Abstract

Chinese bayberry (Myrica rubra Sieb. et Zucc.) fruit (CBF) is widely growing in eastern Asia, mainly in China. CBFs contain a high number of polyphenols, especially anthocyanins. However, CBF can be easily damaged and cannot be stored for more than 3 days at 20–22 °C and 9–12 days at 0–2 °C. Thus, this review explores the potential options for the long-term preservation and consumption of CBFs, as well as the importance of CBF by-products. The review also addressed the biological activity of CBFs and their food products. The consumption period of CBF can be increased by employing a variety of processing techniques, including rapid freezing, drying, juicing, making wine and vinegar, and adding it to meals. Additionally, oil and bioactive substances can be extracted from the CBF by-products, such as kernel and pomace. The greatest options to extend the duration of CBF ingestion are thought to be CBF powder, juice, and wine. Furthermore, CBFs and their derivatives exhibit many biological activities such as antibacterial, anticancer, antidiabetic, and antioxidant properties. The two biological activities that were most potent were antidiabetic and antioxidant. However, more biological research, particularly clinical-based research, is advised to investigate the potential health benefits of CBF and its products.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Bayberry is also known as Chinese bayberry (Myrica rubra Sieb. et Zucc.), yangmei, yamamomo, Japanese bayberry, yumberry, waxberry, red bayberry, which belongs to the Myricaceae family, and Myrica genus. Chinese bayberry is a tropical or subtropical fruit tree, that produces delicious fruit known as Chinese bayberry fruit (CBF), which widely grows in eastern Asia (Korea, Japan, and the Philippines), mainly in China (Ju et al., 2018, 2019). In Chinese history, CBF cultivation has been documented for over two millennia. Mid-June to early July is the main commercial harvest period for CBF in China. Eastern and southern China, particularly the provinces of Zhejiang and Jiangsu, which are the primary producers of CBF in China, saw a commercial growth in CBF (Chen et al., 2015; Sun et al., 2013; Zhang et al., 2008, 2021), with an annual production of over 300,000 tons (data provided by Zhejiang Agricultural Office) (Cheng et al., 2009). CBF weighs from 9 to 25 g and is shaped like a large cherry with segmented flesh, a central stone, and a circular form. CBF is a tasty fruit with a pleasing flavor, color, and economic worth. Due to the presence of anthocyanins (ACNs), particularly cyanidin-3-O-glucoside (C3G), it has a reddish-purple tint (Saeed et al., 2024; Sun et al., 2012). Natural phytochemicals, including soluble sugars, organic acids, flavonoids, proanthocyanidins, and phenolics, are also abundant in CBF. Owing to its great therapeutic potential, Chinese traditional medicine has long used CBF to treat diarrhea, coughing, congestion, and digestive issues (Yang et al., 2009; Zhang et al., 2015; Zhong et al., 2008). According to several recent research, CBF has a variety of bioactivities that include preventing cancer, reducing inflammation, preventing diarrhea, preventing diabetes, fighting bacteria, and addressing other health problems (Guo et al., 2014; Li et al., 2012; Sun et al., 2011; Yang et al., 2011; Yao et al., 2011). Nevertheless, CBFs have a limited shelf life and should only be kept uncontrolled for four days (Tian et al., 2019); thus, in order to offer long-term storage of CBFs, processing technologies are needed. CBFs are typically processed into a variety of forms, such as dried fruit, juice, wine, vinegar, jam, and can be utilized as food additives in order to attain a longer consumption time (Cheng et al., 2008; Guo et al., 2014; Zhang et al., 2022b; Zhou et al., 2009). This review comprehensively discusses the nutritional compositions, the potential ways for extending consumption time, by-products importance, and the potential biological activities of CBFs and their products, such as antioxidants, anti-obesity, antidiabetic, anti-inflammatory, anti-microbial, and anticancer activity. As a result, this evaluation may provide valuable information for industry professionals working on CBF and CBF-based food items as well as food researchers.

The Compositions of Chinese Bayberry Fruit and Kernel

The relative amounts of each nutritional component, such as carbs, protein, fats, minerals, and vitamins, are frequently used to evaluate meals and their products chemically. Growing consumer awareness of the health advantages of different nutrients is facilitated by nutritional labeling, which shows how each food component contributes to the daily required intake of nutrients (Rashwan et al., 2020). Therefore, understanding the nutritional makeup of CBF is crucial in determining the fruit’s suitability for direct consumption and/or the development of CBF-based food products. The skin has a waxy layer, and CBF is often spherical. Fruit sizes and weights vary from 9 to 25 g, depending on the cultivar and ripening date. Fruit dimensions range from 2.6 to 3.7 cm in width and 2.6 to 3.9 cm in length (Zhang et al., 2022a). Total phenolics (mg of gallic acid equivalent/100 g of fresh weight (FW), flavonoids (mg of rutin equivalents/100 g of FW), procyanidins (mg catechin equivalents/100 g of FW), and anthocyanins (mg of cyanidin-3-O-galactoside equivalents/100 g of FW) ranged from 24.6–253.9, 11.6–122.3, 3.6–9.6, and 0.1–7.2, respectively, based on CBF cultivars (Bao et al., 2018; Tian et al., 2019). Additionally, Table 1 provides more information about the contents of phenolics, flavonoids, anthocyanins, and antioxidants that are found in different cultivars of CBF (Bao et al., 2018; Fang et al., 2009; Tian et al., 2019). Moreover, CBF features a large edible portion in its stone kernel, like that of plum and peach (Fig. 1). 5.59–8.58% moisture, 3.38–4.02% ash, 25.04–27.64% protein, 62.55–68.18% fat, and 1.58–1.99% soluble sugars were found in CBF kernels (CBFK) from five distinct cultivars (Cheng et al., 2008). With concentrations of 4624.33–7808.92, 2842.89–3710.05, and 959.39–2451.70 mg/kg, respectively, the CBK was extremely rich in calcium, magnesium, and potassium. CBFK had between 25.0–26.64% dry weight (DW) protein, with most of the storage protein being in the globulin form. Methionine, arginine, aspartic, and glutamic acids were abundant in the kernel protein, whereas lysine was the limiting amino acid (Cheng et al., 2008). The most notable aspect of CBFK was its high fat content (62.5–68.1% DW). About 84.9–90.1% of the fatty acids were unsaturated, consisting of 34.1–46.8% linoleic acid and 43.3–50.7% oleic acid (Cheng et al., 2008). When compared to other berries, CBF has a high C3G content, meaning that it makes up at least 85% of the ACNs in the fruit (e.g., 64.8 mg/100 g weight gain in the ‘Biqi’ cultivar). This is comparable to that of blackberries and significantly higher than that of cranberries, blueberries, bilberries, lingonberries, or chokeberries (Zhang et al., 2008, 2022a). Three CBF cultivars (Biqi, Dongkui, and Fenhongzhong) were found to have fifty-five volatile components (ten aldehydes, nine alcohols, eight esters, seventeen terpenes, and eleven other compounds) according to optimized HS-SPME/GC–MS analysis (Cheng et al., 2015a). Eighty-two volatile chemicals, including alcohols, acids, terpenes, esters, and aldehydes, were also found in Biqi, Dongkui, and Fenhongzhong, according to Cheng et al. (2015b).

Processing Technologies for Developing CBF-Based Food Products

CBF is easily ruined and should not be kept in storage for longer than 3 days at 20–22 °C or 9–12 days at 0–2 °C. This is due to CBF’s softness, high perishability, water loss, sensitivity to mechanical harm, degeneration of the body, and microbial degradation (Liu et al., 2022; Xia et al., 2021). The primary issue impeding the CBF sector is the challenge of maintaining the freshness of CBF. As a result, the researchers look for a workable solution to increase CBF’s shelf life. Quick freezing technology (QFT) is said to be an efficient way to preserve color, flavor, nutritional content, and texture in frozen foods since it can quickly freeze food, minimizing the size of ice crystals inside (Xin et al., 2015). For instance, the quick freezing of CBF under the following conditions, the velocity of cold N2 (2 m/s), temperature (–120 °C), ti (2.27 min), and v (8.51 cm/h) showed that thawing loss was 1.9%, and this due to the high freezing rate may decrease the damage of ice crystals to the cell membrane, which is helpful to preserve the moisture and quality of frozen CBF (Zhao et al., 2020).

Furthermore, there was hardly any variation in pH between fresh and frozen CBF (0.18); this is because faster-freezing results in less moisture loss and cell damage, which modifies the H+ concentration. Furthermore, the examination of the textural profile of frozen CBF was most like that of fresh CBF. Additionally, the appearance of frozen CBF that had been thawed and kept for six months was most similar to that of fresh CBF (Zhao et al., 2020). In contrast, the treatment of CBF via air (HA) at 48 °C for 3 h significantly inhibited natural decay and maintained the quality of CBF during storage at 4 °C by reducing the growth of pathogenic fungi, especially Botryotinia spp., Candida spp., Davidiella spp., and Hanseniaspora spp. In which the canonical correspondence analysis showed that Botryotinia spp. and Davidiella spp. correlated positively with fruit decay and weight reduction (Dai et al., 2021).

Furthermore, vacuum impregnation (VI) pretreatment can extend the shelf life of CBFs. When calcium ascorbate (CaC12H14O12) was used with VI in conjunction with disodium stannous citrate (C6H8Na2O7Sn) or alone, the reduction of firmness (4–10 days), increase in weight loss (2–10 days), decay rate (4–10 days), and microbial growth (2–10 days) of CBF were all significantly inhibited. Furthermore, VI containing either a single CaC12H14O12 or a mixture of C6H8Na2O7Sn or both strongly reduced the growth in color difference between the sixth and tenth day of CBF storage. VI combined with CaC12H14O12 and C6H8Na2O7Sn had the greatest impact on the sensory characteristics of CBF (Li et al., 2018). The decay incidence of CBF (genotype N1MR06) was considerably reduced to just 18% after 10 days at 5 °C by treating it with acetic acid for 1 h using ultrasonic fog, as opposed to 70% for untreated control fruit (Perkins et al., 2017).

Furthermore, titratable acidity measures, total soluble solids analysis, and sensorial quality demonstrated that the acetic acid treatment had no negative impact on the sensorial quality of CBF (Perkins et al., 2017). This could be due to the antibacterial properties of weak organic acids, such as acetic acid, which result from the cytoplasm becoming more acidic due to the passage of un-dissociated molecules into the cell. Consequently, it can lower the rate of CBF deterioration without affecting the sensorial quality of CBF (Vardar et al., 2012). Additionally, the authors investigated the effects of pulsed light (PL) as one of the non-thermal sterilization technologies on the qualities of Chinese bayberries during storage at 10 °C, 95% relative humidity (RH) for 12 days. They found that the decay index of PL1 (9 kJ m− 2 for 1 min), PL2 (18 kJ m− 2 for 2 min), PL5 (45 kJ m− 2 for 5 min) per side, and CK (control groups) at 12 d was 13.75%, 11.25%, 8.75% and 22.51%, respectively. The decay of PL1, PL2, and PL5 significantly decreased by 38.92%, 50.02%, and 61.12% at 12 d compared to CK groups. Besides, the weight loss (WL) of PL1, PL2, PL5, and CK at 12 d were 13.65%, 16.03%, 18.69%, and 9.39%, respectively. WL of PL1, PL2, and PL5 significantly increased by 45.37%, 70.71%, and 99.04% at 12 d compared to CK groups. In addition, PL therapy successfully reduced polyphenol oxidase (PPO) activity within the initial few days. Additionally, PL was found to dramatically boost phenylalanine ammonia-lyase (PAL) activity by 53.89% after 6 days and by 96.59% at 9 days (Wang et al., 2023). Furthermore, Colletotrichum cordylinicota was suppressed by PL treatment throughout the storage period, with the relative abundance decreasing from 27.6% at 0 d to 2.2% at 12 d in CK groups (averaged 13.4%) and from 13.86% at 0 d to 12.72% at 12 d in PL groups (averaged 6.97%). Diaporthe sp. and Dirofilaria hongkongensis were the two primary species in the Diaporthe genus, and they reacted differently in the CK and PL groups. While in CK groups, they originally maintained a low relative abundance. However, their relative abundance increased dramatically after 6 d and continued to rise during the entire storage period in PL groups. Diaporthe sp. accounted for 0.22% initially and rose to 26.4% after 12 days, whereas D. hongkongensis accounted for 0.09% at 0 days and increased to 26.0% after 12 days. Hanseniaspora uvarum was more abundant in PL groups (average 25.11%) than in CK groups (17.64%). Overall, PL treatment decreased the abundance of Monographella nivalis and C. cordylinicota while increasing the abundance of Diaporthe sp. and D. hongkongensis (Wang et al., 2023). However, most of these methods or treatments are considered expensive ways to prolong the freshness of CBF, as well as needing professional people to do them. Therefore, many scientists recommended using CBF directly in food products such as dried fruits, juice, wine, powder, etc. (Cheng et al., 2017; Liu et al., 2022, 2023; Tian et al., 2019).

Chinese Bayberry Powder

Removing as much moisture as possible from food is the rationale behind food preservation through drying, as it prevents microorganisms and enzymes from functioning. Thus, the researchers concentrated more on adopting state-of-the-art fruit-drying processes, like hot air drying (HAD), freeze-drying (FD), spray-drying (SD), microwave drying (MD), vacuum drying (VD), and others, to make dried products. These techniques speed up the drying process without sacrificing the quality of the final products (Table 2) (Ashar et al., 2023a; Cheng et al., 2017; Fang & Bhandari, 2011, 2012; Liu et al., 2017, 2022). For instance, the retention of the total phenolic content and total ACNs during the SD process were about 96% and 94%, respectively, which indicates that SD was a satisfactory technique for drying heat-sensitive polyphenols (Fang & Bhandari, 2011). Moreover, incorporating additional dietary elements into CBF juice throughout the SD procedure can enhance the recovery of CBF powder. According to Fang and Bhandari (2012), adding 1.0% whey protein isolate to bayberry juice produced a 53% powder recovery; however, when the protein ratio increased to 10%, the beverage’s powder recovery did not significantly increase. Furthermore, CBF juice powder with a 74.16 ± 2.0% yield, 3.14 ± 0.10% moisture content, 9.5 ± 0.0% hygroscopicity, 43.6 ± 1.3 °C glass transition temperature, 16.5 ± 2.5 total color difference, 26.8 ± 0.2 Hunter a redness, 92.3 ± 0.9% ACNs retention, 79.9 ± 4.1% phenolics retention, and 28.5 ± 0.4 mmol Trolox equivalents/g antioxidant capacity was obtained by scanning CBF juice using response surface methodology (Liu et al., 2017). However, the CBF powder produced by FD usually preserved more total polyphenols, gallic acid, protocatechuic acid, C3G, and ACNs than the powder produced by SD when both procedures were stored for the same length of time (Cheng et al., 2017). CBFs dried by the FD technique had higher amounts of total phenolic, total flavonoid, and total ACN, as well as stronger antioxidant and hypoglycemic qualities, in comparison to CBFs dried by the HA method (Liu et al., 2022). Compared to freeze-dried CBF (Biqi), freeze-dried CBF (Dongkui) showed stronger α-glucosidase inhibition but equivalent antioxidant and α-amylase inhibitory effects. Furthermore, compared to HA-dried samples, CBF samples that were dried by FD showed higher concentrations of C3G, myricitin-3-O-rhamnoside, quercetin-3-O-galactoside, quercetin-3-O-glucoside, and quercetin-3-O-rhamnoside (Liu et al., 2022). Additionally, the drying methods can affect the solubility and bulk density of Chinese bayberry pomace powder, for example, the solubility of Chinese bayberry pomace powder after using HAD, VD, and FD was 32.98 ± 2.81, 35.84 ± 2.31, and 36.5 ± 3.17%, respectively, as well as bulk density was 0.63 ± 0.02, 0.58 ± 0.00, and 0.07 ± 0.00 g/mL, respectively (Saili et al., 2023).

Chinese Bayberry Juice

The CBF juice exhibits a robust antioxidant capacity that is linked to the presence of ACNs, phenolics, and ascorbic acid (AA). For instance, the total contents of phenolics, anthocyanins, and flavonoids in bayberry juice from different cultivars ranged from 1149 to 2243 mg GAE/L, 238 to 324 mg C3GE/L, and 286 to 907 mg RutinE/L, respectively (Tian et al., 2019). Yu et al. (2018) reported that the total polyphenol (mg/L) in CBF juice content ranged from 1.083 ± 0.156 to 1.949 ± 0.204, and another study showed that the content of total phenols in bayberry juice was 283.31 mg GAE/100 mL (Cao et al., 2018). Moreover, the raw bayberry juice contained a total phenolic content (mg/L) was 1104.94 ± 10.44, total anthocyanins (mg/L) was 193.12 ± 4.61, and Inhibition of DPPH (%) was 60.39 ± 0.44 (Chen et al., 2019). In addition, 13 different types of amino acids were found in the cultivars of Biqi and Lizhi, 12 different types in Baiyangmei and Dingao, 11 different types in Tanmei, and 10 different types in Zaoda and Zaose. Dingao juice had the highest total amino acid content (1.672 g/L), followed by Lizhi (1.557 g/L), Baiyangmei (1.124 g/L), Tanmei (1.167 g/L), and Lizhi (1.557 g/L). Dongkui juice had the lowest total amino acid content, with only 0.057 g/L (Tian et al., 2019). Therefore, the researchers try to find the optimal processing technologies for improving and/or saving quality, as well as increasing the quantity of CBF juices. The authors investigated the impact of three pretreatment methods, namely the addition of sulfur dioxide (SO2), pasteurization of the crushed pulp, and blanching before fruit crushing, on the production of fresh bayberry juices on a large-scale industrial level. They found that centrifuged juice yield varied between 73 and 78% (w/w), while only 12–27% of ACNs and 20–32% of polyphenolics were recovered in the ultrahigh temperature juices. The earliest stages of blanching, crushing, pasteurization, and depectinization resulted in a significant reduction in both total and specific polyphenolic compounds (Fang et al., 2006).

Conversely, ACNs and polyphenolics were present by 52–58% and 30–35%, respectively, in the centrifuged cakes. Moreover, pasteurization- and blanching-treated sample juices showed a higher total monomeric ACNs than SO2-treated samples, while SO2-treated samples juice had a higher total monomeric ACNs than control juice. Besides, initial processing steps increased the polyphenolic profile in bayberry juices by 50–150% as hydroxybenzoic acids owing to the flavonol glycoside-gallates’ liberated gallic acid (Fang et al., 2006). Furthermore, high-pressure processing improved the stability of ACNs in CBF juice during storage, where the retention ratio of C3G and AA content after pressure treatment was more than 98% and 96%, respectively. C3G and AA levels in pressure-treated juice were more stable throughout storage than in untreated control juice (Yu et al., 2013). Raw materials, heat treatment, and storage time can also affect the flavor of CBF juice, where the CBF juice produced fermentation-like flavors with increased alcohols by 11.45% and with decreased esters and total sugar by 14.91% and 3.27 g/L, respectively, after storage for nine months. Besides, the contents of alcohols, esters, titratable acidity, and total sugar of the rancid flavor raw CBF juice were 8.24%, 6.03%, 5.56 g/L, 0.18 g/L less than those of pleasing flavor raw CBF juice (PF), whereas the average amount of aldehydes was 4.19% greater than that of PF (Xu et al., 2014). Another study sought to distinguish between the aroma profiles of CBF juice under four squeezing conditions including freshly/frozenly squeezed at room temperature/4°C. Twenty-five active aromas and sixty-six volatiles were recognized as having “green,” “floral,” “fruity,” and “woody” scents. The freshly squeezed groups had much greater volatile content than the frozenly pressed groups, including alcohols, esters, and aldehydes. It was discovered that juices that were squeezed at room temperature tasted “fermented.” Particularly β-caryophyllene and humulene, the total volatile content in the frozenly squeezed at room temperature was the lowest. The freshly squeezed bayberry juice at 4 °C had the best flavor quality, as determined by principal component analysis and GC-MS-O. This would be the ideal condition for the CBF squeezing procedure (Cheng et al., 2021). Additionally, Chen et al. (2022) investigated the impact of fermentation settings on the physicochemical characteristics and flavor quality of fermented bayberry juice. They discovered that fermenting bayberry juice with a combination of Lactobacillus acidophilus (LA) and Streptococcus thermophilus (ST) increased the juice’s sensory assessment ratings and microbiological viability. On the other hand, the anthocyanin content of the juice was reduced (fresh juice: 20.60 ± 0.46 to 10.54 ± 0.98 fermented juice (mg/100 g), the total phenolic content was maintained (fresh juice: 62.24 ± 1.17 and fermented juice: 62.19 ± 4.36 (mg GAE/100 g), and the antioxidant capacity was slightly reduced (fresh juice: 77.91 ± 0.54 and fermented juice: 70.61 ± 1.58%) during the fermentation process conducted under the following conditions: ST and LA in a mass ratio of 3:1; 0.6% (mass concentration) inoculation; fermentation time, 48 h, at 37 °C; 10% (mass concentration) added sucrose. Gas chromatography-mass spectrometry-olfactometry (GC-MS-O) measurements showed the reduction of aroma volatiles from 42 compounds in fresh juice 33 compounds in fermented juice. Additionally, the quantity of alcohol rose while the amount of aldehyde decreased (Chen et al., 2022).

Moreover, thermal processing (TP), ultrasound (US), and ultrasound with cooling (USC) treatment effectively inactivated the polyphenol oxidase (PPO) and peroxidase (POD) in CBF juice. The increasing temperature or ultrasound intensity and prolonging the treatment time also continuously decreased the residual activity of the two enzymes. In comparison with thermal treatment, ultrasound treatment reduced the inactivation time and enhanced the inactivation efficiency of enzymes. Besides, the treatment of CBF juice by USC showed a significantly lower inactivation rate of PPO and POD than that from US treatment (Cao et al., 2018), indicating that the heat generated by ultrasound treatment enhanced enzyme denaturation in addition to the effect of cavitation. However, using an ice bath or recirculating cooling water system to control the heat (to control temperature lower than 60 °C) brought out during ultrasound treatment was beneficial for the color and phenolic compounds retention of CBF juice (Cao et al., 2018; Li et al., 2019). Besides, C3G of bayberry juice treated-ultrasound within 4 min even showed an increasing tendency by 0.71–4.91%, which might be attributed to the extraction of bound anthocyanins from the suspended juice (Cao et al., 2019). Furthermore, another approach used for controlling scent includes boosting bayberry distinctive aroma while minimizing some off-flavor chemicals created by heat sterilization by adding some exogenous polyphenols such as (-)-Epicatechin, (-)-Epicatechin gallate, (-)-Epigallocatechin, (-)-Epigallocatechin gallate, resveratrol, daidzein, grape seed extract, and tea polyphenol. The addition of exogenous polyphenols (10 mg/15 mL juice) could maintain the aroma profile of heat-sterilized bayberry juice closer to fresh bayberry juice and improve the odor preference of heat-sterilized bayberry juice, among which resveratrol and daidzein were most effective (Liu et al., 2023).

Chinese Bayberry Wine

CBF wine is considered one of the important CBF beverages. However, studies on the production of wines from CBFs are limited compared with the production amount of CBF. Based on the scientific study by Du et al. (2016), the optimum fermentation conditions for CBF wine were as follows: initial sugar (22.0 °Brix), pH value (2.9), fermentation temperature (26.5 °C), and inoculum concentration of dry yeast Saccharomyces cerevisiae (0.3%) (Fig. 2). Wine under these conditions had 13.4% of final alcohol, 77 mg/L ACNs, and the residual sugar content was 1 g/L (Du et al., 2016). The authors studied the changes in composition and color parameters of CBF wines during storage for 70 days at 4, 25, and 37 °C in the dark. They observed that the color parameters, ACNs, total phenols, and total flavonoids dropped as polymeric pigments increased at all temperatures, but the 5-Hydroxymethylfurfural and browning index increased only at 37 °C. Wines kept at higher temperatures contained more polymeric pigments (Zhang et al., 2019). Another study investigated the effect of oxalate, citrate, tartrate, malate, and succinate on C3G oxidation mediated by iron in model CBF wine. The results showed that Fe (II) oxidation was found to follow an increasing order in malate < tartrate < citrate < oxalate model wine, while it hardly happened in succinate model wine. In contrast, C3G oxidation mediated by iron followed a decreasing order in tartrate < malate < succinate < oxalate < citrate model wine. Citrate and oxalate model wines contained fewer degradation products than succinate, malate, and tartrate model wines. In oxalate, succinate, malate, and tartrate model wines, C3G degradation mediated by Fe (II) was slower than that mediated by Fe (III), but not in citrate model wine (Zhang et al., 2020a). About forty-six volatile flavor compounds, including nineteen esters, seven alcohols, six acids, two aldehydes, two ketones, three terpenes, and seven other compounds, were identified in bayberry wine by the researchers. The most significant contributors to the aroma of CBF wine were, respectively, esters and alcohols (Cao et al., 2020). Package oxygen is an important agent for the wine quality (color and volatile composition) during storage, where Zhang et al. (2020b) reported that high package oxygen accelerated deterioration of color, degradation of ACN, formation of polymeric pigments, and production of acetaldehyde in CBF wine. The molar ratio of produced protocatechuic acid to degraded ACN after storage increased from 5.08 to 25.18% as package oxygen content increased. Additionally, the total volatile esters and acids concentration increased by up to 19.74% and 41.03%, respectively, as the package oxygen increased (Zhang et al., 2020b). This result may be attributed to a higher monomeric ACN degradation rate or more consumption of monomeric ACN involved in polymerization in wines with higher package oxygen (Zhang et al., 2020b).

Chinese Bayberry Vinegar

Vinegar is a liquid produced by the alcoholic (Saccharomyces cerevisiae), and acetic (Acetobacter aceti) fermentation of any suitable sugar source, such as fruits, malt, molasses, sugarcane juice, etc. (Fig. 2). The vinegar produced from the raw materials of red CBF has many health care functions at the method of surface static fermentation. In CBF vinegar, around nineteen kinds of amino acids were identified, among them eight essential amino acids that represent about 38.79% of all identified amino acids, as well as eight kinds of organic acids such as acetic acid, citric acid, etc. Besides, CBF vinegar is rich in sixteen kinds of trace elements such as Ca, Mg, and Se, as well as the vitamin C content was 9.74 mg/kg. Upon completion of fermentation, the ACN concentration will also be no lower than 4.1 × 10− 5 mol/L in the optimal fermentation condition (Zhu et al., 2009). The data from GC-MS analysis showed that the main aromatic components of red CBF vinegar were alcohols (40.81%), esters (19.10%), and acids (19.39%) (Zhong et al., 2013).

The Importance of Chinese Bayberry By-Products

By-products of CBF are derived from agro-industrial production, which are considered environmental problems. However, these residues have recently attracted the attention of many researchers as sources for recovering and isolating high-polyphenolic products, whereas these bioactive compounds can be utilized as functional ingredients (as food additives) and as natural antioxidant agents to replace their synthetic equivalents that have experienced increasing rejection (Qian et al., 2023; Rashwan et al., 2023a; Zhou et al., 2009).

Chinese Bayberry Pomace

Pomace is the residue that is remaining after converting the fruit to juice, wine, or other products. Many scientific studies reported that fruit pomaces contain a significant quantity of phenolic compounds (Ameer et al., 2017; Wang et al., 2015; Yang et al., 2012; Zhang et al., 2013; Zhu et al., 2020). The pomaces from five cultivars of CBF (Biqi, Dongkui, Dingao, Myrica rubra, Wandao, and Zaodamei) contained a high C3G (3073.3–6219.2 mg/kg dry weight (DW) as the main anthocyanin, while quercetin-3-O-glucoside (296.2–907.9 mg/kg DW) was the main flavonol. The dominant phenolic acids were gallic acid (102.9–241.7 mg/kg DW) and protocatechuic acid (29.5–57.2 mg/kg DW) (Zhou et al., 2009). Moreover, it was found that CBF pomaces contained several compounds such as quercetin, myricetin, p-hydroxybenzoic acid, vanillic acid, caffeic acid, p-coumaric acid, and ferulic acid.

Additionally, the presence of quercetin deoxyhexoside and myricetin deoxyhexoside in bayberry pomaces was tentatively determined (Zhou et al., 2009). Fermentation of red CBF pomace with mixed probiotics (acetic acid bacteria, lactic acid bacteria, and yeast) is feasible. The fermentation process increased the total polyphenol contents (mg/L GAE (gallic acid equivalent) from 1529.92 to 1868.33 mg/L before fermentation to 2076.75–2522.08 after fermentation and the overall flavonoid content (mg Rutin/L) increased from 400.78 to 513.85 to 617.18–814.62, while total ACN content (mg C3G/L) was decreased from 95.19 to 127.06 to 42.42–53.46 (Zhu et al., 2020). These results may be owing to pH change or the functional change of enzymes or microorganisms (yeast or bacteria), inducing the release of phenolics and flavonoids from the plant after the fermentation process (Rashwan et al., 2022). In addition, the antioxidant activity was improved, which may be attributed to the increase in total polyphenols, flavonoids, and polysaccharides (Zhu et al., 2020). Besides, CBF pomace can be utilized to generate fermented beverages using mixed fermentation (Acetic acid bacteria, lactic acid bacteria, and yeast), where mixed fermentation may preserve the beverage’s color and impede anthocyanin oxidation. The enhancement of the beverage’s color can be attributed to the interplay between anthocyanins and acetaldehyde, acetic acid, and lactic acid, which are generated by lactic acid bacteria and acetic acid bacteria. Mixed fermentation encouraged the process of transforming flavonoids into flavonol aglycones even though the action of the enzymes would severely impair the color and exacerbate the degradation of anthocyanins. The phenolic acid type remained the same after combined fermentation and enzyme action, but the amount increased. The results of DPPH-HPLC showed that myricetin was unable to scavenge DPPH free radicals. Consequently, mixed fermentation may enhance the beverage’s quality (Zhu et al., 2022a). Adding polysaccharides of CBF pomace to CBF wine enhanced the antioxidant ability of the wine (scavenge DPPH·, ABTS·+, and ferric reducing antioxidant power). Additionally, it was observed that polysaccharides exhibited an enhanced inhibitory effect on HepG2 cells and contributed to greater antiproliferative rates of CBF wine. The use of polysaccharides in bayberry pomace wine resulted in enhanced quality and improved coloration (Zhu et al., 2022b).

Chinese Bayberry Kernel

Despite the consumption of CBFs as fresh fruits, they also can be processed into juice, wine, and pulp powder, while their seeds (a small stone in which a typical kernel is contained (Fig. 1) are discarded as waste without further utilization. Bayberry kernels represent about 10% or more by weight of the CBFs remaining after CBF-industrial production. Therefore, researchers try to use these seed kernels for producing great economical products such as oil and protein (Fig. 3), where these wasted seed kernels are excellent sources of oils (62–68%) and proteins (25–28%) (Cheng et al., 2008, 2009; Rashwan et al., 2023b; Zhang et al., 2012). The authors reported that the aqueous enzymatic extraction (AEE) was a more efficient method to extract polyunsaturated fatty acid from Myrica rubra kernels than the organic solvent process. The optimal extraction conditions for kernel oil yield were the following: mixed enzyme amount, liquid/solid ratio, time, and temperature: 3.17% (w/w), 4.91 mL/g, 4 h, and 51.6 °C. The experimental yield of extracted oil was 31.15% under optimal conditions (Zhang et al., 2012). In contrast, Myrica rubra kernel oil was extracted utilizing the organic solvent leaching method, with the extraction duration, liquid/solid ratio, and temperature optimized via the response surface methodology. The results demonstrated that the optimal extraction time, liquid/solid ratio, and temperature for kernel oil yield were 140 min, 7.5:1 (v/w), and 48.5 °C, respectively. Under optimum conditions, the yield of oil was 62.52% (w/w). The analysis of fatty acid content in kernel oil using gas chromatography-mass spectrometry showed that oleic acid accounted for 47.90% and linoleic acid accounted for 37.30% of total fatty acids in the Myrica rubra kernels. Furthermore, a small amount of linolenic acid (0.12%), 11-eicosenoic acid (0.29%), and palmitic acid (0.88%) were also found in the extracted oil of Myrica rubra kernels (Li et al., 2016).

Biological Activity of Chinese Bayberry and Its Products

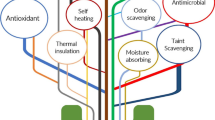

CBFs and their products exert excellent biological activity, including antioxidants, anti-obesity, anti-diabetic, anti-inflammatory, anticancer activity, and so on, as present in Fig. 4.

Antioxidant and Anti-inflammatory Activities

Several studies have confirmed antioxidant activity as a key mechanism for preventing and/or inhibiting many chronic diseases, including diabetes, cancer, and cardiovascular disease. Ferric reducing antioxidant power (FRAP) assay and 2,2-diphenyl-2-picrylhydrazyl (DPPH) radical scavenging capacity showed that the antioxidant capacity of CBFs was directly associated with CBF color and highly correlated with their antioxidant components (Zhang et al., 2008). In which, dark-red CBF (Biqi) demonstrated much stronger radical scavenging activity than ‘Fenhong’, ‘Shuijing’, or ‘Baizhong’. The distinctive red color of bayberry fruit is due to the presence of ACN, especially C3G, which is the main ACN in the fruit (Zhang et al., 2008). The antioxidant activities of red CBF systematically decreased from juice and wine to vinegar, especially in low-concentration testing levels. However, the antioxidant power of the vinegar enhanced with an 88.3% hydroxyl radical scavenging rate and 63% DPPH radical scavenging rate as testing concentration increased, which were comparable to those of fruit juice in 30% testing concentration (Si-yun et al., 2012). Furthermore, the authors studied the antioxidant properties of four common (e.g., Biqi, Dongkui, Fenhong, and Xianju) and four new (e.g., Yingsi, Xishanbai, Heitan, and Ruansi) bayberry cultivars growing in China. They found that IC50 (mg/mL) of Biqi, Dongkui, Fenhong, and Xianju using ABTS (2,2′-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) was 3.39, 6.68, 8.37, and 6.30, respectively, while IC50 (ABTS) of Yingsi, Xishanbai, Heitan, and Ruansi was 3.22, 14.19, 6.27, 4.93, respectively. Besides, according to hydroxyl radical scavenging activity, the most effective radical scavenger was determined to be the aqueous extract of CBF (IC50 28.09 µg/mL), which was followed by the extracts from N-butanol (IC50 169.77 µg/mL), petroleum ether (IC50 69.74 µg/mL), and ethyl acetate (IC50 49.22 µg/mL). Furthermore, the most effective radical scavenger, according to the superoxide anion scavenging activity experiment, was the CBF aqueous extract (IC50 34.59 µg/mL), which was followed by the N-butanol extract (IC50 119.25 µg/mL), petroleum ether extract (IC50 81.53 µg/mL), and ethyl acetate extract (IC50 86.79 µg/mL). Additionally, the FRAP assay revealed that the N-butanol extract (0.34 mg TEAC (Trolox equivalent antioxidant capacity), petroleum ether extract (0.23 mg TEAC), and ethyl acetate extract (0.22 mg TEAC) had the lowest reducing activity, with the aqueous extract of CBF having the highest reducing activity (0.56 mg TEAC) (Chen et al., 2015). Furthermore, the IC50 (DPPH) of the common cultivars ranged from 3.24 to 8.98, and the IC50 (DPPH) of the new cultivars ranged from 2.91 to 14.04. Moreover, FRAP (g vitamin C equivalents (VCE)/kg fresh weight (FW) ranged from 1.18 to 1.60 and 0.65 to 2.39 for common and new bayberry cultivars, respectively (Chen et al., 2016). Moreover, ABTS (IC50) and FRAP assay showed that the antioxidant activity of Anhaizaomei was 2.95 mg/mL and 401.32 mg. VCE/kg FW, respectively, as well as the antioxidant activity of Yingsi was 3.28 mg/mL, and 400.81 mg VCE/kg FW. A further cellular assay revealed that the common cultivar Dongkui (2 mg/mL) had the highest ROS scavenging efficacy (Bao et al., 2018). Peroxyl radical scavenging capacity also showed that wild pink CBF had the highest value of the total antioxidant activity was 451.47 µmol VCE/100 g FW and free cellular antioxidant activity was 184.99 µmol quercetin Equiv./100 g FW (without phosphate-buffered saline (PBS) wash), and 117.78 µmol quercetin Equiv./100 g FW (with PBS wash) (Xia et al., 2021). The measurement of antioxidant activity of fermented CBF pomace showed a higher antioxidant than unfermented CBF pomace. ABTS, FRAP, and DPPH assay revealed that the antioxidant activity of fermented CBF pomace was 13.13 to 15.03 (Mm), 10.33 to 11.52 (Mm), and 94.38 to 95.19%, while 9.61 (Mm), 7.35 (Mm), 91.82% for unfermented CBF pomace, respectively (Zhu et al., 2020). This could be attributable to anabolic and catabolic new phenolic compounds or metabolites (Rashwan et al., 2021, 2022).

The topical anti-inflammatory effect indicated that components of the essential oil isolated from Myrica esculenta could relieve rheumatism and offer the further advantage of suppressing the inflammatory reaction triggered by tissue injury. In which M. esculenta essential oil inhibited 85.3% of inflammation compared with Diclofenac (87.5% inhibition) as a standard drug (Agnihotri et al., 2012). In a randomized, placebo-controlled, double-blind, crossover study using 44 participants (ages 18–25 y), consumption of CBF juice (250 mL) twice daily for 4 weeks significantly reduced the plasma levels of protein carbonyl groups, TNF-α, and IL-8 compared to the placebo. The apoptosis markers analysis uncovered fundamental differences between the CBF juice treatment and the placebo in the levels of tissue polypeptide-specific antigen and cytokeratin-18 fragment M30 (Guo et al., 2014). Furthermore, macrophages exposed to the Dongkui CBFE by the ultrasonic extraction method significantly inhibited LPS-induced production of TNF-α at a concentration of the extract of 0.25 mg/mL (Kuan-Hung et al., 2019).

Antidiabetic and Anti-obesity Activities

Diabetes is known as a chronic, multifactorial disorder characterized by the body failing to produce insulin in the case of type 1 diabetes (T1D) or by defects in insulin action in the case of type 2 diabetes (T2D) (Patra et al., 2022; WHO, 2021). A range of metabolic problems, including obesity, hyperlipidemia, and inflammation, frequently accompanies the first sign of diabetes. According to the World Health Organization (WHO) report, the prevalence of diabetes and its associated problems has significantly increased in the previous few decades, where approximately 422 million people have diabetes worldwide, and 1.5 million deaths are directly attributed to diabetes each year (WHO, 2021). T2D accounts for more than 90% of diabetes in adults (WHO, 2021). Therefore, there are urgent programs needed to prevent and/or control the increasing diabetes incidence and its complications. Epidemiological studies and meta-analyses have described the use of fruits rich in bioactive compounds to control diabetes (Gowd et al., 2020; Rashwan et al., 2020, 2021). For example, β cells pretreatment with C3G-rich CBF extract (containing 0.5 µmol/L C3G) inhibited cell death, raised cellular viability, and dropped mitochondrial reactive oxygen species production as well as cell necrosis induced by 800 or 1200 µmol/L H2O2. C3G-rich CBF extract dose-dependently upregulated pancreatic duodenal homeobox 1 gene expression, resulting in increased insulin-like growth factor II gene transcript levels and insulin protein levels in INS-1 cells. Additionally, treating diabetic mice (streptozotocin-induced diabetic ICR mice) with C3G-rich CBF extract (150 µg of C3G/10 g of body weight twice per day) significantly decreased blood glucose and enhanced glucose tolerance as measured by an oral glucose tolerance test (Sun et al., 2011). CBF extract (CBFE) blocked body weight gain, improved glucose tolerance, and insulin resistance, and lowered serum and liver triacylglycerol (TG) contents in HFD-fed mice. CBFE also inhibited the mRNA expression levels of liver X receptor (LXR) α and its target genes, and increased peroxisome proliferator-activated receptor (PPAR) α and its target genes (Yu et al., 2015). Furthermore, the flavonol extracts from CBF pulp (six cultivars) significantly inhibited α-glucosidase activities (IC50 = 15.4 to 69.5 g/mL) compared with positive control acarbose (IC50 = 383.2 g/mL). Four purified compounds, including C3G, myricetin-3-O-rhamnoside, quercetin-3-O-galactoside, and quercetin-3-O-rhamnoside exerted α-glucosidase inhibitory activities, with IC50 values of 1444.3 g/mL, 418.8 g/mL, 556.4 g/ml, and 491.8 g/mL, respectively (Yan et al., 2016). The activation of the AMPK pathway may play an important role in the antidiabetic effects of CBFE, and CBF may be an effective dietary food for the management of type 2 diabetes and its complications (Shishir et al., 2020; Zhang et al., 2011). Treatment of male diabetic KK-A(y) mice using CBFE (200 mg /kg) for five weeks significantly reduced fasting blood glucose, enhanced glucose tolerance, and insulin sensitivity, as well as decreased liver weight and liver lipid accumulation. Besides, CBFE markedly decreased serum concentrations of glucose, lipids, inflammation, and liver function markers, including insulin, glucagon, leptin, total cholesterol (TC), triglycerides (TG), low-density lipoprotein cholesterol (LDL-c), interleukin-1β, and alanine transferase in KK-A(y) mice (Zhang et al., 2016). Furthermore, it appeared that the hypoglycemic effect of CBFE was partially mediated by inhibiting hepatic gluconeogenesis, which was supported by reducing PPAR γ coactivator 1-α (PGC-1 α) and phosphoenolpyruvate carboxykinase (PEPCK) mRNA expressions in the liver of KK-A(y) mice and by decreasing glucose production, increasing glycolysis as well as reducing gene expression levels of PGC-1 α, PEPCK, and glucose-6-phosphatase (G6Pase) in HepG2 cells. In the liver of KK-A(y) mice, CBFE also down-regulated gene expressions of hepatic lipid metabolism and inflammatory markers (Zhang et al., 2016). In diabetic KK-Ay mice, consumption of Shui Jing fruit extract (SJE) (200 mg/kg body weight) for five weeks significantly decreased fasting blood glucose, elevated glucose tolerance, and insulin sensitivity. Besides, SJE markedly attenuated body weight gain and decreased glycolipid metabolism-related markers, including insulin, leptin, glucagon, TG, TC, LDL-c, and alanine aminotransferase levels in mice. Liver weight and hepatic lipid accumulation also decreased considerably by the SJE. Gene expressions of insulin 1 and glycogen synthase kinase-3 β (GSK-3 β) were significantly inhibited, while the hepatic phosphorylation of AMPKα was markedly raised in the liver of SJE-treated mice, indicating that the SJE may exert an antidiabetic effect through an AMPK-dependent pathway (Liu et al., 2020).

Antimicrobial and Antidiarrheal Activities

The inhibition zone diameter (IZD) values showed that CBF pomace extract had a wide range of antibacterial activities against both gram-positive (G-PB) and gram-negative bacteria (G-NB). However, G-PBs were more sensitive to CBF pomace extract than G-NBs, whereas Micrococcus luteus was the most sensitive to CBF pomace extract treatment (IZD 30.3 mm for ethyl acetate phase of bayberry extract (EA), followed by Staphylococcus aureus (19.69 mm for EA). On the contrary, Serratia marcescens was more sensitive to EA (IZD 30.46 mm) compared to Pseudomonas aeruginosa (15.25 mm) or Escherichia coli (13.21 mm) (Li et al., 2012). The antibacterial activity of CBF pomace extract may be because of the presence of dodecanol, phytol, furfural, and 4 H-pyrane-4-ol compounds in the extract, which work as antimicrobial compounds (Bhatt et al., 2020; Qian et al., 2023). Another study revealed that CBFE had the greatest IZD against nine tested foodborne pathogens, which reached 22.1 mm. Among these nine tested foodborne pathogens, Listeria innocua, Listeria monocytogenes, and Salmonella paratyphi were most sensitive to CBFE, and the lowest minimum inhibitory concentration value was 2.07 mg/mL. The polyphenol content in CBFE was the highest at 24.11 mg/mL; besides, the primary bacteriostatic constituent of CBFE was identified as C3G (Ju et al., 2018). The high sensitivity of G-PBs to CBFE might be owing to their differences in cell membrane constituents and arrangement. In which G-PB contains an outer peptidoglycan layer, which is an ineffective permeable barrier, while the resistance of G-NB towards antibacterial substances may be because of the outer phospholipidic membrane carrying structural lipopolysaccharide components, making it impermeable to lipophilic solutes and porins and constituting a selective barrier to hydrophilic solutes (Ashar et al., 2023b; Li et al., 2012). The activity of CBF wine against diarrhea was assessed using the growth curve approach (E. coli, S. aureus, and B. subtilis) and explored the inhibition mechanism of bacterial growth (Fig. 5). In vitro tests were used to examine the antibacterial properties of functional components that were extracted using ether, water, or ethyl acetate. The mouse model was utilized to analyze the active components’ anti-diarrheal properties. Compared to regular saline or kaoliang spirit, the results illustrated that CBF wine significantly reduced the growth and proliferation of pathogenic bacteria. The CBF wine also demonstrated stronger anti-diarrheal activity, which could suppress the activation of the Nuclear Factor Kappa B (NF-κB) signaling pathway and downregulate the expression of interleukin-8 (IL-8) and tumor necrosis factor-α (TNF-α) (Kaiqun et al., 2019). Moreover, CBFE (total phenolic was the greatest) has a promising inhibitory effect on the growth curve of six foodborne pathogens, and the average IZD reached 19.5 mm. Furthermore, C3G, flavonoid deoxy hexacoside, quercetin-3-O-glucoside, and quercetin deoxidized hexacoside are the main antimicrobial components in CBFE (Ju et al., 2019).

Anticancer and Antiproliferative Activities

In vivo, the study showed that CBFE supplement significantly reduced the 1,2-dimethylhydrazine-consumption induced intestinal aberrant crypt foci development and adenoma or adenocarcinoma formation. The reduced levels of glutathione and activities of superoxide dismutase, catalase, and glutathione reductase were increased in both hepatic and colonic tissues after CBFE treatment. In contrast, CBFE treatment inhibited the activities of glutathione-S-transferase and glutathione peroxidase (Yang et al., 2011). Furthermore, an in vitro study reported that treatment of cells using C3G extracted from CBF decreased cell proliferation, reduced cell adherence, and abnormal morphological changes characteristics of apoptosis, all in dose-dependent manners. Besides, raised concentrations of C3G treatment caused to rise in the inhibition of matrix metalloproteinase 2 (MMP-2) in SGC7901 cells, which may provide important information for the possible mechanism of C3G-induced anti-tumor activity against gastric adenocarcinoma cells (Sun et al., 2012). Myrica esculenta extracts exhibited potent anticancer properties, resulting in a 70–92% decrease in the viability of C33A, SiHa, and HeLa cells without cytotoxicity to normal transformed cell lines (Saini et al., 2013). In addition, CBF extracts significantly decreased the antiproliferative activity of HepG2 cells, and wild pink CBF had the lowest EC50 value (8.50 mg/ml), which was likely associated with cell cycle arrest and apoptosis induction (Xia et al., 2021).

Challenges and Future Perspectives

Many powerful bioactive substances, such as C3G, myricanol, isoquercitrin, myricetin, proanthocyanidins, anthocyanins, and flavonols, are found in the fruit, kernel, and pomace of Chinese bayberries (Saili et al., 2023; Wang et al., 2022). Many of these substances show potential for industrial use and demand more research. However, the short shelf-life of CBF and fast deterioration under non-controlled conditions (3 days at 20–22 °C and 9–12 days at 0–2 °C) represent a big challenge for the development and/or improvement of CBF-based food products, therefore, more advanced research is recommended to find suitable options to extend the fruit shelf-life including using an edible coating (e.g., gelatin, chitosan, whey protein, casein, gam Arabic, guar gum, etc.) soaking in a salt solution, using citric acid or ascorbic acid, and so on (Chettri et al., 2023). Despite also bayberry kernels possessed high protein content (25.0–27.64% DW) and abundant fat content (62.5–68.1% DW) with approximately 84.9–90.1% of the fatty acids being unsaturated oleic acid (43.3–50.7%) and linoleic acid (34.1–46.8%), the kernels contain the antinutritive compounds such as tannin (0.16–0.22 g/100 g) and cyanide (1.14–2.03 mg HCN/kg) (Cheng et al., 2008). These antinutritional factors may contain indigestible components that hinder the capacity of digestive enzymes to access the proteins, or they may contain substances that limit protein digestion or absorption. Since tannin-protein complexes are insoluble and have an adverse influence on protein digestion, tannins’ nutritional effects are primarily linked to their interactions with proteins. Besides, because of the potential release of HCN, Cyanogenic glycosides may cause toxicity (Rashwan et al., 2021). Therefore, the presence of these antinutritional factors in kernels of bayberry can show a negative effect on the extraction of oil and protein, thereby reducing the ability to use them in the food industry. Hence, several processing technologies can be applied as pretreatment before using the bayberry kernel for food purposes such as soaking (water, acids, alkaline, etc.), germination, fermentation, cooking (heat treatment), and others, causing the degradation of the Cyanogenic glycosides and tannins, thus, decreasing the toxicity in kernels (Abdelhalim et al., 2019; Sorour et al., 2017). However, bayberry tannin can be positively used in food applications. As is well known, tannins have a strong antimicrobial activity, hence, the possibility of using bayberry tannin as a cross-linker and functional additive to develop biomaterials-based films (edible coating) can be studied as done by Liao et al. (2022). Additionally, based on its fatty acid profile, bayberry kernel oil may have potential as a healthy edible oil source. Nine types of fatty acids have been previously reported in bayberry kernel oil, which is approximately 85% unsaturated fatty acids. Consuming unsaturated fatty acids in the human diet has the potential to lower the risk of cardiovascular diseases (Xia et al., 2013). Therefore, more future works are recommended to study the oxidative stability and toxicological safety of bayberry kernel oil in different food products. Furthermore, the kernel protein was rich in methionine, arginine, aspartic, and glutamic acids while the limiting amino acid was lysine, which indicates that bayberry kernel has the potential to be exploited as a new protein source, especially in China (Cheng et al., 2009). In summary, in-depth biological studies, including clinical-based research, are recommended for CBF products. Apart from this, processing technologies could produce toxic components during CBF-products development; thus, the toxicity and safety aspects of CBF-based products are also required before commercialization. Based on the above discussions, CBFs and their products are useful as functional food for human health.

Conclusion

Bayberry or Chinese bayberry fruit (CBF) belongs to the Myricaceae class and Myrica genus, which widely grows in eastern Asia, mainly in China. CBFs are an abundant source of functional phytochemicals, especially anthocyanins like cyanidin-3-O-glucoside. However, soft, highly perishable, water loss, susceptibility to Mechanical damage, physiological degeneration, and microbiological decay of CBFs make it easily damaged and cannot be stored for more than 3 days at 20–22 °C and 9–12 days at 0– 2 °C. Therefore, this review highlighted the nutritional importance and potential ways for the long-term preservation of CBFs. Our review also addressed the health advantages of CBFs and their food products. Many processing technologies can be applied to extend the consumption time of CBF, such as quickly freezing, drying (powder), juicing, producing wine and vinegar, using as food additives, and others. Besides, the bioactive compounds can be recovered from CBF by-products, e.g., pomace, CBF kernel can be utilized for producing oil. Based on our investigation, CBF powder and juice were a better option to prolong CBF consumption time. Additionally, CBFs and their products exert excellent biological activity, including antioxidants, anti-obesity, antidiabetic, anti-inflammatory, anticancer activity, and so on. Among all biological activities, CBF and its products showed the strongest antioxidants and antidiabetic activity.

Data Availability

Not applicable.

References

Abdelhalim, T. S., Kamal, N. M., & Hassan, A. B. (2019). Nutritional potential of wild sorghum: Grain quality of Sudanese wild sorghum genotypes (Sorghum bicolor L. Moench). Food Science & Nutrition, 7(4), 1529–1539. https://doi.org/10.1002/fsn3.1002

Agnihotri, S., Wakode, S., & Ali, M. (2012). Essential oil of Myrica Esculenta Buch. Ham.: Composition, antimicrobial and topical anti-inflammatory activities. Natural Product Research, 26(23), 2266–2269. https://doi.org/10.1080/14786419.2011.652959

Ameer, K., Shahbaz, H. M., & Kwon, J. H. (2017). Green extraction methods for polyphenols from Plant matrices and their byproducts: A review. Comprehensive Reviews in Food Science and Food Safety, 16(2), 295–315. https://doi.org/10.1111/1541-4337.12253

Ashar, A., Qayyum, A., Bhatti, I. A., Aziz, H., Bhutta, Z. A., Abdel-Maksoud, M. A., Saleem, M. H., & Eletmany, M. R. (2023a). Photo-Induced Super-hydrophilicity of Nano-Calcite @ Polyester Fabric: Enhanced solar photocatalytic activity against Imidacloprid. ACS Omega, 8(39), 35722–35737. https://doi.org/10.1021/acsomega.3c02987

Ashar, A., Bhutta, Z. A., Shoaib, M., Alharbi, N. K., Fakhar-e-Alam, M., Atif, M., Kulyar, M. F. A., Mahfooz, A., Boruah, P., Eletmany, M. R., Al-Saeed, F. A., & Ahmed, E. A. (2023b). Cotton fabric loaded with ZnO nanoflowers as a photocatalytic reactor with promising antibacterial activity against pathogenic E. Coli. Arabian Journal of Chemistry, 16(9), 105084. https://doi.org/10.1016/j.arabjc.2023.105084

Bao, T., Li, Y., Xie, J., Sun, C., Li, X., Pu, Y., & Chen, W. (2018). Systematic evaluation of bioactive components and antioxidant capacity of some new and common bayberry cultivars using an in vitro gastrointestinal digestion method. Food Research International, 103, 326–334. https://doi.org/10.1016/j.foodres.2017.10.062

Bhatt, I. D., Rawat, S., & Rawal, R. S. (2020). Chapter 28 - Himalayan bayberries. In A. K. Jaiswal (Ed.), Nutritional Composition and Antioxidant Properties of Fruits and Vegetables (pp. 457–465). Academic Press, p 457–465. https://doi.org/10.1016/B978-0-12-812780-3.00028-3

Cao, X., Cai, C., Wang, Y., & Zheng, X. (2018). The inactivation kinetics of polyphenol oxidase and peroxidase in bayberry juice during thermal and ultrasound treatments. Innovative Food Science & Emerging Technologies, 45, 169–178. https://doi.org/10.1016/j.ifset.2017.09.018

Cao, X., Cai, C., Wang, Y., & Zheng, X. (2019). Effects of Ultrasound Processing on Physicochemical Parameters, Antioxidants, and Color Quality of Bayberry Juice. Journal of Food Quality, 2019, 7917419. https://doi.org/10.1155/2019/7917419

Cao, Y., Wu, Z., & Weng, P. (2020). Comparison of bayberry fermented wine aroma from different cultivars by GC-MS combined with electronic nose analysis. Food Science & Nutrition, 8(2), 830–840. https://doi.org/10.1002/fsn3.1343

Chen, W., Zhou, S., & Zheng, X. (2015). A new function of Chinese bayberry extract: Protection against oxidative DNA damage. LWT - Food Science and Technology, 60(2, Part 2), 1200–1205. https://doi.org/10.1016/j.lwt.2014.09.011

Chen, W., Zhao, J., Bao, T., Xie, J., Liang, W., & Gowd, V. (2016). Comparative study on phenolics and antioxidant property of some new and common bayberry cultivars in China. Journal of Functional Foods, 27, 472–482. https://doi.org/10.1016/j.jff.2016.10.002

Chen, H., Chen, Y., Ye, X., Liu, D., & Chen, J. (2019). Turbidity, antioxidant compounds, color, and dynamics of clarification of bayberry juice using various polysaccharide-based clarifying agents. Journal of Food Processing and Preservation, 43(7), e13980. https://doi.org/10.1111/jfpp.13980

Chen, Y., Liu, F., Chen, J., Chen, J., Chen, S., Wu, D., Ye, X., & Cheng, H. (2022). Effects of fermentation conditions on physicochemical properties and flavor quality of fermented bayberry juice. Food Quality and Safety, 6, fyac023. https://doi.org/10.1093/fqsafe/fyac023

Cheng, J., Ye, X., Chen, J., Liu, D., & Zhou, S. (2008). Nutritional composition of underutilized bayberry (Myrica rubra Sieb. Et zucc.) Kernels. Food Chemistry, 107(4), 1674–1680. https://doi.org/10.1016/j.foodchem.2007.09.042

Cheng, J., Zhou, S., Wu, D., Chen, J., Liu, D., & Ye, X. (2009). Bayberry (Myrica rubra Sieb. Et zucc.) Kernel: A new protein source. Food Chemistry, 112(2), 469–473. https://doi.org/10.1016/j.foodchem.2008.05.106

Cheng, H., Chen, J., Chen, S., Wu, D., Liu, D., & Ye, X. (2015a). Characterization of aroma-active volatiles in three Chinese bayberry (Myrica rubra) cultivars using GC–MS–olfactometry and an electronic nose combined with principal component analysis. Food Research International, 72, 8–15. https://doi.org/10.1016/j.foodres.2015.03.006

Cheng, H., Chen, J., Li, X., Pan, J., Xue, S. J., Liu, D., & Ye, X. (2015b). Differentiation of the volatile profiles of Chinese bayberry cultivars during storage by HS-SPME–GC/MS combined with principal component analysis. Postharvest Biology and Technology, 100, 59–72. https://doi.org/10.1016/j.postharvbio.2014.09.003

Cheng, A. W., Xie, H. X., Qi, Y., Liu, C., Guo, X., Sun, J. Y., & Liu, L. N. (2017). Effects of storage time and temperature on polyphenolic content and qualitative characteristics of freeze-dried and spray-dried bayberry powder. LWT - Food Science and Technology, 78, 235–240. https://doi.org/10.1016/j.lwt.2016.12.027

Cheng, H., Chen, Y., Chen, Y., Qin, D., Ye, X., & Chen, J. (2021). Comparison and evaluation of aroma-active compounds for different squeezed Chinese bayberry (Myrica rubra) juices. Journal of Food Processing and Preservation, 45(11), e15924. https://doi.org/10.1111/jfpp.15924

Chettri, S., Sharma, N., & Mohite, A. M. (2023). Edible coatings and films for shelf-life extension of fruit and vegetables. Biomaterials Advances, 154, 213632. https://doi.org/10.1016/j.bioadv.2023.213632

Dai, K., Han, P., Zou, X., Jiang, S., Xu, F., Wang, H., Wei, Y., & Shao, X. (2021). Hot air treatment reduces postharvest decay in Chinese bayberries during storage by affecting fungal community composition. Food Research International, 140, 110021. https://doi.org/10.1016/j.foodres.2020.110021

Du, J., Han, F., Yu, P., Li, J., & Fan, L. (2016). Optimization of fermentation conditions for Chinese bayberry wine by response surface methodology and its qualities. Journal of the Institute of Brewing, 122(4), 763–771. https://doi.org/10.1002/jib.384

Fang, Z., & Bhandari, B. (2011). Effect of spray drying and storage on the stability of bayberry polyphenols. Food Chemistry, 129(3), 1139–1147. https://doi.org/10.1016/j.foodchem.2011.05.093

Fang, Z., & Bhandari, B. (2012). Comparing the efficiency of protein and maltodextrin on spray drying of bayberry juice. Food Research International, 48(2), 478–483. https://doi.org/10.1016/j.foodres.2012.05.025

Fang, Z., Zhang, M., Sun, Y., & Sun, J. (2006). How To Improve Bayberry (Myrica rubra Sieb. et Zucc.) Juice Color Quality: Effect of Juice Processing on Bayberry Anthocyanins and Polyphenolics. Journal of Agricultural and Food Chemistry, 54(1), 99–106. https://doi.org/10.1021/jf051943o

Fang, Z., Zhang, Y., Lü, Y., Ma, G., Chen, J., Liu, D., & Ye, X. (2009). Phenolic compounds and antioxidant capacities of bayberry juices. Food Chemistry, 113(4), 884–888. https://doi.org/10.1016/j.foodchem.2008.07.102

Gowd, V., Xie, L., Sun, C., & Chen, W. (2020). Phenolic profile of bayberry followed by simulated gastrointestinal digestion and gut microbiota fermentation and its antioxidant potential in HepG2 cells. Journal of Functional Foods, 70, 103987. https://doi.org/10.1016/j.jff.2020.103987

Guo, H., Zhong, R., Liu, Y., Jiang, X., Tang, X., Li, Z., Xia, M., & Ling, W. (2014). Effects of bayberry juice on inflammatory and apoptotic markers in young adults with features of non-alcoholic fatty liver disease. Nutrition (Burbank, Los Angeles County, Calif.), 30(2), 198–203. https://doi.org/10.1016/j.nut.2013.07.023

Ju, J., Yao, W., Sun, S., Guo, Y., Cheng, Y., Qian, H., & Xie, Y. (2018). Assessment of the antibacterial activity and the main bacteriostatic components from bayberry fruit extract. International Journal of Food Properties, 21(1), 1043–1051. https://doi.org/10.1080/10942912.2018.1479861

Ju, J., Xie, Y., Guo, Y., Cheng, Y., Qian, H., & Yao, W. (2019). Antibacterial activities of bayberry extract on foodborne pathogens and identification of its active components. Food and Agricultural Immunology, 30(1), 385–397. https://doi.org/10.1080/09540105.2019.1589427

Kaiqun, D., Lili, Q., Jinbo, W., & Yusheng, S. (2019). The anti-diarrheal effect and mechanism of Chinese bayberry wine on Diarrhea of mice. Journal of Nuclear Agricultural Sciences, 33(5), 911–916. https://doi.org/10.11869/j.issn.100-8551.2019.05.0911

Kuan-Hung, L. I. N., Chun-Ping, L. U., Jia-Wei, C., & Yi-Ping, Y. U. (2019). Antioxidant properties and anti-inflammatory effects of the hydroethanolic extracts of two varieties of Bayberry fruit (Myrica rubra Sieb et zucc.) Prepared by stirring and Ultrasonic methods. Notulae Botanicae Horti Agrobotanici Cluj-Napoca, 47(3). https://doi.org/10.15835/nbha47311420

Li, J., Han, Q., Chen, W., & Ye, L. (2012). Antimicrobial activity of Chinese bayberry extract for the preservation of surimi. Journal of the Science of Food and Agriculture, 92(11), 2358–2365. https://doi.org/10.1002/jsfa.5641

Li, K., Huang, Y. F., Ma, J. K., Li, L. M., & Li, Z. J. (2016). Extraction and characterization of oil from Mudong bayberry (Myrica rubra) kernels. Emirates Journal of Food Agriculture, 28(10), 689–694. https://doi.org/10.9755/ejfa.2016-05-508

Li, L., He, X., Li, C., Sun, J., Ling, D., Sheng, J., Rao, C., Xiao, Z., Li, J., & Zheng, F. (2017). Effects of different drying methods on quality and antioxidant activity of dried bayberries. Food Research and Development, 38(23), 1–5. http://www.tjfrad.com.cn/html/2017/23/201723001.htm

Li, Y., Zhang, L., Chen, F., Lai, S., & Yang, H. (2018). Effects of Vacuum Impregnation with Calcium Ascorbate and Disodium Stannous Citrate on Chinese Red Bayberry. Food and Bioprocess Technology, 11(7), 1300–1316. https://doi.org/10.1007/s11947-018-2092-7

Li, J., Cheng, H., Liao, X., Liu, D., Xiang, Q., Wang, J., Chen, S., Ye, X., & Ding, T. (2019). Inactivation of Bacillus subtilis and quality assurance in Chinese bayberry (Myrica rubra) juice with ultrasound and mild heat. LWT - Food Science and Technology, 108, 113–119. https://doi.org/10.1016/j.lwt.2019.03.061

Liao, J., Deng, S., Essawy, H., Bao, X., Wang, H., Du, G., & Zhou, X. (2022). Investigation of potential use of soybean protein isolate–Chinese Bayberry Tannin Extract cross-linked films in Packaging Applications. Materials, 15(15), 5260.

Liu, Y., Chen, F., & Guo, H. (2017). Optimization of bayberry juice spray drying process using response surface methodology. Food Science and Biotechnology, 26(5), 1235–1244. https://doi.org/10.1007/s10068-017-0169-0

Liu, Y., Zhang, X., Zhan, L., Xu, C., Sun, L., Jiang, H., Sun, C., & Li, X. (2020). LC-Q-TOF-MS characterization of polyphenols from White Bayberry Fruit and its antidiabetic effect in KK-Ay mice. ACS Omega, 5(28), 17839–17849. https://doi.org/10.1021/acsomega.0c02759

Liu, Z., Zhang, J., Lu, S., Tang, W., Zhou, Y., & Quek, S. Y. (2022). Effects of different drying methods on phenolic components and in vitro hypoglycemic activities of pulp extracts from two Chinese bayberry (Myrica rubra Sieb. Et zucc.) Cultivars. Food Science and Human Wellness, 11(2), 366–373. https://doi.org/10.1016/j.fshw.2021.11.014

Liu, F., Chen, Y., Chen, J., Xu, E., Pan, H., Chen, S., Ye, X., & Cheng, H. (2023). Characteristic aroma improvement mechanisms of heat-sterilized bayberry juice regulated by exogenous polyphenols. Food Chemistry, 427, 136644. https://doi.org/10.1016/j.foodchem.2023.136644

Patra, S., Makal, P., Jaryal, S., Nilesh, M., & Kaki, V. R. (2022). Anthocyanins: Plant-based flavonoid pigments with diverse biological activities. International Journal of Plant Based Pharmaceuticals, 2(1), 118–127. https://dergipark.org.tr/en/pub/ijpbp/issue/64303/1049824

Perkins, M. L., Yuan, Y., & Joyce, D. C. (2017). Ultrasonic fog application of organic acids delays postharvest decay in red bayberry. Postharvest Biology and Technology, 133, 41–47. https://doi.org/10.1016/j.postharvbio.2017.06.009

Pojer, E., Mattivi, F., Johnson, D., & Stockley, C. S. (2013). The case for anthocyanin consumption to Promote Human Health: A review. Comprehensive Reviews in Food Science and Food Safety, 12(5), 483–508. https://doi.org/10.1111/1541-4337.12024

Qian, M., Ismail, B. B., He, Q., Zhang, X., Yang, Z., Ding, T., Ye, X., Liu, D., & Guo, M. (2023). Inhibitory mechanisms of promising antimicrobials from plant byproducts: A review. Comprehensive Reviews in Food Science and Food Safety, 22(4), 2523–2590. https://doi.org/10.1111/1541-4337.13152

Rashwan, A. K., Karim, N., Shishir, M. R. I., Bao, T., Lu, Y., & Chen, W. (2020). Jujube fruit: A potential nutritious fruit for the development of functional food products. Journal of Functional Foods, 75, 104205. https://doi.org/10.1016/j.jff.2020.104205

Rashwan, A. K., Yones, H. A., Karim, N., Taha, E. M., & Chen, W. (2021). Potential processing technologies for developing sorghum-based food products: An update and comprehensive review. Trends in Food Science & Technology, 110, 168–182. https://doi.org/10.1016/j.tifs.2021.01.087

Rashwan, A. K., Karim, N., Xu, Y., Cui, H., Fang, J., Cheng, K., Mo, J., & Chen, W. (2022). Chemical composition, quality attributes and antioxidant activity of stirred-type yogurt enriched with Melastoma Dodecandrum Lour fruit powder [10.1039/D1FO03448K]. Food & Function, 13, 1579–1592. https://doi.org/10.1039/D1FO03448K

Rashwan, A. K., Bai, H., Osman, A. I., Eltohamy, K. M., Chen, Z., Younis, H. A., Al-Fatesh, A., Rooney, D. W., & Yap, P. S. (2023a). Recycling food and agriculture by-products to mitigate climate change: A review. Environmental Chemistry Letters, 21(6), 3351–3375. https://doi.org/10.1007/s10311-023-01639-6

Rashwan, A. K., Osman, A. I., Abdelshafy, A. M., Mo, J., & Chen, W. (2023b). Plant-based proteins: Advanced extraction technologies, interactions, physicochemical and functional properties, food and related applications, and health benefits. Critical Reviews in Food Science and Nutrition, 1–28. https://doi.org/10.1080/10408398.2023.2279696

Rashwan, A. K., Osman, A. I., Karim, N., Mo, J., & Chen, W. (2023c). Unveiling the mechanisms of the Development of blueberries-based Functional foods: An updated and Comprehensive Review. Food Reviews International, 1–28. https://doi.org/10.1080/87559129.2023.2245025

Saeed, M., Zhao, H., Chen, Z., Ju, P., Wang, G., Zhou, C., Jia, H., Zhu, C., Jia, H., Jiao, Y., Gao, Z., & Zhao, L. (2024). Wax bayberry is a suitable rootstock for Chinese red bayberry cultivated in saline-alkali soil. Scientia Horticulturae, 323, 112463. https://doi.org/10.1016/j.scienta.2023.112463

Saili, Z., Xiangjun, F., Weijie, W., Yuan, G., Hangjun, C., Hailong, Y., & Haiyan, G. (2023). Effects of different drying methods on antioxidant ability and flavor of bayberry pomace powder. Acta Agriculturae Zhejiangensis, 35(6), 1440. https://doi.org/10.3969/j.issn.1004-1524.2023.06.21

Saini, R., Garg, V., & Dangwal, K. (2013). Effect of extraction solvents on polyphenolic composition and antioxidant, antiproliferative activities of Himalyan bayberry (Myrica esculenta). Food Science and Biotechnology, 22(4), 887–894. https://doi.org/10.1007/s10068-013-0160-3

Shishir, M. R. I., Karim, N., Xie, J. H., Rashwan, A. K., & Chen, W. (2020). Colonic delivery of pelargonidin-3-Oglucoside using pectin-chitosan-nanoliposome: Transport mechanism and bioactivity retention. International Journal of Biological Macromolecules, 159, 341–355. https://doi.org/10.1016/j.ijbiomac.2020.05.076

Si-yun, X., Rui-min, Z., Zi-jun, X., & Ze-yuan, D. (2012). Preliminary investigation of in vitro antioxidant activities for red bayberry fruit vinegar. Food Machinery, 28(6), 125–128. https://doi.org/10.3969/j.issn.1003-5788.2012.06.031

Sorour, M. A., Mehanni, A. E., Taha, E. M., & Rashwan, A. K. (2017). Changes of total phenolics, tannins, phytate and antioxidant activity of two sorghum cultivars as affected by processing. Journal of Food and Dairy Sciences, 8(7), 267–274. https://doi.org/10.21608/jfds.2017.38699

Sun, C. D., Zhang, B., Zhang, J. K., Xu, C. J., Wu, Y. L., Li, X., & Chen, K. S. (2011). Cyanidin-3-Glucoside-Rich Extract from Chinese Bayberry Fruit protects pancreatic β cells and ameliorates hyperglycemia in Streptozotocin-Induced Diabetic mice. Journal of Medicinal Food, 15(3), 288–298. https://doi.org/10.1089/jmf.2011.1806

Sun, C., Zheng, Y., Chen, Q., Tang, X., Jiang, M., Zhang, J., Li, X., & Chen, K. (2012). Purification and anti-tumour activity of cyanidin-3-O-glucoside from Chinese bayberry fruit. Food Chemistry, 131(4), 1287–1294. https://doi.org/10.1016/j.foodchem.2011.09.121

Sun, C., Huang, H., Xu, C., Li, X., & Chen, K. (2013). Biological activities of extracts from Chinese bayberry (Myrica rubra Sieb. Et zucc.): A review. Plant Foods for Human Nutrition, 68(2), 97–106. https://doi.org/10.1007/s11130-013-0349-x

Tian, J., Cao, Y., Chen, S., Fang, Z., Chen, J., Liu, D., & Ye, X. (2019). Juices processing characteristics of Chinese bayberry from different cultivars. Food Science & Nutrition, 7(2), 404–411. https://doi.org/10.1002/fsn3.778

Vardar, C., Ilhan, K., & Karabulut, O. A. (2012). The application of various disinfectants by fogging for decreasing postharvest diseases of strawberry. Postharvest Biology and Technology, 66, 30–34. https://doi.org/10.1016/j.postharvbio.2011.11.008

Wang, L., Cheng, F-R., Li, Y-X., Huang, Y-S., & Yuan, K. (2015). Studies of the extraction-purification and the content analysis on the anthocyanin in the Myrica rubra Pomace. International Conference on Medicine and Biopharmaceutical China. https://doi.org/10.1142/9789814719810_0143

Wang, Y., Chen, J., Wang, Y., Zheng, F., Qu, M., Huang, Z., Yan, J., Bao, F., Li, X., Sun, C., & Zheng, Y. (2022). Cyanidin-3-O-glucoside extracted from the Chinese bayberry (Myrica rubra Sieb. Et zucc.) Alleviates antibiotic-associated diarrhea by regulating gut microbiota and down-regulating inflammatory factors in NF-κB pathway [Original Research]. Frontiers in Nutrition, 9, 970530. https://doi.org/10.3389/fnut.2022.970530

Wang, Y., Zheng, Y., Shang, J., Wu, D., Zhou, A., Cai, M., Gao, H., & Yang, K. (2023). Pulsed light reduces postharvest losses of Chinese bayberries by affecting fungal microbiota during cold storage. Food Control, 146, 109524. https://doi.org/10.1016/j.foodcont.2022.109524

Wei, L., Haiyan, G., Hangjun, C., & Weijie, W. (2017). Effect of drying methods on quality characteristics of bayberry powder [Journal Article]. Food Science China, 38(13), 77–82. https://doi.org/10.7506/spkx1002-6630-201713013

WHO. (2021). Diabetes. World Health Organization. https://www.who.int/health-topics/diabetes#tab=tab_1. Accessed 16 July 2023.

Wu, D., Cheng, H., Chen, J., Ye, X., & Liu, Y. (2019). Characteristics changes of Chinese bayberry (Myrica rubra) during different growth stages. Journal of Food Science and Technology, 56(2), 654–662. https://doi.org/10.1007/s13197-018-3520-4

Xia, Q., Pan, S., Zheng, M., Chen, J., Fang, Z., Johnson, S., Yang, Y., Xing, J., & Lu, S. (2013). Fatty acid profile, oxidative stability and toxicological safety of bayberry kernel oil. Food and Chemical Toxicology, 60, 92–97. https://doi.org/10.1016/j.fct.2013.06.054

Xia, W., Gong, E., Lin, Y., Li, T., Lian, F., Zheng, B., & Liu, R. H. (2021). Comparison of phytochemical profiles, antioxidant and antiproliferative activities in Chinese bayberry (Myrica rubra Sieb. JOURNAL OF FOOD SCIENCE, 86(10), 4691–4703. https://doi.org/10.1111/1750-3841.15899. et Zucc.) fruits [https://doi.org/10.1111/1750-3841.15899].

Xia, S., Wei, Z., Kong, X., Jia, B., & Han, S. (2022). Antioxidative properties of bayberry tannins with different mean degrees of polymerization: Controlled degradation based on hydroxyl radicals. Food Research International, 162, 112078. https://doi.org/10.1016/j.foodres.2022.112078

Xin, Y., Zhang, M., Xu, B., Adhikari, B., & Sun, J. (2015). Research trends in selected blanching pretreatments and quick freezing technologies as applied in fruits and vegetables: A review. International Journal of Refrigeration, 57, 11–25. https://doi.org/10.1016/j.ijrefrig.2015.04.015

Xu, Y. X., Zhang, M., Fang, Z. X., Sun, J. C., & Wang, Y. Q. (2014). How to improve bayberry (Myrica rubra Sieb. Et zucc.) Juice flavour quality: Effect of juice processing and storage on volatile compounds. Food Chemistry, 151, 40–46. https://doi.org/10.1016/j.foodchem.2013.10.118

Yan, S. X., Zhang, X. A., Wen, X., Lv, Q., Xu, C. J., Sun, C. D., & Li, X. (2016). Purification of flavonoids from Chinese bayberry (Morella rubra Sieb. Et zucc.) Fruit extracts and α-glucosidase inhibitory activities of different fractionations. MOLECULES, 21(9), 1148. https://doi.org/10.3390/molecules21091148

Yang, Z., Zheng, Y., & Cao, S. (2009). Effect of high Oxygen Atmosphere Storage on Quality, antioxidant enzymes, and DPPH-Radical scavenging activity of Chinese Bayberry Fruit. Journal of Agricultural and Food Chemistry, 57(1), 176–181. https://doi.org/10.1021/jf803007j

Yang, Z., Cao, S., & Zheng, Y. (2011). Chinese bayberry fruit extract alleviates oxidative stress and prevents 1,2-dimethylhydrazine-induced aberrant crypt foci development in rat colon carcinogenesis. Food Chemistry, 125(2), 701–705. https://doi.org/10.1016/j.foodchem.2010.09.070

Yang, J., Zhou, L., Han, X., & Chen, Q. (2012). Research on Ultrasound-assisted extraction of Water Soluble Dietary Fiber from Bayberry Pomace. Hans Journal of Chemical Engineering and Technology, 2, 23–28. https://doi.org/10.4236/hjcet.2012.22005

Yao, W. R., Wang, H. Y., Wang, S. T., Sun, S. L., Zhou, J., & Luan, Y. Y. (2011). Assessment of the antibacterial activity and the Antidiarrheal function of flavonoids from Bayberry Fruit. Journal of Agricultural and Food Chemistry, 59(10), 5312–5317. https://doi.org/10.1021/jf200211m

Yu, Y., Lin, Y., Zhan, Y., He, J., & Zhu, S. (2013). Effect of high pressure processing on the stability of anthocyanin, ascorbic acid and color of Chinese bayberry juice during storage. Journal of Food Engineering, 119(3), 701–706. https://doi.org/10.1016/j.jfoodeng.2013.06.036

Yu, L., Cai, W., Zhang, Y., Feng, L., & Huang, C. (2015). Red bayberry extract prevents high-fat diet-induced metabolic disorders in C57BL/6 mice. Journal of Functional Foods, 14, 278–288. https://doi.org/10.1016/j.jff.2015.02.003

Yu, H., Zhang, Y., Zhao, J., & Tian, H. (2018). Taste characteristics of Chinese bayberry juice characterized by sensory evaluation, chromatography analysis, and an electronic tongue. Journal of Food Science and Technology, 55(5), 1624–1631. https://doi.org/10.1007/s13197-018-3059-4

Zhang, W., Li, X., Zheng, J., Wang, G., Sun, C., Ferguson, I. B., & Chen, K. (2008). Bioactive components and antioxidant capacity of Chinese bayberry (Myrica rubra Sieb. And Zucc.) Fruit in relation to fruit maturity and postharvest storage. European Food Research and Technology, 227(4), 1091–1097. https://doi.org/10.1007/s00217-008-0824-z

Zhang, B., Kang, M., Xie, Q., Xu, B., Sun, C., Chen, K., & Wu, Y. (2011). Anthocyanins from Chinese Bayberry Extract protect β cells from oxidative stress-mediated Injury via HO-1 Upregulation. Journal of Agricultural and Food Chemistry, 59(2), 537–545. https://doi.org/10.1021/jf1035405

Zhang, Y., Li, S., Yin, C., Jiang, D., Yan, F., & Xu, T. (2012). Response surface optimisation of aqueous enzymatic oil extraction from bayberry (Myrica rubra) kernels. Food Chemistry, 135(1), 304–308. https://doi.org/10.1016/j.foodchem.2012.04.111

Zhang, Y., Kong, L., Yin, C., Jiang, D., Jiang, J., He, J., & Xiao, W. (2013). Extraction optimization by response surface methodology, purification and principal antioxidant metabolites of red pigments extracted from bayberry (Myrica rubra) pomace. LWT - Food Science and Technology, 51(1), 343–347. https://doi.org/10.1016/j.lwt.2012.09.029

Zhang, X., Huang, H., Zhang, Q., Fan, F., Xu, C., Sun, C., Li, X., & Chen, K. (2015). Phytochemical characterization of Chinese Bayberry (Myrica rubra Sieb. Et zucc.) Of 17 cultivars and their antioxidant Properties. International Journal of Molecular Sciences, 16(6), 12467–12481. https://doi.org/10.3390/ijms160612467