Abstract

Applying value-adding techniques to fish filleting co-products is rendered difficult due to their high susceptibility to lipid oxidation, microbial spoilage, and amine formation. In this study, a recyclable dipping strategy was developed and investigated for its ability to stabilize herring (Clupea harengus) co-products (head, backbone, caudal fin, intestines, belly flap, skin, and in some cases roe) against oxidation and microbial spoilage. From initial screening of seven antioxidative components/formulas in minced herring co-products during ice storage, an oil-soluble rosemary extract (RE-B) and isoascorbic acid (IAA) were identified as most promising candidates. These compounds were then formulated to a recyclable solution to be used for dipping of the herring co-products. The commercial Duralox MANC antioxidant mixture was used as a positive control. Dipping in 0.2% RE-B solution ± 0.5% IAA or in 2% Duralox MANC solutions remarkably increased the oxidation lag phase from < 1 day to > 12 days during subsequent storage on ice (0–1 °C) of minced or intact co-products, respectively, even when the antioxidant solutions were re-used up to 10 times. The dipping also reduced microbiological growth and total volatile basic nitrogen, but the effect became weaker with an increased number of re-using cycles. The presented dipping strategies could hereby facilitate more diversified end use of herring co-products from current fish meal to high-quality minces, protein isolates, or oils for the food industry.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fisheries and aquaculture yearly generate around 156 million ton fish and shellfish which are dedicated food production. About 70% of the fish is processed before final sale, resulting in 20–80% of fish co-products (also called by-products) depending on the level of processing and type of fish (Ghaly et al., 2013). In Northern Europe, herring (Clupea harengus) is an important pelagic fish species, and among the main food application areas are pickled/marinated products which are based on fillets. Hereby, around 60% of the total weight of the herring end up as co-products, such as the head, backbone, caudal fin, skin, and intestines (Sajib et al., 2020). Despite large amounts of residual muscle, the herring co-products are still mainly targeted for feed production in the form of fish meal/fish oil.

The global demand for fish protein is steadily increasing in response to dietary recommendations and population growth. However, wild fisheries cannot expand further based on the endurance of ecosystems and climate change, and the expected aquaculture expansions will not be able to sustain the demand (Alexandratos & Bruinsma, 2012). Therefore, fish co-products are crucial contributions to meet this demand as they are high in protein and also contain important micronutrients such as long chained n-3 polyunsaturated fatty acids (LC n-3 PUFA), vitamin D, selenium, iodine, and vitamin B12 (Abdollahi et al., 2021). Several innovative techniques exist to separate muscle proteins from bone and skin of fish co-products, such as the pH-shift process, classic meat-bone separation, and enzymatic or non-enzymatic hydrolysis (Abdollahi et al., 2018; Nolsøe & Undeland, 2009; Rustad et al., 2011). However, the herring co-products are highly susceptible to lipid oxidation and microbial growth due to their complex nature and abundance of, e.g., PUFA, blood/blood-derived hemoglobin (Hb), and enzymes (Maqsood & Benjakul, 2013; Wu et al., 2020), limiting the possible time frame from co-product generation to subsequent value-adding processes. Effective methods for extending the shelf life of herring co-products are thus needed, thereby allowing for enough holding or transport time prior to processing.

Previous studies have reported a variety of preservation strategies to extend the microbial and chemical shelf life of fish. Dipping, glazing, and spraying of fillets with solutions containing antioxidants and/or antimicrobial agents are examples of such strategies (Cavonius & Undeland, 2017; Fan et al., 2008); another is to mix antioxidants or antimicrobials into a mince (Wu et al., 2020). Among natural antimicrobial preservatives reported on are chitosan from shellfish, extracts from plants containing, e.g., essential oils and organic acids, and lactic acid bacteria and bacteriocins from microbiological sources (Miranda et al., 2018; Vatavali et al., 2013). In combating lipid oxidation of fish muscle, extracts from, e.g., bladder wrack (Fucus vesiculosus) (Jónsdóttir et al., 2016), herbs such as rosemary (Li et al., 2012), and seaweed (Babakhani et al., 2016) have been used with great success. To date, there is however very limited knowledge on antioxidative and antimicrobial strategies suitable for fish co-products, which, according to the complexity outlined above, have different profiles of lipid substrates, pro‐and antioxidants, and bacterial load (e.g., from the digestive system) compared to pure fish muscle (Aspevik et al., 2017).

We recently revealed how short incubation of herring co-products in five volumes of a solution made from the commercial antioxidant Duralox MANC-213 (a mixture of rosemary extract, citric acid, ascorbic acid and tocopherol) prior to subsequent grinding extended the oxidation lag phase of herring co-products from < 1 day to > 12 days at 0–1 °C and from < 0.5 to > 3.5 days at 20 °C (Wu et al., 2021b). It was proven that Duralox MANC could prevent auto-oxidation and hemin loss of herring Hb, which was a likely antioxidative mechanism. In these studies, streptomycin was added to prevent bacteria; thus, the effects of Duralox MANC on bacterial growth were never evaluated. However, based on the fact that polyphenols can have antimicrobial properties (Maqsood et al., 2013) and that extracts from edible medicinal plants such as herbs can inhibit bacterial growth in seafood (Bouarab Chibane et al., 2019), we hypothesized that Duralox MANC, and not least its rosemary extract component, could prolong also the microbial shelf life of herring co-products. To meet the current wishes within the seafood industry for clean label, i.e., a minimum of additives and preferably from natural sources, as well as to keep costs down during value adding of low value materials as fish co-products, we also identified a need to evaluate more simplistic solutions than the Duralox MANC mixture. Investigating how individual components affect lipid oxidation and microbial growth in fish co-products would also help to better understand their mechanisms of action.

The first aim of the present study was to investigate how seven components/formulas (water-soluble rosemary extract (RE-A), oil-soluble rosemary extract (RE-B), isoascorbic acid (IAA), esculetin, α-tocopherol (α-TOC), and two rosemary-containing commercial mixtures, Duralox MANC-213 (MANC) and EVESA-C5 (EVESA)) affect lipid oxidation in minced herring co-products. Second, the most promising candidates, based on both cost and efficiency, were to be included in a dipping solution for herring co-products, which after treatment were stored in minced or intact form to investigate shelf life extension from both oxidation and microbial perspectives. The re-use of the antioxidant solution for repeated dipping treatments would be investigated to affect lipid oxidation and microbial perspectives.

Materials and Methods

Chemicals and Natural Antioxidants

Sodium chloride, isoascorbic acid, esculetin, α-tocopherol, trichloroacetic acid, 2-thiobarbituric acid, and ferrous sulfate were obtained from Sigma Chemical Co. (St. Louis, MO). Duralox MANC-213 was purchased from Kalsec (Kalamazoo, Mich., UK). EVESA-C5 was supplied by Extractos Vegetales SA (La Línea de la Concepción, Cádiz, Spain). Water-soluble and oil-soluble rosemary extracts were kindly provided by Senyuan Bencao (Yuzhou, Henan Province, China). All other chemicals used were American Chemical Society (ACS) grade or better.

Preparation of Herring Co-products

Herring (Clupea harengus) was caught off the west coast of Sweden between October 2019 and April of 2020. Fresh filleting co-products (head, backbone, caudal fin, skin, intestines, and, in some occasions, roe) were provided by Scandic Pelagic Ellös AB, Sweden. The time between filleting of the herring and arrival of the co-products in our lab was 2–6h. During transportation, the co-products were stored in a plastic bag covered by ice.

Addition of Antioxidants to Minced Herring Co-products

Two kilograms of fresh herring co-products was ground using a table top meat grinder (C/E22 N, Minerva Omega group, Italy) equipped with a plate with 4.5 mm holes and thereafter stirred to complete homogeneity. Seven components/formulas were directly added into the minced co-products: water-soluble rosemary extract (RE-A), 0.2%; oil-soluble rosemary extract (RE-B), 0.05%; isoascorbic acid (IAA), 0.5%; esculetin, 0.09%; α-tocopherol, 0.02%; and two rosemary-containing commercial mixtures, Duralox MANC-213, 0.5%, and EVESA-C5, 0.5%. The concentrations of these antioxidants were used according to the cost and our previous studies (Wu et al., 2020, 2021b). The minced co-products were transferred into screw-capped Erlenmeyer flasks where they were flattened out into a thin layer at the bottom and then stored on ice according to the method reported by Wu et al. (2020).

Preparation of Dipping Solutions

All dipping solutions were prepared in tap water containing 0.9% NaCl in order to maximize the stability of red blood cells (Ghirmai et al., 2020). Antioxidants were added to the 0.9% NaCl solution as follows: (1) 0.5% RE-B; (2) 2% IAA; (3) 0.5% IAA; (4) 0.2% RE-B; (5) 0.2% RE-B + 0.5% IAA; and (6) 2% Duralox MANC. All dipping solutions were freshly prepared and stored at 4 °C for at least 5h before use.

Dipping Treatment of Intact Herring Co-products

Fresh herring co-products were immersed in pre-chilled (4 °C) antioxidant-containing solutions for 30s in a 1:2 ratio (weight/volume) and then drained well (~15s) in a fine stainless steel strainer. The dipping solutions were re-used up to 10 times in some experiments as described in Fig. 1. Drained samples were cold stored in minced or intact form. For the storage trial of minces, drained co-products were ground and transferred to screw-capped Erlenmeyer flasks for storage as described in the “Addition of Antioxidants to Minced Herring Co-products” section. Samples were taken using the method as described by Wu et al. (2020). On an industrial scale, it is expected that fish co-products are not minced immediately as there is often a higher capacity of the filleting lines than of potential value adding processes dedicated the co-products. With this background, it was also investigated how pre-dipped herring co-products developed lipid oxidation when stored intact. For this purpose, the dipped co-products were stored in a plastic container (20 cm × 26 cm × 30 cm) covered by a plastic bag and stored at 4 °C. At each sampling point and for each treatment, 3 individual samples of each co-product fraction (head, backbone with caudal fin, intestines, belly flap, skin and in some cases roe) were ground together as described in the “Addition of Antioxidants to Minced Herring Co-products” section and stirred to complete homogeneity. At regular intervals, samples (5.0 g) of this mince were taken for immediate microbiological analysis. Samples for chemical analysis (5.0 g) were wrapped in aluminum foil and stored at −80 °C until analyzed.

Change in Weight of Co-products Subjected to Dipping Treatments

The weight of co-products was carefully recorded before and after the dipping in antioxidant-containing solutions, and the change in weight was calculated using the following equation:

Chemical Analyses

pH

The pH of the minced co-products was measured with an Orion combination epoxy Ross® Sure-Flow™ Electrode (Thermo Orion, Beverly, MA, USA) in conjunction with a pH meter (PHM210 Radiometer Analytical S.A., Villeurbanne Cedex, France). One-part minced co-products were manually stirred with 9 parts distilled water prior to the measurements.

Total Volatile Basic Nitrogen (TVB-N)

TVB-N was analyzed using Conway diffusion cells according to a method described by Sajib and Undeland (2020). Briefly, 2 g of sample was mixed with 8 mL of trichloroacetic acid (TCA) solution and centrifuged. Then, 2 mL of the supernatant was used in the Conway cell for incubation at 37 °C for 60 min, in the presence of boric acid and a potassium carbonate solution. Upon completion, the sample solution was titrated using hydrochloric acid (HCl), and the results were expressed as mg TVB-N per 100 g sample.

Peroxide Value (PV) and Thiobarbituric Acid Reactive Substances (TBARS)

Total lipids were extracted from 1-g samples of minced co-products using chloroform–methanol (2:1) according to the method described by Wu et al. (2021a). The lower phase (chloroform) was collected for PV analysis as described by Larsson et al. (2007). Briefly, 1.33 mL ice-cold chloroform–methanol (1:1) was mixed with 2.0 mL of the chloroform extracts, and hereafter ammonium thiocyanate (8.76 M) and iron(II) chloride (18 mM) (33.4 μL of each) were added with 2−4s vortexing between each addition. The sample was incubated for 20 min at room temperature, and the absorbance was read at 500 nm. Blanks were prepared according to the described procedure by replacing the 1 g of mince by 0.8 mL of ice-cold distilled water. A standard curve was prepared using cumene hydroperoxide and PV were expressed as μmol lipid hydroperoxide/kg of herring mice.

The upper phase (water–methanol) from the lipid extraction was used to determine TBARS according to the method of Schmedes and Hølmer (1989). An aliquot (2.5 mL) of the water–methanol extract was mixed with 2.5 mL TBA reagent (including 5.0% TBA and 0.5% TCA) in a screw capped test tube. All samples were then heated in boiling water for 30 min, and then the tubes were cooled in tap water. The absorbance was measured at 532 nm, and results were expressed as µmol peroxides or µmol TBARS/kg of minced co-product.

Bacteriological Analyses

Total viable counts (TVC) were determined using the method described by Li et al. (2012). Briefly, 5 g of sample was mixed with 45 mL of 0.9% saline in stomacher plastic bag and treated in a Stomacher lab blender for 60s. Then, 1 mL of the solution at the appropriate dilution was transferred to a petri dish and mixed with plate count agar media and incubated for 2 days at 25 °C. Each sample was processed in duplicate and then cultured in duplicate.

Statistics

All statistical analysis was conducted with SPSS software (IBM SPSS Statistics Version 22, IBM Inc., Chicago, USA). The results were reported as mean ± standard deviation (SD) (n ≥ 2). Duncan’s multiple range test was used to compare the means. Variance (ANOVA) was used to analyze the significant differences between treatments and/or storage points. Differences are regarded as significant when p < 0.05.

Results and Discussion

Antioxidant Screening in Minced Herring Co-products

In this sub-study, four rosemary sources (extracts or extracts as part of mixtures) and three individual components that potentially could be used as antioxidants in the fish industry were directly added to minced herring co-products to inhibit lipid oxidation during ice storage. Figure 2A shows that the PV for the control mince, without antioxidants added, were 304.8 ± 30.73 and 646.1 ± 43.1 μmol/kg at days 1 and 2, respectively, which were significantly (p < 0.05) higher than at day 0, 97.4 ± 40.3 μmol/kg. A similar result was observed in the TBARS analyses (Fig. 2B). PV and TBARS results together indicated that the lag phase for lipid oxidation in minced herring co-products was less than 1 day, illustrating that this raw material is highly susceptible to lipid oxidation.

α-Tocopherol (0.02%) delayed the onset TBARS by 1 day, but it then rapidly increased shortly thereafter (Fig. 2B). However, there were no significant differences for PV values between control and α-tocopherol (0.02%) at day 1 and day 2 (Fig. 2A). These results indicated that α-tocopherol did not show a promising ability to inhibit lipid oxidation in herring co-products. Tang et al. (2001) on the other hand reported that α-tocopherol (0.02%) completely inhibited lipid oxidation for 10 days and 3 days in 4 °C-stored minced whiting and mackerel muscle, respectively, illustrating that more powerful protection is needed for co-products as compared to pure fillets due, e.g., to higher heme content (Wu et al., 2020).

Several authors have previously described how lipoxygenases (LOX) are contributing to lipid oxidation in fish tissue, but also that these enzymes are important for the odor of completely fresh fish (Banerjee, 2006; Fu et al., 2009). Wang et al. (2012) found that LOX of grass carp gradually increased in the order skin and muscle < gill < viscera < blood, and these enzymes could therefore be particularly enriched in the co-product fraction. Esculetin (6,7-dihydroxycoumarin), one of the main active compounds in the bark of Cortex fraxini, is a known inhibitor of mammalian and fish LOX and also acts as a radical scavenger (Kemal et al., 1987). Esculetin inhibited the production of 12-hydroxyeicosatetraenoic acid (12-HETE) generated via the reaction between LOX and arachidonic acid in mackerel muscle (Saeed & Howell, 2001). Here we investigated esculetin both to understand whether lipid oxidation in the minced herring co-products was caused by other pro-oxidants than Hb/heme and to evaluate if it could be a potential candidate to inhibit lipid oxidation in this challenging system. The addition of esculetin (0.09%) gave rise to a slight increase in PV from day 0 to day 3 which then rapidly increased shortly thereafter (Fig. 2A). Similarly, the TBARS of esculetin-treated samples was completely inhibited up to day 3 and then rapidly increased (Fig. 2B). These results indicated that inhibition of the LOX activity could decrease the onset of lipid oxidation in herring co-products somewhat, suggesting that LOX is one of the pro-oxidants in this system. However, since esculetin did not completely inhibit lipid oxidation, it appears as if it does not target Hb, something which could be confirmed in future studies comprising simpler model systems.

IAA (0.5%) completely inhibited PV and TBARS up to 10 days and 12 days, respectively, which was different our previous study, where we found IAA (0.2%) together with 0.044% EDTA to only slightly delay lipid oxidation when added into minced herring co-products (Wu et al., 2021b); thus, the higher concentration used here was obviously required. The mechanism by which IAA prevented oxidation could be attributed to the scavenging of free radicals and reduction of hypervalent forms of Hb (metHb or ferrylHb) (Kröger-Ohlsen & Skibsted, 1997).

Four different sources of rosemary-derived compounds were compared to the above three antioxidants. Figure 2A showed that RE-B (0.05%), Duralox MANC (0.5%), and EVESA-C5 (0.5%) completely inhibited PV formation up to day 12. However, the water-soluble RE-A (0.2%) only increased the PV lag phase to 4 days, something which was also confirmed by the TBARS results (Fig. 2B). This reveals that lipophilic compounds in rosemary, such as carnosic acid and carnosol, are more powerful antioxidants in herring co-products than the aqueous rosemary acid. The order of activity for all tested compounds was as follows: RE-B (0.05%) = MANC (0.5%) = EVESA (0.5%) > IAA (0.5%) > RE-A (0.2%) > esculetin (0.09%) > α-TOC (0.02%). Considering their high activity at low levels plus their low cost, we selected RE-B and IAA as candidate compounds when constructing antioxidant solutions for the subsequent dipping trials. Based on the good results with Duralox MANC (2.0%) in our previous dipping study (Wu et al., 2021b), this commercial mixture was also included in our dipping trials as a reference.

Dipping Herring Co-products in Antioxidant-Containing Solutions

Lipid Oxidation

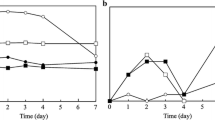

Figure 3A and B show the PV and TBARS during 12-day storage of the minced herring co-products previously dipped in antioxidant-containing solutions. PV and TBARS of the non-dipped control rapidly increased within 1 day of storage on ice, which was in agreement with the data of Fig. 2, and also our previous study (Wu et al., 2020). Dipping in RE-B (0.5%) and IAA (2%) solutions under recycling of the solutions up to four times (both compounds) and ten times (RE-B) strongly inhibited PV and TBARS (Fig. 3A and B). Based on these findings, the RE-B and IAA concentrations in the dipping solution were further reduced to 0.2% and 0.5%, respectively, and combinations of RE-B with IAA were evaluated in two separate trials: one where the co-products were minced after the dipping (Fig. 4A and B) and one when they were stored in intact form (Figs. 5A and 4B). Dipping in IAA (0.5%) completely inhibited PV and TBARS until 6 days of storage, where after values started to increase (Fig. 4A and B). Thus, to reach complete inhibition, higher IAA levels are needed (Fig. 3). The dipping treatments performed with RE-B (0.2%) alone, or its combination with IAA (0.5%), completely inhibited PV and TBARS throughout 12 days in storage, even though the dipping solutions were used up to ten times (Fig. 4A, B). Also, when co-products were dipped in antioxidant solutions which had been recycled ten times, and then stored in intact form (Fig. 5A and B), 0.2% RE-B ± 0.5% IAA completely prevented oxidation for the whole 12-day storage at 4 °C. The main difference achieved when adding IAA to the dipping solution was that the redness of the co-products was better maintained (data not shown), which indicated that Hb was kept in a reduced form. Dipping herring co-products in 0.9% NaCl alone prior to storage in intact form only slightly reduced PV and TBARS levels, but did not delay the oxidation lag phase. This was in line with our previous findings showing that Hb removal from the surface of herring co-products when dipping in water or 0.9% NaCl was only minor (~10%), and it was not enough to significantly delay oxidation, especially as we also expect that endogenous antioxidants are removed from the surface (Wu et al., 2020).

PV (A), TBARS (B), and TVC (C) development during ice storage of a mince made from herring co-products that had been pre-dipped with 0.5% RE-B or 2% IAA. TVC data are only shown at days 0 and 12. The antioxidant solution was re-used up to 10 times, and samples were taken after the 1st, 4th, and 10th dipping cycle. The ratio of herring co-products to solution was 1:2 weight/volume. The dipping time was 30s. RE-B, oil-soluble rosemary extract; IAA, isoascorbic acid

Changes in PV (A), TBARS (B), TVC (C), and TVB-N (D) development during ice storage of a mince made from herring co-products that had been pre-dipped with 0.5% IAA, 0.2% RE-B, or their mixture. TVC and TVB-N data are only shown at days 0 and 12. The antioxidant solution was re-used up to 10 times, and samples were taken after the 1st and 10th dipping cycle. The ratio of herring co-products to solution was 1:2 weight/volume. The dipping time was 30s. Panels E and F show the immediate change in weight and pH, respectively, as a result of the dipping treatment. RE-B, oil-soluble rosemary extract; IAA, isoascorbic acid

PV (A) and TBARS (B) and TVC (C) development during storage of herring co-products dipped with antioxidant solution and subsequently stored intact at 4 °C for up to 12 days. TVC data are only shown at days 0 and 12. The antioxidants were 0.9% NaCl, 0.2% RE-B, 0.2% RE-B + 0.5% IAA, or 2% MANC and re-used up to 10 times, and samples were taken after the 10th dipping cycle. The ratio of herring co-products to solution was 1:2 weight/volume. The dipping time was 30s. RE-B, oil-soluble rosemary extract; IAA, isoascorbic acid; MANC, Duralox MANC 213

The strong effect of the oil-soluble rosemary extract RE-B in all trials is ascribed to carnosic acid and carnosol. Aruoma et al. (1992) reported that carnosol and carnosic acid have been suggested to account for over 90% of the antioxidant properties of rosemary extract. The mechanism of action of these phenolic compounds is expected to involve free radical scavenging (Nieto et al., 2018), i.e., conversion of lipid and hydroxyl radicals into stable products, thereby reducing the formation of reactive species derived from both oxygen and fatty acids (Gordon, 1990). Specifically, it has been shown that it is the 12- or 14-position of carnosic acid that primarily reacts with radical species, such as lipid peroxyl radicals, by an oxidative coupling reaction (Masuda et al., 2001).

Changes in Microbiological Growth

Numerous studies have proven that rosemary extracts can exhibit broad antimicrobial properties and effectively inhibit most foodborne pathogens and spoilage organisms (Fernandez-Lopez et al., 2005). With this background, we turned our attention to the potential of dipping treatments with RE-B to inhibit microbial growth in our samples. Figure 3C shows the total viable counts (TVC) for the minced herring co-products dipped in antioxidant-containing solutions prior to subsequent cold storage (i.e., day 0) and after 12 days of storage. There were no significant differences (p ≥ 0.05) in initial TVC among the differently treated herring samples, which had a mean of 5.8 log10CFU/g. This value was higher than the initial TVC previously documented in skin-on herring fillets (4.0 Log10CFU/g) (Özogul et al., 2000) and in whole gutted silver carp (3.1 Log10CFU/g) (Fan et al., 2008). It was also higher than the starting TVC value we found in our subsequent trials (Figs. 4C and 5C), 3.5 and 4.0 Log10CFU/g, respectively, which could be attributed to a longer pre-processing storage period in the refrigerated sea water (RSW) tanks. Overall, the fact that the skin, intestines, and gills constitute a significant part of the co-products could however make a higher bacterial load expected compared to fillets and gutted fish (Ghosh & Ray, 2017).

For the non-dipped control of the first dipping trial (Fig. 2C), the TVC had increased to 8.56 Log10CFU/g after 12 days of storage, which was higher than the maximal recommended limit of 7.0 Log10CFU/g in raw fish material (ICMSF, 2011). The TVC of minced herring co-products previously dipped in solutions with 0.5% RE-B were however significantly lower (p < 0.05) than the control after 12 days (Fig. 3C), 6.45 log10CFU/g after the first dipping and 6.83 log10CFU/g when the solution had been recycled four times. When the solution had been recycled ten times, TVC was higher than in the non-dipped control, 7.97 Log10CFU/g. These results indicated that rosemary extract could significantly inhibit the growth of microorganisms, but that its antimicrobial properties decreased with increasing recycling of the solution. Figure 4C shows that also the TVC of samples treated with solutions containing a lower level (0.2%) of RE-B ± 0.5% IAA prior to mincing were significantly lower (p < 0.05) than the control after 12 days of storage, and here even after the 10th dipping cycle. This effect was however not seen when the co-products were stored whole after the dipping treatment (Fig. 4C); then only RE-B + IAA gave slightly, yet significantly, lower TVC than the control. This could indicate that the more even distribution of RE-B into the samples following mincing gave a better protection against bacterial growth. Antimicrobial properties of rosemary extracts have been reported also in other fish species. Gao et al. (2014) reported that dipping of pompano (Trachinotus ovatus) fillets in a rosemary extract solution (0.2%, 30 min) exerted an inhibitory effect on the growth of microorganisms. Also Kenar et al. (2010) found that pre-dipping of sardine (Sardina pilchardus) fillets for 4 min in a 1% rosemary extract solution retarded the increase in TVC. The antimicrobial activity of RE-B in this study could be attributed to the presence of carnosic acid, carnosol, and other phenolic compounds. The described mechanism for antimicrobial action of rosemary extracts involves its interaction with bacterial membranes, resulting in changes in the genetic material, overall metabolism, fatty acid production, and electron transport as well as leakage of cellular components (Nieto et al., 2018).

When it comes to IAA and its effects on the bacterial growth, the TVC of herring co-products treated with 2% IAA in the first dipping cycle was 6.53 Log10CFU/g after 12 days, which was significantly lower (p < 0.05) than the non-dipped control (8.56 Log10CFU/g) (Fig. 3C). Figure 4C shows that also a lower level of IAA (0.5%) could significantly inhibit the growth of microorganisms in minced herring co-products, although not as efficiently as RE-B. The antimicrobial action of IAA could be attributed to the lower pH of the IAA-treated samples compared to the control, 6.48 vs 6.78 (Fig. 4F). When comparing the effect of 0.2% RE without and with 0.5% IAA added, both after the 10th dipping (Fig. 4C), no synergistic action was not observed. This could be due to dilution of the IAA when dipping solutions were recycled, something which is confirmed in Fig. 3C, showing that there was no significant difference between the control and samples dipped in a 2% IAA solution which was recycled 4 times.

Total Volatile Basic Nitrogen

Total volatile basic nitrogen (TVB-N), which is composed mainly of ammonia and primary, secondary, and tertiary amines, results from the degradation of proteins and non-protein nitrogenous compounds, which is caused chiefly by enzymatic processes or microbial activity (Fan et al., 2008). TVB-N is widely used as a quality indicator for fish products (Olafsdottir et al., 1997). The TVB-N values on days 0 and 12 for minced non-dipped herring co-products and co-products previously subjected to dipping treatments with 0.2% RE-B and 0.5% IAA are shown in Fig. 3D. The average initial TVB-N value was 4.9 mg N per 100 g for all samples, indicating that the herring co-products used in this trial were of good quality, which supports the relatively low initial TVC. After 12-day storage, the TVB-N value of samples dipped in solutions with 0.2% RE-B ± 0.5% IAA which had been recycled ten times had increased significantly (p < 0.05) and could not be differentiated from the non-dipped control. Thus, the fact that RE-B did not inhibit the formation of TVB-N contradicted the TVC data and also previous studies revealing that dipping pompano (Trachinotus ovatus) fillets and crucian carp (Carassius auratus) fillets in 0.2% RE delayed TVB-N formation (Gao et al., 2014; Li et al., 2012). This inconsistency may be attributed to the repeated dipping cycles used in our study, which we expect gradually diluted the RE-B concentration. On the contrary, the TVB-N values of minced co-products previously dipped in 0.5% IAA were significantly lower (p < 0.05) than the control (Fig. 4D), which was consistent with the TVC results (Fig. 4C). The range of TVB-N values found in all samples after 12-day storage, 17.8–27.3, was lower than the acceptable limit of 30 mg TVB-N per 100 g of fish sample (Ocaño-Higuera et al., 2011).

Weight Change After the Dipping Treatments

The dipping treatment is an exchange process, in which the antioxidants are expected to be left as a residual on the surface of the herring co-products, while blood and muscle juice are diluted into the dipping solutions. The latter was confirmed in our previous study, where we found a 10% reduction in Hb of mixed herring co-products after 20 min rinsing in 0.9% NaCl solution with or without Duralox MANC (Wu et al., 2021b). Although physiological salt solution was used as a solvent for the antioxidants in order to minimize osmotic pressure, the weight change of the herring co-product samples as a function of the dipping(s) was recorded to allow correct interpretation of the lipid oxidation data. Figure 4E shows the weight change of the herring co-products after being immersed in the antioxidant-containing solutions for 30 s followed by draining. When the dipping solutions were used only once, the weight of the herring co-products treated with 0.5% IAA was reduced by 2.0%. However, when the herring co-products were treated with 0.2% RE-B ± 0.5% IA, and dipping solutions were recycled up to ten times, the weight of the herring co-products increased by 1.3–3.3%. These results confirm that there was a small transfer of constituents between the dipping solution and the herring co-products, something which was also visible. Whether or not the thin film of solution remaining on the co-products per se may have acted as an oxygen barrier can at this stage not be confirmed. Using 0.9% NaCl alone, this was at least not the case (Fig. 5A and B), but possibly the antioxidants changed the nature of this film.

pH Changes After the Dipping Treatments

The pH plays an important role in Hb-mediated lipid oxidation of fish muscles (Undeland et al., 2004). A lowering of pH will lower Hb oxygenation of acidic Hbs, which could promote lipid oxidation via acceleration of Hb autoxidation (Richards & Hultin, 2000). Thus, it was necessary to investigate the effect of the antioxidant dipping treatments on the pH of the herring co-products. Figure 4F shows that there was no significant difference (p ≥ 0.05) in pH of the herring co-products dipped in 0.2% RE-B which had been recycled ten times, compared to the non-dipped control. However, following the first dipping in 0.5% IAA and dipping in 0.2% RE-B + 0.5% IAA which had been recycled ten times, the pHs of the herring co-products were 6.48 and 6.65, respectively, which were significantly (p < 0.05) lower than the control, 6.77. Thus, IAA (0.5%) in the dipping solution significantly reduced the pH of herring co-products, even after re-using the solution 10 times, which could counteract the positive effect of IAA itself.

Conclusions

From a screening in minced herring co-products, it was evident that all seven tested antioxidants or antioxidant mixtures delayed lipid oxidation, but to different extents. The order found was as follows: RE-B (0.05%) = MANC (0.5%) = EVESA (0.5%) > IAA (0.5%) > RE-A (0.2%) > esculetin (0.09%) > α-tocopherol (0.02%). When including the two most promising candidates (RE-B and IAA) in dipping solutions for herring co-products prior to subsequent ice storage, a striking finding was that dipping in solutions with 0.2% RE-B ± 0.5% IAA, which had been re-used up to ten times, remarkably increased the oxidation lag phase from < 1 day to > 12 days both when the co-products were stored in minced and intact form. The same dipping treatment also significantly inhibited the growth of microorganisms during subsequent storage and kept it below the acceptable limits for fish even after 12 days. In tests with 0.5% RE or 2% IAA alone, however, the antimicrobial effect decreased with an increased number of re-using cycles. The effect from dipping on TVB-N was none or minor, revealing that non-microbial processes such as protein degradation largely influenced this parameter. The presence of IAA in the dipping solutions particularly contributed to a better retention of red color in the co-products. The evaluated dipping strategies, all comprising natural extracts or compounds, could thus extensively prolong both the chemical and microbial shelf life of herring filleting co-products during ice storage, which could facilitate for more diversified end use of this biomass including different food applications.

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Abdollahi, M., Rezaei, M., Jafarpour, A., & Undeland, I. (2018). Sequential extraction of gel-forming proteins, collagen and collagen hydrolysate from gutted silver carp (Hypophthalmichthys molitrix) a biorefinery approach. Food Chemistry, 242, 568–578. https://doi.org/10.1016/j.foodchem.2017.09.045

Abdollahi, M., Wu, H., & Undeland, I. (2021). Impact of processing technology on macro- and micronutrient profile of protein-enriched products from fish backbones. Foods, 10(5), 950. https://doi.org/10.3390/foods10050950.

Alexandratos, N., & Bruinsma, J. (2012). World agriculture towards 2030/2050: The 2012 revision. Rome: ESA Working paper FAO. https://doi.org/10.22004/ag.econ.288998

Aruoma, O., Halliwell, B., Aeschbach, R., & Löligers, J. (1992). Antioxidant and pro-oxidant properties of active rosemary constituents: Carnosol and carnosic acid. Xenobiotica, 22(2), 257–268. https://doi.org/10.3109/00498259209046624

Aspevik, T., Oterhals, Å., Rønning, S. B., Altintzoglou, T., Wubshet, S. G., Gildberg, A., et al. (2017). Valorization of proteins from co-and by-products from the fish and meat industry. In C. Lin (Ed.), Chemistry and chemical technologies in waste valorization (pp. 123–150). Springer. https://doi.org/10.1007/s41061-017-0143-6.

Babakhani, A., Farvin, K. S., & Jacobsen, C. (2016). Antioxidative effect of seaweed extracts in chilled storage of minced Atlantic mackerel (Scomber scombrus): Effect on lipid and protein oxidation. Food and Bioprocess Technology, 9(2), 352–364. https://doi.org/10.1007/s11947-015-1630-9

Banerjee, S. (2006). Inhibition of mackerel (Scomber scombrus) muscle lipoxygenase by green tea polyphenols. Food Research International, 39(4), 486–491. https://doi.org/10.1016/j.foodres.2005.10.002

Bouarab Chibane, L., Degraeve, P., Ferhout, H., Bouajila, J., & Oulahal, N. (2019). Plant antimicrobial polyphenols as potential natural food preservatives. Journal of the Science of Food and Agriculture, 99(4), 1457–1474. https://doi.org/10.1002/jsfa.9357

Cavonius, L. R., & Undeland, I. (2017). Glazing herring (Clupea harengus) fillets with herring muscle press juice: Effect on lipid oxidation development during frozen storage. International Journal of Food Science & Technology, 52(5), 1229–1237. https://doi.org/10.1111/ijfs.13399

Fan, W., Chi, Y., & Zhang, S. (2008). The use of a tea polyphenol dip to extend the shelf life of silver carp (Hypophthalmicthys molitrix) during storage in ice. Food Chemistry, 108(1), 148–153. https://doi.org/10.1016/j.foodchem.2007.10.057

Fernandez-Lopez, J., Zhi, N., Aleson-Carbonell, L., Pérez-Alvarez, J. A., & Kuri, V. (2005). Antioxidant and antibacterial activities of natural extracts: Application in beef meatballs. Meat Science, 69(3), 371–380. https://doi.org/10.1016/j.meatsci.2004.08.004

Fu, X., Xu, S., & Wang, Z. (2009). Kinetics of lipid oxidation and off-odor formation in silver carp mince: The effect of lipoxygenase and hemoglobin. Food Research International, 42(1), 85–90. https://doi.org/10.1016/j.foodres.2008.09.004

Gao, M., Feng, L., Jiang, T., Zhu, J., Fu, L., Yuan, D., & Li, J. (2014). The use of rosemary extract in combination with nisin to extend the shelf life of pompano (Trachinotus ovatus) fillet during chilled storage. Food Control, 37, 1–8. https://doi.org/10.1016/j.foodcont.2013.09.010

Ghaly, A., Ramakrishnan, V., Brooks, M., Budge, S., & Dave, D. (2013). Fish processing wastes as a potential source of proteins amino acids and oils: A critical review. Journal of Microbial & Biochemical Technology, 5(4), 107–129. https://doi.org/10.4172/1948-5948.1000110

Ghirmai, S., Eriksson, L., Wu, H., Axelsson, M., & Undeland, I. (2020). Improving the stability of red blood cells in rainbow trout (Oncorhynchus mykiss) and herring (Clupea harengus): Potential solutions for post-mortem fish handling to minimize lipid oxidation. Food and Bioprocess Technology, 13(8), 1344–1355. https://doi.org/10.1007/s11947-020-02472-3

Ghosh, K., & Ray, A. K. (2017). Aquafeed formulation using plant feed stuffs: Prospective application of fish-gut microorganisms and microbial biotechnology. In A. M. Grumezescu & A. M. Holban (Eds.), Soft chemistry and food fermentation (pp. 109–144). Elsevier. https://doi.org/10.1016/B978-0-12-811412-4.00005-9.

Gordon, M. (1990). The mechanism of antioxidant action in vitro. In B. J. F. Hudson (Ed.), Food Antioxidants (pp. 1–18). Springer. https://doi.org/10.1007/978-94-009-0753-9.

ICMSF. (2011). International Commission on Microbiological Specifications for Foods. Microorganisms in foods: Use of data for assessing process control and product acceptance. Springer Science.

Jónsdóttir, R., Geirsdóttir, M., Hamaguchi, P. Y., Jamnik, P., Kristinsson, H. G., & Undeland, I. (2016). The ability of in vitro antioxidant assays to predict the efficiency of a cod protein hydrolysate and brown seaweed extract to prevent oxidation in marine food model systems. Journal of the Science of Food and Agriculture, 96(6), 2125–2135. https://doi.org/10.1002/jsfa.7328

Kemal, C., Louis-Flamberg, P., Krupinski-Olsen, R., & Shorter, A. L. (1987). Reductive inactivation of soybean lipoxygenase 1 by catechols: A possible mechanism for regulation of lipoxygenase activity. Biochemistry, 26(22), 7064–7072. https://doi.org/10.1021/bi00396a031

Kenar, M., Özogul, F., & Kuley, E. (2010). Effects of rosemary and sage tea extracts on the sensory, chemical and microbiological changes of vacuum-packed and refrigerated sardine (Sardina pilchardus) fillets. International Journal of Food Science & Technology, 45(11), 2366–2372. https://doi.org/10.1111/j.1365-2621.2010.02414.x

Kröger-Ohlsen, M., & Skibsted, L. H. (1997). Kinetics and mechanism of reduction of ferrylmyoglobin by ascorbate and D-isoascorbate. Journal of Agricultural and Food Chemistry, 45(3), 668–676. https://doi.org/10.1021/jf9604798

Larsson, K., Almgren, A., & Undeland, I. (2007). Hemoglobin-mediated lipid oxidation and compositional characteristics of washed fish mince model systems made from cod (Gadus morhua) herring (Clupea harengus) and salmon (Salmo salar) muscle. Journal of Agricultural and Food Chemistry, 55(22), 9027–9035. https://doi.org/10.1021/jf070522z

Li, T., Li, J., Hu, W., Zhang, X., Li, X., & Zhao, J. (2012). Shelf-life extension of crucian carp (Carassius auratus) using natural preservatives during chilled storage. Food Chemistry, 135(1), 140–145. https://doi.org/10.1016/j.foodchem.2012.04.115

Maqsood, S., & Benjakul, S. (2013). Effect of kiam (Cotylelobium lanceolatum Craib) wood extract on the haemoglobin-mediated lipid oxidation of washed Asian sea bass mince. Food and Bioprocess Technology, 6(1), 61–72. https://doi.org/10.1007/s11947-011-0530-x

Maqsood, S., Benjakul, S., & Shahidi, F. (2013). Emerging role of phenolic compounds as natural food additives in fish and fish products. Critical Reviews in Food Science and Nutrition, 53(2), 162–179. https://doi.org/10.1080/10408398.2010.518775

Masuda, T., Inaba, Y., & Takeda, Y. (2001). Antioxidant mechanism of carnosic acid: Structural identification of two oxidation products. Journal of Agricultural and Food Chemistry, 49(11), 5560–5565. https://doi.org/10.1021/jf010693i

Miranda, J. M., Trigo, M., Barros-Velázquez, J., & Aubourg, S. P. (2018). Quality enhancement of chilled lean fish by previous active dipping in Bifurcaria bifurcata alga extract. Food and Bioprocess Technology, 11(9), 1662–1673. https://doi.org/10.1007/s11947-018-2131-4

Nieto, G., Ros, G., & Castillo, J. (2018). Antioxidant and antimicrobial properties of rosemary (Rosmarinus officinalis, L.): A review. Medicines, 5(3), 98. https://doi.org/10.3390/medicines5030098

Nolsøe, H., & Undeland, I. (2009). The acid and alkaline solubilization process for the isolation of muscle proteins: State of the art. Food and Bioprocess Technology, 2(1), 1–27. https://doi.org/10.1007/s11947-008-0088-4

Ocaño-Higuera, V., Maeda-Martínez, A., Marquez-Ríos, E., Canizales-Rodríguez, D., Castillo-Yáñez, F., Ruíz-Bustos, E., Graciano-Verdugo, A., & Plascencia-Jatomea, M. (2011). Freshness assessment of ray fish stored in ice by biochemical, chemical and physical methods. Food Chemistry, 125(1), 49–54. https://doi.org/10.1016/j.foodchem.2010.08.034

Olafsdottir, G., Martinsdóttir, E., Oehlenschläger, J., Dalgaard, P., Jensen, B., Undeland, I., Mackie, I., Henehan, G., Nielsen, J., & Nilsen, H. (1997). Methods to evaluate fish freshness in research and industry. Trends in Food Science & Technology, 8(8), 258–265. https://doi.org/10.1016/S0924-2244(97)01049-2

Özogul, F., Taylor, K., Quantick, P., & Özogul, Y. (2000). Chemical microbiological and sensory evaluation of Atlantic herring (Clupea harengus) stored in ice modified atmosphere and vacuum pack. Food Chemistry, 71(2), 267–273. https://doi.org/10.1016/S0308-8146(00)00169-2

Richards, M. P., & Hultin, H. O. (2000). Effect of pH on lipid oxidation using trout hemolysate as a catalyst: A possible role for deoxyhemoglobin. Journal of Agricultural and Food Chemistry, 48(8), 3141–3147. https://doi.org/10.1021/jf991059w

Rustad, T., Storrø, I., & Slizyte, R. (2011). Possibilities for the utilisation of marine by-products. International Journal of Food Science & Technology, 46(10), 2001–2014. https://doi.org/10.1111/j.1365-2621.2011.02736.x

Saeed, S., & Howell, N. K. (2001). 12-Lipoxygenase activity in the muscle tissue of Atlantic mackerel (Scomber scombrus) and its prevention by antioxidants. Journal of the Science of Food and Agriculture, 81(8), 745–750. https://doi.org/10.1002/jsfa.878

Sajib, M., Albers, E., Langeland, M., & Undeland, I. (2020). Understanding the effect of temperature and time on protein degree of hydrolysis and lipid oxidation during ensilaging of herring (Clupea harengus) filleting co-products. Scientific Reports, 10(1), 1–13. https://doi.org/10.1038/s41598-020-66152-0

Sajib, M., & Undeland, I. (2020). Towards valorization of herring filleting by-products to silage 2.0: Effect of temperature and time on lipid oxidation and non-enzymatic browning reactions. LWT-Food Science and Technology, 127, 109441. https://doi.org/10.1016/j.lwt.2020.109441

Schmedes, A., & Hølmer, G. (1989). A new thiobarbituric acid (TBA) method for determining free malondialdehyde (MDA) and hydroperoxides selectively as a measure of lipid peroxidation. Journal of the American Oil Chemists’ Society, 66(6), 813–817. https://doi.org/10.1007/Bf02653674

Tang, S., Sheehan, D., Buckley, D. J., Morrissey, P. A., & Kerry, J. P. (2001). Anti-oxidant activity of added tea catechins on lipid oxidation of raw minced red meat, poultry and fish muscle. International Journal of Food Science & Technology, 36(6), 685–692. https://doi.org/10.1046/j.1365-2621.2001.00497.x

Undeland, I., Kristinsson, H. G., & Hultin, H. O. (2004). Hemoglobin-mediated oxidation of washed minced cod muscle phospholipids: Effect of pH and hemoglobin source. Journal of Agricultural and Food Chemistry, 52(14), 4444–4451. https://doi.org/10.1021/jf030560s

Vatavali, K., Karakosta, L., Nathanailides, C., Georgantelis, D., & Kontominas, M. (2013). Combined effect of chitosan and oregano essential oil dip on the microbiological chemical and sensory attributes of red porgy (Pagrus pagrus) stored in ice. Food and Bioprocess Technology, 6(12), 3510–3521. https://doi.org/10.1007/s11947-012-1034-z

Wang, J. H., Liu, D. M., Zheng, A. N., Liu, Y. L., Chen, Q., Wang, F. X., et al. (2012). Preliminary purification and distribution of lipoxygenase in grass carp. In Z. Liu, F. Peng, & X. Liu (Eds.), Advanced materials research (pp. 1468–1472). Trans Tech Publications Ltd. https://doi.org/10.4028/www.scientific.net/AMR.550-553.1468.

Wu, H., Abdollahi, M., & Undeland, I. (2021a). Effect of recovery technique antioxidant addition and compositional features on lipid oxidation in protein enriched products from cod-salmon and herring backbones. Food Chemistry, 360, 129973. https://doi.org/10.1016/j.foodchem.2021.129973

Wu, H., Ghirmai, S., & Undeland, I. (2020). Stabilization of herring (Clupea harengus) by-products against lipid oxidation by rinsing and incubation with antioxidant solutions. Food Chemistry, 316, 126337. https://doi.org/10.1016/j.foodchem.2020.126337

Wu, H., Sajib, M., & Undeland, I. (2021b). Controlling hemoglobin-mediated lipid oxidation in herring (Clupea harengus) co-products via incubation or dipping in a recyclable antioxidant solution. Food Control, 125, 107963. https://doi.org/10.1016/j.foodcont.2021.107963

Acknowledgements

This project has received funding from Region Västra Götaland (project RUN 2019-00345), the Bio Based Industries Joint Undertaking (JU) under grant agreement (No. 837726), and the Swedish Research Council for sustainable development Formas (grant #2016-01181). The JU receives support from the European Union’s Horizon 2020 research and innovation program and the Bio-Based Industries Consortium. This output reflects only the authors’ view and the JU cannot be held responsible for any use that may be made of the information it contains.

Funding

Open access funding provided by Chalmers University of Technology.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wu, H., Forghani, B., Sajib, M. et al. A Recyclable Dipping Strategy to Stabilize Herring (Clupea harengus) Co-products During Ice Storage. Food Bioprocess Technol 14, 2207–2218 (2021). https://doi.org/10.1007/s11947-021-02717-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-021-02717-9