Abstract

Metal matrix composites manufactured by stir casting method provide significant benefits in aeronautical and automobile applications. Nowadays, composite material usage is improving in all engineering fields as an outcome of high strength, good wear, and corrosive resistance. This research work deals with the manufacturing of hybrid metal matrix composites of Al alloy as base metal reinforced by varying B4C (0.0, 1.0, 2.0, 3.0, and 4.0) and fly ash (9.0, 8.0, 7.0, 6.0) particles having particle mesh size of 150 μm using liquid metallurgy stir casting technique. The tensile, compression, percentage of elongation is tested using computer interfaced universal testing machine; the hardness of composites are tested by using the Brinell hardness test; the wear rate of composites are investigated experimentally. Through computer-aided scanning electron microscopy test, it is noticed that reinforced particles have been uniformly distributed into the aluminum metal matrix. It was observed from outcomes that the mechanical and tribological attributes are enhanced by reinforcement of B4C and fly ash with aluminum metal matrix alloy. The results reveal that mechanical and tribological properties are improved for Al 7075 wt% 90, B4C wt% 3, and fly ash wt% 7 such as hardness is 111 BHN, UTS is 290 MPa, % elongation is 0.75 mm, impact strength is 0.76 J, and wear rate is 1.4 mm3/min.

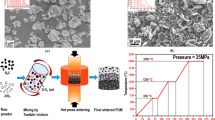

Graphical abstract

Similar content being viewed by others

References

Suresh S, Gowd GH, Kumar MLSD (2019) Mechanical and wear characterization of Al/nano-SiC NMMCs by liquid state process. Journal of Bio-and Tribo-Corrosion 5:43

Patel SK, Singh VP, Kumar N, Kuriachen B, Nateriya R (2019) Wear Behaviour of Al-Silicon (LM13) Alloy Composite Reinforcement with TiC and ZrSiO4 Particles. Silicon

Fenghuang C, Chang C, Zhenyu W, Muthuramalingam T, Anbucheziyan G (2019) Effects of silicon carbide and tungsten carbide in aluminium metal matrix composites. Silicon

Casati R, Vedani M (2014) Metal matrix composites reinforced by nano-particles—a review. Metals 4(1):65–83

Owoeye SS, Folorunso DO, Oji B, Borisade SG (2019) Zinc-aluminium (ZA-27)- based metal matrix composites: a review article of synthesis, reinforcement, microstructural, mechanical and corrosion characteristics. Int J Adv Manuf Technol 100:373–380

Kumar Yadav P, Dixit G (2018) Erosive-corrosive wear of aluminium-silicon matrix (AA336) and SiCp/TiB2p ceramic composites. Silicon

Suresh S, Gowd GH, Kumar MLSD (2019) Mechanical and wear characterization of Al/Nano-SiC NMMCs by liquid state process journal of bio- and Tribo-corrosion, Springer Science and Business Media LLC, 5

Jayakumar T, Annamalai K (2019) Investigation of Hot Tensile Behaviour of Silicon Carbide and Magnesium oxide Reinforced Aluminium Matrix composites. Silicon 11:935–945

Villa JC, Bouix J, Gonzalez G, Esnouf C (1997) Chemical reactivity of aluminum with boron carbide. J Mater Sci 32:4559–4573

Kumar A, Patnaik A, Bhat IK (2019) Tribology analysis of cobalt particulate filled Al 7075 alloy for gear materials: a comparative study. Silicon 11:1295–1311

Raj N, Radhika N (2019) Tribological characteristics of LM13/Si3N4/Gr hybrid composite at elevated temperature. Silicon 11:947–960

Stalin B, Sudha GT, Ravichandran M (2018) Investigations on characterization and properties of Al-MoO3 composites synthesized using powder metallurgy technique. Silicon 10:2663–2670

Vinod B, Ramanathan S, Ananthi V, Selvakumar N (2019) Fabrication and characterization of organic and in-organic reinforced A356 aluminium matrix hybrid composite by improved double-stir casting. Silicon 11:817–829

Ebenezer Jacob Dhas DS, Velmurugan C, Dev Wins L (2018) Investigations on the effect of tungsten carbide and graphite reinforcements during spark erosion machining of aluminium alloy (AA5052) Hybrid composite. Silicon 10:1–13

Ponesakki Raja P, Bensam Raj J (2018) Investigations on mechanical and metallurgical properties of friction welding of AlB2 reinforced aluminium matrix composites. Silicon 10:1385–1391

Yuvanarasiemman P, Malayalamurthi R (2018) Studies on fractures of friction stir welded Al matrix SiC-B4C reinforced metal composites. Silicon 10:1375–1383

Thirumoorthy A, Arjunan T, Kumar KS (2018) Latest Research Development in Aluminium Matrix with Particulate Reinforcement Composites- A Review. Mater Today: Proceedings 5:1657–1665

Poria S, Sahoo P, Sutradhar G (2016) Tribological characterization of stir-cast aluminium-TiB2 metal matrix composites. Silicon 8:591–599

Pradhan S, Barman TK, Sahoo P, Sutradhar G, Ghosh S (2016) Tribological behaviour of Al-Sic metal matrix composite in acidic medium. Int J Eng Technol 8:24–31

Monikandan VV, Joseph MA, Rajendrakumar PK, Sreejith M (2015) Tribological behavior of liquid metallurgy-processed AA6061-B4C composites. Material Research Express, IOP Publishing 2:016507

Premanth AA, Alwarswamy T, Rajmohan T, Prabhu R (2014) The influence of alumina on mechanical and tribological characteristics of graphite particle reinforced hybrid Al-MMC. J Mech Sci Technol 28:4737–4744

Reddy PS, Kesavan R, Vijaya Ramnath B (2018) Investigation of mechanical properties of aluminum 6061-silicon carbide, Boron Carbide Metal Matrix Composite. Silicon 10:495–502

Chen X, Peng Z, Yu X, Fu Z-q, Yue W, Chengbiao W (2011) Microstructure and tribological performance of self-lubricating diamond/ tetrahedral amorphous carbon composite film. Appl Surf Sci 257:3180–3186

Zhao JF, Liu ZH, McLaughlin J (1999) Wear effect on the microstructure of DLC films PECVD-deposited on Al2O3: TiC substrates - a confocal micro-Raman study. Thin Solid Films 357:159–165. https://doi.org/10.1016/S0040-6090(99)00656-2

Das D, Chakraborthy V, Nanda BK, Routara BC (2018) Turning performance of Al 7075/Sip MMC and multi-response optimization using WPCA and Taguchi. Approach Materials Today: Proceedings 5:6030–6037

Vakis A, Yastrebov V, Scheibert J, Nicola L, Dini D, Minfray C, Almqvist A, Paggi M, Lee S, Limbert G, Molinari J, Anciaux G, Aghababaei R, Restrepo SE, Papangelo A, Cammarata A, Nicolini P, Putignano C, Carbone G, Stupkiewicz S, Lenkiewicz J, Costagliola G, Bosnia F, Guarino R, Pugno N, Muser M, Ciavarella M (2018) Modeling and simulation in tribology across scales: an overview. Tribol Int 125:169–199

Naeem M, Iqbal J, Zakaullah M, Mujahid Z, Diaz-Guillen J, Lopez-Badillo C, Sousa R, Khan M (2019) Enhanced wear and corrosion resistance of AISI-304 Steel by duplex cathodic cage plasma treatment. Surf Coat Technol 375:34–45

Acknowledgments

The corresponding author would like to thank Dept. of Mechanical Engineering and Management of S.V. College of Engineering and Dept. of Manufacturing Engineering, Anna University, Chennai, India for providing their support in research work, and the authors would like to extend their thanks to Mr. P. Muni Chengaiah from SVCE, Tirupati and Mr. R. Selva Rajan, Center for Nanoscience and Technology, Anna University for providing the infrastructural facility to perform the experimentation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 1475 kb)

Rights and permissions

About this article

Cite this article

Reddy, T.P., Kishore, S.J., Theja, P.C. et al. Development and wear behavior investigation on aluminum-7075/B4C/fly ash metal matrix composites. Adv Compos Hybrid Mater 3, 255–265 (2020). https://doi.org/10.1007/s42114-020-00145-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-020-00145-5