the fabricated composite were analyzed by regression analysis and the results are presented.

Similar content being viewed by others

References

Ghasali, E., Pakseresht, A., Rahbari, A., Eslami-shahed, H., Alizadeh, M., Ebadzadeh, T.: Mechanical properties and microstructure characterization of spark plasma and conventional sintering of Al–SiC–TiC composites. J. Alloys Compd. 666, 366–371 (2016). https://doi.org/10.1016/j.jallcom.2016.01.118

Chandla, N.K., Kant, S., Goud, M.M.: Mechanical, tribological and microstructural characterization of stir cast Al-6061 metal/matrix composites—a comprehensive review. Sadhana (2021). https://doi.org/10.1007/s12046-021-01567-7

Alaneme, K.K., Aluko, A.O.: Fracture toughness () and tensile properties of as-cast and age-hardened aluminium (6063)–silicon carbide particulate composites. Sci. iran. 19(4), 992–996 (2012). https://doi.org/10.1016/j.scient.2012.06.001

Ramesh, P., Nataraj, M.: Automotive industry application of aluminium-based hybrid metal matrix composite. Int. J. Heavy Veh. Syst. 27(1/2), 18 (2020). https://doi.org/10.1504/ijhvs.2020.104412

Alaneme, K.K., Babalola, S.A., Chown, L.H., Bodunrin, M.O.: Hot deformation behaviour of bamboo leaf ash-silicon carbide hybrid reinforced aluminium based composite. Manuf. Rev. (Les Ulis.) 7, 17 (2020). https://doi.org/10.1051/mfreview/2020014

Kumar, J., Singh, D., Kalsi, N.S.: Tribological, physical and microstructural characterization of silicon carbide reinforced aluminium matrix composites: a review. Mater. Today 18, 3218–3232 (2019). https://doi.org/10.1016/j.matpr.2019.07.198

Sharma, A., Sharma, V.M., Mewar, S., Pal, S.K., Paul, J.: Friction stir processing of Al6061-SiC-graphite hybrid surface composites. Mater. Manuf. Process. 33(7), 795–804 (2018). https://doi.org/10.1080/10426914.2017.1401726

Suresh, S., Shenbag, N., Moorthi, V.: Aluminium-titanium diboride (Al-TiB2) metal matrix composites: challenges and opportunities. Procedia Eng. 38, 89–97 (2012). https://doi.org/10.1016/j.proeng.2012.06.013

Yaghobizadeh, O., Baharvandi, H.R., Ahmadi, A.R., Aghaei, E.: Development of the properties of Al/SiC nano-composite fabricated by stir cast method by means of coating sic particles with Al. SILICON 11(2), 643–649 (2019). https://doi.org/10.1007/s12633-018-9867-3

Sharifitabar, M., Sarani, A., Khorshahian, S., Shafiee Afarani, M.: Fabrication of 5052Al/Al2O3 nanoceramic particle reinforced composite via friction stir processing route. Mater. Eng. 32(8–9), 4164–4172 (2011). https://doi.org/10.1016/j.matdes.2011.04.048

Siva Prasad, D., Shoba, C.: Hybrid composites – a better choice for high wear resistant materials. J. Mater. Res. Technol. 3(2), 172–178 (2014). https://doi.org/10.1016/j.jmrt.2014.03.004

Sathish, T., Saravanan, S., Vijayan, V.: Effect of reinforced aluminium alloy LM30 with pure ceramic particles to evaluate hardness and wear properties. Mater. Res. Innovations 24(3), 129–132 (2020). https://doi.org/10.1080/14328917.2019.1614321

Butola, R., Lakshay, T., Kem, L., Ranganath, M. S., Murtaza, Q.: "Mechanical and wear properties of aluminium alloy composites: a review." Manuf. Eng. pp. 369–391 (2020)

Khelge, S., Kumar, V., Shetty, V., Kumaraswamy, J.: Effect of reinforcement particles on the mechanical and wear properties of aluminium alloy composites. Mater. Today Proc. 52, 571–576 (2021)

Manna, A., Bains, H.S., Mahapatra, P.B.: Experimental study on fabrication of Al—Al2O3/Grp metal matrix composites. J. Compos. Mater. 45(19), 2003–2010 (2011). https://doi.org/10.1177/0021998310394691

Radhika, N., Subramanian, R.: Effect of reinforcement on wear behaviour of aluminium hybrid composites. Tribol. Mater. Surf. Interfaces 7(1), 36–41 (2013). https://doi.org/10.1179/1751584x13y.0000000025

Asif, M., Chandra, K., Misra, P.S.: Wear characteristic of al-based metal matrix composites used for heavy duty brake pad applications. Mater. Sci. For. 710, 407–411 (2012). https://doi.org/10.4028/www.scientific.net/msf.710.407

Palanisamy, D., Devaraju, A., Manikandan, N., Balasubramanian, K., Arulkirubakaran, D.: Experimental investigation and optimization of process parameters in EDM of aluminium metal matrix composites. Mater. Today 22, 525–530 (2020). https://doi.org/10.1016/j.matpr.2019.08.145

Karthik, S., Prakash, K.S., Gopal, P.M., Jothi, S.: Influence of materials and machining parameters on WEDM of Al/AlCoCrFeNiMo0.5 MMC. Mater. Manuf. Process. 34(7), 759–768 (2019). https://doi.org/10.1080/10426914.2019.1594250

Shridhar, T.N., Krishnamurthy, L., Sridhara, B.K.: Machinability studies on aluminium matrix hybrid composites. Adv. Mat. Res. 894, 27–31 (2014). https://doi.org/10.4028/www.scientific.net/amr.894.27

Rajmohan, T., Palanikumar, K.: Experimental investigation and analysis of thrust force in drilling hybrid metal matrix composites by coated carbide drills. Mater. Manuf. Process. 26(8), 961–968 (2011). https://doi.org/10.1080/10426914.2010.523915

Ravi Kumar, K., Kiran, K., Sreebalaji, V.S.: Micro structural characteristics and mechanical behaviour of aluminium matrix composites reinforced with titanium carbide. J. Alloys Compd. 723, 795–801 (2017). https://doi.org/10.1016/j.jallcom.2017.06.309

Dhanalakshmi, S., Rameshbabu, T.: Multi-Aspects optimization of process parameters in CNC turning of LM 25 alloy using the taguchi-grey approach. Metals (Basel) 10(4), 453 (2020)

Thankachan, T.P.: Production and machining performance study of nano Al2O3 particle reinforced LM25 aluminum alloy composites. J. Appl. Mech. Tech. Phys. 60(1), 136–143 (2019)

Altunpak, Y., Akbulut, H.: Effects of aging heat treatment on machinability of alumina short fiber reinforced LM 13 aluminum alloy. Int. J. Adv. Manuf. Technol. 43(5–6), 449–454 (2009)

Dhanalakshmi, S., Rameshbabu, T.: Comparative study of parametric influence on wet and dry machining of LM 25 aluminium alloy. Mater. Today Proc. (2020). https://doi.org/10.1016/j.matpr.2020.06.101

Katamreddy, S.C., Punnath, N., Radhika, N.: Multi-response optimisation of machining parameters in electrical discharge machining of Al LM25/AlB2 functionally graded composite using grey relation analysis. Int. J. Mach. Mach. Mater. 3, 193–213 (2018)

Udaya, P.J., Moorthy, T.V.: Adhesive wear behaviour of aluminium alloy/fly ash composites. Adv. Mat. Res. 622–623, 1290–1294 (2012)

Sharma, V.K., Singh, R.C., Chaudhary, R.: Effect of flyash particles with aluminium melt on the wear of aluminium metal matrix composites. Eng. Sci. Technol. Int. J. 20(4), 1318–1323 (2017)

Subramaniam, B., Natarajan, B., Kaliyaperumal, B., Chelladurai, S.J.S.: Investigation on mechanical properties of aluminium 7075 - boron carbide - coconut shell fly ash reinforced hybrid metal matrix composites. China Foundry 15(6), 449–456 (2018)

Kavimani, V., Soorya Prakash, K., Thankachan, T.: Multi-objective optimization in WEDM process of graphene – SiC-magnesium composite through hybrid techniques. Meas. (Lond.) 145, 335–349 (2019)

Sharma, V.K., Singh, R.C., Chaudhary, R.: Wear and friction behaviour of aluminium metal composite reinforced with graphite particles. Int. J. Surf. Sci. Eng. 12(5/6), 419 (2018)

Sahoo, B., Kumar, R., Joseph, J., Sharma, A., Paul, J.: Preparation of aluminium 6063-graphite surface composites by an electrical resistance heat assisted pressing technique. Surf. Coat. Technol. 309, 563–572 (2017)

Alaneme, K.K., Sanusi, K.O.: Microstructural characteristics, mechanical and wear behaviour of aluminium matrix hybrid composites reinforced with alumina, rice husk ash and graphite. Eng. Sci. Technol. Int. J. 18(3), 416–422 (2015)

Dev, S., Aherwar, A., Patnaik, A.: Preliminary evaluations on development of recycled porcelain reinforced LM-26/Al-Si10Cu3Mg1 alloy for piston materials. SILICON (2016). https://doi.org/10.1007/s12633-018-9979-9

Pawar, S.Y., Kharde, Y.R.: Effect of dual reinforced ceramic particles on elevated temperature tribological properties of hybrid aluminium matrix composites. Adv. Mater. Process. Technol. (2020). https://doi.org/10.1080/2374068X.2020.1853495

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Prakash, C., Senthil, P., Manikandan, N. et al. Investigations and regression modeling on mechanical characterization of cast aluminum alloy based (LM 26 + graphite + fly ash) hybrid metal matrix composites. Int J Interact Des Manuf (2022). https://doi.org/10.1007/s12008-022-00881-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-022-00881-6