Abstract

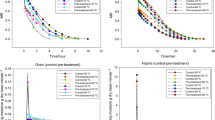

Walnut green husk (WGH) is a common agricultural by-product with high yield and serious pollution problem. The present study aimed to evaluate the impacts of sun drying (SD), pulsed vacuum drying (PVD), short and medium infrared radiation drying (SMIR), hot air drying based on temperature and humidity control (TH-HAD), and heat pump drying (HPD) on the drying characteristics, energy consumption, physico-chemical properties, bioactive compounds content and antioxidant capacity of WGH. Drying characteristics and drying kinetics showed that artificial drying could significantly improve drying efficiency. Compared with SD, the drying time of PVD, SMIR, TH-HAD, and HPD reduced by 63.6, 78.7, 66.3, and 54.0%, respectively. Specific energy consumption analysis demonstrated that HPD showed the lowest specific energy consumption of 2.2 kW·h/kg. Hydration properties analysis revealed that PVD resulted in sample of best water-holding capacity and the HPD sample had the highest water solubility index (43.44%). Structural analysis showed that the cell wall structure of WGH was damaged by different drying methods. Generally, among the five drying methods, HPD was found to be in the middle range in terms of active substance content and antioxidant capacity of dried samples, but it had the least energy consumption. Therefore, HPD has great potential for commercial-scale drying of WGH, offering a new approach for low-energy food processing.

Similar content being viewed by others

Data Availability

The datasets generated or analysed during this study are available from the corresponding author upon reasonable request.

Notes

SD: sun drying; PVD: pulsed vacuum drying; SMIR: short and medium infrared radiation drying; TH-HAD: hot air drying based on temperature and humidity control; HPD: heat pump drying.

SD: sun drying; PVD: pulsed vacuum drying; SMIR: short and medium infrared radiation drying; TH-HAD: hot air drying based on temperature and humidity control; HPD: heat pump drying.

SD: sun drying; PVD: pulsed vacuum drying; SMIR: short and medium infrared radiation drying; TH-HAD: hot air drying based on temperature and humidity control; HPD: heat pump drying.

SD: sun drying; PVD: pulsed vacuum drying; SMIR: short and medium infrared radiation drying; TH-HAD: hot air drying based on temperature and humidity control; HPD: heat pump drying.

SD: sun drying; PVD: pulsed vacuum drying; SMIR: short and medium infrared radiation drying; TH-HAD: hot air drying based on temperature and humidity control; HPD: heat pump drying.

SD: sun drying; PVD: pulsed vacuum drying; SMIR: short and medium infrared radiation drying; TH-HAD: hot air drying based on temperature and humidity control; HPD: heat pump drying.

References

Adenitan, A. A., Awoyale, W., Akinwande, B. A., Busie, M. D., & Michael, S. (2021). Mycotoxin profiles of solar tent-dried and open sun-dried plantain chips. Food Control, 119, 107467. https://doi.org/10.1016/j.foodcont.2020.107467.

Ai, Z., Zhu, G., Zheng, Z., Xiao, H., Mowafy, S., & Liu, Y. (2023). Successive two-stage hot air-drying with humidity control combined radio frequency drying improving drying efficiency and nutritional quality of Amomi fructus. Food and Bioprocess Technology, 16, 149–166. https://doi.org/10.1007/s11947-022-02928-8

Asgari, K., Labbafi, M., Khodaiyan, F., Kazemi, M., & Hosseini, S. S. (2020). High-methylated pectin from walnut processing wastes as a potential resource: Ultrasound assisted extraction and physicochemical, structural and functional analysis. International Journal of Biological Macromolecules, 152, 1274–1282. https://doi.org/10.1016/j.ijbiomac.2019.10.224.

Aydogdu, A., Sumnu, G., & Sahin, S. (2015). Effects of Microwave-Infrared combination drying on quality of eggplants. Food and Bioprocess Technology, 8, 1198–1210. https://doi.org/10.1007/s11947-015-1484-1.

Benseddik, A., Azzi, A., Zidoune, M. N., & Allaf, K. (2018). Mathematical empirical models of thin-layer airflow drying kinetics of pumpkin slice. Engineering in Agriculture Environment and Food, 11, 220–231. https://doi.org/10.1016/j.eaef.2018.07.003.

Bettaieb, R. I., Bourgou, S., Ben, K. S., Aidi, W. W., Ksouri, R., Saidani, T. M., & Fauconnier, M. L. (2020). On the effect of initial drying techniques on essential oil composition, phenolic compound and antioxidant properties of anise (Pimpinella anisum L.) seeds. Food Measure, 14, 220–228. https://doi.org/10.1007/s11694-019-00284-4.

Cosmulescu, S., Trandafir, I., Nour, V., Ionica, M., & Tutulescu, F. (2014). Phenolics content, antioxidant activity and color of green walnut extracts for preparing walnut liquor. Notulae Botanicae Horti Agrobotanici Cluj-Napoca, 42, 551–555. https://doi.org/10.15835/nbha4229649.

Deli, M., Petit, J., Nguimbou, R. M., Beaudelaire, D. E., Njintang, Y. N., & Scher, J. (2019). Effect of sieved fractionation on the physical, flow and hydration properties of Boscia senegalensis Lam., Dichostachys glomerata Forssk. and Hibiscus sabdariffa L. powders. Food Science and Biotechnology, 28, 1375–1389. https://doi.org/10.1007/s10068-019-00597-6.

Deng, L., Mujumdar, A. S., Yang, W., Zhang, Q., Zheng, Z., Wu, M., & Xiao, H. (2020). Hot air impingement drying kinetics and quality attributes of orange peel. Journal of Food Processing and Preservation, 44, 14294. https://doi.org/10.1111/jfpp.14294.

Deng, L. Z., Pan, Z., Mujumdar, A. S., Zhao, J. H., Zheng, Z. A., Gao, Z. J., & Xiao, H. W. (2019). High-humidity hot air impingement blanching (HHAIB) enhances the drying quality of apricots by inactivating the enzymes, reducing drying time and altering cellular structure. Food Control, 96, 104–111. https://doi.org/10.1016/j.foodcont.2018.09.008.

FAO. (2023). Statistical database. Food and Agriculture Organization. https://www.fao.org/faostat/en/#data/QCL. Accessed 16 June 2023.

Fei, X., Jia, W., Wang, J., Chen, T., & Ling, Y. (2020). Study on enzymatic hydrolysis efficiency and physicochemical properties of cellulose and lignocellulose after pretreatment with electron beam irradiation. International Journal of Biological Macromolecules, 145, 733–739. https://doi.org/10.1016/j.ijbiomac.2019.12.232.

Geng, Z., Zhu, L., Wang, J., Yu, X., Li, M., Yang, W., Hu, B., Zhang, Q., & Yang, X. (2023). Drying sea buckthorn berries (Hippophae rhamnoides L.): Effects of different drying methods on drying kinetics, physicochemical properties, and microstructure. Frontiers in Nutrition, 10, 1106009–1106009. https://doi.org/10.3389/FNUT.2023.1106009.

Han, B., Ding, C., Jia, Y., Wang, H., Bao, Y., Zhang, J., Duan, S., Song, Z., Chen, H., & Lu, J. (2023). Influence of electrohydrodynamics on the drying characteristics and physicochemical properties of garlic. Food Chemistry: X, 19, 100818. https://doi.org/10.1016/j.fochx.2023.100818.

Hnin, K. K., Zhang, M., Devahastin, S., & Wang, B. (2020). Combined Infrared freeze drying and infrared drying of rose-flavored yogurt melts—effect on product quality. Food and Bioprocess Technology, 13, 1356–1367. https://doi.org/10.1007/s11947-020-02486-x.

Hu, Y., Que, T., Fang, Z., Liu, W., Chen, S., Liu, D., & Ye, X. (2013). Effect of different drying methods on the protein and product quality of hairtail fish meat gel. Drying Technology, 31, 1707–1714. https://doi.org/10.1080/07373937.2013.794831.

Igbozulike, A. O., Ndirika, V. I. O., & Simonyan, K. J. (2023). Evaluation of energy consumption in drying African oil bean seeds using response surface methodology. Arab Journal of Basic and Applied Sciences, 30, 137–145. https://doi.org/10.1080/25765299.2023.2191955.

Ismail, O., Seyhun, K. A., & Doymaz, I. (2019). Drying of Okra by different drying methods: Comparison of drying time, product color quality, energy consumption and rehydration. Athens Journal of Sciences, 6, 155–168. https://doi.org/10.30958/ajs.6-3-1

Jiang, L., Wang, F., Xie, X., Xie, C., Li, A., Xia, N., Gong, X., & Zhang, H. (2022). Development and characterisation of chitosan/guar gum active packaging containing walnut green husk extract and its application on fresh-cut apple preservation. International Journal of Biological Macromolecules, 209, 1307–1318. https://doi.org/10.1016/j.ijbiomac.2022.04.145.

Kusuma, H. S., Izzah, D. N., & Linggajati, I. W. L. (2023). Microwave-assisted drying of Ocimum sanctum leaves: Analysis of moisture content, drying kinetic model, and techno-economics. Applied Food Research, 3, 100337. https://doi.org/10.1016/j.afres.2023.100337.

Laeliocattleya, R. A., Martati, E., Alwi, N. S., Aulia, L. P., & Yunianta. (2020). The characteristics of corn silk (Zea mays L.) herbal drinks tea with vacuum drying method as an antioxidant. IOP Conference Series: Earth and Environmental Science, 475, 012023. https://doi.org/10.1088/1755-1315/475/1/012023

Li, T., Wang, L., Chen, Z., Li, C., Li, X., & Sun, D. (2020). Structural changes and enzymatic hydrolysis yield of rice bran fiber under electron beam irradiation. Food and Bioproducts Processing, 122, 004. https://doi.org/10.1016/j.fbp.2020.04.004.

Liu, X., Wu, Y., Lu, Y., Liu, X. W., Liu, J., Ren, J., Wu, W., Wang, Y., & Li, J. (2022). Enhanced effects of walnut green husk solution on the phytoextraction of soil cd and zn and corresponding microbial responses. Chemosphere, 289, 133136. https://doi.org/10.1016/J.CHEMOSPHERE.2021.133136.

Lugo, L., Ureña, N., & Barrera, D. (2017). Gamma irradiated orange peel for cr (VI) bioreduction. Separation Science and Technology, 52, 2443–2455. https://doi.org/10.1080/01496395.2017.1302477.

Mozaffari, P., Pashangeh, S., Berizi, E., Majlesi, M., Hosseinzadeh, S., Salehi, S. O., Derakhshan, Z., & Giannakis, S. (2022). Potential of nanochitosan coating combined with walnut green husk to improve the preservation of rainbow trout (Oncorhynchus mykiss) during refrigerated storage. Environmental Research, 214, 114019. https://doi.org/10.1016/j.envres.2022.114019.

Namjoo, M., Moradi, M., Dibagar, N., & Niakousari, M. (2022). Cold plasma pretreatment prior to ultrasound-assisted air drying of cumin seeds. Food and Bioprocess Technology, 15, 2065–2083. https://doi.org/10.1007/s11947-022-02863-8.

Namsanguan, Y., Tia, W., Devahastin, S., & Soponronnarit, S. (2004). Drying kinetics and quality of shrimp undergoing different two-stage drying processes. Drying Technology, 22, 759–778. https://doi.org/10.1081/DRT-120034261.

Nguyen, V. T., Van, V. Q., Bowyer, M. C., Van, A., & Scarlett, C. J. (2015). Effects of different drying methods on bioactive compound yield and antioxidant capacity of Phyllanthus amarus. Journal of Drying Technology, 33, 1006–1017. https://doi.org/10.1080/07373937.2015.1013197

Onwude, D. I., Hashim, N., Abdan, K., Janius, R., & Chen, G. (2018). Investigating the influence of novel drying methods on sweet potato (Ipomoea batatas L.): Kinetics, energy consumption, colour, and microstructure. Journal of Food Process Engineering, 41, 12686. https://doi.org/10.1111/jfpe.12686.

Ozsoy, N., Can, A., Yanardag, R., & Akev, N. (2008). Antioxidant activity of Smilax Excelsa L. leaf extracts. Journal of Food Chemistry, 110, 571–583. https://doi.org/10.1016/j.foodchem.2008.02.037

Qin, D., Xiang, B., Zhou, X., Qiu, S., & Xi, J. (2022). Microemulsion as a solvent for naphthoquinones extraction from walnut (Juglans mandshurica Maxim) green husk using high voltage electrical discharge. Separation and Purification Technology, 281, 119983. https://doi.org/10.1016/J.SEPPUR.2021.119983.

Raut, S., Md Saleh, R., Kirchhofer, P., Kulig, B., Hensel, O., & Sturm, B. (2021). Investigating the effect of different drying strategies on the quality parameters of Daucus carota L. using dynamic process control and measurement techniques. Food and Bioprocess Technology, 14, 1067–1088. https://doi.org/10.1007/s11947-021-02609-y.

Romano, R., Aiello, A., Meca, G., De, L. L., Pizzolongo, F., & Masi, P. (2021). Recovery of bioactive compounds from walnut (Juglans regia L.) green husk by supercritical carbon dioxide extraction. International Journal of Food Science & Technology, 56, 4658–4668. https://doi.org/10.1111/IJFS.15161.

Sarkar, T. (2021). Drying kinetics, Fouruer-transform infrared spectroscopy analysis and sensory evaluation of sun, hot-air, microwave and freeze-dried mango leather. Journal of Microbiology Biotechnology and food Sciences, 10, 3313. https://doi.org/10.15414/jmbfs.3313.

Seerangurayar, T., Abdulrahim, M., AlIsmaili., Janitha, J., & Nasser, A. (2019). Effect of solar drying methods on colour kinetics and texture of dates. Food and Bioproducts Processing, 116, 227–239. https://doi.org/10.1016/j.fbp.2019.03.012.

Senadeera, A., Önal, D. M., & Russo (2020). Influence of different hot air drying temperatures on drying kinetics, shrinkage, and colour of persimmon slices. Foods, 9, 101–101. https://doi.org/10.3390/foods9010101.

Shen, H. Y., Hou, Y. J., Xi, M. H., Cai, Y. Y., Ao, J. F., Wang, J., Li, M., & Luo, A. W. (2022). Electron beam irradiation enhanced extraction and antioxidant activity of active compounds in green walnut husk. Food Chemistry, 373, 131520. https://doi.org/10.1016/j.foodchem.2021.131520.

Singh, S., Agrawal, N., Habou, D., Asere, A. A., Alhassan, A. M., Eklou, A. S., Ines, M. S., & Francis, N. (2021). Effect of drying methods on the nutritional content and In-vitro antioxidant capacity of Chenopodium album L. and Spinacia oleracea L. Research Journal of Pharmacy and Technology, 14, 4361–4366. https://doi.org/10.52711/0974-360X.2021.00757.

Tu, J., Liu, H., Sun, N., Liu, S., & Chen, P. (2018). Optimization of the steam explosion pretreatment effect on total flavonoids content and antioxidative activity of seabuckthom pomace by response surface methodology. Molecules, 24, 60. https://doi.org/10.3390/molecules24010060.

Tunckal, C., & Doymaz, İ. (2020). Performance analysis and mathematical modelling of banana slices in a heat pump drying system. Renewable Energy, 150, 918–923. https://doi.org/10.1016/j.renene.2020.01.040.

Vidinamo, F., Fawzia, S., & Karim, M. A. (2022). Investigation of the effect of drying conditions on phytochemical content and antioxidant activity in pineapple (Ananas comosus). Food and Bioprocess Technology, 15, 72–81. https://doi.org/10.1007/s11947-021-02715-x.

Wang, Y., & Ding, C. (2023). Effect of electrohydrodynamic drying on drying characteristics and physicochemical properties of carrot. Foods, 12, 4228. https://doi.org/10.3390/foods12234228.

Xiang, J., Li, W., Ndolo, V. U., & Beta, T. (2019). A comparative study of the phenolic compounds and in vitro antioxidant capacity of finger millets from different growing regions in Malawi. Journal of Cereal Science, 87, 143–149. https://doi.org/10.1016/j.jcs.2019.03.016.

Xie, L., Mujumdar, A. S., Fang, X. M., Wang, J., Dai, J. W., Du, Z. L., Xiao, H. W., Liu, Y., & Gao, Z. J. (2017). Far-infrared radiation heating assisted pulsed vacuum drying (FIR-PVD) of wolfberry (Lycium barbarum L.): Effects on drying kinetics and quality attributes. Food and Bioproducts Processing, 102, 320–331. https://doi.org/10.1080/07373937.2020.1818254.

Xie, L., Zheng, Z. A., Mujumdar, A. S., Fang, X. M., Wang, J., Zhang, Q., Ma, Q., Xiao, H. W., Liu, Y. H., & Gao, Z. J. (2018). Pulsed vacuum drying (PVD) of wolfberry: Drying kinetics and quality attributes. Drying Technology, 36, 1501–1514. https://doi.org/10.1080/07373937.2017.1414055

Xu, P., Peng, X., Yang, J., Li, X., Zhang, H., Jia, X., Liu, Y., Wang, Z., & Zhang, Z. (2021). Effect of vacuum drying and pulsed vacuum drying on drying kinetics and quality of bitter orange (Citrus aurantium L.) slices. Food Process, 45, 16098. https://doi.org/10.1111/jfpp.16098.

Xu, Y., Xiao, Y., Lagnika, C., Li, D., Liu, C., Jiang, N., Song, J., & Zhang, M. (2020). A comparative evaluation of nutritional properties, antioxidant capacity and physical characteristics of cabbage (Brassica oleracea var. Capitate var L.) subjected to different drying methods. Food Chemistry, 309, 124935. https://doi.org/10.1016/j.foodchem.2019.06.002.

Zang, Z., Zhang, Q., Huang, X., Jiang, C., He, C., & Wan, F. (2023). Effect of ultrasonic combined with vacuum far-infrared on the drying characteristics and physicochemical quality of Angelica sinensis. Food and Bioprocess Technology, 16, 2455–2470. https://doi.org/10.1007/s11947-023-03076-3.

Zhang, Q., Li, S., Zhang, M., Mu, G., Li, X., Zhang, G., & Xiong, S. (2022). Heat pump drying of kelp (Laminaria Japonica): Drying kinetics and thermodynamic properties. Processes, 10, 514. https://doi.org/10.3390/PR10030514.

Zheng, X., Wang, J., Liu, X., Sun, Y., Zheng, Y., Wang, X., & Liu, Y. (2015). Effect of hydrolysis time on the physicochemical and functional properties of corn glutelin by Protamex hydrolysis. Food Chemistry, 172, 407–415. https://doi.org/10.1016/j.foodchem.2014.09.080.

Funding

We gratefully acknowledge the financial support from the National Key Research and Development Program of China (2023YFD2201300) and the National Key Research and Development Program of China (2019YFD1002404).

Author information

Authors and Affiliations

Contributions

Jingfang Ao: Methodology, Investigation, Data curation, Formal analysis Writing-Original draft preparation; Jun Wang: Reviewing and Editing; Heyu Shen: Methodology, Data curation, Software; Meihua Xi: Investigation, Data curation, Software; Yujie Hou: Methodology, Data curation, Software; Yingying Cai: Reviewing; Mei Li: Reviewing and Editing; Anwei Luo*: Writing- Reviewing and Editing. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ao, J., Wang, J., Shen, H. et al. Impact of Various Drying Technologies on the Drying Characteristics, Physico-chemical Properties, and Antioxidant Capacity of Walnut Green Husk. Food Bioprocess Technol (2024). https://doi.org/10.1007/s11947-024-03394-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11947-024-03394-0