Abstract

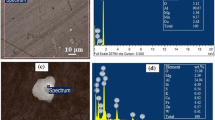

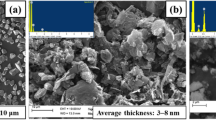

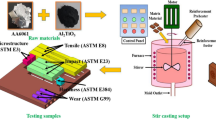

Despite the high strength-to-weight ratio, the poor tribological behavior and sea water corrosion performance of aluminum alloy limit its engineering applications. In this investigation, an attempt is made to obtain good wear and corrosion resistance by fabricating MoS2 and CeO2 reinforced aluminum 7075 matrix hybrid composites through friction stir processing. The microstructural observation suggests intermetallic free uniformly distributed composites are formed. The specific wear and corrosion rates of the fabricated composites are analyzed. The reason behind variation of the responses is investigated. The processing conditions such as rotational speed, traverse speed, tilt angle and mixing ratio of reinforcement powder are optimized for low specific wear rate and low corrosion rate using Taguchi optimization method. The effects of the processing conditions on individual responses are also investigated. Gray relation approach is also adopted for optimizing the processing conditions while considering equal importance of both the output responses.

Similar content being viewed by others

References

D.K. Lim, T. Shibayanagi, and A.P. Gerlich, Mater. Sci. Eng. A 507, 194. (2009).

M. Bahrami, K. Dehghani, and M.K.B. Givi, Mater. Des. 53, 217. (2014).

R. Hashemi, and G. Hussain, Wear 324–325, 45. (2015).

H.G. Rana, V.J. Badheka, and A. Kumar, Proc. Technol. 23, 519. (2016).

S. K. Coburn, in Sel Mater Serv Env. (Source B. Ser.) (1987), pp. 318–324.

C.E. Prema, S. Suresh, G. Ramanan, and M. Sivaraj, Mater. Res. Express 7, 016524. (2020).

S. Suresh, G.H. Gowd, and M.L.S. Devakumar, J. Bio-Tribo-Corros. 4, 1. (2018).

V. Shrivastava, P. Singh, G.K. Gupta, S.K. Srivastava, and I.B. Singh, J. Alloys Compd. 857, 157590. (2021).

S.A. Hosseini, K. Ranjbar, R. Dehmolaei, and A.R. Amirani, J. Alloys Compd. 622, 725. (2015).

Z. Du, M.J. Tan, J.F. Guo, G. Bi, and J. Wei, Mater. Sci. Eng. A 667, 125. (2016).

R. Palanivel, I. Dinaharan, R.F. Laubscher, and J.P. Davim, Mater. Des. 106, 195. (2016).

I. Sudhakar, V. Madhu, G.M. Reddy, and K.S. Rao, Def. Technol. 11, 10. (2015).

L.R. Kumar, A. Saravanakumar, V. Bhuvaneswari, G. Gokul, D.D. Kumar, and M.P.J. Karunan, Mater. Today Proc. 45, 9549. (2019).

M. Rouhi, M. Moazami-Goudarzi, and M. Ardestani, Trans. Nonferr. Met. Soc. China 29, 1169. (2019).

Z. Zheng, M.C. Zhao, L. Tan, Y.C. Zhao, B. Xie, D. Yin, K. Yang, and A. Atrens, Surf. Coat. Technol. 386, 125456. (2020).

L. Wang, M. Chen, H. Liu, C. Jiang, V. Ji, and F. Moreira, Surf. Coat. Technol. 331, 196. (2017).

T. Saravanakumar, V. Kavimani, K.S. Prakash, and T. Selvaraju, Prog. Org. Coat. 129, 32. (2019).

P. Maji, S.K. Ghosh, R.K. Nath, and R. Karmakar, J. Braz. Soc. Mech. Sci. Eng. 42, 191. (2020).

R.K. Nath, P. Maji, and J.D. Barma, JOM 73, 1774. (2021).

P. Maji, R. Karmakar, R.K. Nath, R.K. Bhogendro Meitei, and S.K. Ghosh, in Next Gener. Mater. Process. Technol., ed. by S. Bag, C.P. Paul, and M. Baruah (Springer Nature Singapore Pte Ltd., 2021), pp. 147–157.

M. Rahsepar, and H. Jarahimoghadam, Mater. Sci. Eng. A 671, 214. (2016).

S.R. Anvari, F. Karimzadeh, and M.H. Enayati, Wear 304, 144. (2013).

V. Sharma, U. Prakash, and B.V.M. Kumar, Mater. Today Proc. 2, 2666. (2015).

P. Maji, R.K. Nath, P. Paul, R.K.B. Meitei, and S.K. Ghosh, J. Manuf. Process. 69, 1. (2021).

P. Maji, R.K. Nath, R. Karmakar, P. Paul, R.K.B. Meitei, and S.K. Ghosh, CIRP J. Manuf. Sci. Technol. 35, 96. (2021).

H. Baker, and A.S.M. Handbook, Alloy Phase Diagrams, vol 3. (ASM, 1998).

F.J. Baldenebro-López, R. Peréz-Bustamante, I. Estrada-Guel, R. Martínez-Sánchez, A. Duarte-Moller, and C.D. Gómez-Esparza, Adv. Mater. Sci. Eng. 2019, 1. (2019).

J.S.D. Joseph, B. Kumaragurubaran, and S. Sathish, SILICON 12, 1481. (2020).

D.K. Sharma, V. Patel, V. Badheka, K. Mehta, and G. Upadhyay, J. Tribol. 141, 1. (2019).

F.A. Mehraban, F. Karimzadeh, and M.H. Abbasi, JOM 67, 998. (2015).

V. Patel, W. Li, A. Vairis, and V. Badheka, Crit. Rev. Solid State Mater. Sci. 44, 378. (2019).

D.K. Sharma, V. Badheka, V. Patel, and G. Upadhyay, J. Tribol. 143, 050801. (2021).

B.N. Popov, Corros. Eng. 865, 181. (2015).

D. Kesavan, M. Gopiraman, and N. Sulochana, Chem. Sci. Rev. Lett. 1, 1. (2012).

V. Patel, V. Badheka, W. Li, and S. Akkireddy, Arch. Civ. Mech. Eng. 19, 1368. (2019).

A. Orozco-Caballero, M. Álvarez-Leal, D. Verdera, P. Rey, O.A. Ruano, and F. Carreño, Mater. Des. 125, 116. (2017).

V.V. Patel, V. Badheka, and A. Kumar, J. Mater. Process. Technol. 240, 68. (2017).

M. Orłowska, E. Ura-Bińczyk, L. Olejnik, and M. Lewandowska, Corros. Sci. 148, 57. (2019).

A. Devaraju, A. Kumar, and B. Kotiveerachari, Mater. Des. 45, 576. (2013).

M.A. Moghaddas, and S.F. Kashani-Bozorg, Mater. Sci. Eng. A 559, 187. (2013).

L. Long, G. Chen, S. Zhang, T. Liu, and Q. Shi, J. Manuf. Process. 30, 562. (2017).

S. Zhang, Q. Shi, Q. Liu, R. Xie, G. Zhang, and G. Chen, Int. J. Heat Mass Transf. 125, 32. (2018).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Maji, P., Nath, R.K., Karmakar, R. et al. Wear and Corrosion Behavior of Al7075 Matrix Hybrid Composites Produced by Friction Stir Processing: Optimization of Process Parameters. JOM 73, 4397–4409 (2021). https://doi.org/10.1007/s11837-021-04945-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04945-y